In the annals of space exploration, few events cast as long and dark a shadow as the Space Shuttle Challenger disaster. It stands as a stark testament to the grim, immutable law of engineering: that the higher we reach, the greater the cost of failure. When humanity dares to ascend atop a column of fuel and fire, launching into the infinite blackness of space, every nut, bolt, and seal must perform flawlessly, for in spaceflight, there are no second chances. On the morning of January 28, 1986, the world witnessed, live and in horror, how even the most sophisticated machinery could be undone by what seemed, on the surface, to be a piece of rubber no larger than a bracelet. This was the tragic culmination of the Space Shuttle Challenger’s tenth flight. It promised triumph, but instead delivered an explosive catastrophe, rooted in a tiny component, flawed decisions, and a fatal disregard for dissent.

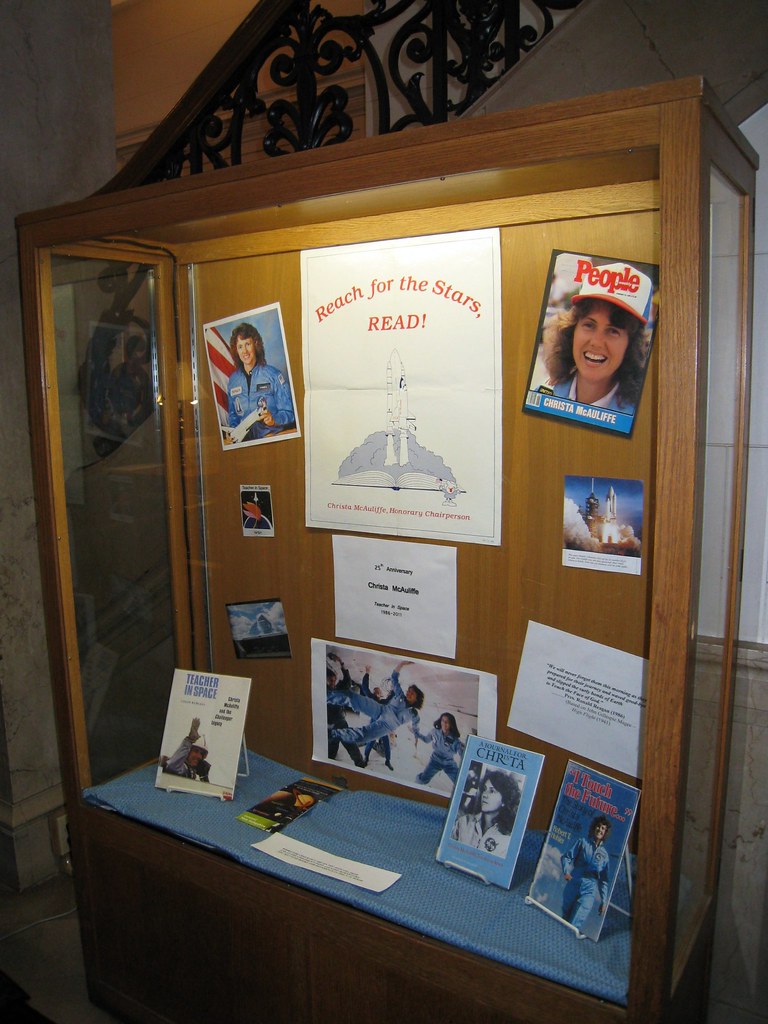

The Space Shuttle program itself was, at the time, NASA’s crown jewel—a gleaming marriage of aeronautical prowess and Cold War optimism. Designed to ferry astronauts, satellites, and science into orbit with the promise of reusability and regularity, the Challenger was a workhorse of the fleet. Onboard were seven crew members, including Christa McAuliffe, a schoolteacher selected to be the first civilian in space, a move intended to inspire a generation and bring the stars closer to home. Millions of children across America tuned in to watch their teacher launch into orbit, but what they witnessed instead was the most public and devastating failure in the history of American spaceflight.

The subsequent investigation would uncover a cause so bafflingly mundane, so alarmingly preventable, that it beggared belief. The immediate mechanical failure, a little thing called an O-ring, was only a symptom of deeper, systemic issues. These issues stemmed from a complex interplay of technical vulnerabilities, organizational pressures, and a culture that, in critical moments, prioritized schedule over safety. To truly comprehend the scope of this tragedy, it is imperative to delve into the specific technical flaws and decision-making processes that culminated in that fateful seventy-three-second ascent.

