The automotive industry is in the midst of a profound transformation, ushering in a new era dominated by electric vehicles. As the first wave of mass-market EVs, such as the Nissan Leaf and the Tesla Model S, now enter their second decade of life, a crucial question emerges: are these pioneering electric cars destined for rapid obsolescence, or will they achieve the multi-decade longevity seen in traditional internal combustion engine vehicles?

This transition into a “brave new world” of vehicle ownership brings with it unique challenges that early adopters are increasingly encountering. The promise of cleaner, more efficient transportation has been met with a dose of reality, revealing unforeseen hurdles ranging from critical component failures to significant financial burdens for repairs. These experiences prompt a critical examination of the durability and long-term viability of these initial electric offerings.

While the long-term verdict on EV lifespan is still being written, the experiences of these early adopters provide valuable insights into the complexities of electric vehicle ownership as the technology matures. We delve into eight key issues that have shocked the market and left many pioneer owners grappling with difficult decisions about their once-revolutionary rides.

1. **Catastrophic Battery Failure from Design Flaws**One of the most alarming issues to surface among early EV owners involves catastrophic battery failure, often stemming from specific manufacturing defects. A notable case brought to widespread attention was that of Mario Zelaya, a Tesla owner whose 2013 Model S battery suddenly died, rendering the entire vehicle useless. This wasn’t just a simple malfunction; Zelaya’s claim pointed to a manufacturing defect allowing condensation from the car’s air conditioner to pool directly on top of the battery, causing severe corrosion and ultimate destruction of the unit.

This particular flaw highlights the vulnerabilities that can arise even in technologically advanced vehicles if fundamental design and engineering considerations are not fully mature. The context explicitly states that Tesla addressed and fixed this issue in cars built after 2014 or so. However, for those early adopters who purchased vehicles before this revision, the defect became a ticking time bomb, leading to complete vehicle immobilization and immense frustration.

The implications of such a defect extend beyond the inconvenience of a broken car. It questions the initial build quality of some of the earliest mass-produced EVs and underscores the learning curve that even innovative companies face when entering a complex manufacturing sector like automotive production. For owners like Zelaya, the experience was a stark reminder that pioneering new technology can sometimes come with unexpected risks.

Read more about: Beyond the Beta Label: Unpacking the Genuine Confusion and Critical Failures in Automotive Software-Defined Vehicles

2. **Exorbitant Battery Replacement Costs**Following a catastrophic battery failure, early EV owners are often confronted with the staggering reality of replacement costs, which can easily eclipse the remaining value of the vehicle itself. In Mario Zelaya’s case, replacing the destroyed battery would have cost more than $20,000. This immense price tag effectively makes the decision to repair an older EV, especially one with an expired warranty, financially unfeasible for many.

The cost issue is compounded by the fact that a dead battery can lock owners out of their own vehicles. Zelaya reported that with his battery dead, he couldn’t even access the car to retrieve his ownership documents, creating a bureaucratic nightmare on top of the financial burden. This scenario illustrates a critical point of friction for early adopters: the high-value component that defines an EV can also be its greatest liability.

Such high replacement costs raise serious questions about the long-term economic viability of early-generation EVs for secondary markets. If the core component of a vehicle costs more than its resale value, the car effectively becomes a disposable asset once its battery life is exhausted or compromised. This reality is a significant driver behind the notion of rapid obsolescence for these pioneering models.

Read more about: Unlock Your Car’s Full Potential: 14 Simple DIY Maintenance Tasks Every Driver Must Master for a Longer, Safer Ride

3. **Rapid Battery Degradation and Range Shrinkage**Even without catastrophic failure, EV batteries, like those in smartphones, inevitably degrade over time, leading to a noticeable reduction in driving range. This decline, while often gradual, can become a major concern for owners of early EVs, particularly those with smaller original battery packs. The original Nissan Leaf, for instance, offered an 82-mile range, which could significantly diminish over a decade of use.

As the battery’s capacity shrinks, drivers begin to experience “major range anxiety,” where even moderately long trips become a source of worry. This degradation transforms a once-capable vehicle into one primarily suitable for short, local errands, potentially necessitating the purchase of a second vehicle for longer journeys. While modern EVs now offer ranges exceeding 200 miles, making a 20% degradation less impactful for daily driving, it was a profound issue for earlier models.

Vehicle electrification expert Hanjiro Ambrose offers practical tips to mitigate this inevitable decline, advising owners to limit DC fast-charging, avoid exposure to extreme temperatures, and maintain the battery charge generally between 25 and 75 percent. These measures, however, only slow the inevitable, confirming that even with careful use, battery performance will degrade, challenging the utility of the vehicle over its lifespan.

