The allure of saving a few bucks by tackling car repairs or home improvements yourself is undeniably strong. Armed with online tutorials and a can-do attitude, many enthusiasts dive headfirst into projects that, at first glance, seem straightforward enough. However, the path to a successful DIY fix is fraught with potential pitfalls, and some amateur attempts can quickly transform a minor issue into a major headache, earning the scorn of professional mechanics everywhere.

When experts speak of the ‘worst’ DIY repair tricks, they’re not merely referring to inconvenient fixes or unsightly blemishes. They’re highlighting approaches that embody fundamental flaws, ranging from dangerous oversights to methods that actively degrade the equipment or component in question. This isn’t just about doing a bad job; it’s about employing methods that are ‘bad or ill in the highest, greatest, or most extreme degree,’ as defined by the very essence of what makes something fundamentally flawed.

In the spirit of offering practical, reliable information, and understanding that prevention is always better than a cure, we’re going to delve into what truly makes a DIY repair ‘worst.’ Rather than cataloging specific, often anecdotal, misguided attempts, we will dissect the core characteristics that define these detrimental approaches. By understanding these underlying traits—each drawn directly from the authoritative definitions of ‘worst’ and ‘bad’—you, the dedicated home mechanic, can learn to identify and steer clear of repair philosophies that lead to disastrous outcomes.

1. **Most Faulty or Unsatisfactory**At the heart of many ill-advised DIY repairs lies the fundamental issue of being ‘most faulty or unsatisfactory.’ This characteristic describes a repair attempt that, despite the effort, fails to achieve its intended purpose or leaves the component in a state that is arguably worse than before the intervention. It’s not just a minor imperfection; it’s a glaring deficiency that undermines the entire objective of the repair.

Consider a situation where a DIYer attempts to fix a leaking pipe with an improper sealant or an inadequate patching method. If the application is ‘most faulty,’ perhaps due to incorrect surface preparation or using the wrong material for the pressure involved, the leak might persist, or even worse, manifest elsewhere with greater intensity. The outcome is ‘unsatisfactory’ because the problem hasn’t been solved effectively, and new complications have often been introduced.

A repair categorized as ‘most faulty or unsatisfactory’ often implies a lack of foundational understanding of the system being worked on. Without knowing why a component failed or how it’s supposed to function optimally, a DIYer might apply a fix that only addresses a symptom, not the root cause. This superficial approach means the repair is inherently flawed, inevitably leading to an outcome that falls far short of acceptable standards.

Read more about: From Bad to Worse (or is it Worst?): Unpacking the Ultimate Grammar Showdown

