The automotive industry is undergoing its most significant transformation in a century, with electric vehicles (EVs) rapidly moving from niche status to the mainstream. President Joe Biden’s commitment to making two-thirds of all new cars in the U.S. electric by 2032, coupled with major manufacturers like General Motors planning to cease internal combustion engine (ICE) vehicle production by 2035, signals a clear and irreversible shift. This evolution, however, doesn’t just impact drivers and manufacturers; it profoundly affects the frontline professionals who keep our vehicles running: the mechanics.

While the promise of a greener, more efficient future is exciting, an unexpected hurdle has emerged for many EV owners: finding a mechanic willing to service their car. This isn’t just about the occasional specialized repair; it’s becoming a widespread issue, particularly for owners of newer or less common EV brands. For mechanics, it’s not a simple refusal of business; it’s a complex decision rooted in a confluence of practical, financial, and technical challenges that fundamentally change the nature of their work.

This in-depth exploration will unpack the primary reasons why many skilled automotive technicians are expressing apprehension, and in some cases, outright refusing to work on modern electric cars. We’ll dive into the specific hurdles that transform a routine service call into a potential quagmire for independent shops, from the demands of specialized training to the complexities of rapidly evolving technology and proprietary systems. Understanding these factors is crucial for anyone navigating the current automotive landscape, whether you’re an EV owner, a prospective buyer, or a professional in the service industry.

1. **Lack of Training and Certification**

One of the most significant and immediate barriers preventing mechanics from confidently working on modern electric vehicles is the profound lack of specialized training and the rigorous certification requirements associated with these complex machines. EVs operate on fundamentally different principles than traditional gas-powered cars, requiring an entirely new skill set. Mechanics must possess a deep understanding of high-voltage electrical systems, intricate software architectures, and often, brand-specific components that are unfamiliar territory for many.

The Motor Vehicle Service and Repair Act, Act 300 of 1974, provides a robust framework for regulating vehicle repair, mandating certification for individuals who recondition, replace, diagnose, adjust, or alter a vehicle’s operating condition for compensation. This includes major repairs, bench repairs within a registered facility, estimating structural damage, or even verifying that no structural repairs are necessary. This legal requirement underscores the importance of proper qualification, which becomes a significant hurdle when dealing with the advanced and distinct systems found in EVs. Independent shops often struggle to acquire the necessary resources and time to get certified across every new EV brand that enters the market, especially given that training can be both expensive and not always readily accessible from manufacturers.

Consequently, many mechanics make the pragmatic decision to stick to the brands and technologies they are familiar with and certified to service. This conservative approach, while understandable from a business perspective, leaves owners of certain EV brands with severely limited options for maintenance and repair. The gap between the rapid proliferation of new EV models and the pace at which the broader mechanic workforce can adapt its skills and certifications creates a bottleneck in the service ecosystem, contributing directly to mechanics’ reluctance to engage with unfamiliar electric vehicle platforms.

Read more about: Navigating the New Reality: Key Shifts and Strategic Imperatives for Car Dealerships in the Coming Year

2. **Proprietary Parts and Tools**

The challenge of proprietary parts and specialized diagnostic tools represents another formidable obstacle that often compels mechanics to refuse work on certain electric vehicle brands. Unlike the relatively standardized components found in many internal combustion engine vehicles, some EV manufacturers opt for exclusive designs and systems that are not openly accessible to independent repair shops. This exclusivity extends beyond physical parts to the sophisticated software and hardware required for diagnostics and programming.

When a mechanic cannot access the precise tools or acquire the correct replacement parts, even basic maintenance or a seemingly straightforward repair becomes fraught with risk. Attempting to service a vehicle without the manufacturer’s approved equipment can lead to unintended damage, compromise the vehicle’s intricate systems, or, critically, void the car’s warranty. This potential for severe financial and reputational repercussions is a powerful deterrent for local shops, who must prioritize safety, efficacy, and customer satisfaction.

Brands that intentionally restrict access to their repair information, require exorbitant investments in brand-specific diagnostic equipment, or maintain tight control over their parts supply chains create a significant barrier for third-party service providers. For a mechanic, taking on a job they cannot complete safely, profitably, or with the assurance of proper functionality is simply not a viable business decision. This proprietary stranglehold, therefore, directly contributes to the reluctance of independent mechanics to service certain EV brands, channeling owners back to often more expensive and less convenient manufacturer-certified service centers.

