The roar of an engine, the sleek lines of a supercar, the promise of unparalleled performance – these often conjure images of carbon fiber. This marvel material has swiftly become a status symbol and a functional necessity in the automotive world. Prized for its lightweight strength, incredible durability, and premium aesthetic appeal, authentic carbon fiber is what enthusiasts dream of for their upgrades. It delivers on the promise of better performance, enhanced aesthetics, and long-lasting quality.

However, as carbon fiber’s popularity has skyrocketed, so too has the market for cheap imitations. The digital storefronts and aftermarket shops are unfortunately flooded with knockoffs that expertly mimic the look of genuine carbon fiber. These products might trick your eyes, but they utterly fail to provide the strength, weight reduction, and durability that make real carbon fiber so valuable. Buyers often find themselves unknowingly investing in plastic, fiberglass, or hydro-dipped patterns that offer zero functional benefits.

The stakes are higher than just aesthetics. Purchasing low-quality or fake carbon fiber can lead to significant problems: poor performance due to added weight, durability issues like fading, cracking, or peeling, and even dangerous structural weaknesses. If a critical component fails, especially at high speeds, the consequences can be catastrophic. This guide is crafted for enthusiasts, racers, and car owners determined to upgrade with authentic parts, understand the critical differences, and ensure a worthwhile investment. By the end, you’ll be armed with the knowledge to spot the fakes and make informed decisions, protecting both your wallet and your ride.

1. **Understanding Real Carbon Fiber Composition**When embarking on the journey to identify genuine carbon fiber, the first crucial step is to grasp what this remarkable material actually is. Its unique composition is the bedrock of its superior properties, setting it apart from all its imitators. True carbon fiber is not just a pattern; it’s a meticulously engineered composite material designed for peak performance and resilience.