Car Model Information: 2024 Nissan Leaf SV PLUS

Name: Nissan Leaf

Caption: Third generation Nissan Leaf

Manufacturer: Nissan

Production: October 2010 – present

ModelYears: 2011–present

Class: Unbulleted list

BodyStyle: Unbulleted list

Layout: Front-engine, front-wheel-drive layout

Predecessor: Unbulleted list

Categories: 2020s cars, All articles containing potentially dated statements, All articles with dead external links, Articles containing Japanese-language text, Articles containing potentially dated statements from December 2015

Summary: The Nissan Leaf (Japanese: 日産・リーフ, Hepburn: Nissan Rīfu; stylized as LEAF) is a battery-electric car manufactured by Nissan, produced since 2010. It was offered exclusively as a 5-door hatchback which since then has become a crossover SUV model. The term “LEAF” serves as a backronym to leading environmentally-friendly affordable family car.

The Leaf was unveiled on 1 August 2009 as the world’s first mass market electric and zero-emission vehicle. Among other awards and recognition, it received the 2010 Green Car Vision Award, the 2011 European Car of the Year, the 2011 World Car of the Year, and the 2011–2012 Car of the Year Japan. The Leaf’s range on a full charge has been steadily increased from 117 km (73 miles) to 364 km (226 miles) (EPA rated) by the use of larger battery packs and several minor improvements.

As of September 2021, European sales totalled more than 208,000, and as of December 2021, over 165,000 had been sold in the U.S., and 157,000 in Japan. Global sales across both generations totalled 577,000 by February 2022. The Leaf was the world’s all-time top selling plug-in electric car until it was surpassed in early 2020 by the Tesla Model 3.

Get more information about: Nissan Leaf

Buying a high-performing used car >>>

Brand: Nissan Model: Leaf

Price: $19,888 Mileage: 15,933 mi.

4. **Immature Production and Quality Control Processes**Many of the leading electric vehicles on the market today are produced by relatively new companies such as Tesla, Rivian, and Lucid. These entities, as pointed out by auto shop owner Pete Gruber, are primarily “tech companies first and foremost, not strictly carmakers.” This distinction has significant implications for production quality and long-term durability.

Gruber notes that these companies “have not matured their production processes and their quality control processes.” Lacking the “decades of experience building cars to nail down procedures” that traditional automakers possess, these newer manufacturers are prone to what Gruber calls an “elevated case of problems with these vehicles.” This can be a surprising reality for consumers, especially given that EVs have a fraction of the moving parts compared to an internal combustion engine car.

Despite the inherent simplicity of an EV powertrain, the overall vehicle manufacturing process is complex. The issues faced by early adopters, such as the Tesla Model S water pooling flaw, underscore the challenges of scaling up production and perfecting quality control without the benefit of a century of automotive engineering know-how. This immaturity in manufacturing processes directly contributes to the early obsolescence experienced by some of the first-generation electric vehicles.

5. **The Tech-First Carmaker Ethos and its Broader Implications**Many of the leading electric vehicles on the market today are produced by companies like Tesla, Rivian, and Lucid, which are primarily “tech companies first and foremost, not strictly carmakers,” as auto shop owner Pete Gruber points out. This foundational identity profoundly shapes their approach to vehicle development. Their primary focus often leans towards rapid software iteration, feature integration, and groundbreaking innovation, sometimes ahead of traditional automotive durability. This distinguishes them sharply from legacy manufacturers.

This ethos, while driving incredible advancements, has significant implications for long-term reliability and manufacturing consistency. Gruber notes that these companies “have not matured their production processes and their quality control processes.” This indicates a different developmental trajectory compared to established automakers, who possess “decades of experience building cars to nail down procedures” to perfect every aspect of vehicle construction over generations.

Consequently, the differences in manufacturing philosophy can lead to specific challenges for early adopters. While it’s true that EVs inherently have “a fraction of the moving parts that an internal combustion engine has,” this tech-first approach can still contribute to “an elevated case of problems.” These aren’t just minor mechanical glitches, but potentially systemic issues arising from less seasoned manufacturing and rigorous quality assurance protocols compared to the entrenched practices of traditional automotive giants.

