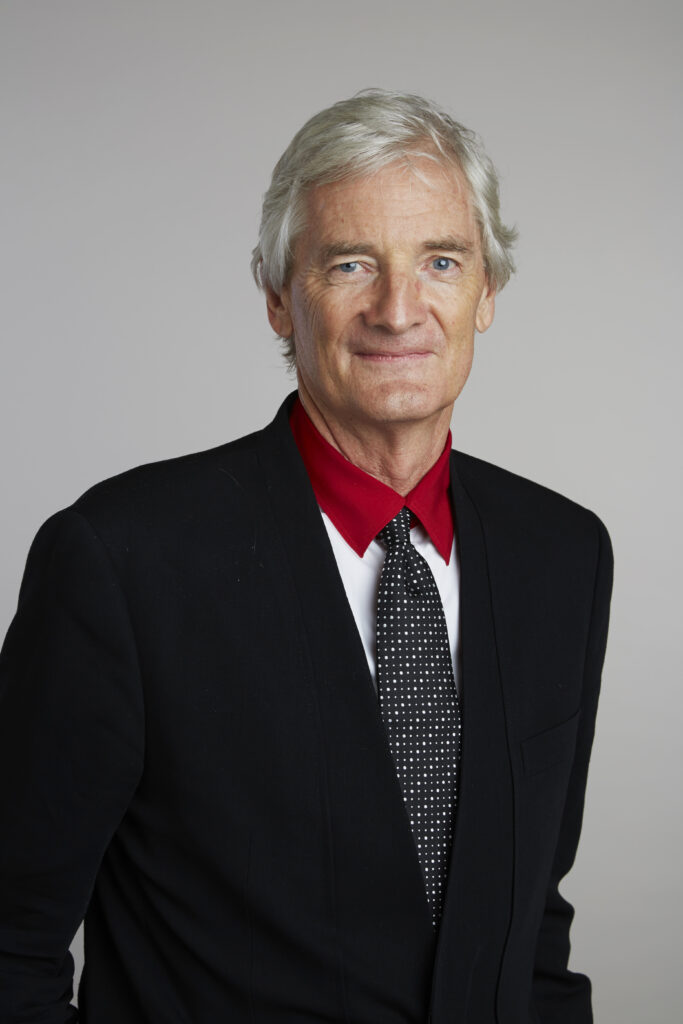

In the vast landscape of global technology, few companies embody the spirit of relentless innovation and design-led engineering quite like Dyson. What began as one man’s profound frustration with a seemingly mundane household appliance has burgeoned into a multinational powerhouse, renowned for reimagining everyday objects with cutting-edge science and distinctive aesthetics. From the humble vacuum cleaner to advanced air purification systems, Dyson’s journey is a compelling narrative of perseverance, strategic ingenuity, and an unwavering commitment to challenging conventional wisdom.

At its core, Dyson’s story is a testament to the transformative power of observation and the courage to pursue a radically different approach. It underscores how a deep understanding of fundamental principles, combined with an experimental mindset, can lead to solutions that not only solve problems but also redefine entire product categories. This is the saga of an enterprise that dared to ask ‘why not?’ in the face of established giants, meticulously developing revolutionary technologies that have since permeated homes and industries worldwide.

As we embark on this in-depth exploration, we will traverse the pivotal moments of Dyson’s foundational years, from the spark of an idea in a cluttered shed to its emergence as a formidable player on the global stage. Our journey will highlight the ingenious solutions, the strategic decisions, and the unyielding spirit that characterize the initial chapters of this remarkable British–Singaporean technology company, laying the groundwork for its enduring legacy of innovation.

1. **The Genesis of Invention: James Dyson’s Frustration and the Cyclonic Idea**

Our story begins in the 1970s, not with a grand vision for a technology empire, but with a simple, relatable annoyance. James Dyson had purchased a Hoover Junior vacuum cleaner, a common household appliance, only to find its suction power rapidly diminish after a period of use. Frustrated by this common deficiency, he investigated, emptying the disposable paper bag in an attempt to restore performance, but to no avail. Upon opening the bag, a revealing layer of fine dust was discovered, clogging the fine material mesh and suffocating the machine’s ability to draw air.

This personal frustration, however, was soon to intersect with a professional insight. Dyson was simultaneously engaged in working on his ballbarrow, a venture where a large vacuum system was employed to contain the fusion bonded epoxy coating applied as a powder. He observed that this industrial system, too, was inefficient. Equipment manufacturers suggested that giant cyclone systems offered a superior alternative, sparking an initial connection between industrial-scale dirt collection and his domestic vexation.

