In the complex ecosystem of modern logistics and transportation, semi-trailers stand as the backbone, tirelessly moving goods across vast distances. Yet, beneath their sturdy exteriors, insidious problems often lurk, compromising their operational integrity even before they embark on their intended journey. Among these, leaks — both from the roof and within the critical air systems — represent a pervasive and often underestimated challenge, leading to significant financial losses, safety hazards, and disruptions in the supply chain.

These seemingly minor breaches are far more than mere inconveniences; they are systemic vulnerabilities that can ripple through an entire operation. Water intrusion into the cargo bay can spoil sensitive goods, degrade packaging, and accelerate corrosion of the trailer’s internal structure. Meanwhile, a compromised pneumatic system, crucial for braking, suspension, and loading mechanisms, can lead to reduced fuel efficiency, impaired braking performance, and unstable cargo, putting both drivers and other road users at significant risk.

Understanding the ‘why’ and ‘how’ behind these leaks is paramount for fleet owners, managers, and manufacturers. This in-depth analysis will dissect the most common causes of trailer roof leaks, explore the methodologies for effective repair, and illuminate proactive preventative maintenance strategies. By dissecting these issues with a Wired-esque analytical lens, we aim to provide a comprehensive guide to fortifying your fleet against these silent saboteurs, ensuring longevity, safety, and optimal performance.

1. **The Silent Degradation: Worn Seals and Cracked Seams**Most trailers are constructed with roof panels, typically made of aluminum or fiberglass, which are meticulously joined at seams. These seams are not merely abutted; they rely on specialized waterproof adhesives or tapes to form a hermetic seal against the elements. However, this critical layer of protection is under constant assault from environmental factors, initiating a process of silent degradation.

Ultraviolet (UV) radiation from sunlight relentlessly bombards these sealants, breaking down their molecular structure over time. Concurrently, the relentless cycle of rain, snow, and extreme temperature fluctuations—from scorching summer days to freezing winter nights—causes these materials to expand and contract. This continuous mechanical stress, combined with chemical degradation, inevitably leads to the sealant drying out, hardening, and developing microscopic cracks.

These seemingly insignificant fissures are the initial breach points. What begins as a hairline fracture can, over time and repeated exposure, propagate into larger gaps. Through these nascent openings, water can insidious seep into the trailer’s interior. This moisture ingress, if left unaddressed, triggers a cascade of problems, including rust formation on metallic components, the proliferation of mold and mildew within the cargo space, and, most critically, progressive structural damage to the trailer’s frame.

Addressing this particular vulnerability requires a sophisticated understanding of material science and environmental engineering. The choice of sealant, its application, and the frequency of reapplication are all critical variables in mitigating the long-term effects of environmental exposure. A proactive approach to monitoring and renewing these seals is not just maintenance; it is an investment in the structural integrity and operational lifespan of the trailer.

2. **External Assault: Road Debris and Roof Panel Damage**The robust construction of semi-trailers often instills a sense of invulnerability, yet their roofs remain susceptible to a variety of external assaults. While designed for durability, the lightweight aluminum and fiberglass panels, chosen for efficiency, are not entirely indestructible. The open road, with its myriad hazards, presents a constant threat to this critical surface.

Consider the impact of a low-hanging tree branch, a common occurrence during routing through less-traveled paths or rural depots. Such an encounter can inflict anything from a superficial scratch to a significant dent or even a tear in the roof panel. Similarly, severe weather events like hailstorms can pummel the roof surface, leaving a constellation of small but critical indentations or punctures. Furthermore, high-speed travel on highways often exposes trailers to flying debris, ranging from small rocks to unsecured cargo from other vehicles, each carrying the potential for a damaging impact.

Even what appears to be a minor puncture, perhaps no larger than a coin, can become a critical vulnerability. These breaches act as direct conduits for rainwater and ambient moisture to infiltrate the trailer’s interior. This infiltration does not just threaten the cargo; it initiates a more insidious process of internal degradation. The constant presence of moisture can weaken the trailer’s structural frame, compromise electrical systems, and accelerate corrosion, leading to more profound and costly long-term problems that extend far beyond the initial cosmetic damage.