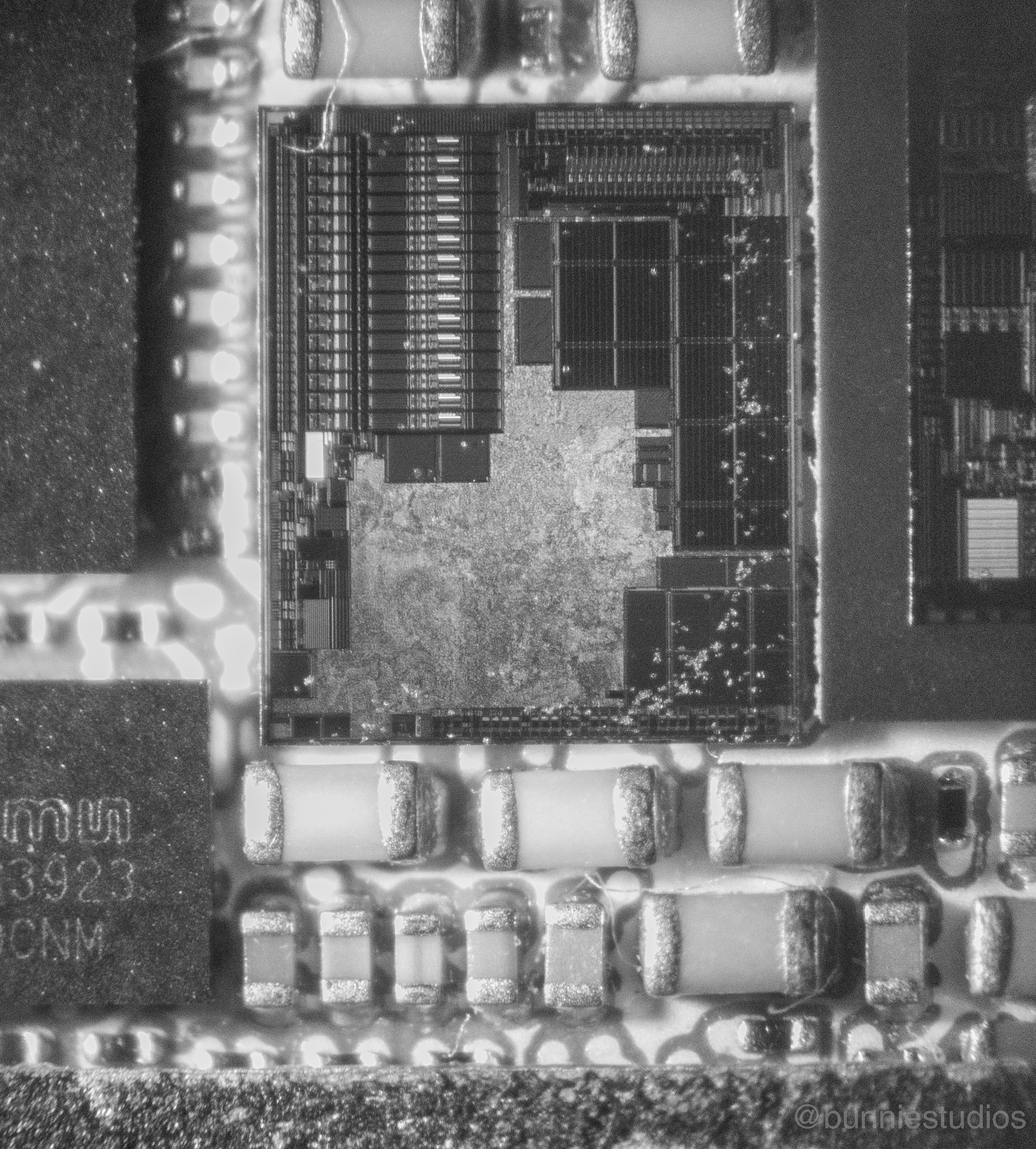

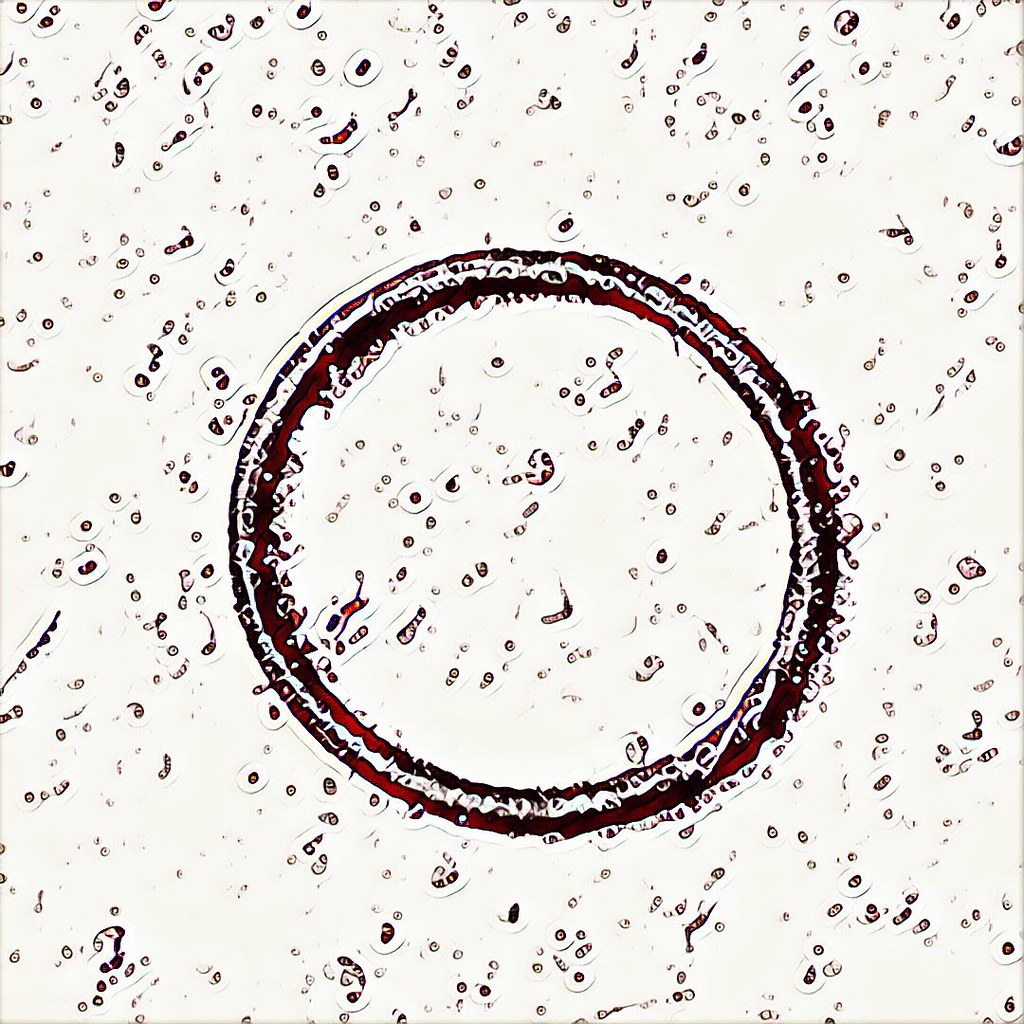

1. **The Flawed O-Ring Design and Material Properties**At the heart of the shuttle’s Solid Rocket Boosters (SRBs), the towering white columns flanking the orbiter, were joints, and within those joints were O-rings. These circular rubber seals were designed to contain the burning hot gases of ignition, ensuring that the boosters remained structurally sound and leak-free. However, for all their utility, as the context states, O-rings have “one damning weakness: They do not perform well in the cold.” This fundamental material property proved to be a critical vulnerability.

The intended mechanism for these seals was known as “pressure actuation.” This process dictated that the O-rings would be “actuated and sealed by combustion gas pressure displacing the putty in the space between the motor segments.” The displacement of this putty was meant to act like a piston, compressing the air ahead of the primary O-ring and forcing it into the gap between the field joint’s tang and clevis. This delicate sequence was essential to maintain the integrity of the seal, especially during the intense ignition transient of the solid rocket motor.

This pressure-actuated sealing was required to occur very early during the solid rocket motor ignition transient. This timing was critical because, as pressure loads were applied to the joint during ignition, the gap between the tang and clevis would increase. Should pressure actuation be delayed to the extent that this gap opened considerably, the risk of disaster dramatically escalated. The possibility existed that the rocket’s combustion gases would then “blow-by” the O-rings, severely damaging or even destroying the seals. Ground tests had already confirmed that reduced temperatures could cause the O-rings’ resiliency to degrade, directly impacting their ability to perform this critical sealing function.

2. **The Unprecedented Cold Launch Conditions**The environmental conditions on January 28, 1986, at Cape Canaveral were a crucial factor that exacerbated the O-rings’ inherent weakness. The temperature on the morning of the launch was below freezing, marking it as “the coldest launch day in shuttle history.” The severity of the cold was visible, with ice having formed on the launch pad itself. This unprecedented chill was a direct environmental stressor on a component already known to be sensitive to low temperatures.

