Walk into any dealership, and the sheer variety of makes and models might lead you to believe that every vehicle on the lot is a completely unique creation, crafted from the ground up to stand apart. Each car brand projects an image of individuality, backed by distinctive styling, marketing campaigns, and a carefully cultivated brand identity. Yet, beneath the polished exterior and sophisticated advertising, a fascinating reality exists within the automotive industry: many models quietly share fundamental components, platforms, and even entire production lines with others you’d never expect.

This intricate web of shared manufacturing and engineering isn’t a secret held to deceive consumers, but rather a strategic cornerstone of modern automotive production. Automakers employ these strategies primarily to achieve significant cost savings, which can translate into more competitive pricing for consumers and healthier profit margins for the companies. Furthermore, this approach helps keep repair costs reasonable, as common components often mean more readily available and less expensive parts. Perhaps even more critically, the reuse of tried-and-true components across multiple platforms can enhance reliability, building on established engineering rather than reinventing the wheel for every new model.

Today, we’re embarking on an in-depth journey to peel back the layers of marketing and delve into the fascinating world of shared automotive production. We’ll uncover ten significant instances where car brands, sometimes within the same corporate family and other times through surprising alliances, leverage shared factories and core mechanicals. From luxury SUVs sharing DNA with their more utilitarian counterparts to sports cars born from a joint vision, these examples illuminate the efficiency and ingenuity driving the global automotive landscape. Understanding these connections offers valuable insights for both experienced drivers and potential car buyers, revealing how closely related many seemingly distinct vehicles truly are.

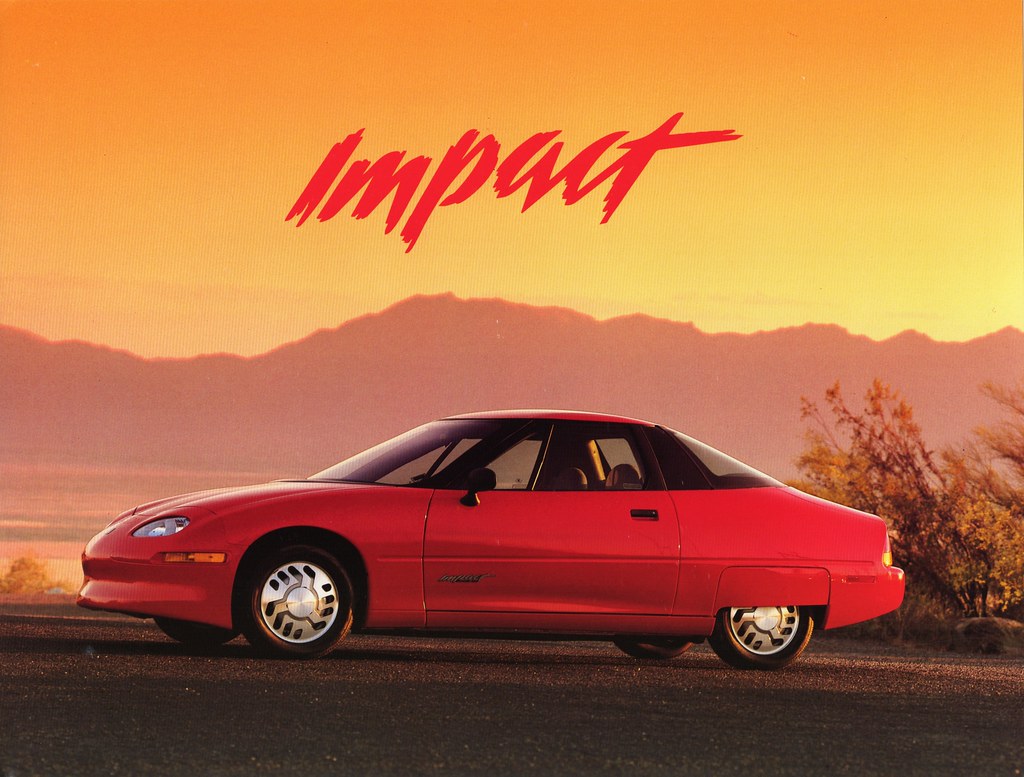

1. **General Motors: The Classic Conglomerate’s Synergy**

General Motors, a behemoth in the American automotive industry and one of the original “Big 3” car companies, has long perfected the art of platform sharing and badge engineering. Their extensive portfolio, which today includes Buick, Chevrolet, Cadillac, and GMC, provides fertile ground for such practices. A quintessential example of GM’s internal synergy can be seen by examining two very different vehicles at first glance: the utilitarian Chevrolet Tahoe and the luxurious Cadillac Escalade.

