You’re driving down the road, music playing, when you hear it—a faint, rhythmic tapping or a deep, unsettling clunking sound coming from under the hood. That sudden intrusion into your peaceful drive sends a chill down your spine. That dreaded sound is engine knocking, and it’s undeniably your car’s way of screaming for help, demanding immediate attention to avoid potentially catastrophic damage.

Ignoring an engine knock is, without a doubt, one of the most expensive mistakes a car owner can make. But what exactly is this perplexing noise? More importantly, what are the crucial steps you should take the moment you hear it? Don’t worry; this comprehensive guide is designed to walk you through everything you need to know, transforming that unsettling sound into a problem you can understand and effectively address.

At its core, engine knocking is a sound generated by a problem within your engine’s cylinders or its intricate moving mechanical parts. It’s important to recognize that not all knocks are created equal. The term is often broadly used to describe two very distinct problems: Spark Knock, also known as Pinging or Detonation, which indicates a combustion issue, and Mechanical Knock, such as Rod Knock, signifying a physical component failure. Being able to identify which type of knock you’re experiencing is the absolutely critical first step toward an accurate diagnosis and an effective repair.

Let’s demystify these noises and break down the most common culprits behind that unsettling sound, starting with those that often have the easiest fixes and progressing towards the more serious mechanical failures that demand immediate professional attention.

1. **Using the Wrong Fuel Octane**One of the most straightforward and, thankfully, least severe causes of engine knocking stems from simply using the wrong type of fuel. The octane rating of gasoline, typically displayed as numbers like 87, 89, or 91, is not just a random figure; it’s a crucial measure of the fuel’s ability to resist detonation, or premature ignition. High-performance or turbocharged engines, in particular, are engineered to compress the air-fuel mixture far more intensely than standard engines, a process that inherently requires higher-octane fuel to prevent early ignition.

If you inadvertently use a lower-octane fuel than your vehicle’s manufacturer recommends, the elevated pressure within the combustion chamber can cause the fuel-air mixture to ignite prematurely, creating what is known as spark knock. This phenomenon is often characterized by a distinct pinging or rattling sound, especially noticeable when the engine is under increased load. Such conditions might include accelerating hard or navigating a steep incline, where the engine is working harder and cylinder pressures are at their peak.

Thankfully, this is often the best-case scenario when it comes to engine knocking. The fix is remarkably simple: the next time you refuel, ensure you fill your tank with the correct, higher-octane fuel as specified in your owner’s manual or on your gas cap. As a temporary measure, you can also consider adding a bottle of octane booster to your current tank to mitigate the immediate effects. In most cases, once the correct fuel is circulating, the problem should resolve itself, offering a quick and affordable remedy.

With the increasing cost of fuel, it can certainly be tempting to opt for the cheapest gasoline available at the pump. However, understanding your vehicle’s specific octane requirements is paramount. Most gasoline vehicles are designed to run perfectly on 87 octane, but for older cars or those with performance-oriented engines, double-checking your owner’s manual is a small step that can save you significant trouble and expense down the road. This preventative measure is one of the easiest ways to ensure your engine runs smoothly and silently.

Read more about: 12 Car Maintenance Myths That Are Costing You Money: A Consumer Reports Deep Dive

2. **Carbon Buildup on Engine Components**Over time, a less obvious yet equally problematic cause of engine knocking is the accumulation of carbon deposits on vital engine components. These hard, black soot-like formations result from unburnt fuel and oil byproducts that settle on your pistons, valves, and cylinder heads. This carbon buildup isn’t just cosmetic; it actively interferes with the engine’s normal operation in several detrimental ways, leading to an unwanted knocking sound.

These deposits essentially do two very bad things to your engine. Firstly, they effectively increase the engine’s compression ratio to levels it was simply not designed to handle. This unprogrammed increase in pressure makes the engine more susceptible to premature ignition. Secondly, these carbon deposits can create “hot spots” within the combustion chamber. These glowing red hot spots can act like unintended, uncontrolled spark plugs, igniting the fuel mixture before the actual spark plug fires, thus causing detonation or spark knock.