Intrigued, Dyson embarked on a self-directed research mission into centrifugal separators, a method typically used in industrial settings for collecting dirt, dust, and debris. Recognizing that sawmills frequently employed such equipment, he meticulously investigated by visiting a local sawmill at night, taking precise measurements to understand the mechanics. This hands-on investigation led him to construct a 30-foot model for the ballbarrow factory, a crucial step in translating theoretical knowledge into practical application.

It was while constructing this larger model at home that Dyson experienced a profound realization: the fundamental function of the cyclone was to extract dust without clogging. This pivotal insight immediately begged the question of whether such a principle could be miniaturized and applied to a home vacuum. In a moment of pure inventive genius, he fashioned a cardboard model secured with sticky tape, connected it to his Hoover with its bag removed, and witnessed its satisfactory performance, confirming the viability of a small-scale cyclonic vacuum.

2. **The Prototypes and Early Rejections: A Path Paved with 5,127 Attempts**

Armed with a working concept, Dyson’s journey was far from smooth. The directors of his ballbarrow company, steeped in conventional wisdom, were skeptical, asserting that if a better vacuum were possible, industry titans like Hoover or Electrolux would have already invented it. Unwavering in his conviction, Dyson found himself undeterred, even as this profound disagreement led to his expulsion from the very company he had founded. This early rejection only solidified his resolve to pursue the revolutionary idea.

His independent pursuit, however, required significant resources. Jeremy Fry, recognizing the potential, provided 49% of the investment necessary for the cyclonic vacuum’s development, with the remainder secured through a loan. This crucial financial backing allowed Dyson to transform his vision into a tangible reality. He retreated to the shed behind his house, a humble setting that would become the crucible of groundbreaking innovation.

Within the confines of that shed, Dyson embarked on an astonishing period of iterative design. Between 1979 and 1984, he meticulously developed an astounding 5,127 prototype designs. This relentless dedication, a testament to his engineering tenacity, demonstrates a profound commitment to perfection and an understanding that true innovation is often a result of countless trials and refinements, meticulously pushing the boundaries of what is possible.

Despite the sheer number of prototypes, the first commercially viable design, a red and blue machine, brought him little immediate success. He struggled extensively to find a licensee for his groundbreaking machine in both the UK and America. Manufacturing giants like Hoover were disinclined to license his design, likely because Dyson’s bagless technology posed a direct and existential threat to the lucrative US$500 million vacuum bag market, which was a significant revenue stream for established players.

3. **The First Steps to Market: Kleeneze, Amway, and the Japanese Breakthrough**

Facing widespread reluctance from major manufacturers, Dyson found an unexpected ally in his former employer, Rotork, the only company to express interest in his radical new cyclonic vacuum technology. This led to the creation of the Kleeneze Rotork Cyclon, built by the Italian appliance maker Zanussi and sold through a mail order catalogue by Kleeneze. This marked the very first public sale of Dyson’s design, though only about 500 units were sold in 1983, a modest debut for such a revolutionary product.

However, a contentious chapter soon unfolded with the American consumer-products maker Amway. In April 1984, Dyson claimed he had sent prototype machines, detailed drawings, and confidential information to Amway as part of a proposed licensing deal. The deal ultimately fell through, but in January 1985, Amway produced the CMS-1000, a machine strikingly similar to Dyson’s design. Less than a month later, Dyson initiated a patent infringement lawsuit against Amway, vigorously defending his intellectual property.

A pivotal turning point arrived in 1985 when a Japanese company, Apex Ltd., expressed genuine interest in licensing Dyson’s innovative design. This partnership proved fruitful, leading to a reworked version of the Cyclon, branded the G-Force, which was put into production in March 1986. The G-Force made a significant splash in the Japanese market, selling for the equivalent of a staggering US$2,000, positioning it as a premium, aspirational product.

Beyond its core function, the G-Force showcased a clever design feature tailored to its market: an attachment that could ingeniously transform the vacuum into a table, a practical solution to save space in smaller Japanese apartments. This thoughtful integration of functionality and lifestyle resonated deeply with consumers. In 1991, the G-Force won the prestigious International Design Fair prize in Japan, elevating its status and solidifying its position as a true symbol of innovation and modern living.