Effective mitigation of these risks requires both diligent driver awareness and robust, regular inspections. Drivers must be trained to identify and avoid common overhead hazards, while maintenance teams must implement rigorous post-trip inspection protocols. The focus should be on detecting even the smallest signs of panel compromise before they evolve into significant structural and functional failures.

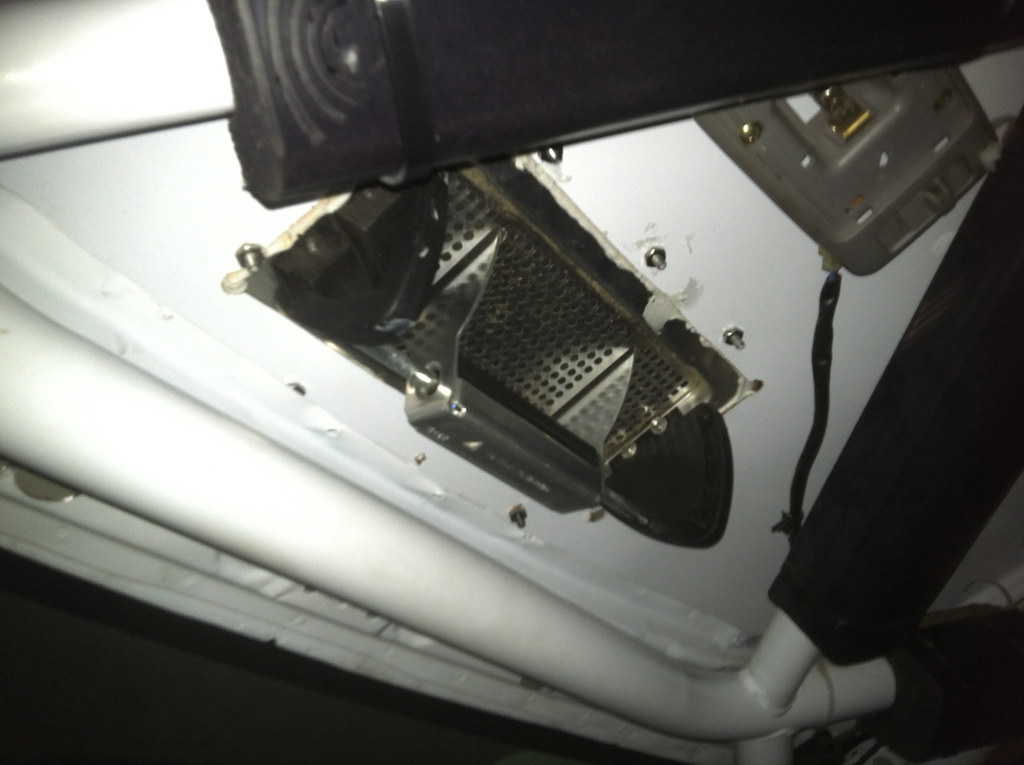

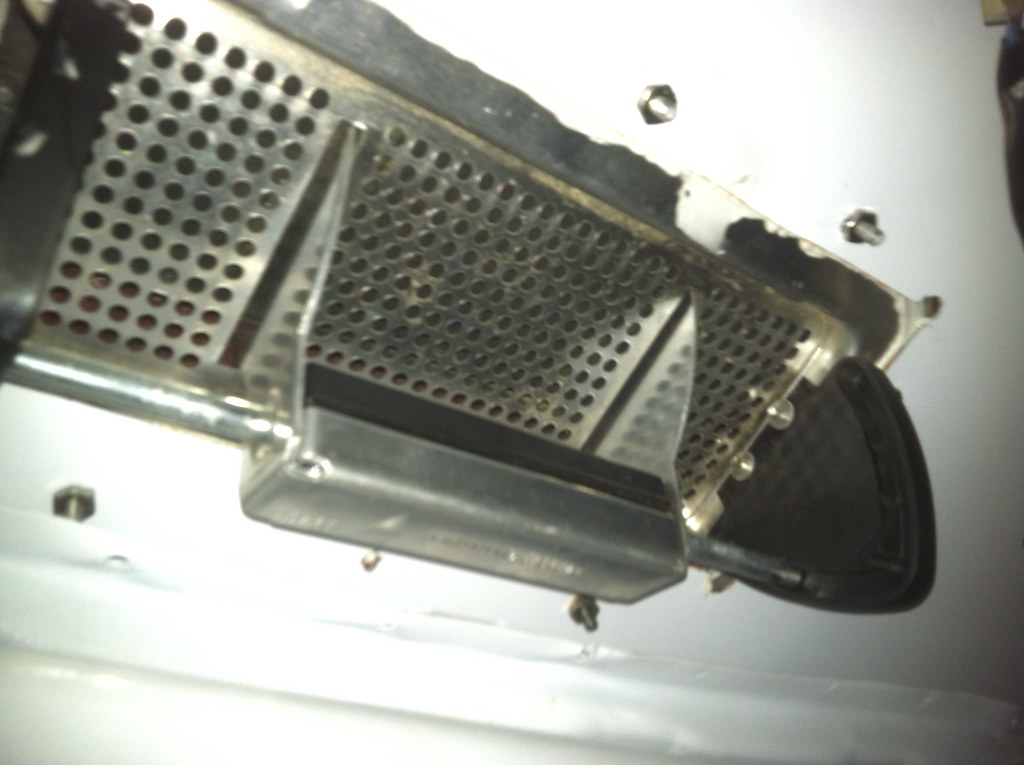

3. **Overlooked Vulnerabilities: Aging Vents and Loose Fasteners**While much attention is often paid to the expansive roof panels and their primary seams, the smaller, integrated components like roof vents and the numerous fasteners that secure the roof often become overlooked vulnerabilities. These elements, though secondary in surface area, are primary points of potential failure, creating pathways for water intrusion with significant consequences for cargo and trailer longevity.

Roof vents are essential for proper ventilation in dry vans and refrigerated trailers, facilitating airflow and temperature regulation. However, their efficacy and watertightness depend heavily on the integrity of their gaskets and seals. Over time, these materials, much like seam sealants, are subject to degradation from UV exposure, temperature fluctuations, and continuous vibration during transit. As they deteriorate, these gaskets and seals lose their elasticity and adhesion, creating subtle gaps around the vent openings. These gaps, often imperceptible without close inspection, become direct entry points for water.

