The roar of an engine, the smell of gasoline – these sensory experiences have defined automotive enthusiasm for over a century. Yet, beneath the hood, the very heart of how fuel meets air has undergone a profound transformation. For nearly a hundred years, a mechanical marvel known as the carburetor faithfully served the internal combustion engine, diligently mixing air with a fine spray of fuel to ignite the power that moved us. Today, however, open the hood of a modern vehicle past the 1990s, and you’ll find no trace of this once-ubiquitous device.

This monumental shift from mechanical carburetors to sophisticated electronic fuel injection systems isn’t just a fleeting trend; it’s a testament to relentless innovation driven by an array of crucial factors. From the pressing demands of environmental sustainability and increasingly stringent emissions regulations to the consumer’s insatiable appetite for enhanced fuel efficiency and superior vehicle performance, the automotive industry has systematically engineered a more precise, reliable, and intelligent method of fuel delivery. The story of the carburetor’s phasing out is, in essence, the narrative of automotive progress itself, marking a pivot point from an era of robust mechanical ingenuity to one of sophisticated electronic control.

In this in-depth exploration, we’ll journey back to the fundamental principles of carburetion, dissecting its core components and tracing its evolution through automotive history. We’ll then unravel the compelling forces that led to its eventual retirement from the mainstream, focusing on how global environmental policies, the relentless pursuit of greater fuel economy, and significant improvements in drivability combined to redefine engine technology. Join us as we shine a spotlight on these venerable components, celebrating their legacy while understanding the undeniable advantages of the systems that have superseded them.

1. **The Automotive Industry’s Shift from Carburetors**Fuel delivery systems have undergone remarkable transformations since the early days of automotive engineering. Carburetors dominated the automotive industry for nearly a century before giving way to more sophisticated technologies. These mechanical devices mixed air and fuel through vacuum pressure, providing a relatively simple but effective solution for internal combustion engines.

Indeed, the automotive industry’s shift from carburetors to fuel injection systems represents one of the most important technological evolutions in vehicle design. This transition occurred primarily because fuel injection systems offer superior precision, efficiency, and reliability compared to their mechanical predecessors.

Once a common component in vehicles, carburetors were responsible for mixing the right amount of fuel with air before sending it into the intake manifold. Today, they have mostly been replaced by more advanced systems, and you likely won’t find one under the hood of any car made after the 1990s.

Understanding why carburetors are no longer used in modern cars can give us insight into how engine technology has improved and the benefits these changes bring to vehicle performance and efficiency. It highlights a critical period where foundational automotive components were entirely reimagined to meet evolving demands.

Read more about: Seriously, What Happened? A Deep Dive into 14 Once-Essential Car Features Drivers Don’t Miss Anymore!

2. **What Exactly is a Carburetor? (Definition, Basic Principles)**A carburetor is a mechanical device found in internal combustion engines that mixes air with a fine spray of liquid fuel to create a combustible mixture. This mixture is then fed into the engine’s intake manifold where combustion occurs to power the vehicle. In essence, it’s the heart of the engine’s fuel preparation system.

Functionally, a carburetor is a device in an internal combustion engine for mixing air with a fine spray of liquid fuel. Combustion engines need them in order to function. Without this crucial mixing of fuel and oxygen, the engine cannot achieve the combustion necessary for propulsion.

Carburetors operate on the vacuum principle created during an engine’s intake stroke. As air flows through the carburetor, it forms a low-pressure area that naturally draws fuel from the reservoir into the airstream. This relies on the Bernoulli principle – faster moving air creates lower pressure, which pulls fuel upward into the airflow.

Various components within the carburetor adjust this air-fuel mixture depending on different engine speeds and loads, attempting to maintain optimal combustion conditions. Though effective for many decades, this mechanical method inherently lacks the precision of modern electronic systems, often resulting in less efficient fuel delivery and combustion compared to fuel injection.