4. **Dyson Appliances is Born: From Licensing to Independent Manufacturing**

Bolstered by the substantial income generated from the successful Japanese license, James Dyson made a decisive move to establish his own manufacturing and brand identity. In 1991, Dyson Appliances Limited was formally set up, though initially registered under the name Barleta Limited. This marked a crucial evolution from merely licensing his pioneering technology to taking full control of the design, production, and marketing of his products.

The inaugural dual-cyclone vacuum produced under the Dyson name, the DA 001, commenced production in January 1993. This initial manufacturing partnership was with the American company Phillips Plastics, utilizing their facility in Wrexham, Wales. The DA 001 quickly established a market presence, selling for approximately £200, representing a significant investment for consumers but promising a fundamentally superior cleaning experience.

However, Dyson’s unyielding commitment to quality soon led to a critical decision. By May 1993, just a few months after production began, Dyson severed the agreement with Phillips Plastics. This bold move was driven by persistent quality control concerns and Phillips’s desire to renegotiate the terms of their manufacturing contract. For Dyson, maintaining the integrity and performance of his products was paramount, even if it meant disrupting established supply chains.

Demonstrating remarkable agility and strategic foresight, Dyson moved swiftly. Within an impressive two-month period, he successfully established an entirely new supply chain and opened a dedicated production facility in Chippenham, Wiltshire, England. The first vacuum cleaner to roll off the line at this new, wholly-owned facility, the DC01, was completed on July 1, 1993, firmly establishing Dyson’s independence in manufacturing and setting the stage for direct market engagement. Dyson also licensed the technology in North America to Fantom Technologies from 1986 to 2001, before directly entering that market.

5. **The Transparent Revolution: How a Clear Bin Changed the Industry**

One of Dyson’s most enduring and recognizable innovations, the transparent dust container, emerged not from market demand, but in defiance of it. Early market research, a cornerstone of product development, indicated a clear preference: people would not be happy with a visible container for the dirt and debris collected by their vacuum cleaners. This insight presented a significant hurdle to what would become an iconic design choice.

However, James Dyson and his team possessed an unwavering conviction in their vision. Despite the market research suggesting otherwise, they made the bold, independent decision to incorporate a transparent container into their vacuum designs anyway. This act of trusting their engineering intuition and commitment to transparency over conventional consumer feedback proved to be a pivotal moment in the company’s design philosophy.

The transparent bin quickly transcended its perceived limitations, becoming not only a popular but a highly enduring feature. It offered users a tangible, visual confirmation of the dirt being removed from their homes, transforming a hidden process into a visible demonstration of efficiency. Its success was so profound that it has been heavily copied across the industry, a testament to its revolutionary appeal and undeniable functional value.

The impact of this design, coupled with the core cyclonic technology, propelled the DC01 to unprecedented success. In just 18 months, it became the biggest selling vacuum cleaner in the UK, fundamentally altering the landscape of household appliances. By 2001, the DC01 commanded an impressive 47% of the upright vacuum cleaner market, solidifying Dyson’s position as a dominant force and a trendsetter in home cleaning technology.

Read more about: The 13 Pivotal Aspects of Silicon: Driving Innovation from Earth’s Crust to Digital Life

6. **Evolving Technology: Root Cyclone and Product Diversification**

Dyson’s journey of innovation extended far beyond the initial dual-cyclone system. The company consistently sought to refine and enhance its core vacuum technology. This pursuit of greater efficiency culminated in April 2001 with the launch of the DC07, a new upright vacuum cleaner that introduced the groundbreaking “Root Cyclone” technology. This advanced design featured seven distinct cyclone funnels, a significant leap from the original dual-cyclone, engineered to capture even finer dust particles with greater consistency.

Alongside these pivotal technological advancements, Dyson embarked on a significant expansion and diversification of its product line. The company introduced a range of cylinder machines, such as the DC02, and released numerous special editions and revised models, including the DC02 Absolute, DC02 De Stijl, DC05, DC04, DC06, and DC04 Zorbster. These iterations underscored a commitment to continuous improvement and market responsiveness. Reflecting its broader aspirations beyond just vacuum cleaners, the company formally shortened its name from Dyson Appliances Ltd. to Dyson Ltd. on January 2, 2001.

