Trucks are the unsung workhorses of global commerce, indispensable for transporting everything from vital goods to specialized equipment across vast distances. Yet, beneath their formidable exteriors and essential functions, these complex machines face a myriad of challenges that can transform them from reliable partners into significant operational hurdles. The perception of a “highway hazard” often emerges from the intricate interplay of design, maintenance, and the sheer demands placed upon these vehicles, making a deeper understanding of their inner workings paramount for operators and consumers alike.

In this in-depth analysis, we adopt a Consumer Reports-style approach, offering a factual, objective, and practical examination of various aspects of trucks. Our goal is to dissect the fundamental elements and operational realities that contribute to their performance, reliability, and potential for disruption. By exploring the evolution of their power sources, their diverse classifications, and the detailed engineering behind their construction, we aim to provide a clearer picture of why these vehicles, despite their robust nature, can encounter persistent issues.

This first section of our comprehensive report will guide you through the initial six critical areas of truck design and foundational technology. We’ll uncover how historical innovations shaped their capabilities, how different sizes dictate their roles, and the precise engineering that goes into their cabs, engines, drivetrains, and frames. Each aspect carries its own set of complexities and demands, directly influencing a truck’s day-to-day operation and its long-term reliability on the road.

1. **The Evolution of Truck Power: From Steam to Electric**The journey of the truck’s propulsion system is a fascinating narrative of innovation, starting long before the internal combustion engine dominated the roads. The earliest ancestor, the steam-powered fardier built by Nicolas-Joseph Cugnot in 1769, laid the groundwork, though steam wagons only became somewhat common in the mid-19th century. These early vehicles were primarily limited to very short hauls, often connecting factories to railway stations, due to the rudimentary roads of the era, which were designed for horse and carriages. It wasn’t until 1881 that the first semi-trailer emerged, pulled by a steam tractor, demonstrating an early vision of articulated transport.

The internal combustion engine, however, marked a pivotal shift. Karl Benz introduced the first internal combustion truck in 1895, swiftly followed by Gottlieb Daimler’s Daimler Motor Lastwagen in 1896. American ingenuity soon followed, with Autocar building its first truck in 1899 and George Eldridge crafting another in 1903. Early trucks of this era were modest, typically featuring two-cylinder engines and a carrying capacity of 1.5 to 2 tons. The period after World War I brought significant advancements, including the introduction of electric starters and more powerful 4, 6, and 8 cylinder engines, dramatically enhancing truck capabilities.

Diesel engines, despite being invented in 1897, did not see production in trucks until Benz introduced them in 1923. Their widespread adoption in Europe occurred by the 1930s, offering greater fuel efficiency and power. In the United States, Autocar pioneered the use of diesel engines for heavy applications in the mid-1930s, eventually launching the “DC” model (diesel conventional) in 1939. However, gasoline engines continued to power heavy trucks in the US until the 1970s, illustrating a slower transition compared to Europe.

The most recent chapter in truck power involves electric motors, which surprisingly predate internal combustion engines and have been continuously available since the mid-19th century. Autocar Trucks was among the first major manufacturers to offer a range of electric trucks in the 1920s, proving successful for urban delivery and specialized roles like forklifts. The higher energy density of liquid fuels temporarily overshadowed electric power, but advancements in battery technology since the 2000s have reignited interest. Today, manufacturers are actively electrifying all truck types, with long-range over-the-road trucks presenting the most significant engineering challenges. There’s an ongoing debate regarding the optimal electric solution; The Economist suggests “Electric lorries will probably run on hydrogen, not batteries, which are too expensive,” while other researchers contend that faster chargers could make batteries competitive for most trucks, except perhaps the heaviest ones.

Read more about: Understanding Electricity: Key Concepts for the Informed Consumer

2. **Understanding Truck Size Classifications: From Ultra-Light to Heavy-Duty**The world of trucks is incredibly diverse, with vehicles precisely engineered for a vast array of tasks, leading to a complex system of size classifications. These distinctions are not merely about physical dimensions but profoundly influence a truck’s intended use, regulatory requirements, and operational characteristics. Understanding these categories is crucial for appreciating the specific challenges and safety considerations associated with each type, from the smallest utility vehicle to the largest road train.

At the lighter end of the spectrum are **ultra-light** trucks, often derived from golf cars and typically used for off-highway applications on estates, golf courses, and parks. While generally not highway-suitable, some variations can be licensed as slow-speed vehicles for street operation, frequently as modified neighborhood electric vehicles. Specialized chassis exist, alongside unique offerings like Zap Motors’ Xebra electric tricycle and the Might-E Truck from Canadian Electric Vehicles, as well as battery-electric models such as the Mitsubishi Minicab MiEV and Dairy Crest electric milk floats.