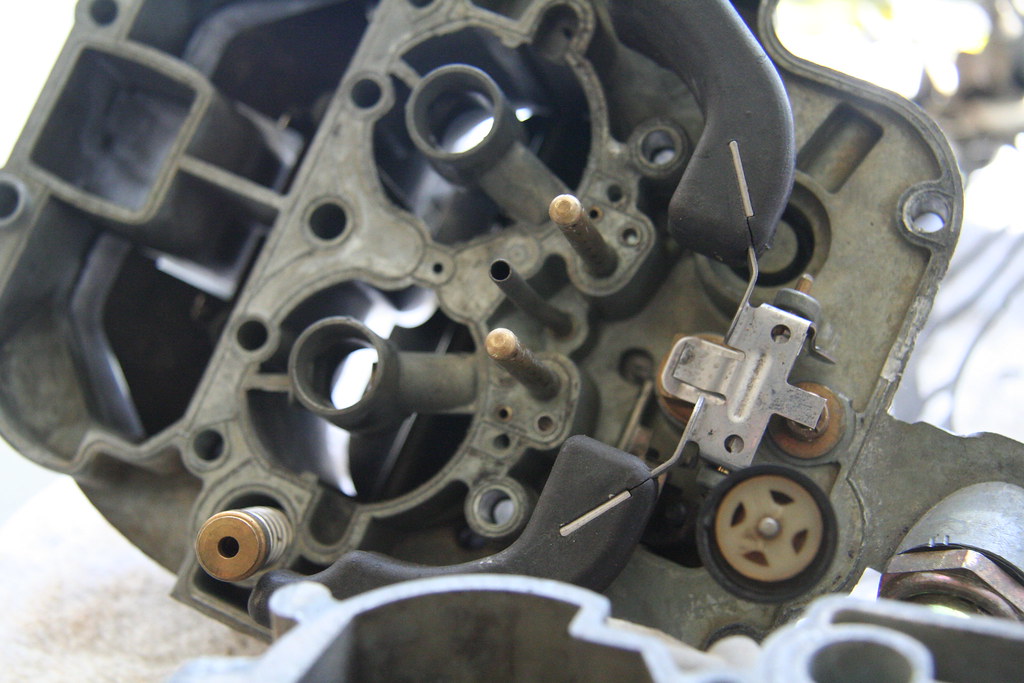

3. **The Essential Components of a Traditional Carburetor**Traditional carburetors contain several key components that work together in a finely tuned mechanical ballet to deliver the proper air-fuel mixture. At its core is the venturi, a narrow section where airflow accelerates, crucially creating the low-pressure zone that draws fuel into the system.

Fuel is stored in the float bowl, a small reservoir that maintains a consistent fuel level through a float mechanism, much like the one found in a toilet tank. From here, jets act as calibrated openings through which fuel passes, with different sized jets controlling fuel flow for various engine conditions, a delicate balance for optimal performance.

Needles and seats meticulously regulate fuel flow based on the engine’s changing demands, ensuring the right amount is delivered at any given moment. During cold starts, the choke valve springs into action, enriching the mixture by restricting airflow, a vital step to get a reluctant engine going.

An accelerator pump provides an essential squirt of extra fuel during sudden throttle openings to prevent hesitation or stumbling, ensuring a smooth pick-up. These intricate mechanical components, while ingenious for their time, require periodic maintenance and adjustment, presenting a significant disadvantage when compared to the ‘set-it-and-forget-it’ reliability of modern electronic systems.

Moreover, these precise components, particularly the small jets, are highly susceptible to clogging from dirt and other impurities present in fuel. Ethanol gas, a common modern fuel additive, is especially hard on carburetors because it can absorb water, which further accelerates corrosion and malfunction, creating a persistent challenge for owners of carbureted vehicles.

Read more about: Seriously, What Happened? A Deep Dive into 14 Once-Essential Car Features Drivers Don’t Miss Anymore!

