The global conflicts of the 20th century, particularly World War II, were crucible moments for technological advancement across countless industries, none more profoundly impacted than the automotive sector. When nations mobilized for war, car manufacturers swiftly pivoted from creating civilian vehicles to producing an astonishing array of military machines. This dramatic shift was not merely a change in product but a fundamental transformation of design philosophies, manufacturing processes, and the very technology underpinning our vehicles. The urgent demands of the battlefield—for durability, reliability, and unprecedented performance under extreme conditions—catalyzed a wave of innovation that continues to resonate in the cars we drive today.

The story of how wartime necessity birthed enduring automotive breakthroughs is a testament to human ingenuity under pressure. From the mud-caked battlefields of Europe to the rigorous supply lines across vast continents, every military vehicle represented a challenge to engineers: how to make it stronger, faster, more reliable, and easier to produce in vast quantities. These challenges forced rapid development, pushing the boundaries of what was thought possible in vehicle engineering. After the war concluded, these hard-won lessons and newly perfected technologies didn’t simply vanish; they trickled down into consumer automobiles, bringing us a wealth of features and capabilities we now consider standard, from improved engine performance to advanced safety systems.

This article delves into the transformative legacy of World War II on the automotive industry, exploring twelve key innovations that emerged directly from military demands and later reshaped civilian transportation. We will uncover how the crucible of conflict forged advancements in vehicle design, propulsion, and manufacturing that not only helped secure Allied victory but also laid the foundation for the modern automotive landscape. Prepare to discover the ingenious solutions that were born from wartime urgency and became permanent features in the cars that populate our roads today.

1. **Four-Wheel Drive Systems**The harrowing conditions of wartime battlefields, characterized by treacherous terrain, deep mud, and uneven surfaces, made it abundantly clear that traditional two-wheel drive vehicles were simply inadequate for military operations. Mobility was paramount, and the ability to traverse difficult landscapes, often far from paved roads, became a critical advantage. This urgent military requirement became the primary driver behind the rapid development and refinement of four-wheel drive technology, a concept that had seen limited civilian application but truly came into its own during the war.

Engineers focused intensely on creating robust and reliable systems that could distribute power to all four wheels, significantly enhancing traction and stability. This allowed military vehicles to maintain forward momentum through conditions that would cripple conventional automobiles, proving invaluable for reconnaissance, troop transport, and supply delivery in the most challenging environments. The ability to climb steep inclines, navigate rocky trails, and slog through heavy mud transformed military logistics and tactics, making previously impassable areas accessible.

The success of four-wheel drive in military applications, particularly with vehicles like the iconic Jeep, provided irrefutable proof of its practical utility and superior performance in adverse conditions. This widespread and rigorous testing in real-world, extreme scenarios allowed engineers to perfect the underlying mechanisms and understand the necessary structural reinforcements. The lessons learned about differential locking, gear ratios, and suspension integration under combat stress proved invaluable for future development.

Following the cessation of hostilities, the profound advantages of four-wheel drive technology became apparent to civilian manufacturers. What had been a niche military feature quickly began to find its way into commercial vehicles, particularly those intended for agricultural use, utility work, and eventually, the burgeoning market for recreational off-roaders. The widespread adoption of four-wheel drive in civilian trucks and later in SUVs directly traces its lineage back to the battlefields of World War II, fundamentally shaping a significant segment of the modern automotive market.

Read more about: 14 Unlikely Automotive Heroes: The Cars That Shocked Everyone and Redefined Success

2. **Advanced Tank and Armored Vehicle Design**World War I had introduced the tank as a revolutionary but rudimentary weapon, often slow and mechanically unreliable. However, the interwar period and particularly World War II sparked an explosion of innovation in armored vehicle design, transforming these early behemoths into sophisticated, effective machines crucial for modern warfare. The demands for greater speed, firepower, and protection against increasingly powerful anti-tank weaponry pushed engineers to rethink every aspect of tank construction, from chassis and suspension to armor and propulsion.