Moving slightly larger, **very light** trucks are popular in Europe and Asia. Many are factory redesigns of light automobiles with monocoque bodies. Others, like the Italian Piaggio Porter, feature substantial frames based on Japanese designs, proving ideal for narrow European city alleyways. In Japan, these mini-trucks are regulated under Kei car laws, which offer tax breaks for smaller, less-powerful vehicles (engine limited to 660 cc). In the United States, Japanese-made mini-trucks compete with off-road ATVs, with import regulations requiring a 25 mph speed governor for classification as low-speed vehicles. These versatile mini-trucks find extensive use in construction, large campuses, agriculture, cattle ranches, and amusement parks. Major manufacturers include Daihatsu, Honda, Tata, Mazda, Mitsubishi, Subaru, and Suzuki.

**Light** trucks encompass car-sized vehicles, with gross vehicle mass limits varying by region—up to 13,900 lb (6.3 t) in the US and no more than 3.5 t (7,700 lb) in the EU, where they can be driven with a standard car license. Pickup trucks, known as “utes” in Australia and New Zealand, and “bakkies” in South Africa, are common in North America, Latin America, Asia, and Africa. However, in Europe, commercial vehicles of this size are more often vans. Examples include the Ford Ranger pickup, the Lindner Unitrac 95L, and the Holden Ute, demonstrating their varied applications from personal utility to agricultural work.

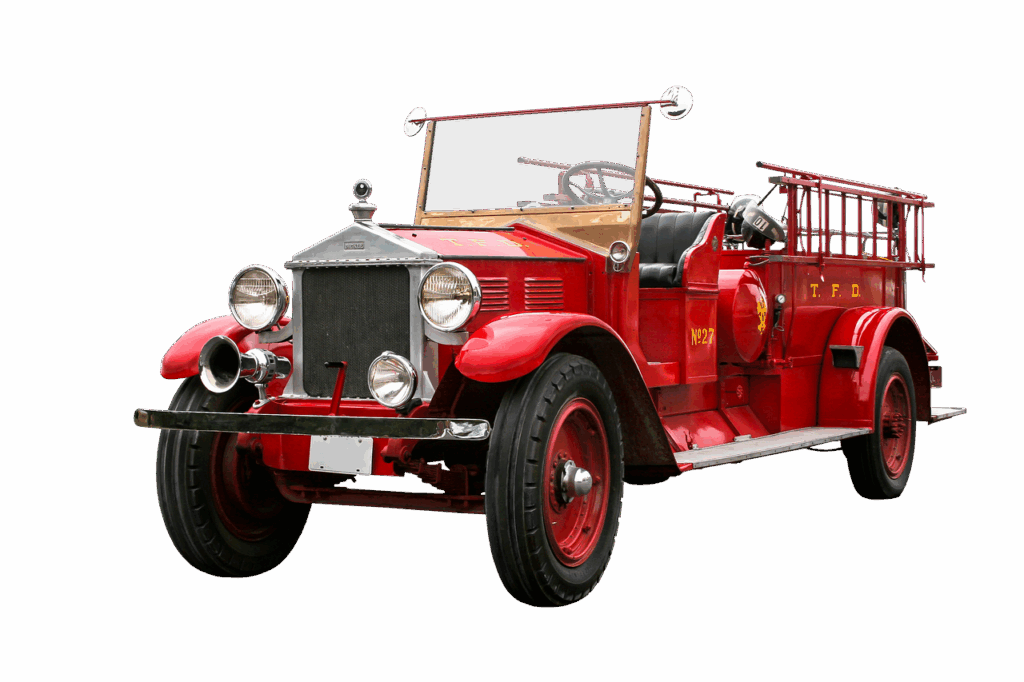

**Medium** trucks bridge the gap between light and heavy categories. In the US, they are defined as weighing between 13,000 and 33,000 lb (5.9 and 15.0 t), while in the UK and EU, the range is between 3.5 and 7.5 t (7,700 and 16,500 lb). This class is typically used for local delivery and public services, encompassing vehicles such as dump trucks, garbage trucks, and fire-fighting trucks. The Fuso Canter and SML Isuzu represent common models in this segment, highlighting their utility in diverse urban and municipal roles.

Finally, **heavy** trucks are the largest on-road vehicles, designated as Class 8. This category includes vocational applications like heavy dump trucks, concrete pump trucks, and refuse hauling vehicles, as well as ubiquitous long-haul 4×2 and 6×4 tractor units. The immense weight of these vehicles means that road damage and wear increase very rapidly with axle weight, making the number of steering axles and suspension type critical factors in infrastructure impact. Many countries with well-maintained roads allow a six-axle truck to carry 44 t (97,000 lb) or more, showcasing their incredible load-bearing capacity. Specialized examples include massive cement mixers, 6×4 trucks hauling freight containers, and Seddon Atkinson Stratos refuse compactors, each designed for the most demanding heavy-duty tasks.