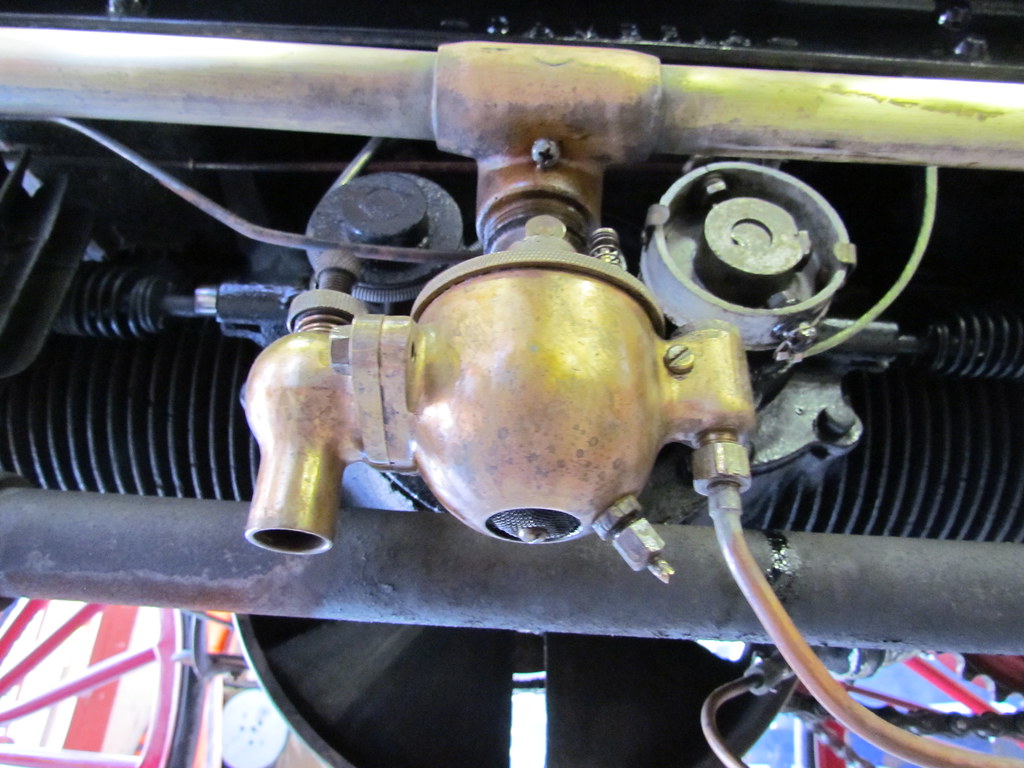

4. **Early Days: The Evolution of Fuel Delivery Systems**The journey of fuel delivery systems began with a monumental invention: Karl Benz of Mercedes-Benz registered the first patent for carburetors in 1886. This was a spectacular innovation for engine mechanics and rapidly became the overall standard for auto manufacturers across the burgeoning industry. Indeed, carburetors offered a remarkably simple yet effective solution for delivering the crucial air-fuel mixture to engines.

Carburetors were created back in the early 1900’s when the first vehicles were being made, proving their worth almost immediately. It’s a testament to their foundational design that even the legendary Wright brothers utilized a carburetor-like contraption on the first airplane they successfully flew, underscoring their ubiquity in early motorized transport.

However, by the 1980s, the automotive landscape began to shift dramatically with manufacturers starting to widely implement electronic fuel injection (EFI) systems. These new systems precisely controlled fuel delivery using sensors and computer-controlled injectors, marking a crucial improvement over carburetors by offering superior fuel atomization, more consistent air-fuel ratios, and significantly reduced emissions.

The transition from carburetors to fuel injection happened in several progressive phases. Initially, first-generation throttle body injection (TBI) systems emerged, placing injectors in a central location reminiscent of carburetors. Subsequently, more advanced multi-port injection systems came into being, featuring dedicated injectors for each cylinder, which further refined efficiency and power delivery. The pinnacle of this evolution, direct injection, sprays fuel directly into the combustion chamber, maximizing both fuel economy and overall performance.

At the core of these modern fuel delivery systems lies the Electronic Control Unit (ECU), acting as the sophisticated ‘brain’ of the operation. These specialized computers analyze data from a multitude of sensors – including oxygen sensors, throttle position sensors, and temperature monitors – making precise fuel delivery adjustments in mere milliseconds. Such instantaneous, data-driven control was utterly impossible with mechanical carburetors, which relied on manual tuning and fixed physical components like jets and floats.

Read more about: From Dorm Room to Digital Giant: 14 Mind-Blowing Facts About Facebook’s Epic Journey, Features, and Fiercest Fights

5. **The Critical Role of Emissions Regulations in Phasing Out Carburetors**Among the many catalysts for the carburetor’s decline, stringent emissions regulations emerged as arguably the primary force behind their elimination from modern vehicles. Governing bodies like the U.S. Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) began implementing increasingly strict standards for vehicle exhaust, benchmarks that carburetors, by their very nature, simply couldn’t meet.

These mechanical devices, with their inherent lack of precision, struggled to effectively control the air-fuel mixture to the degree necessary to reduce harmful pollutants. Substances like nitrogen oxides (NOx) and particulate matter, common byproducts of incomplete combustion, became targets for reduction, and carburetors proved incapable of the fine-tuned control required.