These two full-size SUVs, despite their distinct badges and vastly different price tags, are fundamentally built upon the same robust foundation. Underneath their unique sheet metal, they share the “same basic frame, engine options, and many suspension parts.” This commonality extends even to their interior architecture, with significant overlap in their infotainment systems. The extensive sharing of core components highlights GM’s efficiency strategy, allowing them to produce a range of vehicles tailored to different market segments from a common engineering base.

However, GM has also evolved its approach to differentiation over the years. While in the past, twinned vehicles might have had minimal variations, today there’s a much stronger focus on tailoring vehicles to appeal to specific customer demographics. As GM spokesman Jim Burke noted, “In recent times we’ve placed much more focus on the type of customer for a particular brand, to what type of features and styling appeals to a Buick Enclave customer versus that of our new Chevrolet Traverse.” This means that while they share “common chassis and powertrain attributes,” Burke emphasizes that “the customer doesn’t see or touch these ‘black metal’ attributes.” Instead, significant effort goes into distinguishing the models through “exterior and interior design.” For instance, the Chevrolet Traverse may feature a unique dual-cockpit design reminiscent of classic Corvettes, with instrumentation and door pads specific to the model.

Beyond aesthetics and interior touches, driving characteristics are also carefully tuned to meet brand expectations. Chevrolet customers, for example, typically anticipate “tighter steering and suspension,” while Buick owners often look for “a softer, more luxurious ride.” These subtle but important differences in feel and performance are achieved through specific tuning of suspension and steering components, even if the underlying hardware is shared. Such detailed customization ensures that despite their shared lineage, vehicles like the Cadillac Escalade, assembled at the Texas Arlington Assembly Plant alongside the Tahoe and Suburban, deliver a driving experience befitting their luxury branding, while the Tahoe maintains its Chevrolet identity.

2. **Toyota and Lexus: Refining Luxury from Reliable Foundations**

The Toyota Motor Corporation, a Japanese-based automaker renowned for its namesake brand’s reliability, has successfully carved out a significant niche in the luxury market with its Lexus division. Like many other major automotive groups, Toyota employs a strategic approach to component sharing between its mainstream and luxury brands. This allows Lexus to benefit from Toyota’s robust engineering and manufacturing prowess while delivering a premium experience.

A prime illustration of this synergy is found in the relationship between the Lexus RX and the Toyota Highlander. These two popular SUVs, despite catering to different consumer expectations—one for luxury and the other for everyday family utility—are closely related beneath the surface. They “both ride on the same GA-K platform and use the same 2.4L turbo engine in some trims.” This shared platform and powertrain are fundamental to their construction, showcasing how Toyota efficiently develops a diverse product lineup.

The rationale behind this strategy is clear: Toyota’s line of vehicles aims to be “more of an everyday kind of vehicle available at more affordable prices,” while the Lexus brand is positioned as their “luxury car line.” By utilizing a common platform, Toyota can streamline production, reduce development costs, and ensure a high level of quality across both brands. The Lexus ES, for instance, is assembled at the Toyota Motor Manufacturing Kentucky plant, the same facility responsible for the ubiquitous Toyota Camry. Similarly, the Lexus TX and Toyota Highlander both see production at Toyota Motor Manufacturing Indiana, illustrating the direct manufacturing overlap.

For consumers, this relationship translates into a foundation of proven reliability for Lexus vehicles, built on the same engineering principles that have made Toyota a global leader. While Lexus models undoubtedly receive more upscale features, plusher interior materials, and a wider range of optional extras to justify their premium positioning, the underlying mechanical robustness is a direct inheritance from their Toyota cousins. This intelligent sharing allows Lexus to offer luxury without compromising the reliability that is a hallmark of the Toyota Motor Corporation, ensuring a strong value proposition for buyers in both segments.

3. **Volkswagen Group: German Engineering, Multiple Personalities**

The Volkswagen Group stands as a testament to the power of shared platforms and components across a vast and diverse brand portfolio. This major German auto brand, initially founded in 1937 to create the “people’s car,” has grown to encompass an impressive array of luxury and performance marques, including Volkswagen (VW), Porsche, Audi, Lamborghini, and Bentley. Their strategy of leveraging common architectures allows for incredible economies of scale while maintaining distinct brand identities.