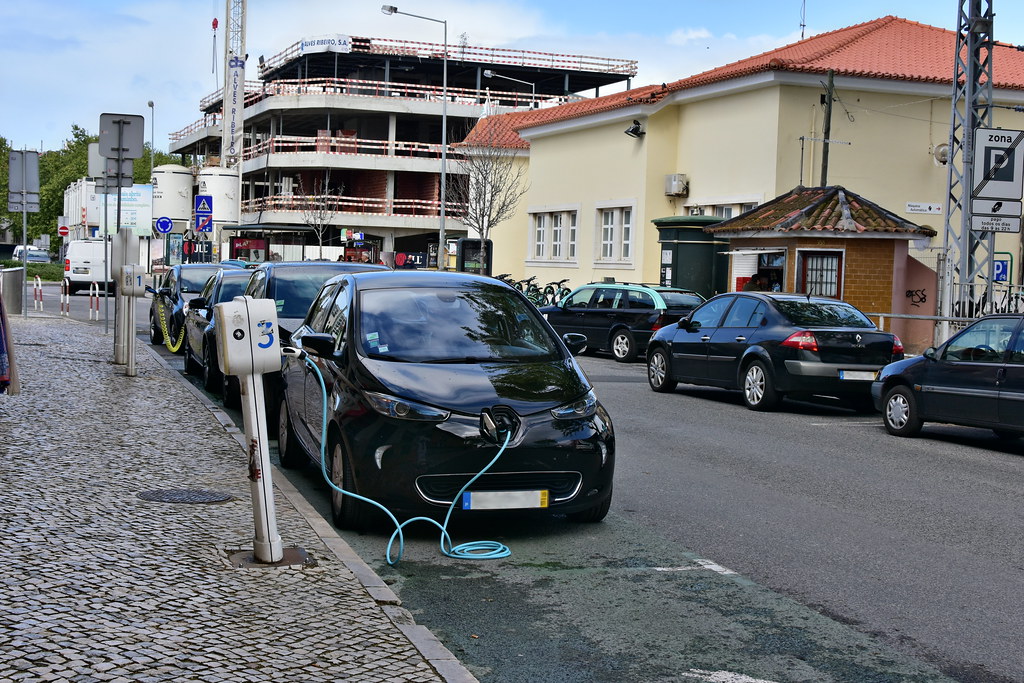

A pivotal shift in Dyson’s strategic direction occurred around 2009, as the company ventured confidently into entirely new technology domains. This era saw the introduction of the Dyson Airblade hand dryer, a product that challenged the conventional and often unhygienic methods of hand drying in public spaces, offering a faster and more efficient alternative. This signaled Dyson’s ambition to apply its engineering principles to a wider array of everyday problems.

Further demonstrating this expansive vision, Dyson unveiled the revolutionary Air Multiplier “bladeless” fan, which created a smooth, uninterrupted airflow without any visible spinning blades, fundamentally rethinking the mechanics of personal cooling. This was followed by the Dyson Hot, a “bladeless” fan heater, extending the same innovative airflow principles to heating. More recently, in October 2019, the Pure Cryptomic was released, available in both fan and heater + fan versions, showcasing the company’s commitment to air quality by actively removing harmful formaldehyde from the air.

7. **Global Manufacturing Footprint: From UK to Malaysia and Beyond**

A significant strategic shift in Dyson’s operational history occurred in 2002 when the company made the decision to transfer its vacuum cleaner production from Malmesbury, Wiltshire, to Malaysia. This move, while economically driven, was not without controversy. Trade unionists in Wiltshire voiced strong concerns, asserting that the relocation would negatively impact the local economy through the loss of manufacturing jobs, highlighting the complex social implications of global supply chain decisions.

The following year, in 2003, washing machine production followed suit, also being transferred to Malaysia. The primary impetus for these moves was demonstrably economic: lower production costs in Malaysia, which were reported to be 30% less than in the UK. This transition, while leading to the loss of 65 jobs in the UK, was framed by Dyson as a necessary step to maintain competitive pricing and ensure the company’s long-term sustainability and growth in a globalized market.

Dyson publicly stated that the cost savings realized from transferring production to Malaysia were not merely for profit maximization but were strategically reinvested. These savings were explicitly channeled into enhancing research and development efforts at their Malmesbury head office. This approach positioned the global manufacturing shifts as a mechanism to fuel further innovation and maintain the UK site as a hub for cutting-edge engineering.