Exposed overnight to these frigid conditions, the O-rings experienced a critical degradation in their physical properties. They “had lost their elasticity” and were, in essence, “too stiff to form a proper seal.” This loss of flexibility meant that when the immense pressures of ignition began, the seals could not adequately expand and fill the crucial gaps as required by their pressure actuation design. The lack of resilience left them vulnerable to the hot gases they were meant to contain.

Indeed, at the moment of ignition, the right-hand booster’s aft field joint was measured as the coldest part of the entire stack, registering a temperature of -2.2 degrees Celsius (28 degrees Fahrenheit). When Challenger’s engines ignited and the SRBs roared to life, the inevitable occurred: superheated gases escaped through the weakened joint of the right booster. This breach formed a jet of flame that began to burn into the adjacent external fuel tank, initiating the catastrophic chain of events.

Further compounding the issue was the potential impact of moisture. The context notes that “a small quantity of rainwater had been found in Columbia’s SRB joints during preparations for STS-9 in November 1983.” Given that 51L had been sitting on Pad 39B for a total of 38 days and had been exposed to significantly more rainfall than Columbia, it was theorized that the disaster could have been aggravated by the “further disruption, and perhaps even ‘unseating,’ of its O-rings by frozen water.” This suggested that ice could have physically interfered with the seals, adding another layer of vulnerability to an already compromised system.

Read more about: Beyond the Headlines: Unraveling 12 Enduring Celebrity Death Mysteries That Still Haunt Us

3. **Management Overruling Engineering**The investigation into the Challenger disaster revealed that the mechanical failure was inextricably linked to a profound bureaucratic failure. This crucial managerial oversight allowed the catastrophe to unfold despite explicit warnings. Engineers at Morton Thiokol, the contractor responsible for the SRBs, had vocally expressed their concerns the night before the launch. Their warning was stark and unambiguous: O-ring performance had never been tested below 53°F, and proceeding in such cold weather was “recklessly uncharted territory.” Their recommendation was clear: delay the launch.