The initial step to combat this issue is often a DIY-friendly solution. Pouring a high-quality fuel system cleaner into your gas tank can work wonders. These cleaners are formulated to dissolve and break down carbon deposits, helping to restore the combustion chamber’s intended efficiency. For situations with more stubborn or extensive buildup, however, a professional mechanic can perform a dedicated engine carbon cleaning service, which is a more intensive but highly effective treatment.

If you decide to tackle a more thorough DIY carbon cleaning, a specific procedure involving an intake valve and turbo cleaner can be followed. This typically involves warming and running the engine at a steady 2,000 RPMs, then spraying the product in short bursts through a vacuum line. After emptying the can, the vehicle is accelerated several times, ensuring not to exceed 3,500 RPMs, followed by an idle period, reassembly of the vacuum line, and then a highway drive. This methodical approach helps ensure the cleaner effectively dislodges and burns off those problematic carbon deposits, restoring balance to your engine’s internal workings.

Read more about: Unveiling the Earth’s Fury: An In-Depth Look at America’s Most Hazardous Volcanoes on High Alert

3. **Faulty or Incorrect Spark Plugs**Spark plugs serve as the unsung heroes at the very heart of your engine’s combustion process, initiating the controlled explosions that power your vehicle. If these critical components are old, worn out, or simply not the correct type for your engine, they can become a direct source of knocking. Their ability to produce a strong, consistent spark is essential for efficient and timely combustion, and any compromise here can lead to trouble under the hood.

Worn spark plugs may not generate a powerful enough spark, leading to incomplete or inefficient combustion. This can cause misfires and, consequently, engine knocking or pinging as the fuel-air mixture fails to ignite smoothly. Even more critically, each engine is designed to operate with a spark plug of a very specific “heat range.” Using a plug that is too “hot” for your engine can lead it to overheat, turning the spark plug itself into an unintentional source of pre-ignition, much like the carbon deposits we just discussed.

The most effective fix for this particular cause is straightforward: replace the spark plugs with the exact type and heat range specified by your vehicle’s manufacturer. This isn’t just about functionality; it’s about ensuring your engine’s design parameters are met precisely. Regularly inspecting and replacing spark plugs as part of your scheduled maintenance is not only a common practice but also a relatively affordable repair that can prevent significant engine stress.

When replacing spark plugs yourself, it involves carefully pulling the wire plug from the engine, fitting a socket wrench with an extension bar, and slowly removing the old spark plug from its housing. The new spark plug must then be threaded in and tightened appropriately, ensuring the gap is precisely within the manufacturer’s recommended range. This simple, yet crucial, maintenance task is a highly effective method to prevent engine knocking and maintain peak engine performance and longevity.

Read more about: Steering Clear of Costly Car Button Blunders: Essential DIY & Key Fob Mistakes That Could Drain Your Wallet

4. **Low Engine Oil or Poor Oil Circulation**Now, we enter truly serious territory, where the warning sound of an engine knock signals a potentially catastrophic problem. Engine oil is unequivocally the lifeblood of your motor, performing the vital role of lubricating all moving parts. It creates an incredibly thin, yet incredibly tough, protective film that prevents destructive metal-on-metal contact within the engine’s intricate machinery. When this lubrication fails, either due to critically low oil levels or oil that is old, degraded, and broken down, that protective film disappears, and the consequences can be dire.

Without adequate lubrication, key internal components such as connecting rods, pistons, and the crankshaft begin to violently slam into each other. This direct metal-on-metal impact generates a deep, heavy, and often terrifying mechanical knock. This sound is distinct from a ping; it’s a “thud” or “clunk” that typically gets faster and louder as you increase the engine’s RPMs, signaling severe internal distress and rapidly accelerating wear.

If you ever suspect that low engine oil is the cause of your knocking, the most critical advice is to stop driving immediately. Pull over safely, turn off the engine, and then diligently check your oil dipstick. If the oil level is indeed critically low, carefully add the correct type and viscosity of oil as specified by your manufacturer. However, if the oil level appears fine but the knocking sound persists, it’s a grim indication that significant damage may already have occurred. In such cases, the vehicle should not be driven further and must be towed directly to a qualified mechanic.