The development of superior suspension systems, for instance, became paramount. Early tanks were notoriously rough rides, limiting speed and accuracy. Wartime engineers perfected torsion bar and Christie suspensions, allowing tanks like the M4 Sherman to traverse rough terrain at higher speeds while providing a more stable firing platform. This emphasis on mobility combined with effective protection led to the creation of specialized vehicles, including the M18 Hellcat tank destroyer, designed for speed and tactical flexibility, and the M8 Howitzer Motor Carriage, which married mobility with heavy artillery.

American automakers played a pivotal role in this transformation, converting their heavy manufacturing expertise to produce these complex machines. Chrysler, for example, constructed tanks at its Detroit Arsenal Tank Plant, including the M3 Grant and the M4 Sherman models, which proved crucial for Allied victories. These facilities demonstrated the immense adaptability of the automotive industry, applying its principles of mass production and precision engineering to military equipment that was orders of magnitude more complex than civilian cars.

The innovations in armor technology and vehicle survivability also had indirect but significant impacts on post-war civilian automotive safety. While passenger cars didn’t suddenly sprout thick steel plates, the principles of structural integrity, compartmentalization, and protecting occupants from external forces gained new urgency. The drive for stronger, more resilient vehicle structures, born from the need to withstand battlefield damage, contributed to a broader understanding of how to build safer, more impact-resistant cars for everyday use, even if the direct application was more conceptual than literal.

Read more about: My Epic 1855-Mile Odyssey: Taming a 10×10 Military HEMTT on Civilian Roads

3. **The Iconic Military Jeep**Perhaps no single vehicle embodies the automotive spirit of World War II more than the iconic Jeep. Born out of an urgent military requirement for a lightweight, rugged, and versatile reconnaissance vehicle, the Jeep quickly evolved from a battlefield necessity into a global symbol of wartime ingenuity and adaptability. Willys-Overland and Ford, under immense pressure, delivered a design that was revolutionary in its simplicity, functionality, and unparalleled off-road capability, producing over 640,000 units during the war.

The Jeep’s design was a marvel of minimalist engineering. It featured a powerful engine, a sturdy ladder frame, robust axles, and most importantly, a highly effective four-wheel drive system, all packaged in a compact and open-topped body. This design allowed it to serve an astonishing array of functions: troop transport, ambulance, reconnaissance, towing light artillery, and even as a mobile command post. Its ability to traverse difficult terrain, from the deserts of North Africa to the muddy roads of the European front, earned it legendary status among Allied forces.

The standardization of parts was a crucial aspect of the Jeep’s success, a principle refined during wartime mass production. This meant that parts were interchangeable between different manufacturers’ Jeeps, simplifying maintenance and repairs in the field—a vital factor when supply lines were stretched and mechanics worked under combat conditions. This emphasis on ease of repair and component commonality would later become a cornerstone of efficient civilian automotive manufacturing, reducing costs and increasing reliability for consumers.

The Jeep’s enduring legacy extends far beyond the war. Its immense popularity and proven capabilities directly inspired the creation of the civilian SUV market. Post-war, Willys-Overland quickly capitalized on its military success, offering civilian versions that retained much of the original’s ruggedness. The Jeep became the progenitor of a new class of utility vehicles, paving the way for generations of off-roaders and family SUVs that dominate roads today, all tracing their lineage back to this humble but heroic wartime workhorse.

Car Model Information: 2021 Jeep Grand Cherokee 80th Anniversary 4X4

Name: Willys MB , Ford GPW , Truck, 1⁄4nbhton, 4×4, command reconnaissance

Origin: United States

Type: 1/4 ton 4×4 utility truck

IsVehicle: true

Service: 1941–2000

UsedBy: allies of World War II

Wars: World War II,Korean War,List of wars: 1945–1989

Designer: Harold Crist

DesignDate: 1940 through early 1942

Manufacturer: Willys,Ford Motor Company

ProductionDate: 1941–1945

Number: WWII total: More than 647,925 *,,including early production units,Willys MB: Over 359,489 *,Ford GPW: Over 277,896 *,Auburn Automobile#Corporate history