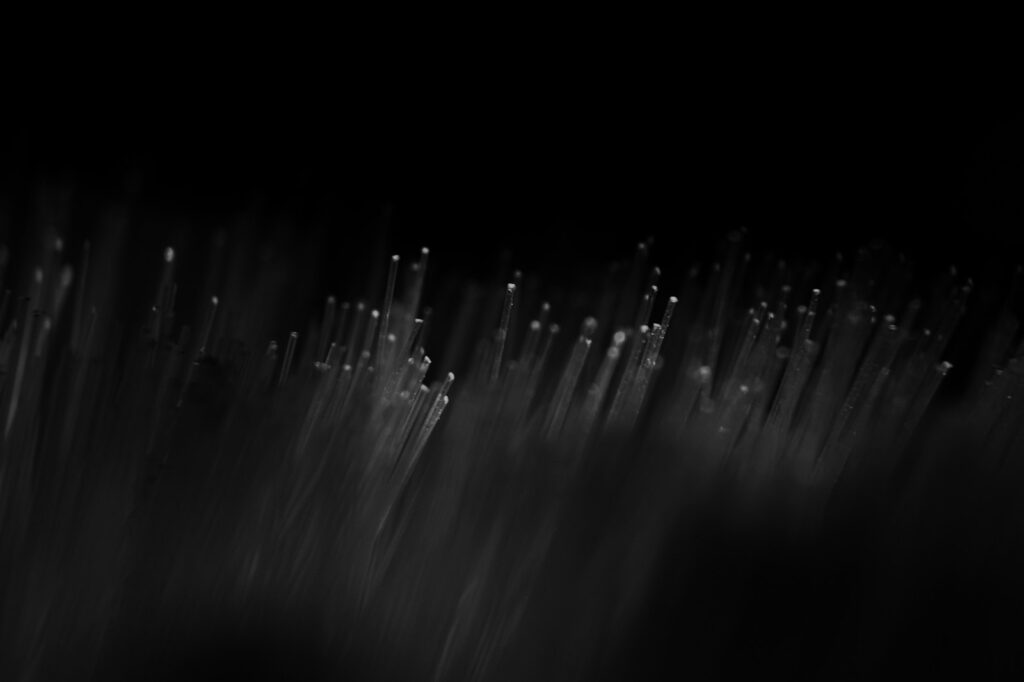

At its core, real carbon fiber consists of countless thin, woven carbon strands. These incredibly fine fibers are then embedded within a specialized resin matrix. This combination creates a material that boasts an extraordinary strength-to-weight ratio, being up to five times stronger than steel while remaining significantly lighter. It’s this fundamental structure—fibers within resin—that gives carbon fiber its legendary rigidity, durability, and resistance to heat and chemicals, making it a cornerstone in aerospace, Formula 1, supercars, and military applications.

Authentic carbon fiber parts are also characterized by their complex and expensive manufacturing process. This isn’t a material that can be cheaply churned out without compromising its inherent benefits. High-quality variants like dry carbon fiber are the lightest and strongest, while prepreg carbon fiber uses pre-impregnated resin for controlled strength, and forged carbon fiber offers a unique marble-like pattern. A key indicator of authenticity is that the weave is an integrated part of the material’s structure, not merely a surface application. Understanding this foundational principle is your first line of defense against counterfeits.

Read more about: 14 Simple Ways to Transform Your Health with Regenerative Farming Products