While a simple oil change can help keep the engine properly lubricated and prevent some forms of knocking caused by degraded oil, it’s essential to understand its limitations. An oil change will only resolve a knock if the direct cause was extremely low or poor-quality oil, and critically, if no permanent mechanical damage has yet occurred. If the knocking originates from worn-out parts like engine bearings, a fresh oil change, while beneficial for the engine’s overall health, will unfortunately not repair the existing physical damage. Regular oil changes, ideally every 3,000 to 7,000 miles depending on your lubricant, are paramount in preventing such severe issues.

5. **A Faulty Knock Sensor**In the realm of modern automotive engineering, our vehicles are equipped with sophisticated guardians designed to protect the engine: tiny microphones known as knock sensors. Their sole and critical purpose is to constantly listen for the very specific frequency of engine pinging or detonation. When these sensors detect such an anomaly, they don’t just sit idly by; they instantly transmit a signal to the engine’s computer, the Electronic Control Unit (ECU), prompting it to adjust the ignition timing without delay. This proactive adjustment is designed to instantly stop the detonation and safeguard the engine from harm.

However, what happens if this crucial sensor itself fails? If a knock sensor becomes faulty, the engine essentially loses its primary defense mechanism against detonation. The ECU, lacking the vital input from the sensor, is unable to make the necessary ignition timing adjustments. This allows the damaging knock to continue unabated, potentially leading to progressively severe internal engine damage. It’s akin to a fire alarm failing to sound when smoke is detected; the danger persists, unseen and unaddressed.

Diagnosing a faulty knock sensor typically requires more than just listening for sounds; it necessitates the use of a specialized diagnostic tool by a mechanic. This tool can communicate with the ECU, read fault codes, and confirm whether the sensor has indeed failed. Once confirmed, the sensor must be replaced. While the failed sensor itself isn’t an immediate catastrophe for your engine’s core components, the unchecked knocking it permits can quickly escalate into a very damaging situation.