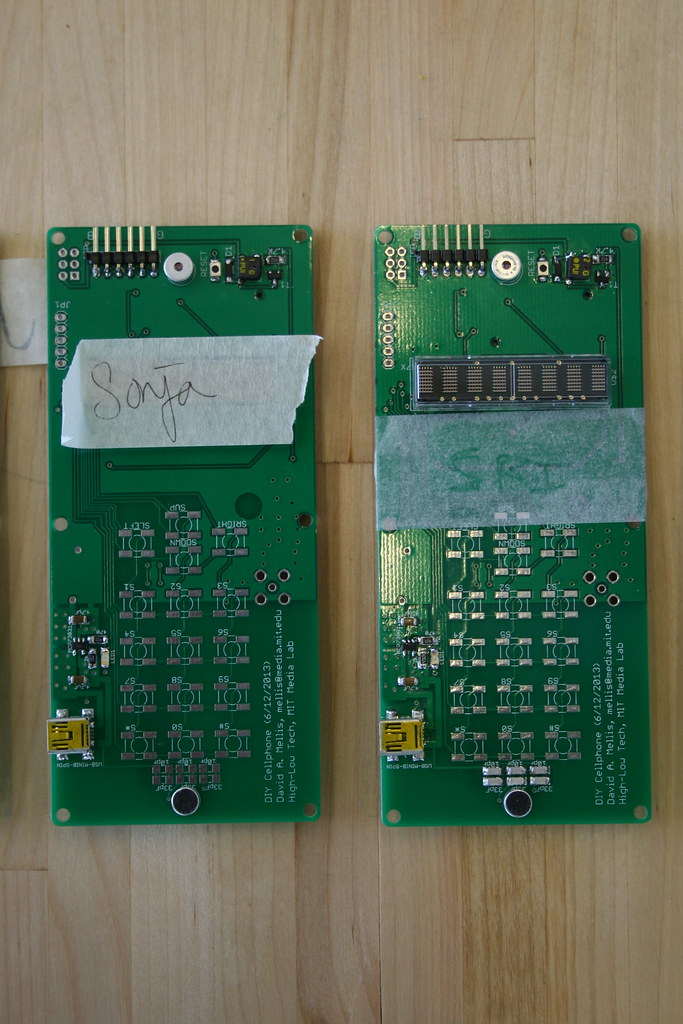

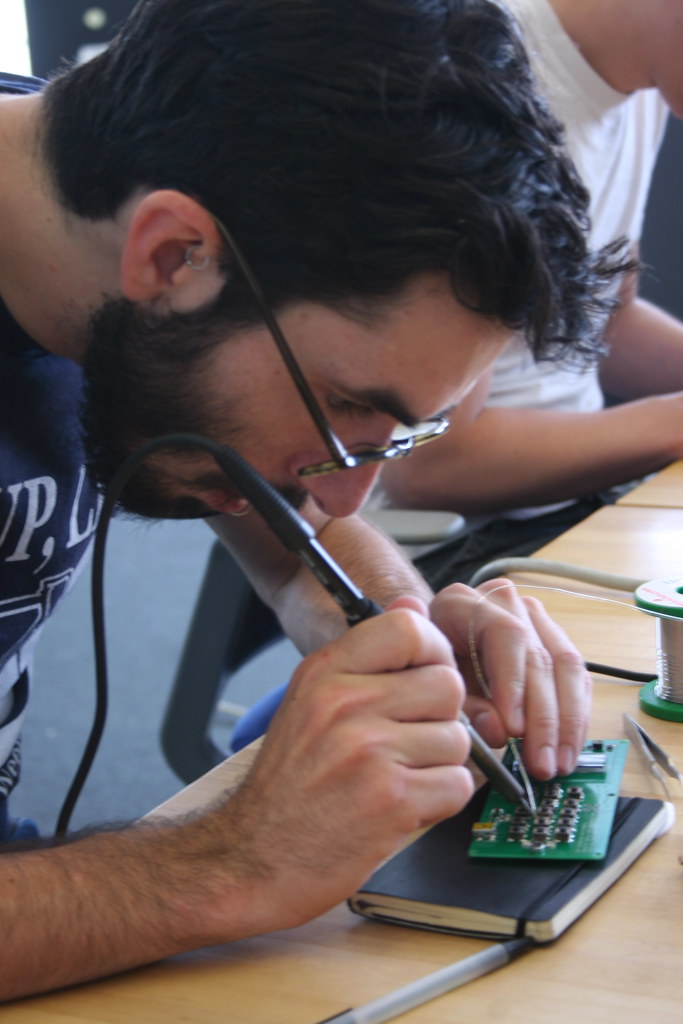

2. **Least Efficient or Skilled**A significant marker of a ‘worst’ DIY repair trick is when the execution demonstrates a profound lack of efficiency or skill. The context defines ‘worst’ as ‘least efficient or skilled,’ and this applies directly to the hands-on aspect of a repair. It’s about performing a task in a manner that is clumsy, unnecessarily complicated, or simply beyond one’s current capabilities, leading to suboptimal results or even further damage.