The investigation into the Challenger disaster revealed that the mechanical failure was inextricably linked to a profound bureaucratic failure. This crucial managerial oversight allowed the catastrophe to unfold despite explicit warnings. Engineers at Morton Thiokol, the contractor responsible for the SRBs, had vocally expressed their concerns the night before the launch. Their warning was stark and unambiguous: O-ring performance had never been tested below 53°F, and proceeding in such cold weather was “recklessly uncharted territory.” Their recommendation was clear: delay the launch.

However, NASA officials were operating under immense pressure to maintain the shuttle’s schedule, which was already delayed and politically burdened. This institutional imperative led them to push back against the engineers’ warnings. A series of meetings ensued, charts were presented, and arguments were made, creating an environment where technical caution clashed directly with programmatic urgency. The tension in these discussions highlighted a critical breakdown in communication and decision-making hierarchy.

The culmination of these debates was a decision that would become a chilling case study in engineering ethics. Morton Thiokol managers, bowing to pressure, reversed their own engineers’ recommendation. The engineers, who possessed the critical technical expertise, were effectively overruled. This reversal represented a tragic failure of leadership and courage, sacrificing engineering truth for what appeared to be bureaucratic convenience. The launch proceeded, as did the O-rings’ failure.

Ultimately, “seven lives were lost, not in a grand experiment gone wrong, but in a failure of leadership, culture, and courage.” This bureaucratic misstep elevated political and scheduling concerns above the fundamental principle of safety, demonstrating a systemic flaw where critical technical warnings were downplayed rather than elevated. The decision to launch, made in an environment dismissive of dissent, highlighted a perilous culture that prioritized convenience over verifiable safety.

4. **”Criticality 1″ vs. “Criticality 1R”: The Misguided Understanding of O-Ring Redundancy**The O-rings’ designation within NASA’s critical items list underwent a significant change that, in hindsight, reflected a profound misunderstanding of their true redundancy. Since December 1982, the O-rings had been designated a “Criticality 1” item by NASA. Prior to that, they were labeled as “Criticality 1R,” a classification that implied a certain level of redundancy. This meant that, while a “total element failure … could cause loss of life or vehicle,” the presence of primary and secondary O-rings theoretically lent “redundancy” to the design, with the secondary seal expected to expand and fill the joint if its primary counterpart failed.

However, this assumption of redundancy was flawed, as NASA itself had acknowledged earlier. In its Critical Items List of November 1980, the agency conceded that “redundancy of the secondary field joint seal cannot be verified after motor case pressure reaches approximately 40 percent of maximum expected operating pressure.” It was known that “joint rotation occurring at this pressure level … causes the secondary O-ring to lose compression as a seal.” This meant that the secondary O-ring, intended as a fail-safe, was not truly capable of providing the necessary backup under operational conditions.

Following a series of high-pressure tests conducted by Morton Thiokol in May 1982, it became unequivocally clear that the secondary seal did not provide sufficient redundancy. Consequently, NASA changed the O-rings’ criticality listing later that year to Criticality 1, signifying that their failure, without a backup, would result in the loss of the shuttle and its crew. Despite this official reclassification, a dangerous complacency persisted. According to then-Associate Administrator for Space Flight (Technical) Michael Weeks, who signed a waiver to accept the new criticality level in March 1983, “we felt at the time that the Solid Rocket Booster was probably one of the least worrisome things we had in the program.” This view was shared by managers and even astronauts, indicating a pervasive underestimation of the risk.

This misguided confidence contributed to a “disturbing chain of thought within NASA and Thiokol,” as explained by the Rogers report. There was an “early acceptance of the problem,” and both organizations “continued to rely on the redundancy of the secondary O-ring long after NASA had officially declared that the seal was a non-redundant, single-point [Criticality 1] failure.” This institutional inertia and a continued reliance on a non-existent backup directly undermined safety protocols, setting the stage for the disaster.

5. **Accumulated Warning Signs: A History of O-Ring Erosion Incidents**The Challenger disaster was not an unforeseen event in isolation; rather, it was the tragic culmination of a series of ignored warning signs spanning several years. The problem with the boosters was first observed in November 1981, shortly after STS-2. Routine inspections at that time revealed significant erosion of the right-hand SRB’s primary O-ring due to hot combustion gases. Although the secondary seal remained intact, this anomaly went unreported at the Flight Readiness Review for STS-3 in March 1982, a critical lapse in communication and oversight.

As the shuttle program progressed, more disturbing instances of O-ring erosion accumulated. By January 1985, when Thiokol structural engineer Roger Boisjoly inspected severely damaged field joints from Mission 51C’s boosters, numerous other missions had yielded alarming signs of degradation. For example, on Mission 41B in February 1984, the left-hand SRB’s forward field joint and the nozzle joint belonging to its right-hand counterpart were found to be badly degraded. This prompted NASA to request Thiokol to investigate means of preventing further erosion, acknowledging the severity of the issue.