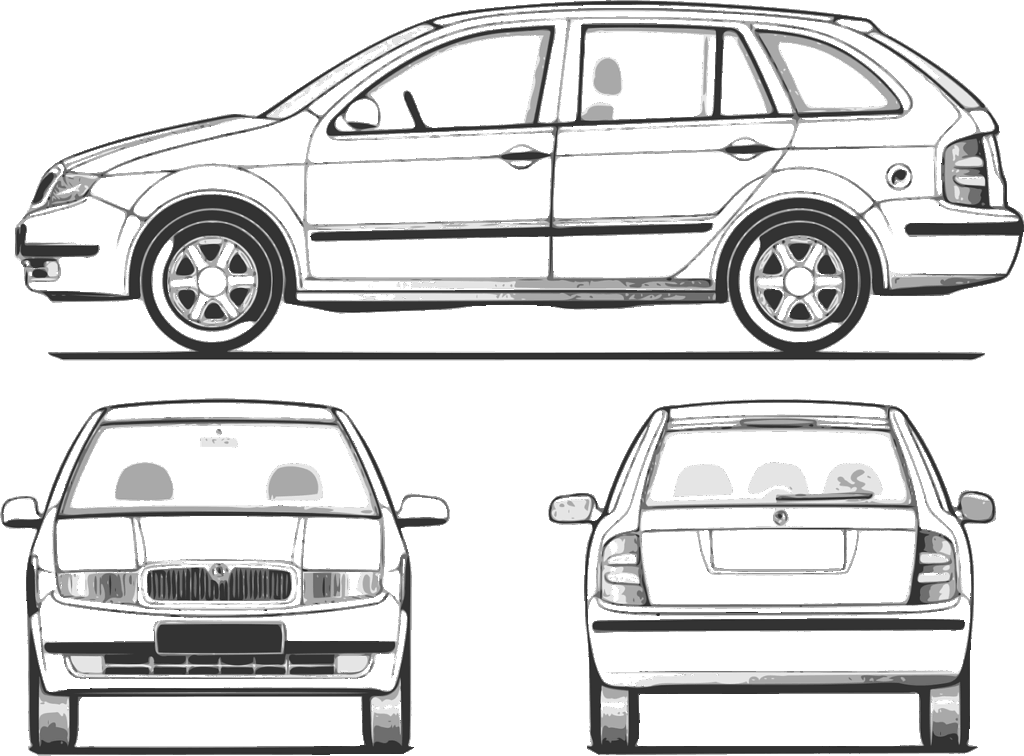

3. **The Anatomy of a Truck: Inside the Cab Designs**The cab, or cabin, is more than just a place for the driver; it is the command center and, for many long-haul operators, a temporary home. Its design plays a crucial role in driver comfort, safety, visibility, and overall vehicle maneuverability, directly impacting operational efficiency and the driver’s ability to navigate various driving conditions. The evolution of cab designs reflects a continuous effort to optimize these factors within the constraints of regulatory frameworks and practical operational needs.

One prominent configuration is the “Cab over engine” (COE), also known as “flat nose.” In this design, the driver is positioned directly above the front axle and the engine. This layout is almost ubiquitous in Europe, where strict overall truck length regulations necessitate a shorter wheelbase for enhanced maneuverability and a smaller turning radius, especially on narrow roads. COE designs were once common in North American heavy-duty trucks but saw a decline in prominence when permitted vehicle lengths were extended in the early 1980s. Nevertheless, they remain popular in North America for medium- and light-duty trucks. To facilitate engine access for maintenance, the entire cab can tilt forward, a feature that has earned this design the descriptive name of “tilt-cab.”

A less common, yet specialized, design is the “Cab-under” configuration, where the driver is positioned at the front at the lowest possible point. This design aims to maximize cargo space and is exemplified by vehicles produced by manufacturers such as Hunslet, Leyland, Bussing, Strick, and Steinwinter. While offering benefits in specific niche applications, its overall adoption has been limited compared to other cab types due to various practical and safety considerations, particularly concerning driver visibility and impact protection.

In contrast to the COE, “Conventional” cabs position the driver behind the engine, mirroring the layout found in most passenger cars or pickup trucks. This design dominates the trucking landscape in North America, Australia, and China, often recognized in the UK as “American cabs” and in the Netherlands as “torpedo cabs.” Modern conventional cabs frequently feature streamlined, sloped hoods and other aerodynamic enhancements designed to reduce drag, improving fuel efficiency and stability at highway speeds. This layout often provides a more spacious feel for the driver and can be preferred for its ride quality and perceived safety in frontal collisions.