In this regulatory crucible, fuel injection systems emerged as the indispensable replacement. Their significantly more accurate control over combustion processes allowed for cleaner burning engines, directly enabling compliance with critical environmental protection mandates and contributing to a substantial reduction in the overall carbon footprint of vehicles on our roads.

Consequently, manufacturers had little choice but to phase out carburetors in new engine designs, acknowledging that the old technology simply couldn’t align with evolving environmental responsibilities. It’s important to remember that classic and older cars were produced long before these stringent environmental guidelines were introduced to the auto industry, explaining their continued use of carbureted systems.

Read more about: Remember These Days? 14 Iconic Manual Transmissions That Vanished Or Are Fading From Our Car Options

6. **Demands for Fuel Efficiency: A Driving Force for Change**Beyond environmental concerns, the relentless demand for improved fuel efficiency significantly accelerated the automotive industry’s shift from carburetors to more sophisticated fuel delivery systems. In an era where every drop of fuel counts, consumers and governments alike pushed for vehicles that could deliver more miles per gallon, a challenge carburetors struggled to consistently meet.

Fuel injection technology masterfully optimizes the amount of fuel delivered, dynamically adjusting based on a multitude of real-time factors. This includes critical parameters like engine temperature, speed, load conditions, and even subtle altitude changes. This adaptive capability stands in stark contrast to the less responsive, mechanically governed operations of carburetors.

The tangible result of this precision is evident: cars equipped with fuel injection systems consistently demonstrate significantly better gas mileage compared to their carbureted predecessors. Modern computerized systems are capable of making minute, micro-adjustments to fuel delivery thousands of times per second, guaranteeing optimal combustion efficiency under virtually any driving condition imaginable.

This unparalleled precision in fuel management translates directly into tangible benefits for consumers, including reduced fuel consumption and notable cost savings at the pump. Simultaneously, it empowers manufacturers to meet increasingly strict government-mandated efficiency standards, cementing fuel injection’s role as a cornerstone of modern automotive engineering. The ability of a fuel injection system to constantly readjust and provide the exact needed fuel and air mixture makes it incredibly efficient.

Read more about: Ignite Your Ride: The Ultimate Guide to Spark Plugs for Peak Engine Performance and MPG Savings

7. **Precision Perfected: Fuel Injection’s Superior Fuel Delivery and Combustion**Modern fuel injection systems have undeniably revolutionized automotive engine technology, offering critical advantages over their traditional carburetor counterparts. At the heart of this transformation lies their unparalleled ability to deliver exact amounts of fuel directly into the engine’s combustion chamber or intake port with astonishing electronic precision. Unlike the mechanical processes of carburetors, electronic fuel injectors leverage sophisticated computer-controlled systems to meticulously calculate and dispense the optimal fuel quantity for virtually any driving scenario imaginable.

This level of precision culminates in significantly more complete combustion, a fundamental improvement that directly translates into tangible benefits. Vehicles equipped with fuel injection often consume up to 20% less fuel compared to their carbureted predecessors, a considerable gain in an era where efficiency is paramount. Furthermore, these advanced systems maintain remarkably consistent air-fuel ratios across a broad spectrum of operating conditions, whether the engine is idling, accelerating at high speeds, navigating varying altitudes, or performing in different temperatures – a consistency carburetors consistently struggled to achieve.

The cumulative effect of this improved combustion efficiency is profound, manifesting as lower emissions and demonstrably better overall engine performance. Such systems are absolutely essential for meeting today’s increasingly stringent environmental regulations, as they allow for a cleaner burning engine that minimizes harmful pollutants. This stark contrast between the electronic accuracy of fuel injection and the inherent mechanical limitations of carburetors underscores why the former has become the industry benchmark.

8. **Reliability Redefined: Fuel Injection’s Mastery Over Cold Starts and Consistent Operation**One of the most dramatic and appreciated improvements offered by fuel injection technology over its carburetor predecessor is its exceptional cold starting capability. In the era of carbureted engines, drivers often had to contend with the finicky ritual of manual choke adjustments during cold weather starts. This process was not only prone to user error but also notoriously inconsistent, leading to frustrating delays and often multiple attempts to get a reluctant engine to fire up.