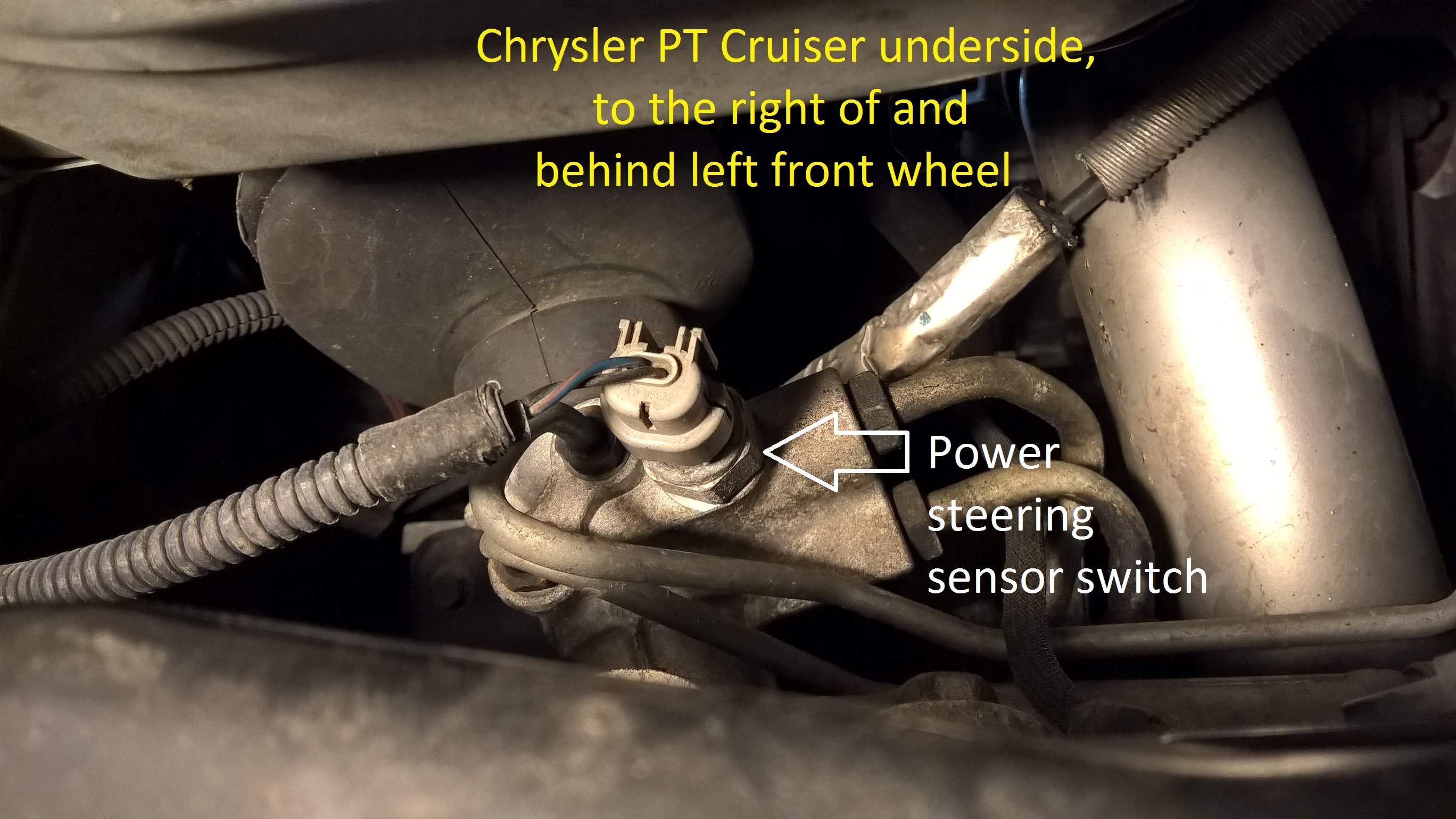

Replacing a knock sensor, depending on its location, can sometimes be a tedious job. Accessing it may involve unplugging electrical connections and possibly removing other components like the oil filter to reach the sensor, which is often located underneath the car, near the engine block. A professional mechanic can efficiently perform this replacement, ensuring the new sensor is correctly installed and functioning, thereby restoring your engine’s critical self-protection system against damaging pre-ignition events.

Read more about: Buyer Beware: 14 Cars Notorious for Breaking Down Prematurely, Especially After 100,000 Miles

6. **Worn Engine Bearings (Rod Knock)**This brings us to perhaps the most feared of all engine noises, a sound that sends shivers down the spine of any experienced mechanic or car enthusiast: the infamous rod knock. Unlike the sharp, metallic ping of spark knock, this is a deep, heavy “thud” or “clunk” that emanates from the very heart of your engine. It’s a sound of severe internal distress, signaling a problem that can swiftly escalate from serious to catastrophic.

Deep inside your engine, the connecting rods play a crucial role, linking the pistons to the crankshaft and converting the linear motion of combustion into rotational power. At these critical connection points are small, incredibly important components called bearings – soft metal inserts designed to provide a cushion and reduce friction between the rapidly moving metal parts. These bearings absorb the violent forces generated by thousands of combustion events per minute, ensuring smooth, precise operation.

However, due to high mileage, prolonged periods of poor maintenance, or, most critically, oil starvation, these vital bearings can wear out. As they deteriorate, the protective gap they maintain between the connecting rod and the crankshaft widens. This extra space allows the connecting rod to violently hammer against the crankshaft with every single rotation, creating that distinctive and deeply unsettling mechanical knock. It’s a literal metal-on-metal impact, steadily grinding away at the engine’s core.