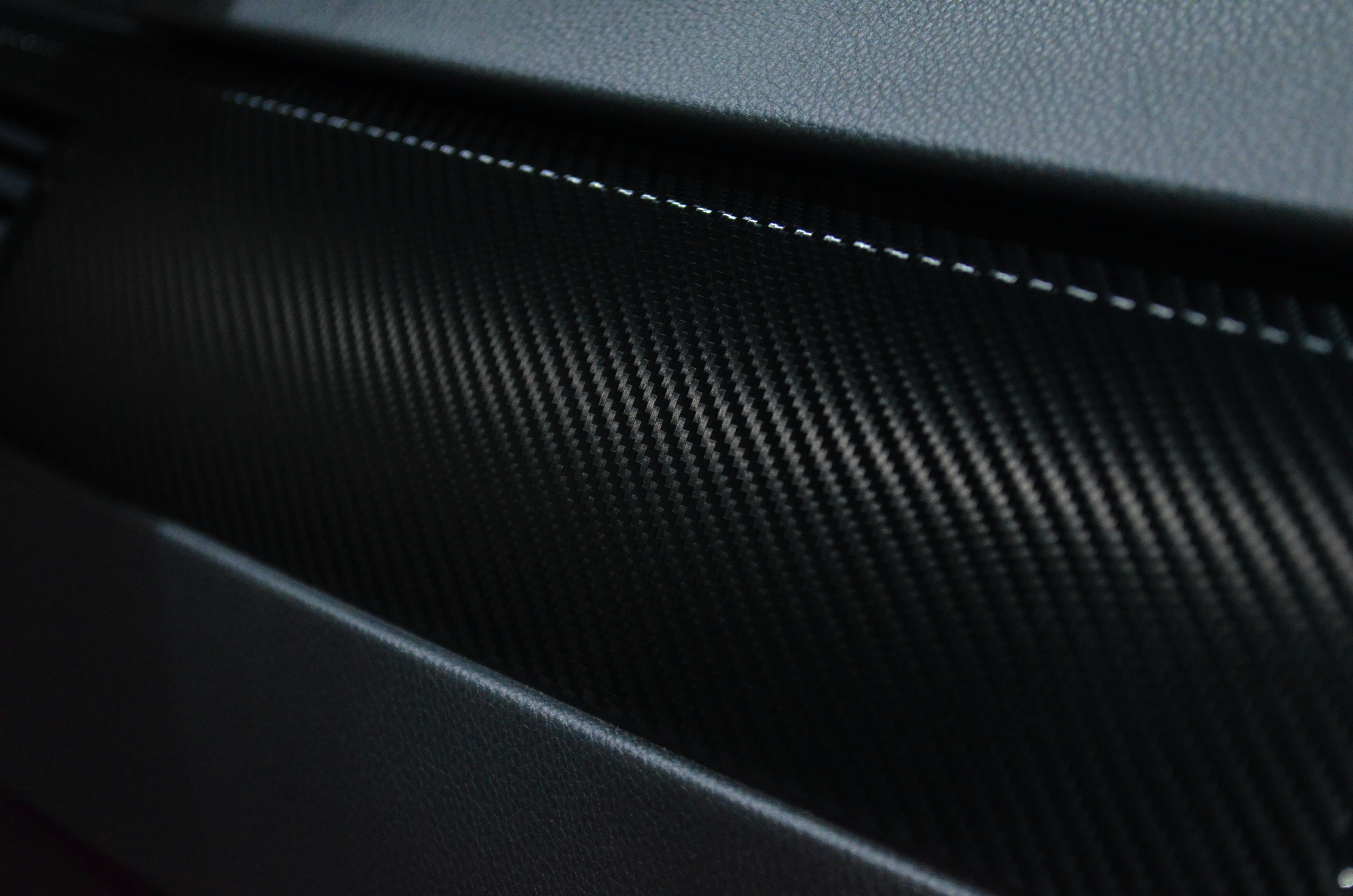

2. **Spotting Carbon Fiber Overlays**One of the more deceptive forms of fake carbon fiber that you’ll encounter is the carbon fiber overlay. This isn’t a standalone material but rather a thin sheet of actual carbon fiber, or even just a vinyl wrap, meticulously applied over a base part made of plastic or metal. The immediate visual appeal can be convincing, giving the illusion of a genuine carbon fiber component. However, this method is purely for aesthetics and offers none of the functional advantages that enthusiasts seek.

The primary problem with carbon fiber overlays is their superficial nature. They provide absolutely no weight savings, which is a core benefit of authentic carbon fiber, nor do they contribute any structural strength. This means that a component advertised with an “overlay” will perform identically to the underlying plastic or metal part, with the added fragility of the thin surface layer. These overlays are easily damaged, prone to scratching, peeling, and fading over time, quickly degrading the premium look they initially offered.

To spot these imposters, pay close attention to the edges of the part. If you can discern a different base material peeking out from beneath the carbon fiber pattern, you’re likely dealing with an overlay. A simple touch test can also reveal the truth: real carbon fiber has a distinct texture and weave depth, whereas an overlay will feel flat and smooth. If the material peels like a sticker or reveals a different substrate when gently probed, it’s a clear sign of a fake. Many cheap “carbon fiber” interior trims often fall into this category, being nothing more than vinyl wraps over plastic.

3. **Identifying Fiberglass Hybrids**Another prevalent form of imitation is the fiberglass with a carbon fiber laminate. This type of fake presents a more cunning disguise, as it does incorporate a thin layer of real carbon fiber. However, this is merely a cosmetic top layer, strategically placed over a fiberglass core. The intent is to give the illusion of a full carbon fiber part, capitalizing on the material’s prestige, without actually delivering its performance attributes.

The core issue with these fiberglass-carbon fiber hybrids is that they completely negate the primary benefit of genuine carbon fiber: weight reduction. Fiberglass is noticeably heavier than pure carbon fiber, meaning that a hybrid part will add weight rather than reduce it. Furthermore, despite the thin carbon layer, the underlying fiberglass makes the component more fragile than full carbon fiber, making it susceptible to cracking under stress where an authentic carbon part would remain steadfast. The carbon fiber layer here serves no real performance purpose, acting purely as a visual veneer.

Identifying these hybrids requires a keen eye and some practical tests. Start by examining the edges of the part; if you observe a yellowish or white core beneath the black carbon pattern, it’s a tell-tale sign of fiberglass. A cautious scratch test can also be illuminating: scratching deep into the surface will reveal the fiberglass underneath, confirming its hybrid nature. The weight test is perhaps the most definitive: genuine carbon fiber feels incredibly light, almost surprisingly so, while fiberglass is distinctly heavier. Many low-cost “carbon fiber” hoods, for instance, are notoriously fiberglass with only a thin carbon layer for show.