The rapid pace of technological change within the EV sector, spearheaded by these innovative companies, means that features and capabilities can evolve at a breathtaking speed. While exciting, this swift progression can also accelerate the perceived obsolescence of older models. A vehicle that was cutting-edge just a few years ago might feel significantly outdated as new iterations bring vastly improved range, charging speeds, and advanced software features, further challenging the notion of long-term retention.

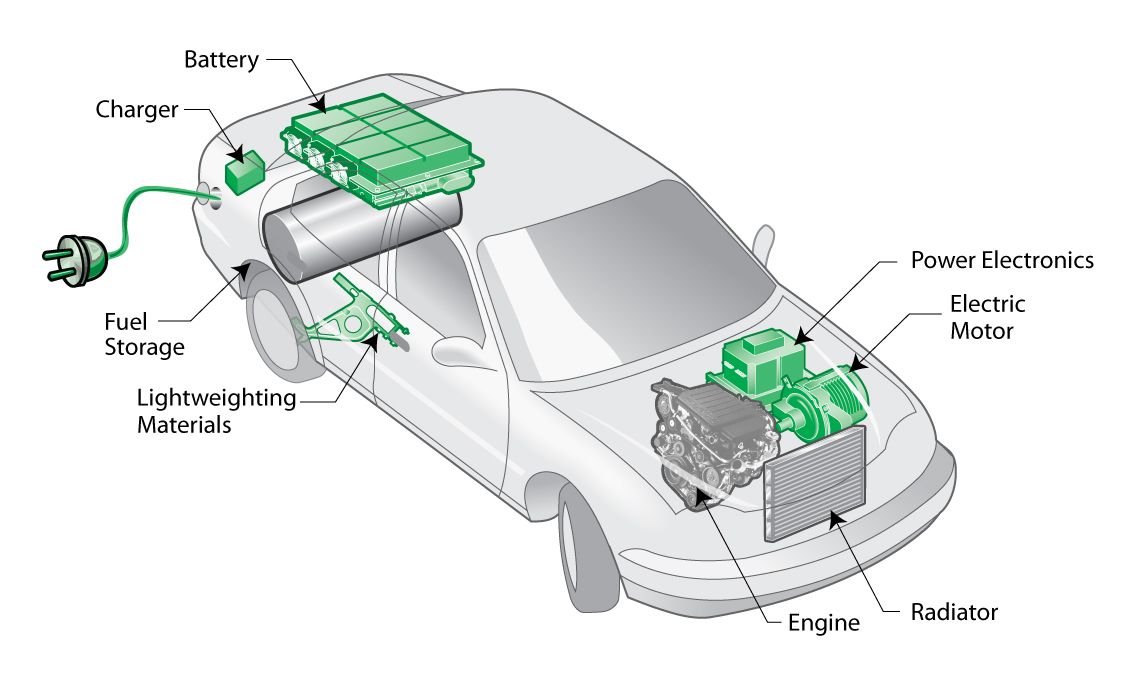

6. **Beyond the Battery: Vulnerabilities of Non-Core Components**While the battery often dominates discussions about EV longevity and potential obsolescence, an electric car is undeniably “more than a battery on wheels.” The long-term durability of its other, less-talked-about components is equally crucial for sustained operation. This offers a vital counterbalance to the prevalent focus solely on battery life, reminding us that a vehicle is an integrated system.

Electric vehicles possess a distinct structural advantage when it comes to mechanical complexity. Pete Gruber highlights that traditional gas-powered cars can contain “more than 2,000 moving parts,” whereas an EV typically has “more like 18 or 20 moving parts.” This dramatic reduction in mechanical elements theoretically translates to “far fewer components that can fail in the long term,” promising a simpler, more robust powertrain.

This simplification means EV owners bypass a host of common issues that plague internal combustion engine vehicles. They don’t “have a transmission that will wear out,” nor do they face the eventual deterioration of “exhaust that will eventually rust through.” Concerns about “bearings and bushings and rings and pistons,” “fuel systems that clog up,” or “starter alternator motors that will eventually go bad” are largely eliminated in the electric architecture, suggesting a different kind of operational longevity.

However, this seemingly rosy picture isn’t entirely without its caveats. Gruber cautions that “the picture isn’t all rosy” when considering all components. He specifically notes that “Some of those parts, such as capacitors, are rated to last only so many years (depending on the amount of miles traveled).” This reveals that even with a reduced number of moving parts, specific electronic components have their own inherent lifespans, which could eventually contribute to a vehicle’s obsolescence or necessitate expensive, specialized repairs.