Beyond vents, the structural fastening of the roof—a network of rivets, screws, and bolts—presents another critical area of concern. These fasteners are subjected to constant stress from road vibrations, flexing of the trailer frame, and aerodynamic forces. Over extended periods, these forces can cause the fasteners to loosen. When a rivet or screw works itself free, it creates a small but consistent opening around its insertion point. This allows water to seep into the fastener holes, initiating slow, chronic leaks that can go unnoticed for extended periods, silently causing significant damage to the trailer’s internal structure and potentially its electrical systems before any external signs become apparent. Correct installation and regular inspection of these components are thus vital to maintaining the overall waterproof integrity of the trailer.

4. **The Persistent Puddle: Standing Water and Poor Drainage**Unlike the sloped roofs commonly found in residential or commercial buildings, the roofs of most semi-trailers are designed with a largely flat profile. This design, while offering practical advantages for cargo loading and aerodynamic efficiency, introduces a significant hydrological challenge: the natural drainage of water. Without an inherent slope to guide precipitation away, trailer roofs are particularly susceptible to the accumulation of standing water.

This phenomenon is exacerbated by minor structural deformations. Even subtle dents, small depressions, or slight sagging sections, which can develop over time due to impacts, uneven loading, or material fatigue, can create localized low points on the roof surface. These depressions act as basins, allowing rainwater to pool rather than drain off. This pooling is not a benign event; it represents a concentrated, persistent load on the roof structure and its various sealing points.