Variants: Ford GPA

SpecLabel: MB and GPW same

Weight: convert

Length: 132 in

Abbr: refn

Width: 62 in

Height: 52 in

Crew: 3 to 4

PrimaryArmament: Designed to mount .30 or .50 caliber machine guns swiveling on a post between front seatbacks

Engine: 134 cuin

EnginePower: 60 hp

PwRatio: 49 hp

Transmission: 3-speed × 2-range transfer case

Suspension: Beam axle#Live axle vs Dead axle

Clearance: convert

PayloadCapacity: 1200 lb

FuelCapacity: 15 USgal

VehicleRange: 300 mi

Speed: 65 mph

Categories: All articles needing additional references, All articles with failed verification, All articles with unsourced statements, Articles needing additional references from September 2021, Articles with failed verification from September 2021

Summary: The Willys MB ( Willis) and the Ford GPW, both formally called the U.S. Army truck, 1⁄4‑ton, 4×4, command reconnaissance, commonly known as the Willys Jeep, Jeep, or jeep, and sometimes referred to by its Standard Army vehicle supply number G-503, were highly successful American off-road capable, light military utility vehicles. Well over 600,000 were built to a single standardized design, for the United States and the Allied forces in World War II, from 1941 until 1945. This also made it (by its light weight) the world’s first mass-produced four-wheel-drive car, built in six-figure numbers.

The 1⁄4-ton jeep became the primary light, wheeled, multi-role vehicle of the United States military and its allies. With some 640,000 units built, the 1⁄4‑ton jeeps constituted a quarter of the total military support motor vehicles that the U.S. produced during the war, and almost two-thirds of the 988,000 light 4WD vehicles produced, when counted together with the Dodge WC series. Large numbers of jeeps were provided to U.S. allies, including the Soviet Union at the time. Aside from large amounts of 11⁄2- and 21⁄2‑ton trucks, and 25,000 3⁄4‑ton Dodges, some 50,000 1⁄4‑ton jeeps were shipped to help Russia during WWII, against Nazi Germany’s total production of just over 50,000 Kübelwagens, the jeep’s primary counterpart.

Historian Charles K. Hyde wrote: “In many respects, the jeep became the iconic vehicle of World War II, with an almost mythological reputation of toughness, durability, and versatility.” It became the workhorse of the American military, replacing horses, other draft animals, and motorcycles in every role, from messaging and cavalry units to supply trains. In addition, improvised field modifications made the jeep capable of just about any other function soldiers could think of. Military jeeps were adopted by countries all over the world, so much so that they became the most widely used and recognizable military vehicle in history.

Dwight D. Eisenhower, the Supreme Commander of the Allied Expeditionary Force in Europe in World War II, wrote in his memoirs that most senior officers regarded it as one of the five pieces of equipment most vital to success in Africa and Europe. General George Marshall, Chief of Staff of the US Army during the war, called the vehicle “America’s greatest contribution to modern warfare.” In 1991, the MB Jeep was designated an “International Historic Mechanical Engineering Landmark” by the American Society of Mechanical Engineers.

After WWII, the original jeep continued to serve, in the Korean War and other conflicts, until it was updated in the form of the M38 Willys MC and M38A1 Willys MD (in 1949 and 1952 respectively), and received a complete redesign by Ford in the form of the 1960-introduced M151 jeep. Its influence, however, was much greater than that—manufacturers worldwide began building jeeps and similar designs, either under license or not—at first primarily for military purposes, but later also for the civilian market. Willys turned the MB into the civilian Jeep CJ-2A in 1945, making the world’s first mass-produced civilian four-wheel drive. The “Jeep” name was trademarked and grew into a successful and highly valued brand.

The success of the jeep inspired both an entire category of recreational 4WDs and SUVs, making “four-wheel drive” a household term, and numerous incarnations of military light utility vehicles. In 2010, the American Enterprise Institute called the jeep “one of the most influential designs in automotive history.” Its “sardine tin on wheels” silhouette and slotted grille made it instantly recognizable, and it has evolved into the currently produced Jeep Wrangler still largely resembling the original jeep design.