One of the clearest examples of this internal collaboration can be seen by comparing the Volkswagen Golf R and the Audi S3. These two vehicles, while marketed under different brands and appealing to slightly different demographics, are undeniably “corporate cousins.” Their shared DNA runs deep, primarily stemming from their use of “VW’s MQB platform.” This modular transversal toolkit is a masterstroke of engineering, allowing a wide range of vehicles to share core components despite varying in size, powertrain, and body style.

Beneath their sporty exteriors, the Golf R and S3 “share engine architecture, all-wheel-drive systems, and even their digital dashboard setups.” The distinction between these high-performance compacts largely comes down to specific “tuning, styling, and interior materials.” Audi, as the premium brand, typically receives more sophisticated finishes and a slightly different driving feel, while the Golf R offers a more accessible, yet equally thrilling, performance experience. This strategic differentiation ensures that each brand maintains its unique appeal despite the substantial mechanical commonalities.

In the United States, Volkswagen also operates its Chattanooga Assembly Plant in Tennessee, which is responsible for assembling models like the Atlas, Atlas Cross Sport, and the ID.4 electric vehicle. While these specific models don’t directly mirror the Golf R/S3 example, the presence of such a versatile assembly facility underscores the Group’s capacity for producing diverse vehicles under various marque names within a single, efficient operation. The ability to share engineering foundations across brands, from the everyman VW to the aspirational Audi, is a core strength of the Volkswagen Group, providing a blend of innovation and cost-effectiveness that benefits its entire lineup.

Read more about: Your Ride, Your Story: Unpacking the Brutal Stereotypes of 14 Popular Car Models

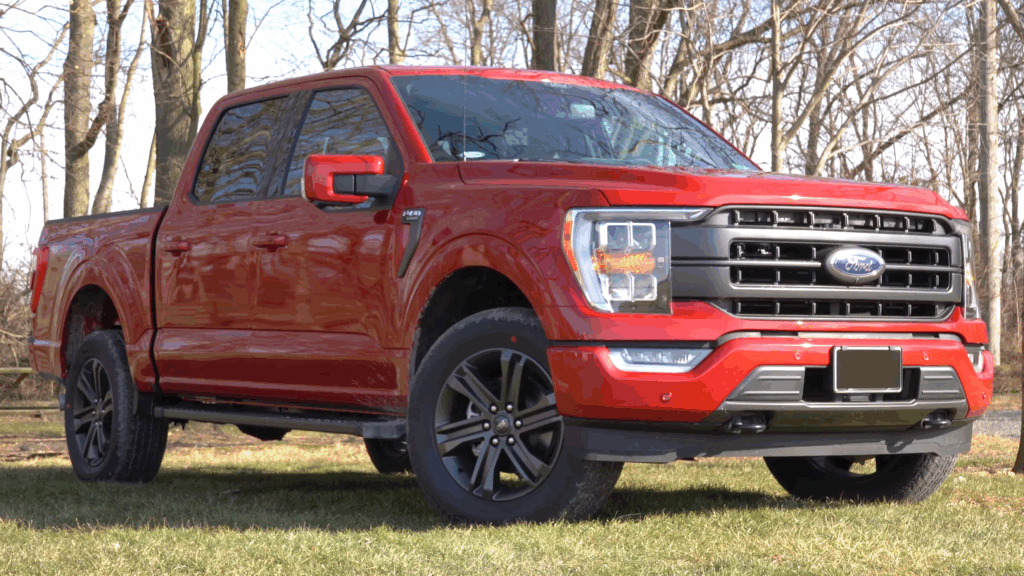

4. **Ford Motor Company: Robust Platforms, Diverse Applications**The Ford Motor Company, an iconic American automotive brand founded in 1903, has been a pioneer in mass production and continues to be a dominant force in the global market. While Ford has streamlined its brand portfolio over the years to primarily focus on Ford and Lincoln today, the principle of sharing robust platforms and powertrains remains central to its strategy, particularly across its truck and SUV lines. This approach allows Ford to maximize efficiency and maintain its competitive edge in key segments.

A prime example of Ford’s internal parts-sharing strategy is evident in the relationship between the full-size Ford Expedition and the luxury Lincoln Navigator. These formidable SUVs, designed to tackle family adventures and command the road, are built upon a heavily shared foundation. They “share major components,” including their fundamental “chassis, powertrains, and electrical systems.” The Navigator, as the premium offering, then elevates the experience with “more chrome and cushier seats,” along with refined styling and additional luxury features.