Lastly, “Cab beside engine” designs are tailored for highly specialized tasks, such as terminal tractors used in shipping yards or vehicles designed to carry unusually long loads, like pipes. These trucks often achieve their unique configuration by replacing the passenger side of a standard cab-over truck with an extended section of the load bed. An even more specialized variant of this concept is the side loading forklift, which integrates the load-handling capabilities directly into a vehicle with similar lateral loading properties, representing a bespoke solution for specific material handling challenges.

4. **Engines and Motors: Diesel’s Dominance and the Rise of Alternatives**The heart of any truck is its engine, a component whose design and fuel source significantly dictate performance, operational cost, and environmental impact. For decades, diesel engines have been the workhorse of the trucking industry, but a rapidly evolving landscape of regulations and technological innovation is driving a shift towards diverse power solutions. Understanding these power plants is crucial for assessing a truck’s overall efficiency, reliability, and its role in the broader transportation ecosystem.

Traditionally, smaller trucks, including sport utility vehicles (SUVs), vans, and pickups, along with light medium-duty trucks in regions like North America, China, and Russia, have predominantly utilized gasoline engines (petrol engines). However, there is a growing trend towards offering diesel-engined models within these categories, recognizing the efficiency benefits. For the vast majority of heavier trucks, the four-stroke diesel engine, often enhanced with a turbocharger and intercooler, remains the standard. Even more impressively, huge off-highway trucks employ locomotive-type engines, such as the powerful V12 Detroit Diesel two-stroke, to handle extreme loads and terrain.

The push for reduced emissions and lower fuel costs has propelled alternative fuels into the spotlight. Compressed Natural Gas (CNG) engines, for example, are widely adopted in specific vocations within the United States, notably in the refuse industry and concrete mixers. These applications benefit from CNG’s lower fuel cost and reduced carbon emissions, making them a viable option for short-range operations. However, range limitations have historically hindered their broader uptake in long-haul freight applications, where diesel’s energy density offers a distinct advantage.

Looking ahead, the industry is witnessing the emergence of heavy electric trucks and hydrogen-powered trucks, both new to the market as of 2021. Major freight haulers are expressing significant interest in these zero-emission solutions, aligning with global efforts to phase out fossil fuel vehicles, a transition that explicitly includes trucks. A central debate within this electrification movement revolves around whether electric lorries will predominantly run on hydrogen or batteries. The Economist suggests hydrogen might be favored, citing the high cost of batteries, while other researchers argue that advancements in faster charging technology could make batteries competitive against diesel for all but perhaps the heaviest trucks, offering a different perspective on future viability.

Manufacturers also play a critical role in this evolving engine landscape. A significant proportion of North American manufactured trucks utilize engines built by independent manufacturers, with Cummins being a prominent example. However, many global Original Equipment Manufacturers (OEMs), such as Volvo Trucks and Daimler AG, are increasingly promoting their own “captive” engines, integrating power plant design more closely with overall vehicle architecture. Furthermore, regulatory bodies, particularly in the European Union, are continually tightening emission standards. All new truck engines must comply with Euro VI regulations, with Euro 7, slated for the late 2020s, promising even stricter exhaust limits and new mandates to limit air pollution from brakes and tires, underscoring the ongoing pressure for cleaner and more sustainable trucking operations.

5. **The Complexity of Truck Drivetrains: Transmissions and Shifting Challenges**The drivetrain of a truck is a sophisticated system responsible for transmitting power from the engine to the wheels, a process that is far more intricate in larger commercial vehicles than in typical passenger cars. This complexity stems from the need to manage immense torque and varying loads, requiring specialized transmissions that demand significant skill and understanding from the driver. The choice and operation of a truck’s transmission directly impact its efficiency, longevity, and the driver’s experience, highlighting a critical area of operational nuance.

Small trucks, such as sport utility vehicles, pickups, and even some light medium-duty models, generally employ the same types of transmissions found in almost all cars, featuring either automatic transmissions or manual transmissions equipped with synchromesh (synchronizers). These systems simplify gear changes, making driving more accessible. However, bigger trucks often utilize manual transmissions without synchronizers, commonly known as “crash boxes.” This design choice helps save bulk and weight, though synchromesh transmissions are also found in some larger trucks, offering a compromise between efficiency and ease of use.