Read more about: The No-Regrets Guide: Unmasking 15 Cars Owners Are Desperate to Trade Up From After Just One Year

3. **Warranty and Liability Concerns**

The landscape of electric vehicle repair is also heavily shaped by substantial warranty and liability concerns that often make mechanics hesitant to work on unfamiliar or niche EV brands. The advanced and high-value components of EVs, particularly the battery pack, come with significant protections and equally significant risks. New electric vehicles are, thanks to federal law, equipped with an 8-year/100,000-mile warranty specifically for the battery, which alone can cost anywhere from $4,000 to $20,000 to replace. This contrasts sharply with the typical 3-year/36,000-mile warranty on popular ICE vehicles like the Ford F-150.

This extended and high-stakes warranty coverage means that manufacturers are often very strict about who can perform repairs or maintenance. If an unauthorized shop undertakes work on an EV, there is a substantial risk that the vehicle’s warranty could be entirely voided. This places an enormous burden of responsibility on independent mechanics, who face not only the potential for costly damages if a repair goes awry but also the risk of rendering a customer’s expensive vehicle uncovered by its warranty. The legal and financial ramifications of such an outcome are a major disincentive.

Furthermore, the inherent complexities and high-voltage systems of EVs introduce new layers of liability. A mistake in servicing could lead to severe injury, property damage, or long-term vehicle malfunctions, for which the mechanic could be held responsible. Faced with these considerable potential legal and financial consequences, many independent mechanics prudently choose to avoid working on unfamiliar EV brands, especially those from newer or less common manufacturers whose warranty terms and technical support structures may be particularly stringent or opaque.

Read more about: Nightmare in the Driveway: 10 SUVs Dealers Say They Can’t Move Due to Lingering Issues

4. **Rapidly Evolving Technology**

The breakneck pace of technological advancement in the electric vehicle sector presents a constant and daunting challenge for automotive mechanics, significantly contributing to their reluctance to service a wide array of EV brands. The internal workings of electric vehicles are in a perpetual state of flux, with new software updates, innovative battery designs, and enhanced safety features being introduced almost annually. This rapid evolution far exceeds the more incremental changes typically seen in the internal combustion engine vehicle market.

While mechanics are accustomed to continuous learning as part of their profession, the sheer speed and breadth of change in the EV world are unprecedented. Keeping abreast of every new development, every software patch, and every hardware revision across multiple EV brands is a nearly impossible task for smaller, independent shops. Many brands further complicate matters by rolling out updates and system changes that can only be handled by their own certified service centers, effectively locking out the independent repair sector from crucial aspects of vehicle maintenance.

This constant need for updated knowledge, specialized tools, and often proprietary software renders broad-spectrum EV servicing an economically and logistically challenging endeavor. Mechanics must weigh the considerable investment of time and money required to stay current against the actual volume of business for specific EV models. Consequently, many independent shops choose to focus their resources on EV brands with more stable, accessible technology, or those for which they can obtain reliable support and training. This dynamic means that owners of vehicles from rapidly innovating or less standardized EV manufacturers often face a narrower pool of qualified service providers.

Read more about: The Great American Road Trip Renaissance: Why Highways Are Conquering the Skies in 2025

5. **Fewer Repair Needs**

Beyond the immediate technical hurdles, a more fundamental economic shift is at play: electric vehicles simply require less maintenance than their internal combustion engine (ICE) counterparts. This reduction in service opportunities poses a significant long-term threat to the business model of independent automotive shops. As one former automotive technician and union official, Sam Cicinelli, succinctly put it, EVs are “going to starve a lot of people out of this industry,” highlighting the profound impact on livelihoods.

The statistics bear this out, illustrating a clear divergence in maintenance requirements. According to AAA’s findings, traditional gasoline-powered vehicles accrue an average of $949 in annual maintenance costs. In stark contrast, electric vehicles cost an average of $330 less to maintain over the same period. This substantial difference is not a minor adjustment; it represents a fundamental change in the volume and type of work available for mechanics, directly impacting their revenue streams and long-term viability.