Read more about: Unlocking Automotive Immortality: The 15 Most Durable Cars Proven to Conquer a Quarter-Million Miles and Beyond

4. **Unmasking Hydro-Dipped Fakes**Hydro-dipped carbon fiber is one of the most widespread and deceptive methods used to fake the appearance of the material. This technique involves applying a printed film with a carbon fiber pattern over a base of plastic or metal using a water transfer process. The result can be visually stunning at first glance, offering a perfect, glossy replication of a carbon fiber weave. However, despite its convincing appearance, hydro-dipped carbon fiber is 100% fake and contains no real carbon fiber whatsoever.

The problems with hydro-dipped parts are numerous. Because they are simply printed patterns, they offer zero real depth or texture. The weave appears completely uniform and unnaturally perfect, lacking the subtle distortions and variations found in authentic carbon fiber, particularly over curved surfaces. Moreover, the durability of hydro-dipped parts is severely lacking compared to genuine carbon fiber. They scratch easily and are prone to fading or peeling, especially when exposed to sunlight and heat, which real carbon fiber is designed to withstand.

To unmask a hydro-dipped fake, several indicators are invaluable. The most striking is the weave pattern itself: if it looks flawlessly uniform and too consistent, especially across complex curves, it’s almost certainly printed. Real carbon fiber, due to its manufacturing process, will exhibit slight, natural distortions. Touch is another critical sense here; hydro-dipped surfaces feel entirely smooth, like plastic, completely devoid of the woven texture you’d expect from real carbon. Lastly, its inability to handle heat is a giveaway; exposure to sunlight or a gentle heat source will cause fading or peeling, a vulnerability unheard of in authentic carbon fiber.

5. **Detecting Plastic Imitations**Beyond the more complex fakes, there are also straightforward plastic imitations designed to mimic carbon fiber. These parts are molded directly from plastic to achieve the visual texture and pattern of carbon fiber. While they might superficially resemble the real deal, they represent the lowest tier of counterfeits, offering absolutely none of the performance benefits associated with genuine carbon. These are purely aesthetic, and often, not even particularly good aesthetics in the long run.

The issues with plastic imitation carbon fiber are glaring and fundamental. Primarily, they are just plastic, meaning they offer zero performance advantages in terms of strength or weight reduction. In fact, many plastic parts molded to look like carbon fiber can be heavier than their authentic counterparts, due to the density required for structural integrity in plastic. Real carbon fiber is renowned for its rigidity, whereas plastic is inherently flexible and prone to bending and breaking easily, especially under stress or impact.

To detect these plastic imposters, simple physical tests are highly effective. The “press test” is a quick and telling method: if you can bend the part easily with your hands, it’s highly unlikely to be genuine carbon fiber. Real carbon fiber is remarkably rigid and will resist significant flex. Similarly, weighing the part can be revealing; if it feels excessively heavy for its size, it’s a strong indicator that you’re holding plastic. Finally, a gentle heat test, applied to an inconspicuous area, will cause plastic to melt or deform, whereas real carbon fiber would remain unaffected. Cheap “carbon fiber” mirror covers are a common example of these simple plastic fakes.

Read more about: The Nanotech Revolution: 15 Everyday Products Poised for Transformation Within Five Years

6. **Recognizing Fake Carbon Fiber Stickers**At the most basic end of the imitation spectrum, we find fake carbon fiber stickers and decals. These are not parts, but rather simple prints on an adhesive sticker, purely intended for cosmetic application. While they may offer a temporary visual change, they provide absolutely no structural integrity, strength benefits, or weight advantages whatsoever. These are purely for show, and often a very short-lived show at that.

The problems with fake carbon fiber stickers are obvious. They offer zero structural integrity, meaning they contribute nothing to the performance or safety of a vehicle. Their appearance is inherently cheap and temporary; they are notorious for peeling off over time, especially when exposed to environmental elements or frequent handling. Their lifespan is severely limited, fading and wearing out quickly, turning what was intended as a visual upgrade into an eyesore. They represent the cheapest, least durable form of carbon fiber imitation.