Operating a “crash box” transmission requires a distinct set of skills, notably “double-clutching” for each shift. This technique, while effective, can lead to repetitive motion injuries over time. Alternatively, experienced drivers might employ a method colloquially known as “floating,” which involves changing gears without using the clutch pedal, except for initial starts and final stops. This technique is favored by some for its potential to achieve faster shifts and reduce clutch wear, though it demands precise timing and engine speed management. The physical effort associated with non-power-assisted clutches further motivates drivers to master these techniques.

Double-clutching is a meticulous process designed to synchronize engine and transmission revolutions for a smooth gear change. When upshifting, the accelerator pedal is released, the clutch pedal is depressed, and the gear lever is moved into neutral. The clutch pedal is then released, allowing the engine speed to drop, and quickly pushed down again as the gear lever is moved to the next higher gear. Finally, the clutch pedal is released, and the accelerator pedal is pressed to achieve the required engine speed. This sequence, though executed rapidly, provides a brief moment in neutral for the engine speed to align with the transmission’s demands relative to the road speed. Downshifting follows a similar pattern, but requires the engine speed to increase in neutral to achieve the necessary synchronization for a smooth, non-collision gear change.

Further adding to the complexity, “skip changing” is a widely used technique, fundamentally operating on the same principles as double-clutching but requiring neutral to be held slightly longer than during a single-gear change. North American heavy trucks commonly feature transmission setups with 9, 10, 13, 15, or even 18 speeds, offering a wide range of gear ratios to handle diverse loads and terrains. In Europe, 8, 10, 12, and 16 gears are common on larger trucks with manual transmissions, while conventional automatic or automated manual transmissions typically offer anything from 5 to 12 gears. Almost all heavy truck transmissions are of the “range and split” (double H shift pattern) type, where the range change and half gears (splits) are air-operated and always preselected before the main gear selection, underscoring the advanced engineering behind these essential components. Due to continuous advancements in both transmission and engine power, automatic and automated manual transmissions are becoming increasingly prevalent in heavy trucks, simplifying operation and potentially reducing the physical demands on drivers.

6. **The Backbone: Importance of the Truck Frame and Chassis**At the core of nearly every truck lies a fundamental construction shared across a vast array of designs, forming the very backbone of the vehicle: the chassis, cab, an area for placing cargo or equipment, axles, suspension, roadwheels, an engine, and a drivetrain. Beyond these primary mechanical components, modern trucks often integrate pneumatic, hydraulic, water, and electrical systems, and many are designed to tow one or more trailers or semi-trailers. This integrated structure is paramount, as it dictates the vehicle’s capacity, stability, and overall durability under strenuous conditions.

The quintessential element of this construction is the truck frame, commonly referred to as a “ladder frame” due to its visual resemblance to a ladder when viewed on end. This frame typically consists of two parallel boxed (tubular) or C-shaped rails, or beams, which are meticulously held together by a series of crossmembers. These rails are engineered with a tall vertical section, or two sections if boxed, complemented by two shorter horizontal flanges. The height of the vertical section is a critical design feature, as it provides robust opposition to vertical flex, ensuring the frame maintains its integrity when substantial weight is applied to its top surface, a property known as beam resistance.

While the rails on heavy-duty trucks are typically flat along their entire length to maximize structural consistency, their design may occasionally incorporate tapering or arching. These modifications are specifically implemented to provide necessary clearance around the engine compartment or over the axles, accommodating the complex mechanical components that are integral to the truck’s operation. Furthermore, the rails are often punctuated with numerous holes. These apertures serve multiple vital functions, including providing secure mounting points for various vehicle components, facilitating the routing of essential wires and hoses, and allowing for precise measurements and adjustments of the rails’ orientation during manufacturing or repair processes, thereby contributing to the vehicle’s alignment and structural accuracy.

The selection of materials for the truck frame is another crucial aspect influencing both performance and operational cost. Frames are predominantly constructed from steel, a material chosen for its exceptional strength and durability, which are essential for supporting heavy loads and withstanding the rigors of commercial use. However, in a strategic effort to reduce the vehicle’s overall weight and improve fuel efficiency, frames, either wholly or in part, can also be fabricated from aluminum. This material offers a lighter alternative without significantly compromising structural integrity, particularly in applications where weight savings are a priority. Furthermore, a tow bar may be found securely attached at one or both ends of the frame for towing capabilities, while heavy tractors almost invariably make use of a fifth wheel hitch, a specialized coupling mechanism designed for towing semi-trailers, highlighting the modular and adaptable nature of truck frame design to meet diverse transport needs.