Get more information about: Willys MB

Buying a high-performing used car >>>

Brand: Willys-Overland Model: Jeep

Price: $23,813 Mileage: 76,309 mi.

Read more about: The 14 Indestructible Off-Roaders Engineered to Conquer a Quarter-Century of Trails

4. **Specialized Military Trucks**Beyond the spotlight of tanks and Jeeps, military trucks formed the unsung backbone of Allied logistical operations during World War II, playing an indispensable role in transporting troops, supplies, and equipment across vast and challenging terrains. The war demanded vehicles capable of reliably carrying heavy loads under all weather conditions, often over rudimentary or non-existent roads. This necessity drove significant advancements in truck design, focusing on durability, payload capacity, and adaptability.

The General Motors’ 2.5-ton “Jimmy” truck, often dubbed “the truck that won the war,” is a prime example of this wartime innovation. Over 800,000 were built, showcasing the incredible manufacturing capacity of the automotive industry and the strategic importance of these vehicles. Similarly, the Dodge WC series of military trucks and command vehicles proved their ruggedness in every theater of the war. These vehicles pioneered advancements in suspension, chassis strength, and engine cooling systems, ensuring they could operate effectively under extreme duress.

The design philosophy behind these military trucks prioritized function over form, focusing on robust construction, powerful engines, and straightforward maintenance. This approach led to innovations in heavy-duty axles, reinforced frames, and more efficient powertrain components that could withstand continuous heavy use and combat damage. The need for interchangeability of parts, common across military vehicle production, further streamlined their repair and maintenance, minimizing downtime in critical situations.

The experience gained in designing and mass-producing these specialized military trucks had a profound impact on the post-war civilian truck market. The lessons in durability, load-bearing capacity, and simplified maintenance directly influenced the development of commercial trucks, leading to more robust and efficient vehicles for construction, transport, and agriculture. The legacy of the “Jimmy” and Dodge WC series can still be seen in the sturdy frames and powerful engines of modern heavy-duty pickup trucks and commercial transport vehicles, fundamentally shaping their evolution.

Read more about: The 14 Indestructible Off-Roaders Engineered to Conquer a Quarter-Century of Trails

5. **Fuel Injection Technology**While carburetors were the standard for automotive engines prior to World War II, the demands of high-performance military applications, particularly in aircraft, rapidly accelerated the development of fuel injection technology. Military aircraft engines required precise fuel delivery for optimal performance at varying altitudes and attitudes, and carburetors were prone to fuel starvation or flooding during aggressive maneuvers or in inverted flight. This critical need for reliable and efficient engine operation became a major impetus for innovation.

Fuel injection offered a significant advantage by directly spraying fuel into the engine cylinders or intake manifold, allowing for more precise control over the air-fuel mixture. This precision resulted in improved engine performance, greater fuel efficiency, and enhanced reliability, especially under the extreme conditions faced by combat aircraft. The technology also made engines less susceptible to issues caused by gravity and negative G-forces during aerial combat, providing a crucial edge for fighter planes like those powered by Allison V-1710 engines.

Although initially developed and refined for aircraft, the benefits of fuel injection—better power output, increased efficiency, and consistent performance—did not go unnoticed by automotive engineers. The knowledge and expertise gained from developing and mass-producing these systems for military aviation created a foundation for their eventual transition to ground vehicles. The wartime investment in researching and perfecting fuel delivery systems laid the groundwork for a technological shift that would fundamentally alter internal combustion engines.

Post-war, as automotive manufacturers resumed civilian production, the proven superiority of fuel injection began to trickle down from aircraft to high-performance and eventually mass-market automobiles. It gradually replaced carburetors, offering consumers improved engine response, better fuel economy, and reduced emissions. Today, virtually all modern gasoline engines utilize some form of fuel injection, a direct descendant of the intensive development spurred by the urgent needs of World War II military aviation.