Spotting these is usually quite straightforward. Unlike a structural carbon fiber component, a sticker can often be removed with a fingernail or by gently peeling back an edge. If the “carbon fiber” you’re inspecting behaves like a decal, it’s not real. Furthermore, genuine carbon fiber has a distinct woven feel and depth when touched, whereas stickers and decals will feel completely smooth and flat, devoid of any genuine texture or dimensionality. Common examples include cheap phone cases, laptop skins, or car badges that claim to be carbon fiber but are merely printed stickers.

7. **The Weave Pattern Test: Exploring Authentic Patterns**Having established the fundamental composition of real carbon fiber and identified various material-based fakes, our attention now turns to one of the most definitive visual indicators of authenticity: the weave pattern. Carbon fiber sheets are crafted by meticulously weaving thin carbon strands into specific patterns, which are then infused with resin. These weave patterns are not just aesthetic choices; they significantly influence the material’s flexibility, strength, and overall appearance, making understanding them crucial for spotting fakes.

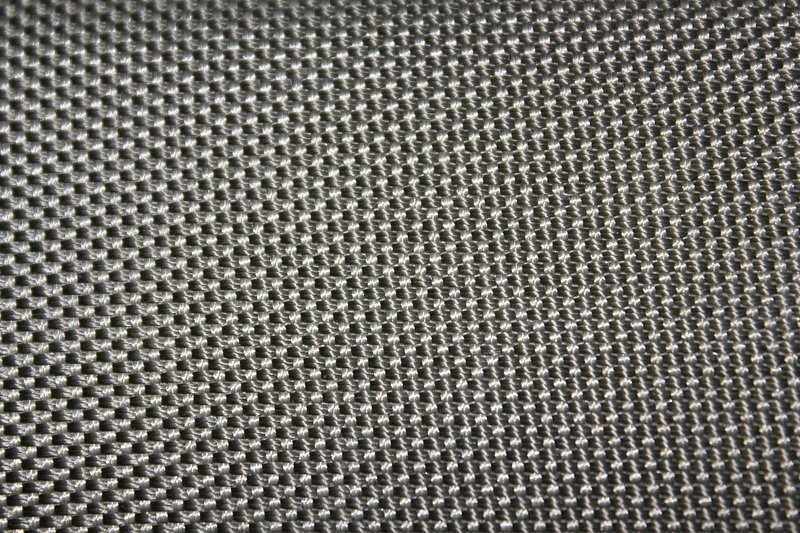

Authentic carbon fiber boasts several common weave types, each with unique visual characteristics. The most recognizable in automotive applications is the **Twill Weave Carbon Fiber**. Found in components like hoods, spoilers, and splitters, it features a distinct diagonal or V-shaped pattern, typically a 2×2 or 4×4 weave. This pattern offers a superb balance of strength and flexibility, making it ideal for both performance and aesthetics in supercars from Ferrari to McLaren. A key point to remember: real twill weave will show subtle distortions over curved surfaces due to its manufacturing, unlike the pixel-perfect symmetry of fake prints.

Next, we have the **Plain Weave Carbon Fiber**, a classic pattern often seen in lightweight panels and aircraft components. It presents a tight, uniform checkerboard-like pattern. While stronger than twill weave, it’s less flexible, making it particularly well-suited for flat surfaces. Brands like BMW M Performance and Porsche Motorsport frequently utilize plain weave in their OEM carbon fiber parts. Authentic plain weave has a subtle depth; if it appears overly glossy and reflective, almost like a printed texture under light, it could be a fake.