Mission 51C, launched in freezing conditions of just 11 degrees Celsius (51.8 degrees Fahrenheit) on January 24, 1985, proved to be particularly revealing. Its recovered left and right SRB nozzles showed clear evidence of “blow-by” between the primary and secondary O-rings. Furthermore, it was the first shuttle mission in which the secondary seal itself displayed the effects of heat. Boisjoly specifically noted the severity of this event for one of the 51C boosters, SRM-15: “that was the first time we had actually penetrated a primary O-ring on a field joint with hot gas, and we had a witness to that event because the grease between the O-rings was blackened, just like coal.” Analysis of this blackened material confirmed the presence of both putty and O-ring products, incontrovertible evidence of seal failure.

These cumulative incidents, particularly the direct link established between cold weather and O-ring damage after Mission 51C, constituted a grave series of missed warnings. Lawrence Mulloy, head of the SRB office, expressed concern over the impact of O-ring problems on future flights, yet Thiokol’s conclusion before the Flight Readiness Review was that, while “low temperature enhanced probability of blow-by … the condition is not desirable, but is acceptable.” This alarming acceptance of a known risk, despite mounting evidence, tragically set the stage for the worst and most public disaster in NASA’s history.

6. **The Compromised Thermal Barrier: Issues with Zinc Chromate Putty**Beyond the O-rings themselves, a seemingly minor component, the zinc chromate putty, played a critical role in the chain of failures leading to the Challenger disaster. This putty was “intended as a ‘thermal barrier’ to keep the combustion gas path away from the two O-rings.” Its purpose was to provide a crucial layer of protection, preventing the searing hot gases from directly impinging upon the rubber seals during ignition. However, as early as 1984, this putty “had been shown … to be susceptible to the formation of ‘blow holes,’ which compromised its effectiveness.”

The proper function of the putty was integral to the O-rings’ pressure actuation process. The Rogers report detailed that “it was intended … that the O-rings be actuated and sealed by combustion gas pressure displacing the putty in the space between the motor segments.” This displacement of the putty would act “like a piston” to compress the air ahead of the primary O-ring, forcing it into the gap to create a seal. The formation of blow holes directly undermined this critical mechanism, creating pathways for gas to bypass the putty’s intended piston-like action.

When blow holes formed in the zinc chromate putty, the thermal barrier was compromised, allowing hot combustion gases to reach the O-rings directly and prematurely. This direct exposure accelerated the erosion of the seals, especially when they were already stiff and brittle due to cold temperatures. The putty, instead of acting as a protective piston, became a point of weakness, allowing the very blow-by it was designed to prevent. This meant that even if the O-rings had possessed their full elasticity, the compromised putty would still have presented a significant risk of failure.

Morton Thiokol engineers recognized the gravity of this issue. They believed that “the erosion had been caused by blow holes in the zinc chromate putty and began tests to alter the method of its application and the assembly of the booster segments.” Despite these efforts, the problem persisted, complicated by changes in putty manufacturers and substitutions. Ultimately, the failure to fully resolve the putty’s vulnerability meant that a key protective element was consistently compromised, adding a critical technical flaw that contributed to the disaster’s inevitability.

7. **The Normalization of Deviance**Beyond the specific technical and managerial missteps, the Challenger disaster stands as a stark lesson in a more insidious organizational phenomenon: the normalization of deviance. This concept, powerfully articulated by social scientists, describes a gradual process whereby an organization repeatedly accepts and then deems acceptable behaviors, conditions, or risks that deviate from established safety standards. Over time, these deviations become the new, unstated norm, eroding safety margins without explicit acknowledgment.

Physicist Richard Feynman, a prominent member of the Rogers Commission, encapsulated this perilous dynamic with a chilling analogy: he described NASA’s attitude as a kind of “Russian roulette.” His point was that the shuttle would fly with O-ring erosion, and when “nothing happens,” it led to a dangerous conclusion that “the risk is no longer so high for the next flights.” This fostered an environment where standards were gradually lowered, fueled by past perceived successes rather than rigorous adherence to safety protocols. Each successful flight under conditions that should have been alarming inadvertently reinforced the flawed belief that the risks were acceptable.

Astronaut Mike Mullane, observing this cultural drift, scathingly termed it the “normalization of deviance.” This mindset allowed significant warning signs, such as the accumulating instances of O-ring erosion and blow-by, to be dismissed or accepted as ‘acceptable’ risks, as evidenced by Thiokol’s own conclusions prior to the Flight Readiness Review. Instead of prompting a halt and thorough redesign, these deviations were incorporated into an ever-expanding definition of what constituted a ‘safe’ operational envelope, leading directly to the catastrophe.

Read more about: The Digital Witness: An In-Depth Examination of Livestreamed Crimes and Their Unsettling Societal Impact

8. **Schedule Pressure and Resource Strain**The ambition inherent in the Space Shuttle program, particularly NASA’s desire to achieve frequent and routine access to low-Earth orbit, inadvertently created an environment of intense schedule pressure that severely strained resources and compromised safety. Initial plans from the mid-1970s envisioned flying the shuttle as often as once every fortnight. While this was acknowledged to be unrealistic with only four operational orbiters, NASA’s December 1985 launch schedule still projected an astonishing 24 missions per year starting from 1987.

Such an aggressive flight rate stretched NASA’s resources to their absolute limits, far beyond what was sustainable. A former shuttle engineer expressed serious doubts that such rates were achievable, even with continuous overtime and three shifts working around the clock in the Orbiter Processing Facility. The reality was that nine or ten missions in any 12-month period already pushed the system to its breaking point, and the constant pressure for speed introduced its own set of risks related to fatigue and human error.