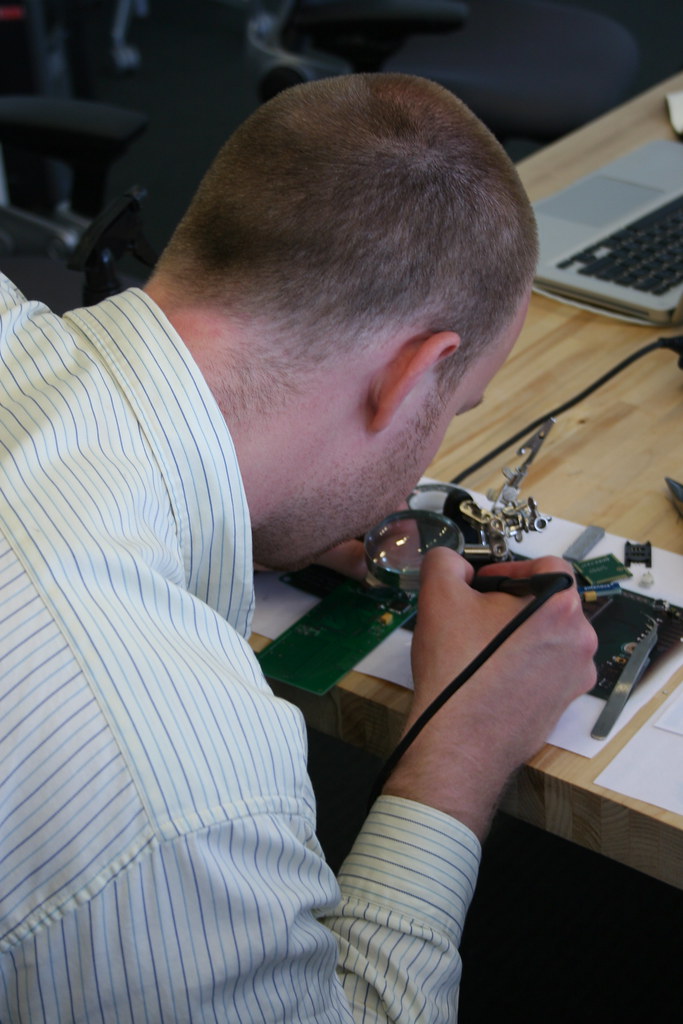

Imagine a repair that requires precision, such as soldering a delicate electronic component or aligning complex mechanical parts. A DIYer operating with ‘least skill’ might use too much heat, apply too much force, or fail to achieve the necessary alignment. This isn’t just about making a mistake; it’s about the entire approach being characterized by an absence of the fine motor control, diagnostic acumen, or procedural knowledge required for the job.

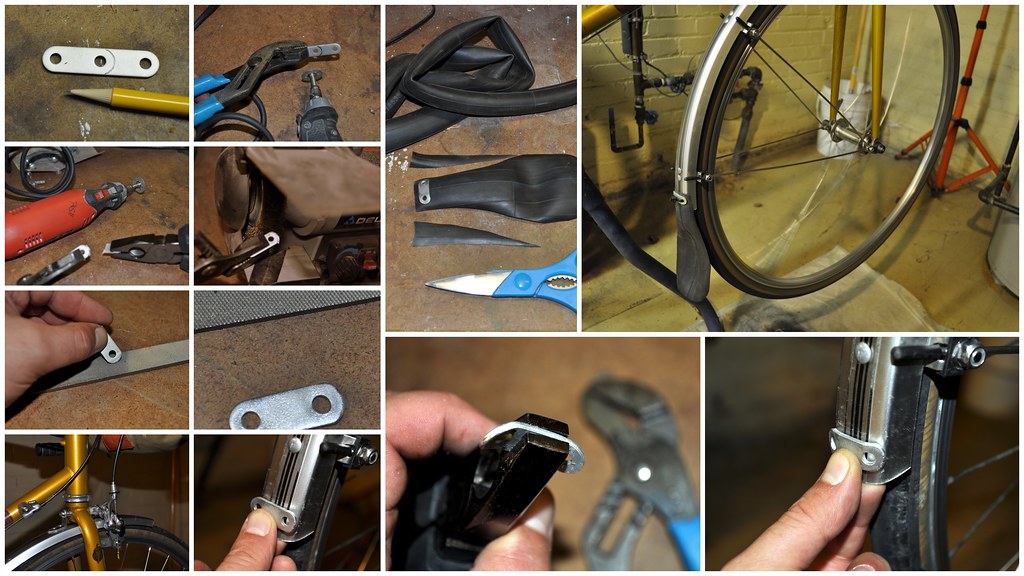

Furthermore, ‘least efficient’ often refers to the methodology chosen. A professional might diagnose a problem and select the most direct, time-saving, and effective solution. A DIYer, lacking experience, might opt for a convoluted workaround that consumes excessive time, uses inappropriate tools, or bypasses proper steps, all while yielding a poorer result. This inefficiency isn’t just a waste of time; it frequently introduces unnecessary wear and tear on components.