Navigating the intricate world of commercial trucking demands an understanding far beyond just the vehicle’s mechanics. It extends into the broader operational landscape, where stringent regulations, environmental stewardship, driver well-being, economic realities, and public safety converge to define the true measure of a truck’s reliability and its impact as a highway presence. Our objective, in the spirit of Consumer Reports, is to shed light on these critical external factors, demonstrating how they shape the daily realities of an industry vital to global commerce yet fraught with its own unique set of challenges. This section of our comprehensive report will delve into the operational realities that often turn reliable workhorses into persistent highway hazards. We will examine the complex web of driving regulations that govern their movement, the significant environmental footprint they leave behind, and the crucial considerations for operator health and safety. Furthermore, we will dissect the economic implications, from the burden of taxes to the physical damage trucks inflict on our roadways, culminating in an objective look at the stark reality of trucking accidents—a persistent hazard that underscores the multifaceted complexities of this essential industry. 7. **Driving Regulations: Navigating the Maze of Licensing and Operational Rules**

Operating a commercial truck is not a simple matter of getting behind the wheel; it requires specialized licensing and adherence to a complex web of regulations that vary significantly across international borders and even within different jurisdictions. These stringent requirements are put in place to ensure driver competency, manage vehicle capabilities, and ultimately enhance safety on public roads. Understanding these diverse frameworks is essential for appreciating the operational hurdles and professional demands placed upon truck drivers worldwide.

In Australia, for instance, a specific truck driver’s license is mandatory for any motor vehicle with a Gross Vehicle Mass (GVM) exceeding 4.5 tonnes (5.0 short tons). This system is further refined into distinct classes, including Light Rigid (LR) for vehicles up to 8 tonnes GVM, Medium Rigid (MR) for 2-axle vehicles over 8 tonnes, and Heavy Rigid (HR) for 3-or-more axle vehicles over 8 tonnes. For articulated vehicles, Heavy Combination (HC) covers typical prime mover-semi-trailer setups, while Multi Combination (MC) is required for larger configurations like B Doubles or road trains. Additionally, a specific transmission condition may be applied if the practical driving test was passed in a vehicle with an automatic or synchromesh transmission, restricting the driver to such vehicles unless the condition is removed by passing a test in a non-synchromesh transmission vehicle.

The European Union and the European Economic Area have largely harmonized driving licensing, establishing common rules that apply across the continent. For licenses acquired after 1997, driving a commercial vehicle over 3.5 tonnes (3.9 short tons) requires a specialist license. More specifically, the C1 license category permits driving vehicles over 3.5 tonnes and up to 7.5 tonnes. The C license category extends this to vehicles over 3.5 tonnes with a trailer up to 750 kg, and the CE category is necessary for driving category C vehicles with a trailer exceeding 750 kg. These classifications reflect a detailed approach to regulating vehicle weight and towing capacity for commercial purposes.

South Africa also implements a tiered licensing system. A Code C1 driver’s license is required for vehicles with a GVM exceeding 3.5 tonnes, escalating to a Code C license for vehicles over 16 tonnes (17.6 short tons). Further restrictions apply when towing a trailer with a GVM over 7.5 tonnes, necessitating an ‘E’ prefix on the license code, indicating an articulated endorsement. Beyond vehicle classes, any driver operating a vehicle designed to carry goods or passengers must possess a Public Driver’s Permit (PrDP), which comes in different classes (‘G’ for general goods, ‘P’ for paying passengers, ‘D’ for dangerous materials) and requires annual renewal, along with stringent criminal record checks and age restrictions.

In the United States, a Commercial Driver’s License (CDL) is mandated for operating any commercial vehicle weighing 26,001 pounds (11,794 kg) or more. Beyond licensing, the federal government imposes strict Hours of Service (HOS) regulations, dictating how many hours a driver can be on duty or driving, and specifying required rest periods—for example, 11 hours driving within a 14-hour on-duty window, followed by 10 hours off, with weekly limits of 70 hours over 8 days or 60 hours over 7 days, and a 34-hour restart option. Violations of these rules carry significant penalties. The US trucking industry faces a persistent “shortage of willing trained long-distance truck drivers,” a situation exacerbated by the economic fallout from deregulation, which, as some researchers argue, has led to “low pay, bad working conditions and unsafe conditions,” contributing to high annual employee turnover.

8. **Environmental Effects: The Heavy Footprint of Road Freight**The environmental impact of commercial trucks is a significant concern, extending across air, noise, and water pollution. Despite advancements in vehicle fuel efficiency within individual categories, the overall societal shift towards trucks and SUVs since 1975 has largely offset many of the benefits from improved fuel economy and reductions in pollution and carbon dioxide emissions. Indeed, without this sectoral shift, energy use per unit distance could have fallen 30% more between 2010 and 2022, highlighting the collective challenge posed by an increased reliance on heavier vehicles.