Read more about: 14 Unlikely Automotive Heroes: The Cars That Shocked Everyone and Redefined Success

6. **Mass Production & Standardization Techniques**World War II necessitated an unprecedented scale of industrial output, forcing automotive manufacturers to refine and accelerate mass production techniques far beyond the innovations of the Ford Model T era. The sheer volume of military vehicles, aircraft, and armaments required could only be met by hyper-efficient assembly lines and rigorous standardization. This wartime pressure transformed factories into true “arsenals of democracy,” forever altering manufacturing processes and industrial capacity for all time.

The automotive industry became a crucial part of the war economy, with companies like Ford and General Motors converting their entire operations towards the war effort. Ford’s massive Willow Run plant, for instance, famously produced one B-24 Liberator bomber every hour at its peak, a testament to the power of assembly line manufacturing applied to complex military equipment. This required immense coordination, retooling of factories, retraining of workers, and an unwavering focus on efficiency that pushed the boundaries of industrial engineering.

Standardization became absolutely essential for military vehicles. With vehicles operating in diverse and remote locations, the ability to easily repair them with interchangeable parts was critical to maintaining operational readiness. This principle meant that a component from one Jeep or truck could be used in another, regardless of its original manufacturing plant. This focus on component commonality and precision manufacturing reduced production times, lowered costs, and ensured consistent quality standards, all vital under wartime conditions.

The advancements in mass production and standardization forged during World War II had a revolutionary impact on the post-war civilian automotive industry. These refined techniques made vehicles more affordable and accessible to everyday consumers, fueling the post-war automotive boom. Toyota’s lean manufacturing principles, which later revolutionized global automotive production, drew heavily from lessons learned in wartime efficiency and quality control. The pursuit of streamlined assembly processes, improved quality control methods, and efficient supply chain management, all accelerated by the war, remains a cornerstone of modern manufacturing across countless industries today.

Read more about: The Unseen Architects: 12 Pivotal Innovations That Forever Changed the Landscape of Film Production

7. **Amphibious Vehicles**The relentless demands of World War II extended beyond land and air, pushing engineers to conquer water obstacles as well. Beach landings, river crossings, and navigating flooded terrains became crucial tactical elements, necessitating vehicles capable of operating seamlessly in both aquatic and terrestrial environments. This urgent military requirement became the fertile ground for the development of groundbreaking amphibious vehicles, pushing the boundaries of what a wheeled machine could achieve.

Among the most iconic of these wartime wonders was the DUKW, famously nicknamed “Duck.” This innovative machine was ingeniously based on a standard GMC truck chassis, but with critical modifications that allowed it to float and propel itself through water, as well as drive effectively on land. These vehicles proved absolutely essential for critical operations, particularly during beach landings and intricate river crossings, where traditional land vehicles would have been rendered useless.

But the DUKW was not alone in demonstrating this remarkable dual-purpose capability. German forces also deployed their own ingenious design, the Schwimmwagen. This amphibious version of the rugged Kübelwagen proved invaluable for navigating the often-treacherous and difficult terrains, especially on the Eastern Front, showcasing the ingenuity applied to various battlefield challenges. Its ability to traverse diverse environments provided a significant tactical advantage.

The engineering principles and practical experience gained from designing and deploying such versatile vehicles during the war had a profound impact on post-war vehicle development. While direct civilian amphibious cars did not become commonplace, the mastery of creating robust, multi-environment vehicles certainly influenced specialized utility designs and contributed to a broader understanding of vehicle sealing, corrosion resistance, and powertrain adaptability that trickled into civilian and commercial applications requiring extreme durability.