Read more about: Mastering the Chuckle: 14 Simple Tricks Top Comedians Use to Craft Hilarious Material

3. **Bad or Ill in the Most Extreme Degree**This definition cuts to the core of what makes a repair truly detrimental: it is ‘bad or ill in the most extreme degree.’ This signifies a level of severity where the DIY trick isn’t just mildly ineffective or slightly flawed, but fundamentally and comprehensively wrong. It’s an approach so utterly misguided that its very existence is a testament to a complete misunderstanding of sound mechanical principles or safety protocols.

Think of a scenario where a critical structural component, like a suspension arm on a vehicle, is repaired using an ordinary adhesive instead of proper welding or bolt replacement. This method is ‘bad in the most extreme degree’ because it jeopardizes the structural integrity of the vehicle, posing an immediate and severe safety risk. The trick is not merely inadequate; it’s catastrophically inappropriate, turning a potentially repairable item into a rolling hazard.

Such a ‘worst’ repair often arises from a combination of ignorance and overconfidence, where the DIYer fails to recognize the gravity of the component’s function or the forces it must withstand. The repair is ‘ill’ not just in its execution, but in its very conception—a choice of action that fundamentally opposes proper engineering and safety standards. It represents the absolute nadir of repair attempts.

Read more about: Deconstructing Failure: Understanding ‘Worst’ in Business and Celebrity Ventures

4. **Most Unpleasant, Unattractive, or Disagreeable**While not always immediately impacting functionality, a DIY repair can be considered ‘worst’ if it is ‘most unpleasant, unattractive, or disagreeable.’ This often pertains to the aesthetic outcome or the sensory experience associated with the repair, but it also reflects underlying issues of craftsmanship and attention to detail. A repair that is visually jarring or creates an unpleasant user experience often hints at deeper, more functional problems.

Consider a crude bodywork repair on a car where the filler is applied unevenly, unpainted, and stands out starkly against the original finish. This is ‘most unattractive’ and visually disagreeable. While the car might still drive, the repair detracts significantly from its value and appearance. Such a visible lack of care can also be a red flag, indicating that if the external appearance is so neglected, the internal aspects might be equally shoddy or incomplete.

Beyond aesthetics, an ‘unpleasant’ repair might involve creating persistent noises, vibrations, or even odors that weren’t present before. For instance, a misaligned exhaust system repair could lead to a constant rattling or an exhaust leak that produces an acrid smell. These disagreeable sensations undermine the overall satisfaction with the item and suggest that the repair was executed without proper tools, parts, or the meticulousness required.

Read more about: From Bad to Worse (or is it Worst?): Unpacking the Ultimate Grammar Showdown

5. **Most Unfavorable or Injurious**The most critical dimension of a ‘worst’ DIY repair trick is its capacity to be ‘most unfavorable or injurious.’ This aspect moves beyond mere inefficiency or poor aesthetics, directly addressing the potential for physical harm to the user, the equipment, or anyone in its vicinity. Any repair approach that escalates risk rather than mitigating it clearly falls under this dangerous category.

An ‘injurious’ repair could manifest in various ways. Imagine a homeowner attempting to bypass a safety circuit in an appliance to get it working. While it might temporarily function, this trick is ‘most injurious’ because it removes a crucial safeguard designed to prevent electrical shock or fire. The consequence is not just a broken appliance, but a potential hazard that could lead to serious injury or catastrophic damage to property.

Similarly, applying excessive torque to fasteners without a torque wrench, or using incorrect fasteners altogether, can be ‘most unfavorable.’ This might strip threads, deform components, or cause parts to fail under operational stress. Such actions don’t just result in a poor repair; they can cause the assembly to fail dynamically, leading to dangerous situations like a wheel detaching from a car or a structural element collapsing, proving truly injurious.

Read more about: 14 Cinematic Catastrophes: Unpacking the Worst Movie Sequels That Tanked a Legacy

6. **In the Poorest Condition (Result)**A hallmark of a ‘worst’ DIY repair is when the component or system ends up ‘in the poorest condition’ as a direct result of the intervention. This implies that the attempted fix not only failed to improve the situation but actively degraded the item, leaving it in a state far worse than its initial broken condition. It’s the inverse of repair; it’s systematic deterioration caused by misguided effort.