The Rogers Commission uncovered disturbing evidence of this strain, noting that numerous contract employees at the Kennedy Space Center frequently worked 72-hour weeks and 12-hour shifts. This level of overwork had tangible safety implications, as demonstrated during the attempted launch of Mission 61C in January 1986, where “fatigue and shift work were cited as major contributing factors to a serious incident involving a liquid oxygen depletion that occurred less than five minutes before scheduled liftoff.”

Compounding these issues were woefully inadequate provisions for spare parts. By January 1986, only 65 percent of the required parts inventory was in place, necessitating a dangerous practice of ‘cannibalism’ – stripping parts from one orbiter to prepare another for flight. An $83.3 million budget cut in October 1985 further exacerbated the problem, leading to major deferrals of spare parts purchases. As STS-6 veteran Paul Weitz testified, this cannibalism significantly increased the exposure of both orbiters to potential damage from human intrusion, raising the risk of misplaced tools or accidental impacts.

Horace Lamberth, KSC’s shuttle engineering chief, predicted that even had Mission 51L flown successfully, the entire schedule would have ground to a halt that spring due to the spare parts problem alone. This critical shortage, coupled with NASA’s difficulty in transitioning from a ‘single flight’ focus to a system capable of efficiently supporting a high flight rate, meant that resources were consistently diverted to immediate issues, leaving longer-term systemic problems unresolved.

Read more about: Navigating the Tire Market: 15 Essential Tips to Secure the Best Price and Maximize Value for Your Next Set of Tires

9. **Roger Boisjoly’s Unheeded Warnings**The catastrophic failure of the Challenger was not merely a technical oversight but a direct consequence of explicit warnings from engineers being systematically dismissed. At the forefront of these dissenting voices was Roger Boisjoly, a structural engineer at Morton Thiokol, who became a crucial figure in the pre-disaster narrative. His concerns were not vague anxieties but meticulously documented analyses based on actual flight data.

Following Mission 51B in April 1985, which saw erosion of the secondary O-ring—a clear indication of primary O-ring failure—Boisjoly’s apprehension deepened. This incident was so severe that it led to a “launch constraint” on subsequent flights, yet this constraint and its waivers were unknown to senior NASA officials. Boisjoly’s colleague, Don Lind, later revealed how close Mission 51B was to disaster, with “61 millimeters” of the last O-ring burned away, preventing an explosion by mere “three-tenths of a second.”

On July 31, 1985, Boisjoly formalized his grave concerns in a memorandum to Thiokol’s vice president of engineering, Bob Lund. He directly challenged the “mistakenly accepted position on the joint problem,” warning that if the scenario seen in the nozzle joint erosion of 51B—where the primary O-ring failed to seal and the secondary was also compromised—were to occur in a field joint, the outcome could be a “catastrophe of the highest order: loss of human life.” This was a clear, unambiguous warning of the precise nature of the disaster that would unfold six months later.

Boisjoly’s memo recommended forming a dedicated Thiokol team to address and resolve the problem, which Lund duly announced on August 20, 1985. However, this team’s efforts were frequently frustrated by senior management. Boisjoly noted in an October 4 memo that “even NASA perceives that the team is being blocked in its engineering efforts.” NASA’s decision to send its own engineering representative to Thiokol underscored their concern that the contractor was not responding quickly enough to the seal problem, highlighting a growing tension between engineering reality and managerial expedience.

Further evidence of continued O-ring issues surfaced on Missions 61A and 61B in late 1985, with nozzle O-ring erosion and blow-by occurring, yet these problems were not adequately addressed or even identified at subsequent Flight Readiness Reviews. Disturbingly, Thiokol later requested to close the O-ring critical problem issue, citing satisfactory test results, a move harshly criticized by the Rogers investigators. As one panel member pointed out, such a closure, while problems persisted, indicated a desire “not to be bothered” with ongoing critical safety concerns. This dismissal of profound, repeated warnings, particularly those voiced by Boisjoly, cemented the path to tragedy.

10. **The Rogers Commission Findings**In the immediate aftermath of the Challenger disaster, a Presidential Commission was convened to investigate the catastrophe, led by former Secretary of State William Rogers. This distinguished body, known as the Rogers Commission, included luminaries such as astronauts Neil Armstrong and Sally Ride, and the renowned physicist Richard Feynman. Their mandate was clear: to uncover the precise causes of the accident and to recommend changes to prevent future tragedies.

The Commission’s exhaustive inquiry confirmed what many engineers had already suspected and warned about: the cause of the disaster was “not a mystery, but a known risk.” Their final report unequivocally pointed to a severe institutional and cultural failing within NASA and Morton Thiokol. It concluded that the culture within NASA had become disturbingly “risk-tolerant,” “dismissive of dissent,” and excessively “sensitive to political pressures.” This environment fostered a dangerous tendency to downplay critical concerns rather than elevate them.