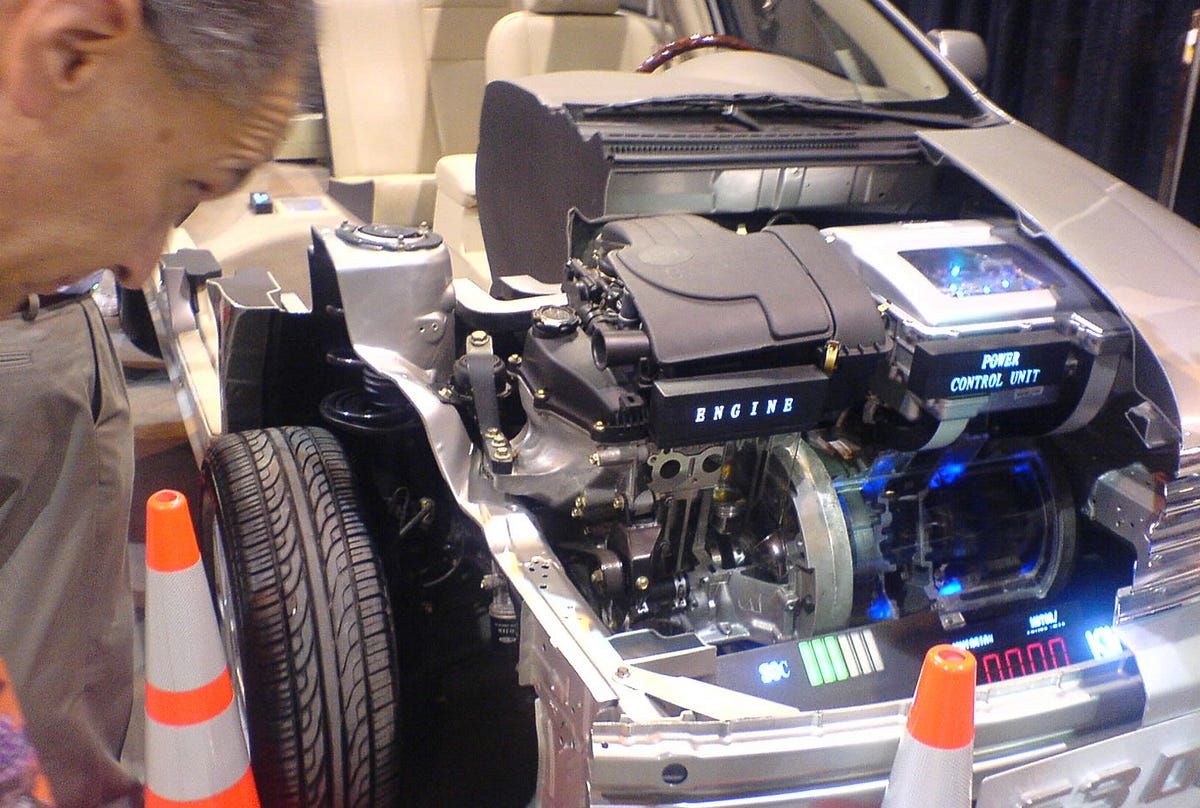

This dramatic reduction in maintenance needs stems from the inherent simplicity of an EV’s powertrain compared to an ICE vehicle. A conventional car boasts approximately 33,000 moving parts, a complex symphony of gears, belts, and fluids all susceptible to wear and tear. An EV, by comparison, operates with a mere 13,000 parts, drastically cutting down on potential failure points. This means no more oil changes, no oil filter replacements, and no elaborate cooling systems specifically designed to prevent an engine from overheating, because, quite simply, there is no engine in the traditional sense. Even components like brakes, while still requiring occasional replacement, do so far less frequently in EVs due to regenerative braking systems that reduce wear.

This reality creates a challenging dilemma for independent mechanics. While they might embrace the environmental benefits of EVs, the economic imperative to maintain a profitable business necessitates a steady flow of repair work. With fewer routine services and less frequent complex repairs, the traditional revenue streams that sustained these shops for decades begin to dwindle, making them understandably apprehensive about a future dominated by vehicles that require substantially less attention under the hood.