The symptoms of rod knock are unmistakable and deeply worrying. You’ll hear a deep, loud, and hollow clunking sound that gets distinctly faster and louder as you increase the engine’s RPMs. Critically, this sound will not go away; in fact, it will only worsen with continued driving. This isn’t a repair you can afford to delay. The fix for worn engine bearings is far from simple, typically requiring a complete engine teardown to replace the bearings, or, in many cases, a full engine replacement. Professional costs for this kind of repair typically range from $2,000 to $3,000, underscoring the severity of this issue.

7. **Issues with Belt-Driven Accessories**Sometimes, that disturbing knocking sound you’re hearing isn’t originating from the engine’s internal combustion processes or its core mechanical components at all. Instead, the culprit might be lurking on the outside of your engine: one of the various belt-driven accessories. These essential components, such as the water pump, alternator, power steering pump, or A/C compressor, rely on a serpentine belt to draw power and perform their crucial functions, contributing to everything from cooling your engine to powering your electrical system.

Each of these accessories contains internal bearings that allow their components to spin freely and quietly. Over time, and often due to age or wear, the internal bearings within one of these accessories can fail. When this happens, the component can begin to seize, wobble, or simply operate with excessive friction, generating a loud rumbling or even a distinct knocking sound. This external noise can be surprisingly deceptive, easily mistaken for a far more serious internal engine issue, causing unnecessary panic for the vehicle owner.

Diagnosing this particular type of knock requires a mechanic to employ a specialized tool: an automotive stethoscope. By carefully listening to various points on the engine and its accessories, a skilled technician can isolate the exact source of the noise, pinpointing the specific failing component. Once identified, that accessory can then be replaced, resolving the knocking sound. For instance, replacing a serpentine belt can be a DIY job, with costs ranging from $25 to $75 for parts, while professional replacement of a faulty accessory can run from $58 to $126 or more, depending on the part.

The good news is that if the knocking sound is indeed traced back to a failing belt-driven accessory, the severity is generally low to moderate. While the faulty part certainly needs to be addressed and replaced to restore full vehicle functionality and eliminate the annoying noise, your engine itself is likely safe from catastrophic internal damage. This type of fix, though sometimes requiring professional attention, is typically far less costly and less urgent than the deep mechanical knocks discussed previously.

8. **Is Engine Knocking Serious? And What About Repair Costs?**We’ve covered a range of causes for engine knocking, from the relatively simple to the truly catastrophic. Now, let’s be absolutely clear: “Is engine knocking serious?” The short, non-negotiable answer is a resounding yes, it is always serious, and you should make every effort to stop driving as soon as it’s safely possible. Continuing to operate your vehicle with a knocking engine is not merely a gamble; it’s a direct invitation to potentially ruinous expenses and irreversible damage.

Consider the consequences if the knock is categorized as spark knock or pinging. While initially less severe than mechanical knock, prolonged and untreated detonation can lead to incredibly damaging outcomes. The excessive heat generated within the cylinders can literally melt pistons, severely damage cylinder walls, and even blow head gaskets. What might begin as a minor adjustment or a simple fuel additive problem can quickly snowball into thousands of dollars in repairs, transforming a manageable issue into a financial nightmare due to neglect.

The stakes become exponentially higher if the noise is a mechanical knock, particularly the dreaded rod knock. In this scenario, you are quite literally on borrowed time. Every single rotation of your engine with worn bearings or components is causing more and more destructive metal-on-metal damage. The worst-case scenario is horrific: a connecting rod can eventually break free from the crankshaft and punch a hole straight through the side of your engine block, causing a complete and utterly irreparable engine failure. This is why if the knock is loud, deep, or accompanied by a flashing check engine light, you must pull over immediately and call for a tow. It’s simply not worth the risk.

The financial impact of engine knocking is as varied as its causes, with repair costs swinging wildly between a few dollars and thousands. For instance, a simple fix like using the correct fuel octane might only cost $10 to $20 for an additive or premium fill-up. Addressing carbon buildup can range from $15 for a DIY cleaner to $150–$400 for a professional service. Replacing faulty spark plugs is often $50–$150 DIY or $200–$500 professionally. Even a faulty knock sensor might cost $150–$450 to replace by a professional.