Perhaps one of the most memorable and impactful moments of the investigation came during a televised hearing when Richard Feynman conducted a simple yet profound demonstration. He placed a piece of O-ring material into a glass of ice water, showing how it quickly became brittle, stiff, and incapable of forming a proper seal. This vivid, undeniable illustration visually underscored the engineers’ warnings about the O-rings’ temperature sensitivity and delivered a haunting verdict: “For a successful technology,” Feynman declared, “reality must take precedence over public relations, for nature cannot be fooled.”

The Rogers report laid bare the systemic flaws in the operation of the shuttle program by both NASA and Thiokol. It found that crucial concerns from individual engineers were often not reaching appropriate managers, and that items designated as “critical” were not receiving the attention they demanded. Most damningly, the report concluded that the need to adhere to an ambitious “schedule” had been allowed to “grossly override safety.” This relentless pursuit of launch deadlines, often driven by political and public relations pressures, led to Thiokol’s fateful decision to ignore its own engineers’ safety concerns in order to accommodate its primary customer, NASA, on the eve of the Challenger launch.

Read more about: The Enduring Legacy of ‘Richard’: A Comprehensive Look at Influential Figures Bearing the Historic Name, Featuring Actor Richard Hatch

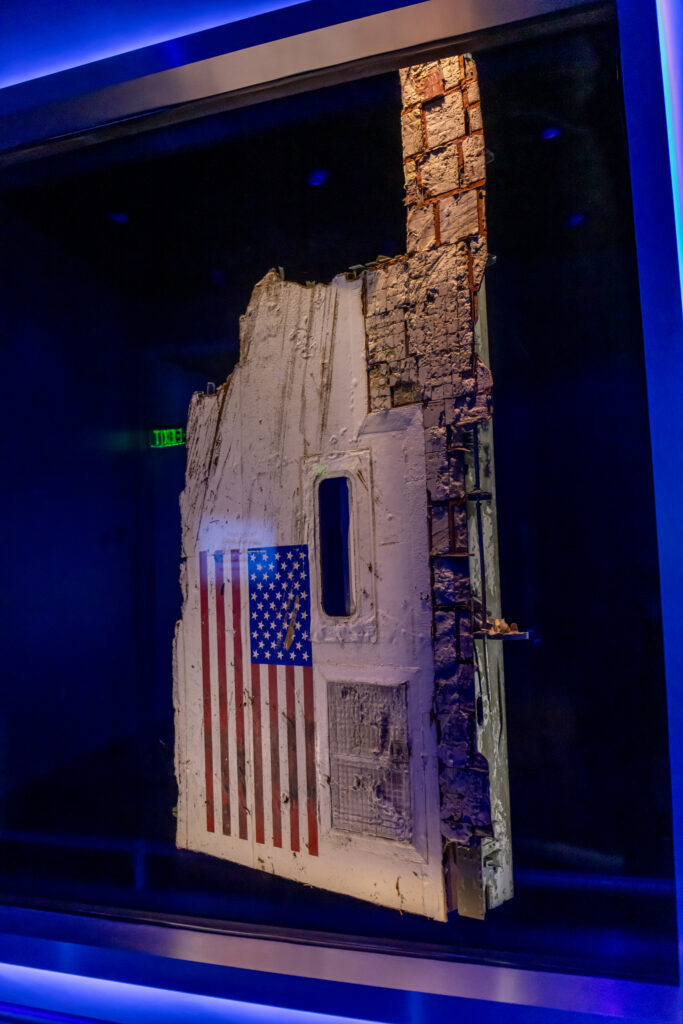

11. **The Crew’s Final Moments**Six weeks after the catastrophic loss of Challenger, on March 7, 1986, divers from the U.S.S. Preserver made a grim discovery: the remains of the shuttle’s crew cabin, lying in 100 feet of water about 16 miles northeast of the Kennedy Space Center. The Rogers Commission’s final report described the cabin as “disintegrated, with the heaviest fragmentation and crash damage on the left side,” noting that the fractures were typical of “overload breaks” from impact with the water’s surface. A U.S. Navy spokesperson starkly clarified that they were dealing with “debris, not a crew compartment, and we’re talking remains, not bodies.”

Veteran astronaut Mike Coats, among the first to examine the wreckage, likened it to “aluminum foil that had been crushed into a ball.” The horrific condition of the remains made identification extremely difficult; only a few strands of Judy Resnik’s hair and a necklace were all that remained identifiable of Mission Specialist Two. This prompted new NASA protocols, requiring all astronauts to submit hair clips and footprints for identification, as even dental records were often insufficient for the 51L crew.

Astronaut Mike Mullane, in his 2006 memoir, expressed a fervent hope that the external tank’s explosive burn had either destroyed the cabin or caused a rapid depressurization, leading to a quick and merciful death. However, evidence from the wreckage contradicted this. The cabin had proven extremely hardy in tests, and there was little indication of an explosive depressurization, which would have caused an upward “buckling” of the flight deck floor, no such buckling was detected. Damage to the windows was so severe that it was impossible to determine if they had broken in-flight or on water impact, though breakup forces alone would not have broken them.

More conclusive and harrowing evidence that at least some of the crew remained alive and conscious for a significant portion of the fall came in mid-March 1986, with the recovery of four Personal Egress Air Packs (PEAPs). These devices provided about six minutes of breathing air for emergencies. Analysis confirmed by May 21 that at least one had been activated post-breakup, and not accidentally upon water impact. On June 9, investigators revealed that one of the activated packs belonged to Pilot Mike Smith.