The constant presence of standing water exerts continuous pressure on roof seams, vent seals, and fastener points. Over time, this sustained exposure to moisture accelerates the degradation of sealants and materials. The water essentially finds and exploits any microscopic weakness, slowly compromising the roof’s integrity. The weight of accumulated water also adds stress to the trailer’s frame, potentially worsening existing dips or creating new ones, thereby perpetuating a vicious cycle of poor drainage and increased leak risk. Effective trailer maintenance must therefore include not just leak detection, but also structural assessments to ensure proper roof contour and unimpeded drainage pathways.

5. **Precision Detection: Identifying Elusive Roof Leak Sources**Before any effective repair can be initiated, the precise source of a roof leak must be identified. This task, often more challenging than it appears, requires a systematic and meticulous approach. Water, after all, has a deceptive way of traveling along internal structures, making the point of entry appear far removed from where it finally manifests inside the trailer.

The initial step in this diagnostic process is a thorough visual inspection of the entire roof exterior. This involves carefully scanning for any visible anomalies that might indicate a compromise in integrity. Technicians should specifically look for tell-tale signs such as fine cracks in sealants along seams, any evidence of peeling paint, areas of rust formation, or loose fasteners. Furthermore, careful attention should be paid to the roof panels themselves, scrutinizing them for any dents, punctures, or signs of wear and tear, even those that seem minor at first glance. All roof-mounted components, like vents and lights, must also be meticulously checked for their seal integrity and structural soundness.

Following the visual assessment, a more dynamic method is often employed: the water test. This involves systematically spraying the roof with a hose or, for a more intense simulation of heavy rainfall, a pressure washer. During this external application of water, a second technician should simultaneously inspect the trailer’s interior, searching for any signs of water entry. This real-time observation allows for a direct correlation between where water is applied externally and where it appears internally, significantly aiding in pinpointing elusive leak sources. Particular attention during this test should be directed towards common leak points such as roof seams, the areas around vents, and the numerous rivets and fasteners that secure the roof panels, as these are historically the most frequent culprits in water intrusion scenarios. This two-pronged approach ensures that both static and dynamic vulnerabilities are uncovered, forming a solid basis for targeted repair.

6. **Engineered Solutions: Step-by-Step Roof Repair Protocols**Once a leak source has been precisely identified, prompt and effective repair is critical to prevent further damage and restore the trailer’s integrity. The repair process is not a one-size-fits-all solution; it depends on the nature and severity of the damage. A structured, step-by-step approach ensures durability and long-term efficacy.

The foundational step for any repair is meticulous surface preparation. The area around the leak must be impeccably clean and free of contaminants. This involves using tools such as a wire brush or sandpaper to thoroughly remove any old, degraded sealant, rust, or peeling paint that could impede proper adhesion. Following mechanical cleaning, the area should be treated with isopropyl alcohol or a suitable degreaser, ensuring all residues are eliminated. This rigorous preparation is non-negotiable, as it guarantees optimal bonding for new repair materials. Crucially, the cleaned surface must then be allowed to dry completely before any further materials are applied, as moisture trapped beneath a repair will inevitably compromise its effectiveness.

For minor leaks and hairline cracks, the application of a high-quality sealant is the go-to solution. It is imperative to bypass standard household caulks, which lack the resilience to withstand the dynamic environment of a moving trailer, including significant temperature fluctuations and constant road vibrations. Instead, a durable urethane or silicone-based sealant should be applied directly over the compromised area. A putty knife or similar tool is then used to spread the sealant evenly, ensuring it completely covers and encapsulates the entire damaged section, forming a watertight barrier.

When dealing with more substantial damage, such as a large hole or a significant tear in the metal, a reinforcement patch becomes necessary. This process begins by cutting an aluminum or EPDM rubber patch, ensuring it is slightly larger than the damaged area to provide ample overlap. This patch is then securely affixed using industrial-grade waterproof roofing tape, which offers robust adhesion and flexibility. To further enhance the repair’s watertight integrity, a generous amount of the aforementioned high-quality sealant should be applied around all the edges of the patch, creating a secondary seal that locks out moisture. For an added layer of durability and extended protection, especially over larger repaired areas, consider applying a liquid roof coating or a high-strength waterproof tape. These specialized coatings are engineered to flex with the trailer’s movement, providing a long-term, resilient barrier against UV damage, corrosion, and future water penetration. Following any repair, it is crucial to allow the sealant to fully cure according to manufacturer specifications. After curing, a final water test should be performed, mimicking real-world conditions, to confirm that the repair holds up and the trailer’s roof has been fully restored to its watertight state.