However, the cost climbs dramatically for more severe issues. Repairing worn belts or pulleys typically falls between $200–$600. But the most alarming figure comes with worn engine bearings or rod knock, where the repair is not DIY possible and can cost anywhere from $2,500 to a staggering $7,000 or more for an engine rebuild or complete replacement. These figures are general estimates, and actual prices can vary significantly based on your specific vehicle model, your location, and the particular repair shop. The message is clear: early diagnosis and action are your absolute best defenses against these potentially crippling costs.

9. **Proactive Prevention Strategies for Engine Knocking**While knowing how to diagnose and fix an engine knock is crucial, the truly smart mechanic – and car owner – understands that the best way to “fix” an engine knock is to never let it happen in the first place. Proactive prevention through diligent and regular maintenance is your ultimate defense against these frustrating and often expensive issues. Embracing a disciplined maintenance routine will not only save you money but also ensure your vehicle runs reliably and efficiently for years to come.

Starting with the easiest and most impactful step, always use the right fuel for your vehicle. This isn’t a recommendation; it’s a fundamental requirement. Check your owner’s manual or the inside of your gas cap for the manufacturer’s recommended octane rating. Using a lower octane than specified in high-performance or turbocharged engines is a direct pathway to spark knock. This simple act of filling up with the correct fuel is a cost-effective and essential preventative measure that directly impacts your engine’s health and longevity.

Equally vital is performing regular oil changes with a high-quality oil and filter. Engine oil is nothing short of your motor’s lifeblood, maintaining that protective film between moving parts and preventing destructive metal-on-metal contact. Following your vehicle’s recommended oil change schedule religiously—ideally every 3,000 to 7,000 miles depending on your lubricant—is paramount. This consistent lubrication regimen prevents the mechanical wear that commonly leads to severe issues like rod knock, ensuring that delicate internal components remain cushioned and cool.

Furthermore, never underestimate the power of following your vehicle’s scheduled maintenance plan. Don’t skip those routine tune-ups! Replacing spark plugs, air filters, fuel filters, and other critical components on time ensures that your engine operates at peak efficiency. Worn spark plugs lead to inefficient combustion, clogged filters starve your engine of vital air or clean fuel, and these seemingly small issues collectively contribute to the conditions ripe for engine knocking. Adhering to the maintenance schedule is an investment in your car’s long-term health.

To further safeguard against carbon buildup, consider using a quality fuel system cleaner every 5,000 to 10,000 miles. These additives, poured directly into your gas tank, are formulated to dissolve and prevent the accumulation of those stubborn carbon deposits that can create “hot spots” and increase compression, leading to detonation. And remember, your check engine light is your car’s early warning system; it’s designed to alert you to problems before they escalate. Never ignore this indicator – get it diagnosed promptly by a professional.

Finally, a holistic approach to preventing engine knock involves being mindful of how you drive and maintaining your engine’s overall health. Avoid pushing your engine too hard under heavy loads, such as excessive towing beyond specifications, or consistent hard acceleration. Regularly monitor your engine’s temperature gauge and take proactive measures to ensure your cooling system is in top condition, as overheating can exacerbate the conditions for knocking. By combining the right fuel, meticulous maintenance, and attentive driving habits, you can keep that annoying and damaging knock at bay, ensuring your vehicle remains a reliable companion on the road.

Read more about: The Shocking Truth About Car Repair Costs: 14 Expensive Fixes That Can Drain Your Wallet

An engine knock is far more than just a bothersome sound; it’s an urgent message from your vehicle, a critical warning sign demanding your immediate attention. While the spectrum of causes ranges from straightforward issues like incorrect fuel to terrifying internal failures, the common thread is the need for swift, informed action. Equipped with the knowledge to identify the different types of knocks, understand their origins, and recognize their severity, you are empowered to make crucial decisions. Whether it’s a simple pour-in solution or the undeniable need for a professional mechanic, addressing that knocking sound quickly is the difference between a minor repair and a potentially devastating engine replacement. Listen to your car, take action, and keep your trusty machine running smoothly, silently, and safely for the many miles ahead.