Read more about: Tire Specialist’s ‘Crucial’ Tips: Double Your Tire Life Without Ever Buying a More Expensive Brand

6. **Extended Manufacturer Warranties**

Another significant factor driving mechanics away from modern electric vehicles, particularly those from newer or less established brands, is the prevalence of extended manufacturer warranties. These comprehensive warranty packages, while a boon for EV owners, channel much-needed service and repair work away from independent shops and directly into dealership service centers. This effectively reduces the accessible market for third-party mechanics, further complicating their business strategies in an evolving automotive landscape.

Federal law plays a crucial role in establishing these extended protections for EVs. Specifically, new electric vehicles are mandated to come with an 8-year or 100,000-mile warranty exclusively for the battery. This is a crucial detail, as the battery pack itself is the most expensive single component in an EV, with replacement costs ranging anywhere from $4,000 to an eye-watering $20,000. Comparing this to a popular internal combustion engine vehicle, like the Ford F-150, which typically offers a 3-year or 36,000-mile warranty, highlights the substantial difference in coverage.

Dave Kusa, owner of AutoTrend Diagnostics in Campbell, California, points to these lengthy warranties as a key reason independent shops are struggling. He notes that shops are “going out of business not just because EVs create fewer service opportunities, but also because they’re sold with hefty warranties.” This dynamic means that for the better part of a decade, and often beyond 100,000 miles, EV owners are incentivized, and often required by warranty terms, to seek service at authorized dealerships. This dramatically limits the window for independent shops to capture repair business, especially for major, high-value components.

For an independent mechanic, investing in the specialized tools, training, and certifications for an EV brand only to find that the vast majority of potential customers are locked into dealership service agreements for years due to warranty clauses represents a poor return on investment. This economic reality reinforces the apprehension, making it a pragmatic business decision to focus on vehicles that offer a more consistent and accessible stream of repair work, leaving a segment of the EV market largely untouched by third-party service providers.

Read more about: The Unvarnished Truth: 10 Electric Vehicles That Failed to Deliver on Reliability for Early Adopters

7. **Limited Support from Certain Brands**

The absence of robust support networks for independent mechanics from certain electric vehicle brands creates a significant barrier to their willingness to service these cars. Unlike established internal combustion engine manufacturers who have decades-long relationships with the aftermarket, some EV brands, particularly newer entrants, prioritize their proprietary service centers. This leaves local independent shops feeling isolated and ill-equipped when faced with the complexities of modern EVs.

When an independent mechanic encounters a diagnostic puzzle or a repair challenge on an unfamiliar EV, the ability to access technical support, detailed service manuals, or even a responsive helpline can be the difference between a successful repair and a frustrated customer. However, not all EV brands have invested adequately in providing this crucial support to the broader repair ecosystem. Some deliberately focus on developing their own branded service infrastructure, inadvertently creating a ‘closed loop’ that excludes third-party repairers.

This lack of readily available technical assistance can transform a seemingly straightforward issue into a protracted and costly ordeal. Imagine a mechanic spending hours trying to diagnose a software glitch or locate a specific wiring diagram without any official guidance – it quickly becomes a “nightmare,” as described in the industry. Brands that are “slow to answer questions or provide manuals” directly contribute to the apprehension among even the most experienced professionals, as they simply cannot afford to dedicate excessive, unbillable time to troubleshooting without manufacturer backing.

Consequently, the decision not to work on certain EV brands often boils down to practical limitations. Without direct manufacturer support, independent shops face increased risk, higher labor costs due to extended diagnostic times, and the potential for reputational damage if they cannot complete a repair effectively. This reality pushes mechanics to gravitate towards brands that offer a more transparent and supportive relationship, ensuring they can confidently and efficiently resolve customer issues.

Read more about: Regulatory Headwinds and Market Shifts: The Uncertain Future of the American V8 Muscle Car

8. **Low Demand for Niche EV Brands**

The economics of low demand for specific, often niche, electric vehicle brands is another compelling reason why many independent mechanics are reluctant to invest in their servicing. For a business to justify the considerable outlay for specialized training, proprietary tools, and a stock of specific parts, there needs to be a consistent and sufficient volume of work for those particular vehicles. When a brand has a limited presence in a given geographic area, that justification simply doesn’t materialize.