In the ongoing quest to fortify semi-trailer fleets against operational compromises, our focus now shifts from the visible threat of water ingress to the often-invisible, yet equally critical, challenges posed by pneumatic system failures. While roof leaks present tangible and immediate risks to cargo and structural integrity, air leaks in a trailer’s pneumatic network introduce a different, insidious kind of vulnerability, impacting everything from braking performance to fuel efficiency and cargo stability. Understanding these air system compromises requires a similarly rigorous, systems-thinking approach, dissecting their mechanics, identifying their signals, and implementing robust preventative measures to ensure holistic fleet reliability. This transition marks our journey beyond water, delving into the nuances of pneumatic system integrity that are paramount for safe and efficient transportation.

7. **The Invisible Threat: Mechanics and Common Causes of Air Leaks**Air leaks in a semi-trailer refer to unintended air escapes within its pneumatic system, a network crucial for operating vital features such as braking, suspension, and loading/unloading mechanisms. These escapes, often imperceptible without keen attention, represent fundamental breaches in system integrity. They manifest from various points within the trailer’s intricate structure, leading to a cascade of decreased system performance and potential safety hazards that demand immediate, informed intervention.

One primary culprit behind these air escapes is the degradation of seals and gaskets. These components are meticulously designed to maintain airtight connections throughout the trailer’s pneumatic system. However, they are under constant assault from environmental stressors. Over time, persistent temperature fluctuations, relentless wear and tear from continuous operation, and sustained exposure to the elements inexorably cause these critical components to degrade, losing their essential elasticity and sealing capabilities. When seals fail, air begins to escape, often unnoticed in its initial stages, leading directly to inefficient operation and a gradual decline in system pressure.

Another significant contributor to air leaks comes from damaged air lines, which serve as the vital conduits for compressed air to travel to and from various trailer components. These lines are subjected to continuous friction, dynamic movement, and potential external impacts during transit. Such stressors can induce punctures or cracks in the lines, creating direct pathways for air to escape. Regular and meticulous inspections of these air lines are therefore essential. They provide the earliest opportunity for detecting these nascent issues, preventing them from escalating into more significant system failures that could compromise operational safety and efficiency.

Finally, faulty valves represent a critical point of failure in the pneumatic system. Valves are precisely engineered to regulate airflow, and any deviation from their optimal operation can precipitate leaks. These components can become clogged by debris, corroded by moisture or chemical exposure, or mechanically compromised through wear, leading to air pressure imbalances that signify a leak. Identifying failing valves is not merely a maintenance task; it is a critical undertaking for upholding the comprehensive integrity of the entire air system, ensuring that air flows only where and when it is intended, and maintaining optimal pressure for all pneumatic functions.

8. **Decoding the Signals: Visual and Performance Indicators of Air Leaks**Detecting air leaks, particularly in their nascent stages, is a critical capability for fleet operators, preventing minor issues from escalating into major operational and safety compromises. While the subtle nature of escaping air can make detection challenging, a combination of diligent visual inspections and an acute awareness of performance indicators can effectively pinpoint these elusive threats. Early detection is paramount, providing the opportunity to address problems before they lead to increased costs or, more significantly, safety incidents.

The initial step in this diagnostic process is performing a thorough visual inspection, meticulously examining components for any visible damage that might indicate a breach. Technicians should carefully scrutinize seals, hoses, and fittings for any signs of wear, cracking, or displacement. A common, often overlooked, visual cue is the presence of moisture or condensation around connections. This seemingly innocuous symptom frequently indicates a potential air leak, as escaping air can lead to a localized drop in temperature, causing ambient humidity to condense at the leak point. Such visual indicators, though subtle, are vital clues in the hunt for air system compromises.