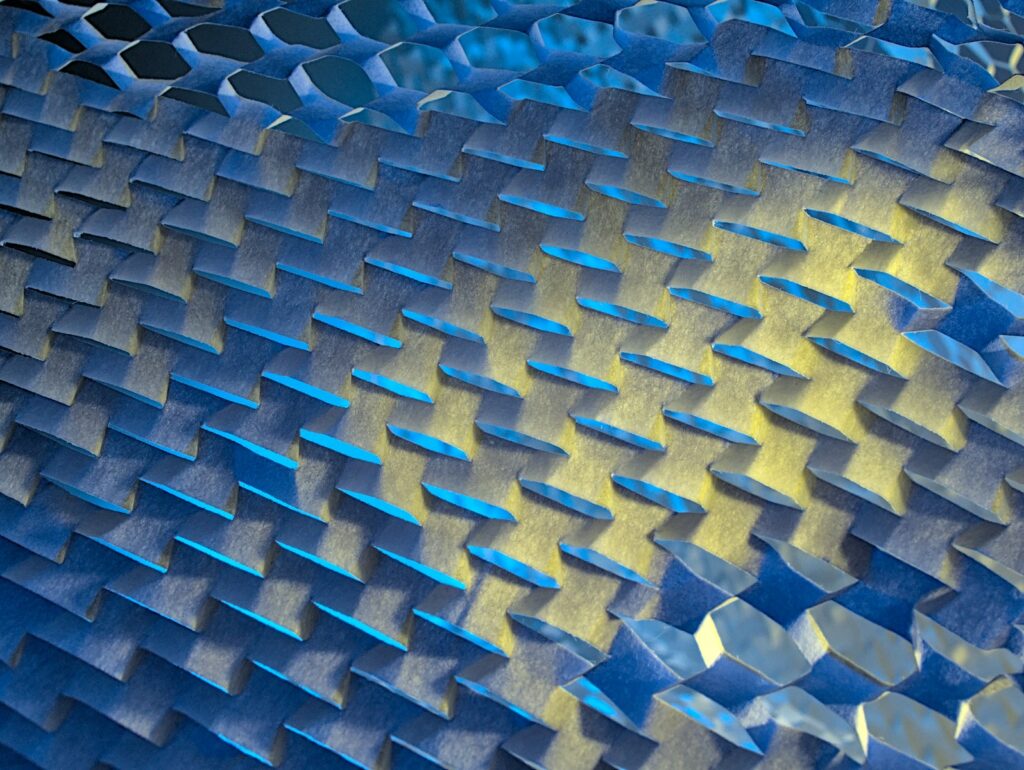

Finally, the more exotic **Forged Carbon Fiber** and **Honeycomb Carbon Fiber** deserve attention. Forged carbon fiber stands apart by not having a traditional weave; instead, it features a marbled, chaotic pattern. This randomized appearance, seen in hypercars like the Lamborghini Huracán Performante, offers superior strength in multiple directions. Real forged carbon will always have depth and texture, feeling anything but flat. Honeycomb carbon fiber, as its name suggests, incorporates a hexagonal pattern within its weave, providing superior weight reduction and rigidity, making it a staple in aerospace and F1 cars. Both these high-tech patterns are difficult to replicate authentically, with fakes often lacking the crucial three-dimensionality and structural depth.

8. **Identifying Common Fake Weave Patterns**As you sharpen your eye for genuine carbon fiber, it’s vital to understand how counterfeiters mimic authentic weave patterns. Many fake products meticulously replicate the *look* but consistently miss the subtle depth, texture, and structural variations of real material. Knowing these common imitations equips you to distinguish functional, high-performance parts from purely cosmetic, often fragile, knockoffs, ensuring your investment is worthwhile.

Hydro-dipped carbon fiber is a prevalent deception, applying a printed film with a pattern onto plastic or fiberglass. These fakes, common in interior trims, are 100% devoid of real carbon fiber. Their key giveaway is an unnaturally uniform and perfectly symmetrical weave, even over curves. Genuine weaves, due to manufacturing, always show subtle distortions. If the pattern is flawlessly consistent without natural imperfections, it’s likely a printed imitation. Similarly, vinyl carbon fiber wraps, adhesive stickers with a pattern, are purely superficial; spot them if the texture doesn’t shift under different lighting or feels perfectly smooth, lacking real woven texture.