Consider a scenario where an independent shop might encounter only one or two vehicles from a less common EV brand throughout an entire year. The cost of obtaining the necessary certifications, purchasing unique diagnostic equipment – which can be expensive – and maintaining an inventory of rare parts becomes disproportionate to the actual revenue those few service calls would generate. Mechanics, as business owners, must make pragmatic decisions to ensure profitability and resource allocation, and servicing an infrequently seen vehicle often doesn’t make financial sense.

This creates a challenging cycle for both owners and mechanics. Fewer shops are willing to invest in supporting rare or niche EV brands because the demand is low. This, in turn, makes it incredibly difficult for owners of those specific vehicles to find qualified local service, thereby further limiting the local demand as potential buyers perceive a lack of robust aftermarket support. The scarcity of service options can even deter future sales of such brands in a given region, perpetuating the problem.

For independent shops, the strategic decision is often to prioritize the EV brands that are gaining significant traction and market share, as these represent a more reliable stream of future business. While they may be open to expanding their capabilities, the initial investment must be met with a reasonable expectation of return. Consequently, owners of vehicles from emerging or less popular EV manufacturers often face a narrower pool of service providers, compelling them to travel greater distances or rely solely on manufacturer-certified dealerships.

Read more about: The Great American Road Trip Renaissance: Why Highways Are Conquering the Skies in 2025

9. **Resistance to Learning New Skill Sets**

Finally, a deeply human, yet significant, factor contributing to mechanics’ apprehension about electric vehicles is an inherent resistance to change and the prospect of learning an entirely new skill set. The automotive service industry has long been built on the principles of mechanical engineering, hydraulics, and combustion. The shift to EVs, however, demands a retooling of the trade, requiring a profound understanding of computer programming, high-voltage electrical systems, and complex software integrations – a stark departure from traditional nuts and bolts.

As David Favre, dean of transportation at Wake Tech, North Carolina’s largest community college, aptly observes, “A lot of people are resistant to change because they have to learn a whole new skill set.” Many veteran mechanics have dedicated decades to mastering internal combustion engine technology. The idea of effectively starting over, or at least undergoing extensive and continuous retraining, can be daunting. It’s not merely about acquiring new knowledge, but about fundamentally altering their diagnostic processes and problem-solving approaches, moving from tactile mechanical repairs to intricate digital troubleshooting.

The transition requires not only classroom learning and hands-on training but also a shift in mindset. For some, the passion for automotive repair stems from the tangible, mechanical nature of the work. The abstract world of software diagnostics and high-voltage safety protocols, while critical, may not resonate with every experienced technician. This can lead to a natural reluctance to embrace the new paradigm, preferring instead to continue working on the ICE vehicles they understand intimately and can service confidently.

While the industry pushes forward, the human element of professional adaptation cannot be underestimated. This resistance, whether due to comfort with established routines, the perceived difficulty of new material, or simply a lack of enthusiasm for the technological shift, contributes to the shortage of EV-ready mechanics. It underscores that the transformation of the automotive industry isn’t just about technology and economics; it’s also about the workforce’s willingness and ability to evolve alongside it, leaving many mechanics in a difficult position as the future rapidly accelerates.

Read more about: Tom Cruise’s Ageless Secret: Unpacking His Extreme Fitness Routine Trainer Reactions and The Big2025Stunt Double Reveal

The journey to a fully electric automotive future is undoubtedly exciting and full of promise, yet it is also fraught with practical challenges that ripple through every layer of the industry. From the specialized training and proprietary tools to the economic realities of fewer repairs and extended warranties, and even the human element of adapting to entirely new skill sets, the reasons why independent mechanics are apprehensive about working on modern electric cars are complex and multifaceted. Understanding these hurdles is not about casting blame, but about acknowledging the profound transformation underway and seeking solutions that support both vehicle owners and the dedicated professionals who keep our cars on the road. As EVs become an increasingly common sight, fostering an environment where mechanics feel equipped, supported, and motivated to service them will be paramount to ensuring a smooth and sustainable transition for everyone involved.” , “_words_section2”: “1774