Beyond static visual cues, operational challenges serve as dynamic red flags, signaling underlying air leaks. Fleet operators should pay close attention to any notable delays in braking response, as a compromised air supply directly impacts the efficacy of the braking system. Unusual noises emanating from the trailer during operation, particularly hissing sounds when the engine is off, are another strong indicator of escaping air. Furthermore, inconsistent suspension performance, where the trailer might sag unevenly or exhibit unusual ride characteristics, can also signify deeper issues within the pneumatic network. Recognizing and understanding these performance shifts is crucial, necessitating immediate attention and further diagnostic investigation to safeguard both operational efficiency and safety.

Read more about: Unmasking the Silent Threat: How to Spot a Slow Tire Leak Early, Without a Gauge, Like a Pro

9. **Cascading Consequences: The Operational and Safety Impact of Air Leaks**The integrity of a semi-trailer’s air system extends far beyond mere functional efficiency; it is intrinsically linked to operational costs, safety performance, and the security of transported cargo. A compromised pneumatic system, even with seemingly minor air leaks, initiates a cascading series of negative consequences that can significantly impact a fleet’s bottom line and jeopardize the well-being of drivers and other road users. Understanding these far-reaching implications underscores the critical importance of proactive maintenance and rapid remediation.

One of the most immediate and financially impactful effects of air leaks is a measurable increase in fuel consumption. When the air system is compromised and continuously losing pressure, the engine is forced to work harder and more frequently to operate the air compressor, maintaining the necessary pressure levels throughout the trailer’s pneumatic network. This constant, elevated demand on the engine translates directly into inefficient fuel use, leading to a substantial uptick in operational costs for fleet operators. Over time, these seemingly small increases can accumulate into significant financial drains, underscoring the economic imperative of an airtight system.

Perhaps the most critical aspect affected by air leaks is the integrity of the braking system, a direct determinant of road safety. A diminished or compromised air supply can lead to a marked reduction in braking efficiency, potentially culminating in total brake failure during critical moments. This scenario poses an unacceptable risk, jeopardizing the safety of the driver, the cargo, and all other road users. Regular, stringent checks on the braking system, coupled with immediate attention to any suspected air leaks, are therefore paramount. Such vigilance is not merely good practice; it is a fundamental requirement to mitigate these profound and potentially catastrophic safety risks, upholding the highest standards of roadworthiness.

Furthermore, an unseen air leak can profoundly compromise the trailer’s suspension system, directly affecting load stability and, consequently, cargo security. The pneumatic suspension relies on precise air pressure to maintain optimal ride height and absorb road shocks. When this pressure fluctuates due to leaks, the suspension can become inconsistent or uneven, causing the load to become unstable. An unstable load is prone to shifting during transit, which can lead to potential accidents, significant damage to the transported goods, and even structural stress on the trailer itself. Ensuring the secure transportation of cargo through a well-maintained and leak-free air system is therefore absolutely essential for mitigating both financial losses and safety hazards.

10. **Advanced Diagnostics: Tools and Techniques for Air Leak Detection**Precisely identifying the source of air leaks within a semi-trailer’s complex pneumatic system is a task that demands both methodical application and the right technological tools. Unlike larger, more obvious issues, air leaks can be elusive, their origin point often hidden within the trailer’s architecture. Before any effective repair can be initiated, mastering advanced diagnostics is crucial, ensuring that resources are applied efficiently and that the integrity of the system is fully restored.

Modern fleet maintenance increasingly relies on a suite of specialized diagnostic tools designed to accurately pinpoint air leaks. Pressure gauges are fundamental, providing real-time data on air pressure within the system, allowing technicians to observe any anomalous drops. For leaks that are not immediately audible, ultrasonic leak detectors are invaluable; these devices use high-frequency sound waves to detect escaping air, converting inaudible signals into a perceptible format. Additionally, smoke test kits offer a visual method, releasing smoke into the system to physically visualize where leaks may be occurring, making even minute breaches apparent. These tools, when utilized systematically, significantly enhance the precision and speed of leak detection.

