The 1940s, a decade synonymous with global conflict and seismic shifts, often conjures images of wartime sacrifice, technological ingenuity, and profound societal change. For automotive enthusiasts, this era might seem like a pause, a moment where the sleek designs and burgeoning innovations of the pre-war years were abruptly halted, with the focus shifting away from the open road to the battlefront. Yet, beneath the surface of rationing, retooling, and relentless conflict, the 1940s silently laid much of the groundwork for the automotive world we know today, creating a fascinating tapestry of challenges, adaptations, and unforeseen breakthroughs.

While the glamour of new models and consumer choice was largely sidelined, the exigencies of war acted as an unexpected crucible for innovation. Engineers, manufacturers, and entire nations grappled with unprecedented demands, giving rise to technologies and strategies that would dramatically influence the future of vehicle design, propulsion, and even the global economic environment in which cars would be built and sold. Many of these pivotal developments, often overshadowed by the larger historical narrative, represent the unsung drivers of automotive evolution—forgotten chapters that deserve a closer look.

Join us as we journey back to this tumultuous yet transformative decade, unearthing 12 pivotal innovations and influences that dramatically reshaped the automotive landscape. From the battle-hardened workhorses that defined utility to the nascent technologies that would eventually revolutionize vehicle intelligence and efficiency, we’ll explore the often-overlooked forces that quietly steered the course of motoring history. Prepare to discover the hidden gears that kept the world moving, even when the civilian automobile itself seemed to take a backseat.

1. **The Unforgettable Icon: The Jeep**

Born of necessity on the battlefields of World War II, “The Jeep” stands as perhaps the most enduring and iconic vehicle to emerge from the 1940s. More than just a piece of military equipment, this rugged, versatile utility vehicle became a symbol of Allied ingenuity and resilience. Its simple yet effective design allowed it to traverse nearly any terrain, performing countless roles from reconnaissance to ambulance, forever changing perceptions of what a vehicle could achieve under extreme conditions.

The Jeep’s origins speak volumes about the era’s urgency; it was developed at breakneck speed in response to the U.S. Army’s need for a light reconnaissance vehicle, capable of replacing horseback and motorcycle use. Its four-wheel-drive system and robust construction proved indispensable across diverse battlefronts, from the deserts of North Africa to the muddy tracks of Europe. This unparalleled adaptability cemented its legendary status, making it a critical asset in the war effort and a household name even amongst civilians back home.

What often gets forgotten in the legend of the wartime Jeep is its profound influence on post-war civilian vehicle design and culture. As soldiers returned home, many craved the utility and go-anywhere capability that their wartime companion offered. This demand directly spurred the creation of civilian models, pioneering the burgeoning market for off-road and sport utility vehicles. The Jeep’s legacy extends far beyond its military service, establishing an entirely new segment of the automotive industry and inspiring generations of rugged, capable vehicles. It embodies how wartime innovation can seamlessly transition into a powerful, lasting consumer desire.

Read more about: Seriously What Happened?! 10 Classic Snacks That Vanished From Grocery Store Shelves — A Taste of Childhood Past!

2. **The Great Retooling: How War Halted Civilian Auto Production**

While specific new civilian automobile models were scarce during the 1940s, a monumental “forgotten” force profoundly shaped the automotive landscape: the complete pivot of industrial might towards the war effort. Across major manufacturing nations, established automobile factories, once humming with the assembly of cars for the masses, were dramatically retooled almost overnight. This wasn’t merely a slowdown in production; it was a wholesale transformation, diverting immense resources and expertise from car building to the creation of tanks, aircraft, military trucks, and munitions.

This industrial metamorphosis meant that the automotive engineers, designers, and skilled laborers who previously innovated for civilian transport were now focused on military hardware. Production lines that once rolled out sedans and coupes were reconfigured to produce B-24 bombers, M4 Sherman tanks, and an array of other vital war materials. This unprecedented shift showcased the incredible adaptability and scale of the automotive industry, demonstrating its capacity to serve national imperatives far beyond passenger vehicles. The expertise honed in mass-producing cars proved invaluable in accelerating military manufacturing.

The long-term impact of this production shift is often overlooked when discussing 1940s automobiles. It created a significant vacuum in the consumer market for new vehicles, leading to pent-up demand that would explode in the post-war boom. Furthermore, the innovations in manufacturing processes, metallurgy, and assembly line efficiency, perfected under the intense pressure of wartime demand, would eventually feedback into civilian car production. The experience of building robust military machines fundamentally informed the design and durability of the next generation of passenger vehicles, making this industrial redirection a silent, yet powerful, catalyst for future automotive development.