Smith’s PEAP was affixed to the back of his seat, out of his reach, strongly implying that either Judy Resnik or Ellison Onizuka, seated behind him, had leaned forward to activate it in a valiant attempt to save his life. The quantity of air remaining in Smith’s pack—barely two and a half minutes’ worth, almost precisely the cabin’s fall time—suggested he had kept his helmet visor closed during the descent. If it had been open, all six minutes of air would have leaked out. With the intercom, lights, and computers dead, communication would have been challenging, though Mullane believed hand signals, common among fighter pilots like Scobee and Smith, would have been effective.

One factor remains almost certain: most, if not all, of the astronauts were acutely aware of their dire predicament. Milliseconds before the External Tank disintegrated, at T+73 seconds, a bright sheet of white vapor engulfed Challenger’s nose. This was likely visible to Smith, who may have uttered a brief exclamation, “Uh, oh,” the last recorded vocal communication from the orbiter. It is also quite possible he witnessed the top of the right Solid Rocket Booster pivot into the side of the External Tank. Despite sensationalized, hoaxed transcripts alleging crew screams, Mullane confidently believed that Commander Dick Scobee and Pilot Mike Smith, with their fighter pilot backgrounds, would have fought heroically to regain control of their crippled ship until the very end.

Read more about: Beyond the Red Carpet: 14 Candid Glimpses of Old Hollywood Stars Living Their Best Off-Set Lives

12. **Interpreting the Wreckage**In the days immediately following the disaster, initial speculation among many astronauts and experts leaned towards a failure or explosion of one or more of the shuttle’s main engines as the most probable cause. However, the comprehensive analysis of the wreckage, meticulously recovered from the Atlantic seabed, definitively steered the investigation away from this hypothesis.

Remnants of all three main engines were successfully dredged from the Atlantic on February 23, still attached to the thrust structure. Upon examination, their controllers were disassembled and their data extracted. All engine debris exhibited burn damage, which the Rogers report attributed to “internal over-temperature typical of oxygen-rich shutdown.” This suggested that the loss of hydrogen fuel, which occurred after the rupturing of the lower part of the External Tank, had caused all three units to begin shutting down within milliseconds of each other at approximately T+73.5 seconds. Crucially, the overall performance of the main engines prior to this point was deemed satisfactory, confirming they did not contribute to the loss of Mission 51L.

Similarly, the gigantic External Tank itself was ruled out as the primary cause. Approximately 20 percent of the tank was recovered, predominantly debris from its inter-tank and lowermost hydrogen section. Initial theories, such as premature detonation of range safety explosives, were discounted because the unexploded ordnance was found among the debris. Theories of structural imperfections or damage incurred at liftoff were also dismissed. Furthermore, the possibility of a liquid hydrogen leak at liftoff was definitively ruled out, as such a leak would have been immediately ignited by the exhaust from the Solid Rocket Boosters or main engines and would have been evident in the downlinked telemetry data.

In total, around 30 percent of Challenger’s structure was recovered and subjected to forensic analysis. Inspections revealed that the orbiter had disintegrated as a result of “massive aerodynamic overloads,” with no evidence of internal burn damage or exposure to explosive forces within the main structure. Chemical analyses, however, indicated that the shuttle’s right side had been sprayed with hot gases, unequivocally pointing towards a leak from the right-side Solid Rocket Booster. Telemetry data confirmed that all of Challenger’s systems operated normally until shortly prior to the breakup, and no problems were detected with either of her payloads, further narrowing the focus of the investigation.

The finger of blame pointed squarely and irrefutably at the Solid Rocket Boosters, and specifically, at the leaking right-side booster. The wreckage analysis, combined with telemetry data, dismissed initial suspicions that range safety explosive charges had been inadvertently fired. For many engineers and managers at Morton Thiokol and within NASA, the interpretation of the wreckage, correlating with years of ignored warnings, confirmed what had been identified more than a year before Challenger’s maiden voyage: the primary and secondary O-rings were incapable of properly sealing the gaps between the SRB joints in extremely cold weather. The compounded effect of cold-weather vulnerability, the compromised zinc chromate putty, and the catastrophic failure of these seals was irrevocably cemented by the physical evidence recovered from the Atlantic, providing the definitive explanation for the disaster.

Read more about: Recovered PL-15E Missile Wreckage Offers Global Intelligence Windfall, Reshaping Strategic Calculations

The story of the Challenger disaster remains an enduring, painful testament to the unforgiving contract between humanity and the laws of physics. It underscores that in the relentless pursuit of progress and exploration, no component is too small to escape scrutiny, no warning too minor to be ignored. The tragedy forced NASA, and indeed the entire aerospace community, into a profound period of introspection, leading to sweeping reforms in engineering protocols, communication structures, and organizational culture. The lessons etched into the fabric of space exploration by the Challenger’s demise—that ethics is not optional, that transparency is paramount, and that “reality must take precedence over public relations”—continue to resonate, shaping every launch and every mission that dares to reach for the stars. It is a legacy forged in fire and ice, reminding us that restraint, diligence, and an unwavering commitment to safety are the true foundations upon which miracles are built, and tragedies averted.