The process of detecting air leaks should follow a rigorous, step-by-step methodology to ensure comprehensive coverage and accuracy. It commences with an initial air pressure check, verifying that the trailer maintains the correct operational pressure and identifying any immediate discrepancies. This is followed by a meticulous visual inspection of all seals, air lines, and fittings, scanning for any apparent damage or points of weakness. With the engine off to minimize ambient noise, technicians must then listen carefully for any tell-tale hissing sounds that indicate escaping air. Finally, leveraging the advanced diagnostic tools—such as ultrasonic detectors or smoke test kits—helps to pinpoint the exact locations of leaks, especially those that are difficult to see or hear. Documenting these findings meticulously is a critical final step, providing clear information for subsequent repair needs and informing future preventative strategies.

11. **Proactive Defense: Strategic Preventative Measures for Air Systems**While addressing existing air leaks is undoubtedly critical, the most effective strategy for maintaining the long-term reliability and safety of a semi-trailer fleet lies in proactive defense. Shifting from reactive repairs to strategic preventative measures can significantly reduce downtime, minimize operational costs, and bolster overall system resilience. This forward-looking approach ensures that the pneumatic system remains robust, enduring the rigors of heavy-duty transportation with consistent performance.

Establishing and strictly adhering to a routine maintenance schedule is absolutely vital for preventing air leaks before they even begin. This involves regularly inspecting air lines and their fittings for any signs of wear, chafing, or potential damage that could compromise their integrity. Similarly, seals and gaskets throughout the pneumatic system must be routinely checked for signs of degradation, such as drying, cracking, or loss of elasticity. Furthermore, all braking system components should be assessed for proper function and any signs of air pressure anomalies. These consistent, detailed checks allow for the early identification and rectification of vulnerabilities, preventing small issues from escalating into costly system failures.

Beyond routine checks, a strategic investment in upgrading components can significantly reduce the inherent risk of air leaks. Incorporating higher-quality, more durable materials for critical pneumatic parts pays dividends in the long run. This means investing in reinforced air lines that are more resistant to friction and impact, selecting durable seals that withstand extreme temperature fluctuations and constant vibration, and utilizing high-quality valves designed for extended operational life. Such upgrades, while potentially representing a higher initial outlay, ultimately bolster the pneumatic system’s resilience, leading to enhanced longevity and a substantial reduction in future maintenance headaches and unexpected downtimes.

Read more about: Beyond the Shadows: An In-Depth Look at Why Modern Cars Are Being Stolen in Broad Daylight

12. **A Holistic Approach to Trailer Longevity**The journey through the complexities of semi-trailer maintenance, from addressing insidious roof leaks to mitigating critical air system compromises, reveals a fundamental truth: the longevity and reliability of a trailer are deeply rooted in a holistic and interconnected approach to its upkeep. It is a systems-thinking perspective, recognizing that the integrity of one component often influences the performance and resilience of others. Isolated fixes, while temporarily effective, fail to address the interwoven vulnerabilities that define a trailer’s operational life.

Our analysis has underscored that both water intrusion and pneumatic system failures are not isolated incidents but rather symptomatic of broader environmental assaults, material degradation, and mechanical stresses inherent in heavy-duty transportation. By applying analytical rigor to both the ‘how’ and ‘why’ of these issues, we empower fleet operators with the knowledge to make informed decisions. This comprehensive understanding moves beyond mere problem-solving; it fosters a culture of anticipatory maintenance, where potential issues are identified and neutralized before they can manifest into costly disruptions or, more importantly, safety hazards.

Read more about: A Highway Hazard: 12 Trucks Towed More Than Driven Due to Constant Electrical Failures

Ultimately, ensuring fleet reliability and safety demands a proactive, forward-looking strategy that integrates both roof and air system maintenance. It calls for diligent regular inspections, the strategic application of engineered solutions, and a commitment to investing in durable, high-quality components. By adopting such a comprehensive maintenance philosophy, operators can not only extend the operational lifespan of their trailers but also significantly enhance their efficiency and safety on the road. This integrated perspective is not just about avoiding repairs; it is about safeguarding investments, protecting cargo, and, most crucially, ensuring the well-being of every individual involved in the vital artery of logistics and transportation. It is about understanding that true longevity comes from nurturing every single, interconnected part of the system.