This strategic commonality allows Ford to develop highly capable vehicles efficiently across different price points. Both the Ford Expedition and the Lincoln Navigator are produced at the Kentucky Truck Plant, a testament to the integrated manufacturing approach where diverse models can roll off the same assembly line. Similarly, Ford extends this philosophy to its smaller vehicles; the Ford Bronco Sport and the Escape, for instance, “share their basic underpinnings, since both use the C2 platform.” This platform flexibility demonstrates Ford’s ability to adapt a common architecture for different vehicle types and market niches, from rugged compact SUVs to family crossovers.

Ford’s manufacturing footprint in the U.S. is extensive, with key facilities like the Dearborn Truck Plant producing the popular F-150 and F-150 Lightning, and the Flat Rock Assembly Plant building the iconic Mustang. This robust domestic assembly network, combined with a strategic approach to platform and component sharing, enables Ford to deliver a diverse range of vehicles that leverage proven engineering and achieve significant economies of scale. It’s a smart business model that ensures durability and accessibility across its Ford and Lincoln marques.

5. **Nissan and Infiniti: Synergistic Luxury and Utility**The Renault-Nissan-Mitsubishi Alliance represents a powerful global partnership, bringing together three distinct automakers under a collaborative umbrella. Within this alliance, Nissan’s strategy of sharing components and even production lines with its luxury division, Infiniti, exemplifies how automotive groups can diversify their offerings while maintaining efficiency. Infiniti, established in 1989, was created to compete in the burgeoning luxury segment, building on Nissan’s established engineering expertise.

One clear illustration of this shared approach comes from the manufacturing alignment in the U.S. While Infiniti models generally boast more upscale features, plusher upholstery, and a wider array of optional extras compared to their Nissan-branded counterparts, they frequently “share many components and, in most cases, are built on the same production lines.” A key example is the Infiniti QX60, whose current generation is assembled at Nissan’s Smyrna Plant in Tennessee. This same facility also produces several core Nissan models, including the Rogue, Murano, Leaf, and Pathfinder, highlighting a direct overlap in manufacturing.

The synergy extends beyond shared factory floors. Consider the Nissan Frontier pickup and the Nissan Pathfinder SUV. Though serving different purposes, these vehicles “have more in common than most buyers realize,” both utilizing “the same 3.8L V6 engine and 9-speed automatic transmission.” While the tuning might be adjusted for their respective roles—one for rugged utility, the other for family adventures—the core mechanical parts are identical. This commonality makes “sourcing replacement parts cheaper and easier for both models,” a significant benefit for owners.

While Nissan is working to increase domestic U.S. production for Infiniti, the brand’s manufacturing footprint is global. The entry-level Infiniti QX50 and QX55 (which are being discontinued after 2025) were built in the COMPAS Plant in Aguascalientes, Mexico, a joint venture between Nissan and Mercedes-Benz that also produces the German automaker’s GLB model. Meanwhile, the larger and more expensive Infiniti QX80 is produced in Nissan’s Shatai Kyushu Plant in Japan, alongside other full-size SUV models for global markets. This complex manufacturing network demonstrates the strategic flexibility employed by the Nissan-Infiniti partnership, balancing localized production with global supply chains to meet diverse market demands while maximizing shared resources.

6. **Subaru and Toyota: A Partnership Forged in Performance**While some automotive collaborations involve parent companies and their luxury divisions, others emerge from a deep technical partnership between ostensibly independent brands. The alliance between Subaru and Toyota is a compelling case in point, demonstrating how two distinct automakers can co-develop and co-produce vehicles, especially in niche segments like sports cars. This synergy allows both companies to pool resources and expertise, creating vehicles that might be more challenging to develop individually.

The most iconic example of this close working relationship is the dynamic duo of the Subaru BRZ and the Toyota GR86. For automotive enthusiasts, these two vehicles represent a remarkable feat of engineering collaboration. As the context reveals, from a mechanical standpoint, they are “nearly identical.” This isn’t just a casual similarity; these rear-wheel-drive coupes are literally “built in the same plant with the same engine and transmission,” a clear indicator of their shared DNA.

This extensive co-development ensures a consistent high-performance foundation for both models. Toyota and Subaru intentionally designed these cars together, leading to a strong, reliable platform that delivers a similar driving experience. The primary differentiators between the BRZ and GR86 ultimately come down to subtle “tuning and design details.” These careful calibrations allow each brand to impart its unique flavor and appeal to its specific customer base, offering distinct aesthetic cues and handling nuances without altering the core mechanical excellence.