A primary area of concern is air pollution, particularly from diesel exhaust, which poses considerable health risks. Unlike most modern cars, the majority of trucks in operation still run on diesel, emitting harmful NOx and particulate matter that are “very dangerous to health,” causing “thousands of early deaths annually in the US alone.” This issue is compounded by older trucks, which are “usually the worst” offenders, leading many cities to ban 20th-century models. Even professional truck drivers face increased health risks due to constant exposure to these airborne pollutants. Regulatory bodies, such as the European Union, continuously tighten emission standards, with all new truck engines needing to comply with Euro VI regulations, and Euro 7 slated for the late 2020s, promising even stricter exhaust limits and new mandates to limit air pollution from brakes and tires.

Beyond localized air quality, road freight accounts for over a quarter of global transport CO2 emissions, with medium and heavy trucks alone contributing over 1,700 million tonnes in 2021. This substantial carbon footprint drives many countries to further restrict truck CO2 emissions as part of global efforts to combat climate change, including pledges for 30% of truck and bus sales to be zero-emission by 2030. Environmental organizations often advocate for laws and incentives to encourage a shift from road to rail transport, particularly in Europe, recognizing the potential for significant emissions reductions through modal shifts.

Noise pollution is another notable environmental effect. Trucks emit considerably higher sound levels at all speeds compared to typical cars, a contrast that is particularly pronounced with heavy-duty vehicles. This acoustic footprint is generated by a combination of continuous sounds, such as tires rolling on the roadway and the constant hum of diesel engines at highway speeds, and less frequent but often more noticeable noises like the sharp whistle of a turbocharger during acceleration or the abrupt blare of an exhaust brake retarder when descending grades. As a result, noise regulations are increasingly being implemented to control when and where the use of engine braking retarders is permitted, aiming to mitigate their impact on communities.

9. **Operator Health and Safety: Protecting the Driver Behind the Wheel**The truck cab, often considered the driver’s command center and temporary home, plays a critical role as a hazard control, actively protecting the operator from hazardous airborne pollutants prevalent in various working environments. Functioning as an engineering control, the enclosed cab, a design principle long utilized in agriculture, mining, and construction vehicles, is crucial for maintaining a safe and healthy environment for its occupant. Most modern enclosed cabs are equipped with sophisticated heating, ventilation, and air conditioning (HVAC) systems, primarily designed to regulate temperature and ensure a supply of breathable air.

Central to the effectiveness of these cab systems is the quality of their filtration. Various levels of filtration can be integrated into the HVAC system, strategically designed to remove airborne pollutants such as dusts, diesel particulate matter (DPM), and other aerosols from the intake airflow. It is widely recommended that an effective filtration system is capable of filtering out at least 95% or greater of airborne respirable aerosols. Furthermore, these systems often incorporate an additional recirculation filtering component for the air already present inside the cab, ensuring continuous purification and maintaining air quality even in highly contaminated external environments.

Equally vital is the enclosure’s integrity, which refers to its sealed isolation from the outside environment. A robust enclosure is necessary to achieve positive pressure inside the cab, a crucial factor that actively prevents wind-driven aerosol penetration. This positive pressure ensures that contaminated external air is unable to force its way into the cab through unsealed points. Minimizing air leakage around the filtration system itself is also paramount, as even small gaps can compromise the overall effectiveness of the pollutant removal process and reduce the protection factor afforded to the operator.

To ensure optimal performance and ongoing safety, test methods and mathematical modeling of environmental enclosures are invaluable tools. These analytical approaches are beneficial for quantifying the protection factor offered by a cab, optimizing filtration system designs for specific hazards, and maintaining the highest possible protection levels for enclosure occupants throughout the vehicle’s operational life. Such rigorous analysis ensures that the cab remains a reliable shield against the occupational health risks faced by truck drivers, underscoring the commitment to operator well-being.

10. **Operations Issues: The Economic Burden of Taxes**Commercial trucks in the United States operate under a distinct economic framework, notably paying “higher road use taxes on a state level than other road vehicles” and being “subject to extensive regulation.” This elevated tax burden is a fundamental aspect of their operational cost, distinguishing them from passenger vehicles and reflecting their significant impact on public infrastructure and services.

There are several compelling reasons why commercial trucks are levied with higher road use taxes. Fundamentally, “they are bigger and heavier than most other vehicles, and cause more wear and tear per hour on roadways.” The sheer scale and weight of these vehicles translate directly into accelerated degradation of roads, bridges, and other infrastructure components. Moreover, “trucks and their drivers are on the road for more hours per day” compared to the average vehicle, further intensifying their contribution to road maintenance needs and the overall operational demands on the highway system.