Consider attempting to service a delicate engine component, like a fuel injector, without the proper tools or knowledge. A DIYer might inadvertently bend or crack a critical part, introduce contaminants, or incorrectly reassemble it. The original problem might have been minor, but the component is now ‘in the poorest condition,’ perhaps completely unusable or requiring far more expensive and complex repairs than before the DIY attempt.

This ‘poorest condition’ outcome also often stems from a lack of respect for the intricate engineering of modern systems. Components are designed to exacting tolerances, and crude, forceful, or incorrect assembly methods can irreversibly damage them. For example, using a hammer where a press is needed, or applying heat where cold is required, can warp metals, compromise seals, and destroy sensitive electronics.

Mechanics frequently encounter items that have been reduced to ‘poorest condition’ by a DIY attempt. They see perfectly good, albeit malfunctioning, parts rendered irreparable due to crude manipulation, cross-threading, stripping, or forcing. This makes their job exponentially harder, as they often have to repair the damage *from* the DIY attempt before even addressing the original issue.

7. **Lacking in Skill, Talent, Proficiency, or Judgment**Finally, many ‘worst’ DIY repair tricks are characterized by a profound ‘lacking in skill, talent, proficiency, or judgment.’ This isn’t just about making an occasional error; it’s about an overarching absence of the necessary attributes for competent mechanical work. It speaks to a fundamental gap in understanding both the theoretical aspects of a repair and the practical ability to execute it correctly.

A DIYer attempting a complex electrical repair without proper understanding of wiring diagrams, current flows, or safety procedures demonstrates a significant ‘lacking in proficiency.’ They might miswire components, create short circuits, or install incorrect fuses, all stemming from a deficit in their practical and theoretical knowledge. The outcome is often not just a failed repair, but potential damage to the electrical system or a fire hazard.

Similarly, ‘lacking in judgment’ can lead to disastrous choices, such as using parts that are clearly unsuitable for the application—like employing wood screws to mount a heavy bracket meant for machine bolts—or attempting a structural repair with materials never intended for load-bearing applications. This isn’t necessarily about physical clumsiness, but rather the inability to make sound decisions about materials, methods, and safety.

This characteristic underpins many of the other ‘worst’ traits. Without skill, repairs are faulty. Without judgment, repairs are injurious. Professionals often note that while enthusiasm is admirable, it cannot substitute for the ‘talent, proficiency, or judgment’ required for safe and effective repairs. Recognizing this deficit is the first step towards avoiding techniques that are inherently ‘worst’ and seeking appropriate guidance or professional assistance when needed.

### Section 2: Beyond the Immediate Fix – Long-Term Damage and Systemic Failures

Having explored the immediate failings and fundamental deficiencies that characterize the ‘worst’ DIY repair tricks, we now turn our attention to the insidious, often less obvious, impacts. This section delves into additional critical aspects, uncovering how misguided attempts lead to long-term damage, substandard outcomes, the misuse of improper materials, and even broader systemic issues. Understanding these nuances is paramount for any home mechanic striving for genuine, lasting solutions rather than temporary, detrimental fixes.

Read more about: 14 Cinematic Catastrophes: Unpacking the Worst Movie Sequels That Tanked a Legacy

8. **Of Low or Inferior Quality; Deficient (Materials)**A significant number of ‘worst’ DIY repairs stem from the use of materials that are “of low or inferior quality; deficient.” This isn’t just about opting for a cheaper alternative; it’s about a fundamental mismatch between the demands of the repair and the inherent properties of the chosen components. Whether it’s using standard hardware where hardened bolts are required, or a general-purpose adhesive for a high-stress, high-temperature environment, the material itself becomes a liability.

Professionals frequently encounter the fallout from this particular misstep. A plastic component attempting to substitute for a metal one, or a thin-gauge wire used in a high-current application, might initially appear to work. However, the inherent deficiency in material quality means it will inevitably fail prematurely, often at the most inconvenient or even dangerous moment. This characteristic highlights a lack of understanding regarding material science and engineering specifications.

Such repairs are ‘worst’ because they introduce a planned obsolescence, often worse than the original component’s natural lifespan. They create a weak link in a system, ensuring future failure and potentially escalating the original problem. The perceived savings from using ‘deficient’ materials are quickly eclipsed by the cost of re-repairing or replacing not just the faulty fix, but additional components damaged by its inevitable failure.