3. **Driving on Fumes: The Realities of Rationing on 1940s Motorists**

Beyond the factories, the experience of owning and operating an automobile in the 1940s was profoundly dictated by a forgotten, yet pervasive, influence: wartime rationing. The sheer scale of global conflict led to severe shortages of critical materials like rubber, metal, and, most crucially for motorists, gasoline. This wasn’t just an inconvenience; it necessitated a complete re-evaluation of how individuals interacted with their vehicles, transforming driving from a commonplace activity into a carefully managed privilege, deeply impacting the role of the car in daily life.

Government programs implemented strict controls on who could drive, how far, and what they could consume. Gasoline was allocated using rationing stamps, often limiting civilians to just a few gallons per week, or even none for non-essential travel. This forced families to embrace carpooling, public transport, or simply park their vehicles for the duration of the war. Tires, made from increasingly scarce rubber, became precious commodities, prompting drivers to meticulously care for their existing sets and prolong their lifespan through careful driving and repairs. This era made car maintenance a patriotic duty.

The ripple effects of these shortages extended beyond daily usage, influencing vehicle design and material science. Manufacturers, even those primarily focused on military contracts, became acutely aware of the need for resource efficiency and the development of alternative materials. The push to conserve metal and rubber, for instance, spurred innovations in synthetics and lightweight construction, lessons that would be carried forward into post-war automotive engineering. This period of constraint, often overshadowed by the war itself, played a critical, if painful, role in fostering a new era of resourcefulness and engineering ingenuity within the automotive sphere.

4. **Beyond the Propeller: The Birth of Jet Propulsion**

While not an automobile in the traditional sense, the 1940s witnessed the groundbreaking “development of jet aircraft,” a forgotten technological leap that profoundly redefined possibilities in propulsion and engineering. Emerging largely from wartime pressures, the first operational jet engines heralded a new era of speed and power, radically shifting the paradigm of how vehicles could be propelled. This wasn’t merely an incremental improvement; it was a fundamental re-imagining of mechanical force, setting the stage for future high-performance transportation across all sectors.

The early jet engines, developed by nations like Germany and Great Britain during the war, were engineering marvels, transforming theoretical principles into formidable operational capabilities. These pioneering jet aircraft demonstrated unprecedented speeds and altitudes, pushing the boundaries of what was physically achievable. The intense research and development poured into jet propulsion during this decade generated invaluable knowledge in thermodynamics, materials science for high-temperature applications, and aerodynamic design—disciplines inherently critical to pushing the limits of any vehicle, including ground-based ones.

The direct link to automobiles might seem distant, but the underlying principles and engineering challenges overcome in jet propulsion had significant, though indirect, implications for automotive development. Concepts of efficiency, power-to-weight ratios, and the use of advanced materials became increasingly scrutinized across all forms of transport design. The sheer ambition to conquer the skies with such force inspired engineers worldwide and fostered a culture of extreme innovation that would eventually feed into automotive research, particularly in areas like engine performance, supercharging, and aerodynamic styling, often in ways now largely forgotten by the general public.

5. **Eyes in the Sky: The Birth of Radar Technology**

Another pivotal, yet often forgotten, technological advancement of the 1940s with far-reaching implications for the automotive world was “the development of radar.” Initially a clandestine military tool vital for detecting enemy aircraft and ships during World War II, radar represented a revolutionary leap in sensory technology. Its ability to “see” beyond visual range, through darkness and weather, opened up entirely new possibilities for spatial awareness and object detection—principles that, decades later, would become indispensable for vehicle safety and autonomous driving systems.

Born from urgent wartime necessity, radar systems rapidly evolved from rudimentary experimental setups to sophisticated networks critical for national defense. Scientists and engineers across the Allied and Axis powers poured resources into refining radar’s capabilities, pushing the boundaries of radio wave transmission, reception, and signal processing. The development of compact, reliable, and increasingly accurate radar units during this decade was a testament to the era’s relentless pursuit of technological superiority, creating a foundation for non-visual environmental sensing.

While 1940s automobiles themselves were devoid of such advanced sensory systems, the foundational work in radar laid critical conceptual and technical groundwork for future integration. The very idea of a machine being able to perceive its surroundings dynamically and react to them without human intervention has its roots in these early radar developments. What began as a tool for protecting convoys and detecting bombers eventually evolved into adaptive cruise control, blind-spot monitoring, and collision avoidance systems in modern cars. The 1940s origin of radar, therefore, represents a forgotten, yet immensely significant, step towards the intelligent vehicles of tomorrow.