Adding another layer of complexity, “Rules on use taxes differ among jurisdictions,” meaning that truck operators often navigate a patchwork of varying tax rates and regulations as they cross state lines or operate in different regions. This necessitates careful planning and compliance, as these taxes significantly influence routing decisions, operational budgets, and ultimately, the cost of goods transported. The constant interplay between infrastructure impact, operational intensity, and a diverse regulatory landscape underscores the substantial economic commitment required to keep commercial trucking viable.

11. **Damage to Pavement: The Cost of Heavy Loads on Infrastructure**The immense weight and continuous operation of commercial trucks present a significant challenge to public infrastructure, directly impacting the longevity and condition of roadways. While the specific lifespan of any pavement is influenced by numerous factors, a critical determinant is the cumulative stress exerted by heavy vehicles. As noted, “Road damage and wear increase very rapidly with the axle weight,” establishing a direct and unavoidable link between a truck’s load-bearing capacity and its physical impact on the asphalt and concrete beneath its tires.

Beyond just the gross vehicle weight, the design specifications of a truck play a crucial role in mitigating or exacerbating this wear. “The number of steering axles and the suspension type also influence the amount of the road wear.” Trucks with more axles distribute their weight more effectively, reducing the load on individual pavement sections, while advanced suspension systems can absorb shocks and distribute forces more smoothly, thereby lessening the localized impact. These design considerations are not merely about vehicle performance; they are critical factors in the ongoing battle against infrastructure degradation and the associated costs.

The continuous and rapid increase in road damage attributable to heavy axle weights leads to substantial maintenance and repair expenses for highway authorities. These costs represent a significant economic implication for society, often necessitating increased public funding for infrastructure upkeep, which is typically derived from various tax revenues, including those specifically levied on commercial vehicles. Understanding this direct relationship is vital for policymakers, engineers, and the trucking industry alike, as efforts to optimize truck design, manage loads, and maintain infrastructure are intertwined in ensuring the long-term viability of road transport.

Read more about: Beyond the Pavement: An In-Depth Look at 14 Off-Road Trucks, From Trailblazers to Trouble Spots

12. **Trucking Accidents: A Persistent Highway Hazard**The stark reality of trucking accidents stands as a persistent highway hazard, posing significant risks to all road users. Data from the United States underscores this grave concern: “In 2018, in the US, 5,096 large trucks and buses were involved in fatal crashes: The number of large trucks involved in fatal crashes is 4,862, The number of large trucks involved in injury crashes is 112,000, The number of large trucks involved in property damage only crashes is 414,000.” These statistics reveal a widespread and deeply troubling pattern of incidents, highlighting the immense human and economic toll exacted by commercial vehicle collisions.

The operational complexities of heavy truck driving, coupled with systemic issues within the industry, can contribute significantly to these accident rates. A notable factor mentioned is “a shortage of willing trained long-distance truck drivers.” This scarcity can lead to increased pressure on existing drivers, potentially impacting their rest, focus, and overall safety performance on the road. The sheer size and momentum of commercial trucks mean that even minor errors can have catastrophic consequences, making driver proficiency and attentiveness paramount.

Moreover, the “economic fallout from deregulation of the trucking industry” has been cited as a contributing factor to these safety challenges. As argued by Michael H. Belzer, an associate professor at Wayne State University, this deregulation has led to “low pay, bad working conditions and unsafe conditions.” Such circumstances can result in “high annual employee turnover” as drivers seek better opportunities, potentially leaving less experienced or overworked individuals behind the wheel. These economic pressures can indirectly, yet profoundly, compromise safety standards and increase the likelihood of accidents.

Ultimately, the high incidence of trucking accidents serves as a sobering reminder of the multifaceted risks inherent in road freight. It underscores the critical need for continued vigilance in driver training, regulatory enforcement, and industry practices that prioritize safety over expediency. Addressing these deep-seated challenges—from ensuring adequate driver compensation and working conditions to exploring advanced safety technologies—is essential for mitigating this pervasive highway hazard and fostering a safer environment for everyone sharing our vital road networks.

The journey of a truck from design blueprint to highway titan is fraught with complexities that extend far beyond its mechanical components. From the labyrinthine regulations governing its operation to its undeniable environmental footprint, the essential considerations for driver health and safety, the economic realities of taxation and infrastructure wear, and the ever-present shadow of accidents, each aspect presents a unique set of challenges. Understanding these multifaceted operational realities is not merely an academic exercise; it is crucial for stakeholders across the industry and for every consumer who relies on these unsung workhorses of global commerce. Only through continuous innovation, stringent oversight, and a commitment to holistic well-being can we truly mitigate the perception of trucks as a “highway hazard” and ensure their role as reliable, safe, and sustainable partners in our interconnected world.