9. **Incorrect, Inaccurate, or Faulty Diagnosis/Methodology**Beyond merely lacking skill in execution, a DIY repair becomes ‘worst’ when it is built upon an “inaccurate; incorrect, or faulty” understanding of the problem itself. This refers to a misdiagnosis of the root cause or the adoption of an entirely incorrect methodology for the repair. It’s like treating a symptom while the underlying disease continues to fester, often exacerbating the issue rather than resolving it.

Consider a situation where an engine misfire is attributed to spark plugs, when in fact, the actual culprit is a failing fuel injector or a vacuum leak. Replacing the spark plugs, while technically a repair, is ‘incorrect’ because it fails to address the actual malfunction. The DIYer, having followed a seemingly logical but ultimately flawed diagnostic path, invests time and money into a solution that will not only fail but also obscure the true problem for future troubleshooting.

This characteristic is particularly insidious because it often convinces the DIYer that they have achieved a fix, only for the problem to re-emerge or worsen. The ‘faulty’ methodology might also involve bypassing proper repair sequences, such as attempting to patch a rusted frame without addressing the structural integrity or underlying corrosion. Such approaches are ‘worst’ not just for their inefficiency, but for actively misleading the mechanic (or future mechanic) about the true state of the vehicle or appliance.

10. **Causing a Diseased, Decayed, or Weakened State**A particularly alarming consequence of a ‘worst’ DIY repair is its capacity to leave the component or system in a “diseased, decayed, or weakened” state. This goes beyond mere functional failure; it implies an active degradation of the item’s integrity, robustness, or health. The attempted fix doesn’t just fall short; it initiates a process of decline that undermines the very foundation of the equipment.

Imagine trying to “fix” a corroded battery terminal by aggressively scraping it with an abrasive tool, inadvertently removing protective coatings and thinning the metal. While the connection might temporarily improve, the component is now in a ‘weakened’ state, far more susceptible to future corrosion and eventual complete failure. This aggressive, ill-informed action has transformed a localized issue into a systemic vulnerability.

This kind of ‘worst’ repair often involves practices that compromise the long-term viability of the equipment. For instance, using excessive heat on delicate electronics or applying incompatible lubricants to moving parts can lead to premature wear, material fatigue, or chemical degradation. The component effectively becomes ‘diseased,’ its internal structure or function compromised, ensuring a shorter lifespan and greater risk of catastrophic failure down the line.

Read more about: From Bad to Worse (or is it Worst?): Unpacking the Ultimate Grammar Showdown

11. **Having a Disastrous or Detrimental Effect, Result, or Tendency**Some DIY tricks are ‘worst’ because they demonstrably “have a disastrous or detrimental effect, result, or tendency,” leading to cascading failures or unintended negative consequences far beyond the immediate repair area. These are the fixes that don’t just fail in isolation but actively damage adjacent components or trigger a chain reaction of problems, embodying the “broader systemic issues” highlighted in our outline.

Consider the amateur installation of aftermarket accessories that draw excessive current, leading to an overload of the vehicle’s electrical system. While the accessory itself might function, the ‘detrimental effect’ can include blown fuses, damaged wiring harnesses, or even a strained alternator. This single, seemingly minor DIY task creates a ‘disastrous tendency’ for electrical malfunctions throughout the entire vehicle, transforming a simple enhancement into a chronic headache.

Such approaches demonstrate a profound lack of understanding of interconnected systems. A DIYer might see a single problem in isolation, failing to grasp how their ‘fix’ will reverberate through complex mechanical, electrical, or hydraulic networks. These ‘worst’ repairs are dangerous because they introduce instability, creating new, often more expensive and complex, problems that require extensive professional intervention to unravel and rectify.

Read more about: 14 Cinematic Catastrophes: Unpacking the Worst Movie Sequels That Tanked a Legacy

12. **Not Suitable or Appropriate**A common pitfall leading to a ‘worst’ DIY repair is the choice of a solution that is simply “not suitable or appropriate” for the specific context. This isn’t necessarily about material quality, but rather the fundamental application of a trick or component in a situation where it inherently doesn’t belong. It can also encompass methods that are “ill-considered,” meaning they were not thought out well in advance or are fundamentally inappropriate for the task.