To solidify and expand its manufacturing prowess, Dyson forged crucial international partnerships. In 2004, the Meiban-Dyson Laundry Manufacturing Plant was inaugurated in Johor, Malaysia. This RM10 million (approximately US$2.63 million) facility was a joint venture between Dyson and the Singapore-based Meiban Group Ltd., a company with extensive manufacturing facilities across China, Malaysia, and Singapore, significantly bolstering Dyson’s production infrastructure in Asia.

Further strengthening its Malaysian ties, Dyson formed a key partnership in 2007 with the Malaysian electronics manufacturer VS Industry Bhd (VSI). This collaboration saw VSI taking on a major role across Dyson’s supply chain, encompassing everything from raw material sourcing and production to global distribution. VSI undertook an extensive production plan, supplying finished products to Dyson’s diverse international markets including America, the UK, and Japan, and later manufacturing the world’s first Dyson hairdryer. However, this complex supply chain faced scrutiny, notably in February 2022 when Channel 4 News reported allegations of “forced labor” conditions at a Malaysian manufacturer of Dyson products, ATA IMS, leading Dyson to terminate contracts, emphasizing its commitment to ethical labor practices.

8. **Expanding the Global Manufacturing and R&D Network: The Strategic Shift to Asia**

Building upon its earlier strategic moves, Dyson solidified its presence in Asia by establishing pivotal manufacturing and research hubs, most notably in Singapore. This strategic geographical realignment was driven by the imperative to optimize operational efficiencies and to position the company closer to its burgeoning Asian customer base and critical supply chains. The shift was not merely about production costs; it was a fundamental re-evaluation of Dyson’s global operational structure to fuel continued innovation and growth.

A significant milestone in this expansion was the launch of a US$360 million plant in Tuas, Singapore, in 2013. This state-of-the-art facility was initially engineered to produce an impressive four million electric motors annually, marking a substantial increase in Dyson’s high-tech manufacturing capabilities. Recognizing the escalating demand and the potential for even greater output, Dyson later injected an additional $100 million into the plant, propelling its estimated digital motor production capacity to 11 million units per year.

Beyond sheer production volume, Singapore has emerged as a cornerstone for Dyson’s advanced research and engineering endeavors. The nation now serves as a central hub for the company’s R&D teams, commercial operations, advanced manufacturing, and intricate supply chain management. Boasting a substantial workforce of over 1,400 staff, including a formidable contingent of 560 engineers and scientists, Singapore embodies Dyson’s commitment to cutting-edge development. This strategic consolidation underscores Dyson’s vision of integrating its design, manufacturing, and intellectual power within a single, dynamic region, further evidenced by a planned S$1.5 billion investment in Singapore, reinforcing its role as a global innovation nexus.

9. **Strengthening Global Presence: Establishing Key Hubs in the US and UK**

Dyson’s global expansion strategy extended beyond manufacturing, embracing a sophisticated network of specialized hubs for market engagement and high-tech research across different continents. This approach demonstrated a commitment to decentralizing certain operations while strengthening core innovative capabilities in key regions. By establishing strategic footholds, Dyson aimed to tap into diverse talent pools and market dynamics.

In North America, Dyson significantly bolstered its presence by relocating its US headquarters and operations to the vibrant Fulton Market District in Chicago. Announced in January 2017, this move was completed by the end of the year, adding 100 employees to the company’s Chicago headcount and securing over 40,000 square feet of newly leased office space. This expansion in a major urban center underscored Dyson’s ambition to deepen its engagement with the American market and talent.

Simultaneously, Dyson affirmed its dedication to its British roots through a significant expansion program in the UK. In February 2017, the company unveiled plans for a new high-tech campus on the former RAF Hullavington Airfield in Wiltshire, approximately five miles south of its established Malmesbury site. This impressive new facility was envisioned as a nexus for advanced research and development.

It was suggested that the Hullavington research campus would primarily focus on pioneering areas such as battery technologies, following Dyson’s acquisition of the US start-up Sakti3, and advanced robotics. This strategic investment reinforced the UK’s role as a vital center for Dyson’s cutting-edge engineering and intellectual property development, showcasing a dual commitment to global market presence and domestic innovation.

10. **The Pivotal Headquarters Relocation to Singapore: A Strategic Reorientation**

In a landmark decision that signaled a profound reorientation of its global strategy, Dyson announced plans to relocate its company headquarters from the United Kingdom to Singapore. This pivotal move, declared on January 22, 2019, reflected a proactive response to evolving global market dynamics and Dyson’s long-term strategic aspirations. It marked a significant shift for a company historically rooted in British innovation.