Beyond this specific sports car project, the relationship between Toyota and Subaru is deeper than many realize. Toyota is noted for holding stakes in other car brands, including Subaru. This financial and strategic investment signifies a broader, long-term partnership that extends beyond individual model development. It underscores a mutual benefit, allowing Subaru to leverage Toyota’s vast resources and Toyota to gain from Subaru’s specialized engineering, especially in areas like all-wheel-drive systems, even if their joint sports car does not utilize that particular technology.

7. **Stellantis: Global Reach, Shared Powerplants**Stellantis, a relatively new automotive giant formed in 2021 from the merger of Fiat Chrysler Automobiles and PSA Peugeot Citroën, embodies a modern approach to global manufacturing efficiency. This conglomerate manages an extensive portfolio of brands, including household names like Jeep, Dodge, Ram, Chrysler, and Alfa Romeo, alongside numerous European marques. Their strategy hinges on maximizing commonality across diverse segments to streamline production and reduce costs, a crucial element for such a broad and varied lineup.

A prime illustration of Stellantis’s internal synergy is the widespread application of its 2.0L turbocharged four-cylinder engine. This single powerplant is found powering a remarkable range of vehicles, including the rugged Jeep Wrangler, the sporty Alfa Romeo Giulia, and the agile Dodge Hornet. This diverse deployment means “It’s one engine, three very different buyers,” demonstrating an astute ability to adapt a core component to suit distinct brand personalities and performance expectations.

This strategy is not merely about engine sharing; it’s a fundamental pillar that “helps the company streamline manufacturing and supply chains.” By using a common engine across multiple platforms, Stellantis reduces the complexity of its production lines, simplifies parts procurement, and enhances overall operational efficiency. For consumers, this translates into benefits such as potentially lower repair costs due to widely available parts and the proven reliability of a well-tested engine design.

Beyond powertrains, Stellantis also practices platform sharing extensively. A notable example is the connection between the Fiat 500X and the Jeep Renegade, which are “built on the same chassis and use the same engine.” This foundational commonality allows for the efficient development of vehicles tailored for different markets—from compact urban crossovers to more adventurous SUVs—all while benefiting from shared engineering and production expertise, including assembly at plants like the Jefferson North Assembly Plant for the Dodge Durango and Jeep Grand Cherokee, and the Warren Truck Assembly Plant for Ram 1500 and Jeep Wagoneer models.

8. **Hyundai Motor Group: Expanding Global Footprint**The Hyundai Motor Group, a formidable force in the global automotive landscape, operates from its base in South Korea and encompasses three distinct yet interconnected brands: Hyundai, Kia, and the rapidly growing luxury division, Genesis. This multi-brand strategy allows the group to cater to a broad spectrum of consumer preferences, from value-oriented compacts to premium SUVs and cutting-edge electric vehicles, all while leveraging shared technological foundations and manufacturing capabilities.

The group’s approach to shared manufacturing and engineering is critical for its global expansion and competitive pricing. By designing common platforms and components, Hyundai, Kia, and Genesis can realize significant economies of scale. For instance, the luxury Genesis brand benefits immensely from the established reliability and advanced engineering developed across the broader Hyundai and Kia portfolios, allowing it to offer premium vehicles built on proven underpinnings.

In the United States, the Hyundai Motor Group boasts a substantial manufacturing presence. The Hyundai Motor Manufacturing Alabama plant is a hub for both Hyundai and Genesis vehicles, assembling models such as the Hyundai Santa Fe, Santa Cruz, and Tucson, as well as the Genesis Electrified GV70. This integrated facility underscores the group’s ability to produce diverse models for different segments under one roof, optimizing production flows and supply chains for domestic markets.

Parallel to this, Kia Motors Manufacturing Georgia plays a vital role in the group’s American production, manufacturing popular Kia SUVs like the Sorento, Sportage, and Telluride, alongside electric vehicles like the EV6 and EV9. Furthermore, the new Hyundai Motor Group Metaplant America in Georgia is set to contribute to EV production with models such as the Ioniq 5 and Ioniq 9. This extensive network of shared and dedicated manufacturing plants across the U.S. demonstrates the Hyundai Motor Group’s commitment to localized production while effectively distributing its engineering and manufacturing prowess across its distinct brands.