Read more about: How Drones Have Taken Over the Ukraine War: An In-Depth Look at the Future of Combat

6. **The Digital Revolution Begins: From Codebreakers to Car Design**

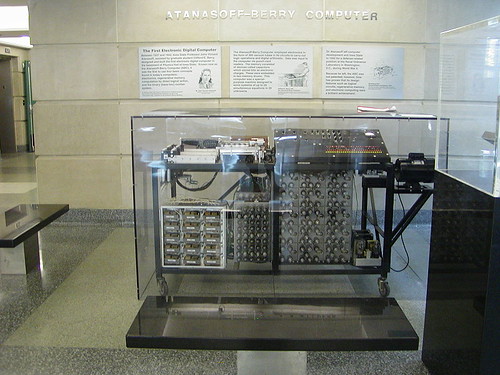

Among the most transformative, yet broadly “forgotten” influences of the 1940s on the future of the automotive industry, was the nascent “development of electronic computing.” While the decade’s iconic machines like the Colossus and ENIAC were gargantuan, room-filling behemoths focused on ballistic calculations and code-breaking, they represented the very genesis of modern computational power. This was the moment when the digital revolution began, laying the theoretical and practical bedrock for every complex system, including those within vehicles, that would follow.

The Atanasoff-Berry Computer, Colossus, the Z3, and ENIAC were not just curiosities; they were instruments of national necessity, accelerating computations that were previously impossible or took human teams weeks to complete. These early computers, often developed under wartime secrecy, proved the viability of electronic calculation, programming, and data processing. Their development spurred intense research into logic, architecture, and memory, establishing the fundamental principles of what would become the digital age. The sheer intellectual and engineering effort behind these machines was staggering.

For the automotive world, the direct impact of these early computers was not immediate, but their long-term significance is undeniable and often unappreciated when reflecting on the 1940s. The ability to perform rapid, complex calculations revolutionized engineering design, crash simulations, aerodynamic modeling, and eventually, the intricate electronic control units that manage everything from engine performance to navigation in modern cars. The analytical power born in the ’40s computing labs created the tools that would empower automotive engineers to design safer, more efficient, and ultimately smarter vehicles, making this pioneering digital leap a truly forgotten, yet foundational, chapter in automotive history.

7. **The Transistor: The Seed of Automotive Electronics**

While the gargantuan electronic computers of the 1940s were just beginning to flex their computational muscle, a far smaller, yet infinitely more disruptive, electronic innovation arrived in the latter half of the decade: the invention of the transistor in December 1947 at Bell Labs. This miniature semiconductor device, capable of amplifying and switching electronic signals, was a quiet revolution that would ultimately dismantle the bulky, power-hungry reign of vacuum tubes and pave the way for modern electronics, including those integral to every car on the road today. Its significance, often overlooked in the dramatic backdrop of post-war rebuilding, is paramount.

The transistor’s fundamental power lay in its ability to perform the same functions as a vacuum tube—acting as an amplifier or a switch—but with unparalleled efficiency, reliability, and most crucially, in a vastly smaller package. This meant that complex electronic circuits, previously limited by size, heat generation, and fragility, could now be miniaturized and integrated into compact systems. The immediate applications weren’t in automobiles, but the potential for robust, low-power electronic control was instantly recognized, sparking a wave of innovation that would redefine engineering across countless industries.

For the automotive world, the transistor represented the dormant seed of its digital future. Though cars of the 1940s remained largely mechanical and electro-mechanical marvels, the invention of the transistor made possible the sophisticated Electronic Control Units (ECUs) that govern everything from engine performance and fuel injection to anti-lock braking systems (ABS), traction control, and airbags in contemporary vehicles. It heralded the shift from analog to digital control, transforming cars from purely mechanical devices into intricate, intelligent machines that could sense, process, and react to their environment with unprecedented precision and speed.

In essence, every piece of advanced automotive technology we take for granted today—from intricate infotainment systems to advanced driver-assistance systems (ADAS) and the ultimate goal of fully autonomous driving—owes its very existence to this humble invention from 1947. The transistor’s development in the post-war era wasn’t just another technological breakthrough; it was the foundational leap that would elevate vehicle design from mere mechanical engineering to a complex symphony of electrical, mechanical, and software integration, profoundly changing the driving experience forever.

8. **The Bretton Woods System: Global Automotive Finance Redefined**

Beyond individual inventions, the latter half of the 1940s witnessed the establishment of new global economic structures that quietly reshaped the landscape for international trade and, by extension, the automotive industry. Among the most impactful of these was the Bretton Woods System, born from the Bretton Woods Conference of July 1944 and effectively established with institutions like the International Monetary Fund (IMF) and the International Bank for Reconstruction and Development (IBRD). This system, designed to regulate the international monetary and financial order after World War II, provided a crucial framework that would profoundly influence how cars were manufactured, bought, and sold across borders for decades.

At its core, the Bretton Woods System sought to prevent a return to the economic chaos of the interwar period, characterized by competitive devaluations and protectionist trade policies. It established a system of fixed exchange rates, with the U.S. dollar pegged to gold and other currencies pegged to the dollar. This framework provided an unprecedented degree of currency stability and predictability. For global industries, including automotive, this meant that manufacturers and consumers could engage in international transactions with far less risk of sudden currency fluctuations eroding profits or purchasing power.