Modern fuel injection systems, however, have eliminated this hassle entirely. They automatically and intelligently adjust the fuel mixture based on a multitude of real-time factors, including engine temperature and prevailing atmospheric conditions. This sophisticated adaptability ensures prompt and reliable starts, even when faced with extreme temperatures, offering a level of convenience and dependability that carbureted engines simply couldn’t deliver. The days of pumping the pedal and wrestling with a choke are largely a distant memory for owners of modern vehicles.

Beyond the convenience of effortless cold starts, fuel injection systems have drastically improved overall engine reliability by eliminating many of the common issues that plagued carburetors. Troublesome problems like clogged jets, which could easily impede fuel flow, the exasperating phenomenon of vapor lock in hot weather, and the corrosive effects of ethanol absorption in modern fuels are largely non-existent in fuel-injected engines. This freedom from such common mechanical frailties means modern vehicles rarely experience the frustrating idling problems or unexpected stalling that were once characteristic of carbureted powerplants.

Furthermore, the maintenance requirements for fuel injection systems have decreased significantly. Gone are the days of frequent adjustments and meticulous cleaning that carburetors demanded. Instead, electronic sensors continuously monitor engine performance, allowing for real-time adjustments that consistently maintain optimal operation without any need for manual intervention. This ‘set-it-and-forget-it’ reliability is a testament to the advanced engineering and electronic control that defines contemporary automotive technology.

9. **Enduring Legacy: Carburetors in Small Engine Applications**While the automotive world has largely transitioned away from carburetors, these venerable devices continue to thrive in specific, niche applications, most notably within the realm of small engines. Their mechanical simplicity and cost-effectiveness make them a particularly attractive and reliable choice for a wide array of equipment where complex electronic systems are neither necessary nor desired. This continued prevalence underscores their fundamental utility in less demanding power applications.

Think about the ubiquitous machinery that powers our daily lives and maintains our surroundings: lawnmowers, portable generators, and even concrete mixers. These are prime examples of equipment that commonly employ carburetor technology. The fundamental reason for this choice lies in the nature of their operation; these applications typically don’t require the ultra-precise fuel delivery or the intricate electronic controls that modern automotive engines demand. Their operational parameters are often less varied, and the need for peak fuel economy under all conditions is less critical.

Moreover, the simplicity inherent in carburetor systems renders them ideal for these smaller power applications. They are robust, generally easy to service, and less expensive to manufacture, all factors that contribute to their enduring presence. In many cases, the emissions regulations governing these types of small engines are also less stringent than those imposed on passenger vehicles, further enabling the continued use of this well-established and straightforward technology.

10. **Niche Powerhouses: Carburetors in Motorcycles and Aircraft**Beyond small utility engines, carburetors maintain a significant, albeit shrinking, presence in other specialized sectors, most notably within segments of the motorcycle and aircraft industries. For motorcyclists, especially those who appreciate the mechanical intricacies and raw feel of a machine, carbureted bikes hold a distinct appeal. While the industry has largely shifted towards fuel injection systems for newer models, carburetors can still be found in less expensive motorcycles and those designed for specific, often classic or retro, markets. Many riders find a distinctive throttle response and a particular engine sound from carbureted machines appealing, cultivating a dedicated niche market for these traditionally-powered two-wheelers.

In the realm of aviation, specifically within piston-engine aircraft, carburetors have historically played a crucial role, and their reliability and straightforward operation continue to provide vital safety benefits. The aviation industry, with its unwavering emphasis on minimizing potential points of failure in flight-critical systems, has long valued the carburetor’s simple, robust design in many small aircraft applications. This mechanical simplicity can often be a virtue when operating far from modern maintenance facilities or in conditions where electronic complexity might introduce unforeseen vulnerabilities.

Piston-powered planes frequently operate at various altitudes where the consistent performance of a well-designed carburetor remains remarkably effective, capable of providing the necessary fuel-air mixture without the intricate sensor networks required by fuel injection at extreme elevations. However, it’s also important to acknowledge the ongoing evolution within this sector; many newer aircraft models are increasingly incorporating advanced fuel injection technology to capitalize on improved efficiency, performance, and environmental compliance, mirroring the broader trends seen across the automotive world.

11. **Decoding Malfunctions: Recognizing Common Carburetor Problems**For those who still operate vehicles equipped with carburetors, understanding the common signs of malfunction is absolutely crucial for maintaining engine health and ensuring drivability. Unlike the ‘check engine light’ warnings of modern fuel-injected systems, carburetor problems often manifest through noticeable and sometimes frustrating symptoms that directly impact engine performance. These mechanical devices, despite their inherent simplicity, are prone to a specific set of issues that can hinder their ability to deliver the proper air-fuel mixture.