The primary motivations behind this relocation were articulated clearly by Dyson: an intention to be geographically closer to its fastest-growing markets throughout the Asia-Pacific region. Furthermore, the company cited its dissatisfaction when dealing with the European Union, which it perceived as being overly bureaucratic. These factors converged to make Singapore an attractive new global base, offering both strategic market access and a streamlined operational environment.

Singapore’s St James Power Station, a historically significant former coal-fired power plant, was selected as the iconic new headquarters. The building underwent extensive restoration works from 2019 to 2021, transforming it into a modern, state-of-the-art facility that respects its heritage. Dyson officially began moving into its new headquarters in late 2021, with the meticulously restored St James Power Station officially completed on March 4, 2022, symbolizing a new chapter for the company.

This strategic relocation was further underscored by Dyson’s announcement in 2022 of a plan to invest an additional S$1.5 billion in Singapore over the ensuing four years. This investment is part of a broader $4.9 billion global strategy initiated in 2020, allocating substantial funds across its global headquarters in Singapore, its two campuses in Wiltshire, and operations in the Philippines. The move firmly cements Singapore as Dyson’s global nerve center, integrating its commercial, advanced manufacturing, and supply chain operations.

11. **Forging New Frontiers: Robotics and the Quest for Intelligent Home Automation**

Dyson’s inherent drive for innovation has consistently pushed beyond traditional appliance design, venturing into the cutting-edge realm of robotics and intelligent home automation. The company has long harbored ambitions to engineer sophisticated household robots, believing that the future of home technology lies in truly intelligent and autonomous solutions. This commitment to advanced R&D is evident in their strategic investments and product development.

A significant step in this direction was taken in 2014 when Dyson invested in a joint robotics lab in collaboration with Imperial College London. This partnership was established with the specific aim of investigating advanced vision systems and engineering a new generation of household robots. The collaboration underscores Dyson’s rigorous, scientific approach to developing technologies that can understand and interact with their environment more effectively.

Dyson’s journey in robotic vacuum cleaners began much earlier, with the company coming close to launching the DC06 in 2001. However, James Dyson ultimately pulled it from the production line, deeming it too heavy and slow for market release, illustrating his uncompromising standards. This early foray paved the way for more refined innovations, leading to the successful launch of the 360 Eye in 2016, followed by the 360 Heurist in 2021, the 360 Vis Nav in 2023, and the anticipated Spot+Scrub Ai in 2025.

These successive generations of robotic vacuums, each incorporating increasingly sophisticated navigation and cleaning technologies, reflect Dyson’s persistent efforts to redefine automated home care. Their ongoing research in vision systems and AI aims to create devices that are not just functional, but truly intelligent and seamlessly integrated into the modern home, pushing the boundaries of what household robots can achieve.

12. **Ambitious Ventures Beyond Home Appliances: Batteries and Electric Vehicles**

Dyson’s technological ambition extends well beyond its core household appliances, evidenced by significant forays into advanced energy storage and an audacious, albeit ultimately unfulfilled, electric vehicle project. Recognizing the fundamental importance of power sources in modern technology, Dyson initiated research into battery technology as early as 2010.

A pivotal moment arrived in March 2015 when Dyson made its first external investment, acquiring an undisclosed stake in the US battery start-up Sakti3 for $15 million. This move signaled a serious commitment to solid-state battery technology, a promising area for higher energy density and improved safety. Later that year, in October 2015, Dyson acquired the remaining stake in Sakti3 for $90 million, bringing the promising technology fully within its research ecosystem.