Finally, some imitations use fiberglass with a thin carbon fiber overlay, creating a visual illusion over a heavier, weaker core. While containing some real carbon, it negates weight reduction and strength. Identify these by inspecting edges for a yellowish or white core peeking through the black carbon, combined with the part’s noticeably heavier weight. Understanding these deceptions is paramount for making informed purchases, protecting both your wallet and your vehicle’s performance integrity.

9. **The Criticality of Weight and Strength**Beyond visual examinations, carbon fiber’s functional advantages—its exceptional strength and surprising lightness—are paramount, serving as definitive tests for authenticity. True carbon fiber is an engineering marvel, providing unparalleled performance benefits. Investing in authentic carbon fiber means embracing superior vehicle dynamics, not merely an aesthetic upgrade, impacting acceleration, handling, and safety.

Consider how lightweight materials dramatically improve vehicle performance. Reduced mass translates to better acceleration and enhanced fuel efficiency, particularly for EVs. Less overall mass also significantly improves handling and braking, allowing for quicker response times and superior control as the vehicle’s systems manage reduced inertia. Genuine carbon fiber excels in delivering these tangible, measurable performance gains, making it a cornerstone for enthusiasts seeking functional advantages.

Equally compelling is carbon fiber’s superior strength. It boasts a strength-to-weight ratio up to five times greater than steel, making it the material of choice for critical structural components in Formula 1 and aerospace. This inherent rigidity ensures real carbon fiber resists bending, twisting, and deformation under immense pressure, maintaining structural integrity. It also absorbs energy effectively during impacts, a crucial safety feature. Remember these fundamental properties are non-negotiable indicators of a part’s true value and authenticity.

10. **Recognizing Weight and Flexibility Red Flags**With knowledge of how real carbon fiber should perform, you can readily identify key red flags in counterfeit or low-quality parts. A primary indicator of a fake is a component that feels unexpectedly heavy for its size. Genuine carbon fiber is incredibly lightweight—up to five times lighter than steel. If the part feels substantial or comparable in weight to a metal or fiberglass alternative, it’s a strong sign you’re dealing with a cheap knockoff, often made with a heavier fiberglass core or dense plastic.

Another crucial red flag is flexibility. Authentic carbon fiber is designed for rigidity and stiffness, resisting bending and holding its form under considerable pressure. If you can easily flex or bend the material by hand with minimal effort, it is highly improbable that it’s a full carbon fiber component. Such pliability indicates materials like plastic or fiberglass, which inherently lack the tensile strength and structural integrity of genuine carbon fiber. A true structural carbon fiber part should feel remarkably solid and unyielding.

Low impact resistance is a further warning sign. Inferior carbon fiber parts may crack or splinter easily from minor impacts, a stark contrast to properly manufactured carbon fiber, engineered to absorb and dissipate energy. Furthermore, fake carbon fiber often suffers from poor durability, showing signs of fading, cracking, or peeling. These red flags highlight that while an imitation might mimic the look, it utterly fails to deliver the performance, longevity, and safety attributes that make real carbon fiber so coveted.

Read more about: Unlock Your Peak Performance: 13 Common Diet Mistakes Professional Athletes Confidently Conquer

Equipped with this comprehensive guide, from understanding carbon fiber’s foundational composition to performing advanced physical tests and shrewdly assessing market factors, you are now empowered to navigate the complex world of aftermarket parts with confidence. You’ve gained the practical knowledge to spot counterfeits, distinguish genuine weaves, verify structural integrity through weight, strength, scratch, and heat tests, and identify trustworthy sellers. Your vehicle upgrades should genuinely enhance performance, aesthetics, and safety. Choose authenticity, invest wisely, and ensure every carbon fiber part you add truly elevates your driving experience, protecting both your wallet and your passion for automotive excellence.