Read more about: Navigating the Future: 2025’s Top Self-Driving Cars and the Tech Powering Autonomous Innovation

9. **Mazda and Toyota: Strategic Factory Alliances**While some automotive groups encompass multiple brands under a single corporate parent, others engage in strategic joint ventures to share manufacturing resources and expertise without direct ownership. The partnership between Mazda and Toyota exemplifies this model, especially evident in their joint manufacturing facility in the United States. This collaboration allows both companies to benefit from shared investment in infrastructure and optimized production processes, even as they maintain their independent brand identities.

At the heart of this alliance is the Mazda Toyota Manufacturing USA (MTMUS) plant located in Huntsville, Alabama. This state-of-the-art facility is a testament to how two distinct automakers can pool their resources to build vehicles side-by-side. The plant is responsible for producing key crossover models for both brands, specifically the Mazda CX-50 and the Toyota Corolla Cross. This direct factory sharing highlights a pragmatic approach to automotive production.

The co-production of the CX-50 and Corolla Cross at the same facility offers several advantages. For Mazda, it provides access to advanced manufacturing techniques and a larger production scale, while for Toyota, it helps expand its production capacity for popular models. Such a partnership allows both companies to efficiently bring new models to market, benefiting from shared overheads and potentially improved component sourcing, ultimately contributing to cost-effectiveness and competitive vehicle pricing.

Despite sharing an assembly line, both the Mazda CX-50 and Toyota Corolla Cross retain their unique brand characteristics, reflecting their respective design philosophies and target audiences. This joint venture demonstrates that sharing a factory doesn’t dilute brand individuality but rather enables efficient manufacturing that supports each brand’s distinct product offerings. It’s a clear example of how strategic alliances are shaping the future of automotive production, fostering efficiency and innovation in the industry.

10. **Honda and Acura: Domestic Luxury, Global Engineering**The Honda Motor Company, another pillar of the Japanese automotive industry, has successfully established a dual-brand strategy with its mainstream Honda line and its luxury division, Acura. This approach allows Honda to leverage its renowned engineering and manufacturing capabilities across a broad market spectrum, delivering both reliable, everyday vehicles and sophisticated, premium offerings. What’s particularly noteworthy is the strong commitment of both brands to North American manufacturing.

Acura has truly embraced its role as a naturalized citizen of the U.S. automotive landscape. Its core internal combustion engine (ICE) lineup, including the Integra and TLX sedans, and the MDX and RDX SUVs, are all proudly built in Ohio at facilities such as the Marysville Auto Plant and the East Liberty Auto Plant. This dedication to domestic production extends even to its past, with the acclaimed NSX supercar, which ceased production in 2022, also having been manufactured in the USA, demonstrating a long-standing commitment to American assembly.

In a fascinating display of cross-brand collaboration, Acura has also ventured into the electric vehicle (EV) market by partnering with General Motors. The Acura ZDX electric SUV is manufactured for Honda at a General Motors factory in Tennessee. This alliance showcases how automakers are increasingly collaborating across corporate lines to develop and produce specialized vehicles, leveraging each other’s expertise and manufacturing capacity for emerging technologies like EVs.

This robust domestic manufacturing network is underpinned by Honda’s broader production footprint in the U.S. Major Honda models like the Accord and CR-V are assembled in Ohio, while the Indiana Honda Manufacturing of Indiana plant produces the Civic Hatchback and additional CR-V units. Furthermore, the Alabama Honda Manufacturing of Alabama facility builds popular models such as the Odyssey, Passport, Pilot, and Ridgeline. This extensive and integrated production capability ensures that both Honda and Acura vehicles benefit from efficient, high-quality domestic assembly, reinforcing their reputation for reliability and value in the North American market.

Read more about: Decoding the Disappointment: 15 Overrated Car Brands That Underperform on Reliability and Rack Up Costly Upkeep Bills for Owners

This journey through the intricate world of shared automotive production reveals a landscape far more interconnected than many perceive. From luxury SUVs sharing a frame with their utilitarian counterparts to performance coupes born from a joint vision, the strategic reuse of platforms, powertrains, and even entire factories is a cornerstone of modern manufacturing. This isn’t about deception; it’s about shrewd business acumen, delivering economies of scale that translate into more affordable cars, easier maintenance, and often, enhanced reliability for you, the consumer. So, the next time you see a familiar badge, remember that beneath the surface, there might just be a fascinating story of collaboration and ingenuity waiting to be discovered, proving that sometimes, the best cars are indeed built in the same factory.