Read more about: The Assembly Line Anomaly: 15 Insanely Quirky Car Designs That Defied Convention and Made It To Production

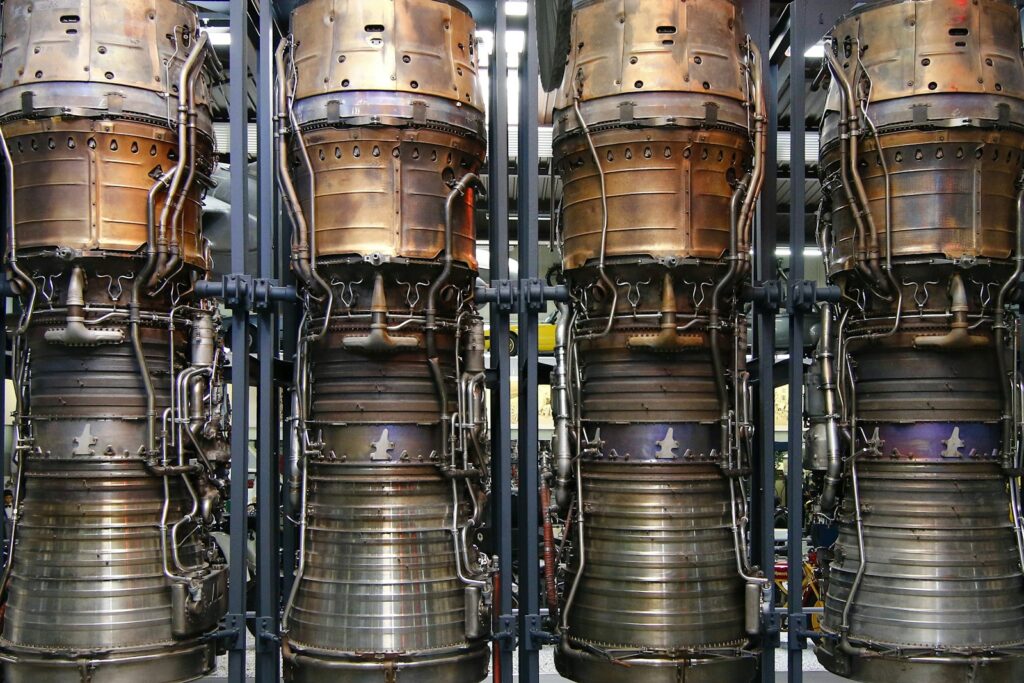

8. **Aircraft Engine Technology Transfer**World War II created an unprecedented synergy between the nascent automotive and established aircraft industries, particularly in the realm of engine design and manufacturing. The high-stakes environment of aerial combat demanded engines that were not only powerful and efficient but also incredibly reliable under extreme conditions. Automotive engineering expertise, honed through decades of mass production, proved invaluable in scaling up the manufacture of these complex powerplants.

American automotive companies, with their formidable manufacturing capacities, were instrumental in producing some of the war’s most crucial aircraft engines. Packard, for instance, undertook the massive task of manufacturing Rolls-Royce Merlin engines under license. These highly advanced engines powered legendary fighters like the P-51 Mustang, giving Allied pilots the performance edge needed to escort bombers deep into enemy territory and achieve air superiority, fundamentally altering the course of the air war.

Similarly, Allison, a division of General Motors, produced the potent V-1710 engines, which were integral to the success of aircraft such as the P-38 Lightning and P-40 Warhawk fighters. What’s truly fascinating is that these engines, designed for the rigors of combat aviation, incorporated advanced technologies and engineering principles that were ripe for transfer. The intensive research and development into optimizing power-to-weight ratios and high-altitude performance had far-reaching implications.

Indeed, many of the aircraft industry’s cutting-edge innovations found their way back to ground vehicles after the war. Technologies like sophisticated fuel injection systems, which were vital for consistent aircraft engine performance at varying altitudes, were refined and adapted for automotive use. Furthermore, superchargers and turbochargers, initially developed to boost aircraft engine power, eventually transitioned into post-war automotive applications, enhancing both performance and fuel efficiency in a new generation of civilian cars, forever changing how we think about engine power.