Despite these current vulnerabilities, there is an expectation that carmakers will proactively address these component-level issues. Gruber anticipates that manufacturers “will likely make their components more robust and eliminate the design flaws that plagued their earliest vehicles.” He believes that “Eventually, they’re going to get it right,” and that these nascent EV companies will ultimately “become real car companies” with the same focus on long-term quality and durability as traditional automakers.

7. **The Looming Shortage of Specialized EV Repair Professionals**Looking ahead, a significant systemic challenge for the long-term viability of early electric vehicles is the “dearth of mechanics who can work on electric vehicles,” as identified by Pete Gruber. This skills gap represents a critical bottleneck for maintenance and repair, directly impacting the ability of owners to keep their pioneering EVs running for extended periods.

The current state of vocational and technical training exacerbates this issue. Gruber points out that “vocational and technical schools are still cranking out mechanics trained to work on internal combustion cars.” This creates a clear mismatch between the skills being developed in the workforce and the rapidly evolving demands of the automotive market, which is increasingly dominated by electric powertrains and complex electronic systems.

This scarcity of specialized expertise has immediate and pressing consequences. Mechanics who possess the “electrical expertise and mechanical curiosity to learn EV maintenance” are extremely valuable. As Gruber explains, these highly sought-after professionals are quickly “snapped up by carmakers who desperately need them to staff their service centers,” particularly as EV sales continue to soar and manufacturers expand their service networks.

The high demand from carmakers leaves a vacuum in the independent repair sector. This means there are “not too many people to open the kind of independent shops like Gruber’s that will be needed to repair old electric vehicles.” For early adopters whose warranties may have expired, this lack of widespread, accessible, and affordable independent repair options could significantly complicate the process of maintaining or extending the life of their older EVs, pushing them towards premature disposal.

8. **The Evolving Outlook: Sustaining Pioneering Electric Vehicles**Despite the significant hurdles faced by early adopters, the long-term prospects for electric vehicle longevity are viewed with growing optimism by some experts. Hanjiro Ambrose, a vehicle electrification expert, states confidently, “I believe, based on all the evidence that I have seen, that batteries are highly likely to outlast vehicles.” This perspective suggests a future where EVs are not inherently disposable assets.

A key reason for this optimism lies in the advancements of modern battery technology and increased vehicle ranges. While early models like the original Nissan Leaf with its 82-mile range suffered profoundly from degradation, “most EVs on sale offer ranges that exceed 200 miles on a charge” today. This means that “even if their batteries degrade severely—by, say, 20 percent or more over the course of a decade—they would still have more than enough for the local driving that composes the majority of American car travel.” This makes range degradation a less impactful daily issue for newer models.

Furthermore, the future of EV maintenance may be profoundly reshaped by technological innovation. Pete Gruber “expects future EVs to use embedded artificial intelligence to diagnose their own mechanical problems.” This represents a radical departure from traditional diagnostic methods, shifting the burden from human technicians to intelligent onboard systems that can identify issues with precision and speed.

These advanced AI capabilities could extend to automating the entire service process. Future EVs “may even auto-schedule a service appointment and communicate with the service center to make sure it has the necessary part in hand.” Such integration promises to streamline repairs, reduce downtime, and significantly improve the convenience of vehicle ownership, potentially making maintenance less of a deterrent to long-term retention.

In the most ambitious vision, Gruber even posits that if cars achieve full self-driving status, “it’s not out of the question they could drive themselves to their own checkups.” This futuristic scenario could signal “the death of dreaded loaner cars” and fundamentally redefine the relationship between owner and vehicle. This automated future contrasts starkly with the “DIY past,” where amateur mechanics dedicated hours to keeping their beloved rides running for decades, highlighting a profound shift in how vehicle longevity will be managed.

Read more about: Elon Musk’s $1 Billion Bet: How a CEO’s Bold Stock Purchase Erased Tesla’s 2025 Losses and Ignited a Bullish Revival

This comprehensive look at the challenges and evolving solutions for early electric vehicles reveals a dynamic landscape. While issues like battery degradation and nascent manufacturing processes initially presented significant hurdles, the industry is rapidly adapting and learning. The insights from experts like Pete Gruber and Hanjiro Ambrose suggest that while the “brave new world” of EVs has its unique growing pains, the trajectory is towards greater durability, improved serviceability, and a reimagined relationship between owner and vehicle. The future promises not just cleaner rides, but potentially smarter, more resilient ones, redefining the very notion of vehicle obsolescence in a dramatically positive light. Many of the initial shockwaves in the market are giving way to a more stable and sustainable future for electric mobility, offering hope for long-term ownership and continued innovation.