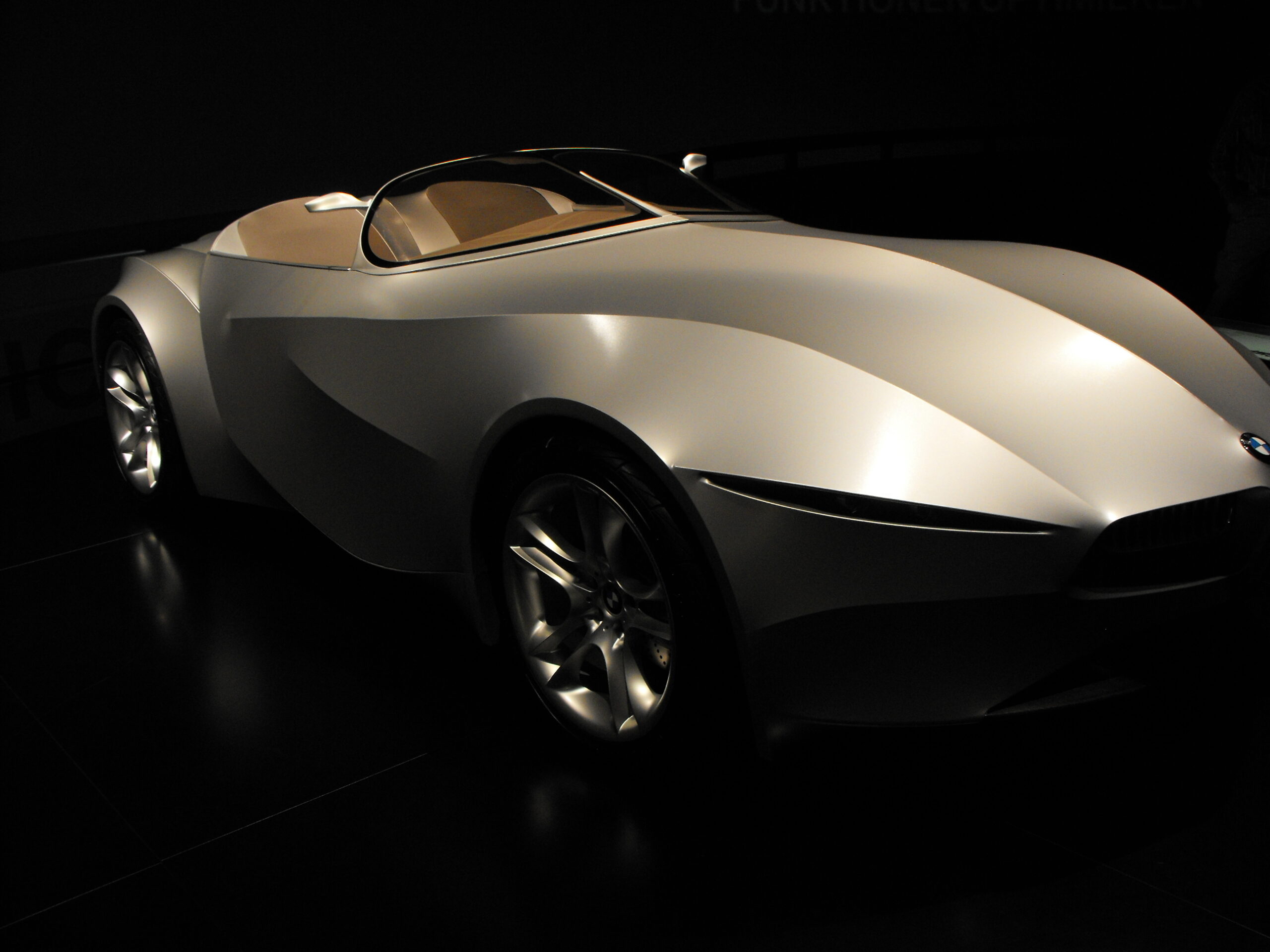

This investment in battery technology laid the groundwork for Dyson’s most ambitious project to date: an electric vehicle. In September 2017, James Dyson revealed that the company had secretly been working for two years, with 400 people dedicated to developing a battery electric vehicle, with a target release date of 2021. Further details emerged in February 2018, outlining plans for three electric vehicles under development as part of an estimated $3 billion project, with a prototype known as the N526 later unveiled and displayed at Dyson headquarters.

However, the project encountered significant commercial challenges. In October 2019, Dyson announced the cancellation of its electric car plans, stating that while their engineers had developed a “fantastic electric car,” it was not “commercially viable” due to a lack of potential buyers. The project had employed over 500 people, mostly in the UK. Despite its termination, the endeavor underscored Dyson’s fearless approach to tackling complex engineering challenges and its willingness to invest heavily in pioneering, albeit risky, technological frontiers, even if the ultimate commercial outcome was not realized. Furthermore, during the COVID-19 pandemic in March 2020, Dyson temporarily diverted its engineering prowess to support UK hospitals by manufacturing medical ventilators, showcasing its versatile engineering capability, although these were eventually deemed “no longer required.”