Read more about: The $15.8 Million Presidential Custom Fleet: A Deep Dive into High-Security Transportation and Campaign Operations

9. **Automatic Transmissions**Prior to World War II, manual transmissions were the overwhelming norm in automobiles, demanding driver skill and constant engagement. However, the unique pressures of wartime, including the need for military vehicles that could be operated by a broader range of drivers, often under stressful combat conditions, spurred significant advancements in automatic transmission technology. Simplicity of operation, robust reliability, and efficiency were key military requirements that propelled this innovation forward.

While the concept of automatic shifting had existed, wartime research and development drastically refined these systems, making them more durable and reliable for heavy-duty military use. The ability for a vehicle to adapt its gearing automatically meant fewer opportunities for driver error and smoother operation, which could be critical for transporting troops or supplies across challenging landscapes without stalling or losing momentum. This wartime testing proved the viability and practical advantages of clutch-free driving.

With the cessation of hostilities, these hard-won lessons and perfected automatic transmission technologies began their inevitable migration to the civilian market. The post-war era saw an explosion of consumer demand for convenience and ease of use in new automobiles. Automatic transmissions became a highly sought-after feature, transforming the driving experience for the average person and making cars more accessible to a wider demographic who might have found manual shifting intimidating.

The widespread adoption of automatic transmissions after the war was a testament to their proven performance under duress and their undeniable appeal to consumers. This innovation, refined during a period of immense national need, became a defining characteristic of post-war automobiles, contributing significantly to the era’s economic prosperity and establishing a new standard for driving comfort and accessibility that continues to this day. It marked a crucial step in modernizing the civilian driving experience.

Read more about: The 15 Hardy Coupes That Can Easily Reach a Quarter Million Miles Unchallenged

10. **Material Science Breakthroughs**World War II posed unprecedented challenges for material supply chains, forcing automotive and other industries to innovate rapidly in material science. Critical shortages, especially after Japan cut off access to natural rubber sources in early 1942, spurred an urgent quest for alternatives and improvements. The military’s demand for lighter, stronger, and more resilient materials for vehicles, aircraft, and equipment further accelerated this research, proving that necessity truly is the mother of invention.

One of the most significant breakthroughs was the development of synthetic rubber. With natural rubber supplies severely constrained, the ability to chemically synthesize rubber was not merely an innovation but a strategic imperative that “saved the entire thing” for the Allied war effort. This new material proved vital for everything from tires and gas masks to seals and pontoon bridges, demonstrating remarkable adaptability and performance under varied conditions, quickly becoming a cornerstone of industrial production.

Beyond rubber, the war drove considerable advancements in lightweight alloys and improved lubricants. The need for faster, more agile aircraft and more fuel-efficient engines pushed metallurgists to develop stronger, lighter aluminum alloys, while engineers developed lubricants that could withstand extreme temperatures and pressures, ensuring reliable operation of everything from tank engines to aircraft components. Even steel availability became a vaudeville joke due to shortages, pushing for innovation in material usage and design.

These wartime material innovations had a profound and lasting impact on post-war civilian automotive production. Synthetic rubber became a standard component in tires, hoses, and other vehicle parts. The lessons learned in lightweight alloy design contributed to more efficient vehicle structures, while advanced lubricants improved engine longevity and performance. The drive to overcome wartime shortages and performance demands irrevocably reshaped the composition and capabilities of modern automobiles, setting new standards for durability and efficiency.

Read more about: Electricity Explained: Unpacking the Invisible Force That Shapes Our Modern Lives

11. **Enhanced Durability and Reliability**Before World War II, while cars were becoming more robust, the extreme conditions of combat introduced an entirely new paradigm for durability and reliability. Military vehicles were expected to operate across treacherous terrains, endure direct hits, and withstand continuous heavy use under unimaginable duress, all while remaining operational. This critical need for uncompromising resilience became a central engineering challenge and a powerful catalyst for innovation that would profoundly influence future automotive design.