For example, attempting to seal a high-pressure hydraulic line with a sealant designed for household plumbing is a glaring instance of an ‘unsuitable’ repair. The materials, pressure ratings, and chemical compatibility are entirely different. While it might hold for a short period, its inevitable failure will be swift and potentially hazardous, highlighting a critical misunderstanding of the component’s operational parameters.

These ‘worst’ tricks reveal a lack of fundamental mechanical knowledge and judgment. The DIYer might force a square peg into a round hole, believing that ‘good enough’ is acceptable when precise engineering is required. This inappropriateness often leads to accelerated wear on surrounding parts, compromised safety features, or an outright failure that is worse than the original problem because it introduces new, complex forms of damage.

Read more about: Unlock Continuous Power: 13 Essential Ways to Keep Your RV’s 12-Volt Battery Charged on Every Adventure

13. **Not Profitable or Worth the Price Paid**Many DIY repair tricks, while seemingly offering immediate cost savings, ultimately prove to be “not profitable or worth the price paid” when viewed through a holistic lens. This characteristic focuses on the economic fallacy of certain amateur interventions, where the cumulative cost in terms of time, additional parts, subsequent professional repairs, and diminished resale value far outweighs any initial perceived benefit.

A classic example is the attempt to rebuild a complex transmission by an inexperienced individual. The cost of specialized tools, replacement parts, and the sheer number of hours invested might already approach or exceed the cost of a professional rebuild or a remanufactured unit. If the DIY attempt then fails—which it often does due to the intricate nature of the work—the vehicle owner is left with a non-functional vehicle and a significant financial loss, making the initial ‘effort’ entirely unprofitable.

This type of ‘worst’ repair represents a miscalculation of true cost. It’s a situation where the initial investment of time and money is “ill-spent” because the outcome is either inadequate, short-lived, or creates further, more expensive problems down the line. Mechanics routinely see vehicles where DIY efforts have turned a manageable repair into an economic write-off, serving as a stark reminder that sometimes the cheapest option upfront is the most expensive in the long run.

Read more about: Buyer’s Remorse: 12 Highly Flawed Collector Cars That Mechanics Refuse to Touch

14. **Ill-Defined or Poorly Understood (Problem)**Finally, many of the ‘worst’ DIY repair tricks originate from a problem that is “ill-defined or poorly understood.” This means the DIYer hasn’t accurately identified the issue, its scope, or its underlying causes before attempting a fix. Without a clear and comprehensive understanding, any repair is essentially a shot in the dark, often leading to temporary patches that obscure the real problem or introduce new complexities.

Imagine a homeowner attempting to fix a persistent electrical fault by repeatedly resetting a circuit breaker, without investigating why the breaker is tripping in the first place. The problem is ‘ill-defined’ because the root cause (perhaps an overloaded circuit, a faulty appliance, or damaged wiring) remains a mystery. The “fix” is purely superficial, creating a false sense of security while a potentially dangerous underlying condition persists, unaddressed.

This lack of precise problem definition ensures that the repair will be inadequate at best and dangerous at worst. It showcases a fundamental gap in diagnostic prowess, often leading to a cycle of trial-and-error that wastes resources and damages components. Professionals consistently highlight that a thorough understanding of the problem is the first and most crucial step in any successful repair. Without it, even the most well-intentioned DIY effort is destined to be among the ‘worst’.

—

As we’ve meticulously dissected these characteristics, it becomes abundantly clear that the ‘worst’ DIY repair tricks aren’t just about a bolt being stripped or a wire being crossed. They are a complex tapestry of misguided intentions, flawed methodologies, and a fundamental underestimation of mechanical complexity and safety imperatives. These are the approaches that mechanics dread, not out of job security concerns, but because they witness firsthand the increased danger, expense, and frustration that result from well-meaning but ill-conceived amateur interventions. By recognizing these inherent ‘worst’ traits, from the initial misdiagnosis to the long-term systemic damage, every home mechanic can move beyond merely attempting a fix and instead cultivate an approach that is truly effective, safe, and, ultimately, respectful of the intricate machines we rely on daily. The goal isn’t to discourage self-reliance, but to empower it with knowledge, judgment, and a healthy respect for the nuances of proper repair.