One of the most frequently encountered problems involves inconsistencies in the engine’s operation. This can include frequent engine stalling or a persistent rough idle, both of which strongly suggest issues with the carburetor’s ability to maintain the correct fuel-to-air ratio. Drivers might also experience significant difficulty starting the engine, often requiring multiple attempts or prolonged cranking, a clear indication that the carburetor is struggling to provide the initial rich mixture needed for ignition. Furthermore, a malfunctioning carburetor can severely impact fuel efficiency, leading to a noticeable decrease in gas mileage as the engine combusts fuel less effectively.

Other tell-tale signs often appear at the exhaust or during acceleration. A rich fuel mixture caused by carburetor problems might produce black smoke from the exhaust, indicating unburnt fuel. Engine misfires, characterized by hesitation or jerking during acceleration, can also point to carburetor issues as the engine struggles to receive a consistent fuel supply. A strong smell of fuel, particularly around the carburetor or exhaust, can signal leaks or other severe problems, while excessive fuel in the combustion chamber can lead to engine flooding, making starting almost impossible. Moreover, drivers might experience pronounced hesitation or lag when accelerating, or even backfiring (loud pops/bangs from the exhaust) due to an overly rich fuel mixture. Finally, physical damage, such as visible cracks, leaks, or worn-out components, directly indicates a need for immediate repair or replacement, often exacerbated by dirt, impurities, or the effects of ethanol in modern fuels.

12. **Preserving Performance: Essential Carburetor Maintenance Tips**Given the mechanical nature of carburetors and their susceptibility to various issues, proper and proactive maintenance is absolutely crucial for keeping them functioning efficiently and ensuring the longevity of carbureted vehicles. Unlike the ‘set-it-and-forget-it’ reliability of modern electronic systems, carburetors demand a more hands-on approach to retain their optimal performance and prevent the frustrating problems discussed earlier. Adhering to a regular maintenance schedule can make all the difference in ensuring a smooth-running engine.

One of the most fundamental maintenance practices is regular cleaning. Carburetors are intricately designed with small jets and passages that are highly susceptible to clogging from dirt, debris, and fuel deposits. Periodic cleaning prevents this buildup, ensuring uninterrupted fuel flow and accurate metering. Concurrently, it’s vital to meticulously check for leaks; inspecting all seals and gaskets for any signs of wear, cracking, or active leakage can prevent fuel loss and maintain the crucial vacuum necessary for proper operation.

Another key aspect involves adjusting the fuel mixture. Ensuring the correct fuel-to-air ratio is paramount to preventing common issues like rough idling, stalling, and overall poor engine performance. This often requires careful manual tuning, a skill that can be developed over time or entrusted to an experienced mechanic. Furthermore, components such as springs, needles, and floats are subject to wear and tear over time. Replacing these worn-out parts proactively can significantly extend the operational life of the carburetor and prevent more significant malfunctions down the line.

Lastly, the quality of the fuel used plays a critical role in carburetor health. Employing high-quality, clean fuel helps prevent the formation of deposits that can clog the delicate internal components. It’s particularly important to be mindful of ethanol gas, as its ability to absorb water can accelerate corrosion and lead to malfunctions, creating a persistent challenge for classic car owners. By consistently following these essential maintenance tips, owners can significantly mitigate common carburetor problems and ensure their classic vehicles continue to operate reliably for years to come.

The journey from the simple, yet ingenious, carburetor to the highly sophisticated electronic fuel injection system truly represents a defining chapter in automotive history. While carburetors faithfully powered vehicles for nearly a century, their mechanical limitations ultimately could not keep pace with the relentless modern demands for cleaner emissions, superior fuel economy, and enhanced performance. Today’s electronic systems deliver a level of precision, adaptability, and reliability that was once unimaginable, transforming everything from cold starts to overall engine efficiency. Though carburetors have largely receded from the mainstream, finding their enduring purpose in select small engines, certain motorcycles, and piston-engine aircraft, their legacy continues to shape our understanding of automotive evolution. As we look to the horizon, the principles that drove this pivotal transition — innovation, efficiency, and environmental responsibility — will undoubtedly continue to inspire and guide the next generation of groundbreaking automotive technologies, further maximizing performance while minimizing our impact on the world around us.