13. **Safeguarding Innovation: Dyson’s Proactive Defense of Intellectual Property**

In an increasingly competitive global landscape, Dyson has consistently demonstrated a vigilant and proactive approach to safeguarding its intellectual property (IP). Recognizing that its distinct designs and innovative technologies are the bedrock of its commercial success, the company has engaged in numerous legal battles to defend its patents, copyrights, and design rights against perceived infringements. This steadfast commitment to IP protection is a defining characteristic of Dyson’s operational philosophy.

Early in its history, Dyson faced significant challenges to its pioneering bagless technology. A notable instance was the patent infringement lawsuit against the American consumer-products maker Amway in 1985, arising from the alleged similarity of Amway’s CMS-1000 machine to Dyson’s design. This early and crucial legal action eventually led to a settlement in 1991, with both parties becoming joint licensees, marking a critical validation of Dyson’s foundational innovation.

Further demonstrating its resolve, Dyson achieved a landmark victory against Hoover in 2000, successfully asserting infringement of its cyclonic technology with Hoover’s Triple Vortex. This high-profile case resulted in a settlement of £4 million plus an additional £2 million in legal costs, reinforcing Dyson’s position as a fierce protector of its patented designs. The company’s defense extended even to the visual aesthetics of spare parts, as seen in the 2006 lawsuit against Qualtex, where Dyson successfully challenged the creation of deliberate imitations of its original vacuum cleaner parts, demonstrating its comprehensive approach to IP.

Dyson has not shied away from challenging large corporations over perceived unfair practices or exaggerated claims. This includes taking legal action against LG and Samsung regarding their vacuum cleaners’ performance claims, highlighting Dyson’s commitment to honest advertising and product representation. A particularly complex and protracted battle involved Siemens and Bosch over EU energy efficiency ratings in 2015, where Dyson alleged that competitors exploited loopholes in testing regulations. Although Dyson lost some of these specific cases, these actions collectively underscore a steadfast resolve to maintain competitive integrity and ensure fair play in the market, demonstrating that Dyson’s pioneering spirit is matched by its unwavering protection of its inventive output.

14. **Investing in Future Engineers: The Dyson Institute and Global Educational Initiatives**

Beyond its commercial and technological pursuits, Dyson has made a profound commitment to fostering the next generation of engineering talent and promoting design innovation on a global scale. This broader contribution to society reflects James Dyson’s personal dedication to solving problems through inventive engineering and addressing critical skills gaps.

A cornerstone of this commitment is the James Dyson Award, an international student design award that operates in 18 countries. Run by the James Dyson Foundation, a charitable trust established by James Dyson himself, the award celebrates and supports aspiring engineers and designers who tackle real-world problems with innovative solutions. It is presented jointly to students and their universities, encouraging a symbiotic relationship between academic pursuit and practical application.

Addressing a pressing engineering skills shortage in the UK, James Dyson announced plans in November 2016 to open a higher education college, the Dyson Institute of Engineering and Technology. This unique institution welcomed its first cohort of undergraduates in September 2017, partnering with the University of Warwick to offer BEng degrees in engineering. Critically, students are also employed as engineers three days a week at Dyson, providing invaluable hands-on experience from day one. The Institute has also made strides in promoting diversity, with its second cohort in September 2018 being 40% female, significantly surpassing the national average of 15.1% for engineering subjects.

The James Dyson Foundation further extends its educational reach through initiatives like ‘Ideas Boxes,’ which have been utilized by over 727 schools in Great Britain and Northern Ireland to help teachers and pupils learn more about the design process. Additionally, the Foundation provides crucial bursaries and scholarships to aspiring engineers, ensuring that financial barriers do not impede promising talent. These comprehensive educational efforts underscore Dyson’s holistic approach, cultivating a pipeline of skilled innovators and contributing significantly to the future of engineering and design worldwide.

This journey through Dyson’s evolution reveals a company built on more than just groundbreaking products; it’s a testament to a philosophy of relentless questioning, iterative design, and strategic foresight. From a single inventor’s shed to a global technology powerhouse spanning continents and diverse technological domains, Dyson continues to reshape industries. Its unwavering commitment to innovation, coupled with a robust defense of its intellectual property and a profound investment in future talent, paints a picture of an enterprise that doesn’t just adapt to the future—it actively engineers it. As Dyson looks forward, its trajectory promises continued disruption, driven by the same inventive spirit that first sought to solve a simple household frustration, forever transforming the landscape of technology and design.