Engineers, tasked with designing vehicles that could survive the battlefield, focused intensely on reinforcing every aspect of automotive construction. This led to significant advancements in frame strength, developing chassis that could withstand twisting and heavy loads without buckling. Suspension systems were redesigned for maximum travel and shock absorption, allowing vehicles to traverse rocky, muddy, or cratered landscapes while maintaining stability. Moreover, engines were engineered not just for power, but for unwavering reliability in dust, extreme temperatures, and often with minimal maintenance.

The lessons learned from this crucible of conflict were invaluable. War-experienced engineers, returning to civilian production, brought with them a new perspective on vehicle design. Their battlefield insights emphasized the paramount importance of building cars that were not merely aesthetically pleasing or fast, but inherently durable and reliable. This shift in mindset led to a post-war era where consumer vehicles benefited from stronger components, more robust construction, and improved resistance to wear and tear.

The legacy of wartime durability continues to resonate in modern vehicle design, more than 75 years later. The expectation that a car should be able to withstand years of varied road conditions, provide consistent performance, and demand reasonable maintenance can be directly traced back to the rigorous testing and improvements driven by World War II. It instilled a fundamental understanding of engineering for extreme conditions that now underpins the quality and longevity we expect from every vehicle on the road.

Read more about: 14 Unlikely Automotive Heroes: The Cars That Shocked Everyone and Redefined Success

12. **Influence on Post-War Aerodynamic and Styling Trends**The aesthetic landscape of automobiles underwent a dramatic transformation in the years immediately following World War II, and remarkably, this shift was heavily inspired by the very machines that dominated the skies during the conflict. Wartime aviation, with its emphasis on speed, efficiency, and powerful presence, provided a rich lexicon of design cues that civilian car manufacturers eagerly adopted, shaping the visual identity of a generation of vehicles.

One of the most striking and iconic elements to emerge from this cross-pollination of design was the prevalence of massive tail fins and expansive chrome details. These features, borrowing directly from the aerodynamic lines and polished metal finishes of fighter planes and bombers, became symbols of post-war prosperity, technological prowess, and a hopeful, forward-looking future. Cars were no longer just transportation; they were statements of progress and aspiration, gleaming with metallic finishes and sleek, dynamic forms.

The broader streamlining movement, which had begun pre-war but gained immense traction post-1945, was directly influenced by aerodynamic principles perfected in aircraft design. Engineers understood that smoother, more rounded contours reduced drag, and while not always critical for everyday driving speeds, these forms conveyed a sense of speed and efficiency. The 1942 Chrysler Newport concept car, with its sleek, rounded look, perfectly exemplified this new direction.

This fascination with aviation-inspired aesthetics and aerodynamics defined American automobiles for more than a decade. The curves, the shiny metallic colors, and the bold, often exaggerated, styling elements like the tail fin and chrome bumper symbolized the growing post-war confidence and a nation embracing a new era of technological advancement and personal mobility. This era solidified a distinctive design language that remains instantly recognizable and beloved today, a true testament to the lasting impact of wartime inspiration.

Wrapping Up

The indelible marks left by World War II on the automotive industry are profound and pervasive, extending far beyond the immediate post-war boom. The crucible of global conflict forced a paradigm shift, pushing manufacturers to innovate at an unprecedented pace, not just in technology, but in manufacturing processes, material science, and even aesthetic design. From the battle-hardened utility of the Jeep to the sleek lines of a 1950s sedan, the legacy of wartime ingenuity is woven into the very fabric of our modern vehicles.

Read more about: Hollywood’s High Octane: Tom Cruise’s 15 Vehicles That Define His Adrenaline Obsession

As we navigate today’s roads, enjoying the comforts of automatic transmissions, the efficiency of advanced engines, or the security of robust frames, it’s easy to overlook the historical journey of these features. Yet, each represents a triumph of engineering born from extreme necessity, a testament to human adaptability under pressure. World War II didn’t just end a global conflict; it accelerated an industrial revolution that continues to shape how we move, influencing everything from the performance under the hood to the very curves of the car’s body. These innovations, forged in the fires of war, became the permanent features that define the automotive world we know today, continually reminding us of the unexpected advancements that can arise from even the most challenging times.