Such stability was a boon for automotive manufacturers eager to expand beyond their domestic markets and rebuild international supply chains. Companies could confidently plan for cross-border investments, export vehicles, and import crucial raw materials or components without the constant threat of unpredictable exchange rate shifts undermining their economic viability. This economic environment fostered the expansion of multinational automotive corporations and facilitated a more integrated global market for vehicles, where designs and production could be optimized for wider consumption.

The long-term impact on the automotive sector cannot be overstated. By creating a stable and predictable international financial order, Bretton Woods underpinned the post-war economic boom, fostering consumer confidence and rising incomes in key global markets. This robust economic backdrop directly fueled the demand for automobiles and enabled the rapid globalization of the auto industry, allowing brands to grow from regional players into international giants. It represented a systemic, often unheralded, change that was as vital to the industry’s expansion as any mechanical innovation.

9. **The Marshall Plan: Fueling Europe’s Automotive Recovery**

In the wake of a devastating global conflict, the economic recovery of nations was not a given, especially in war-torn Europe. It was here that another forgotten, yet immensely impactful, economic innovation of the late 1940s took center stage: The Marshall Plan. Officially known as the European Recovery Program, this ambitious American initiative, launched in 1948, poured billions of dollars into rebuilding Western European economies. While its primary aim was geopolitical stability, its direct and indirect effects on the automotive industry were transformative, reviving critical markets and manufacturing bases.

The Marshall Plan provided essential capital, raw materials, and machinery that were desperately needed to rebuild industrial infrastructure, including countless automotive factories that had been destroyed or repurposed during the war. This wasn’t merely humanitarian aid; it was a strategic investment designed to restart production, re-establish supply chains, and enable European manufacturers to retool for civilian vehicle output. Factories that once produced tanks and planes could begin to assemble cars again, thanks to the influx of resources and technical assistance.

Beyond industrial rebuilding, the plan’s success in revitalizing national economies had a profound ripple effect on consumer demand for automobiles. As European nations recovered, incomes rose, and a sense of normalcy returned, the ability and desire to purchase private vehicles surged. This renewed consumer market was precisely what manufacturers like Volkswagen, Fiat, Renault, and countless others needed to not only resume operations but also to innovate and expand, catering to a burgeoning post-war middle class eager for personal mobility.

Ultimately, the Marshall Plan stands as a critical, albeit often unremembered, catalyst for the resurgence of the European automotive industry. It provided the financial and material lifeline that prevented a more prolonged economic depression, allowing Europe’s storied car makers to rebuild, innovate, and eventually compete on a global scale. The investment ensured that Europe remained a vibrant market and a crucial manufacturing hub, directly influencing vehicle development, design philosophies, and export strategies for decades to come, thereby shaping the competitive landscape of the global auto market.

_-_filtered.jpg)

10. **Breaking the Sound Barrier: Aerodynamic Lessons for the Road**

While the sight of a 1940s automobile might suggest a world far removed from the cutting edge of aerospace, the decade’s later half brought a triumph that profoundly, though indirectly, influenced automotive engineering: the breaking of the sound barrier in October 1947. This incredible feat, achieved by Chuck Yeager in the Bell X-1, was not about cars, but it dramatically pushed the boundaries of speed, aerodynamics, and material science, demonstrating engineering prowess that resonated across all high-performance design disciplines, including the automotive sector.

The pursuit of supersonic flight presented unprecedented engineering challenges. Designers and engineers had to contend with phenomena like compressibility, shockwaves, and extreme material stresses that were poorly understood at the time. The solutions developed—ranging from revolutionary wing designs to high-strength, lightweight alloys capable of withstanding immense forces—generated invaluable knowledge in fluid dynamics, structural integrity, and propulsion efficiency. This research, initially focused on aircraft, created a deep well of scientific data applicable to any object moving through air.

For the automotive industry, these advancements, though not immediately translated into specific car features, fostered a heightened awareness of aerodynamic efficiency and the importance of scientific rigor in design. As civilian car production resumed and demand for performance grew in the post-war era, lessons in drag reduction and managing airflow—even at much lower speeds—became increasingly relevant. The sleek, flowing lines that would characterize future automotive designs, aimed at reducing wind resistance and improving fuel economy, owed a conceptual debt to the breakthroughs achieved in supersonic flight.

More broadly, breaking the sound barrier was a monumental psychological and technological achievement. It symbolized humanity’s ability to overcome seemingly insurmountable physical limits through ingenuity and relentless research. This pioneering spirit, coupled with the new understanding of physics and materials, contributed to an overarching ethos of innovation that permeated all engineering fields. It spurred automotive engineers to consider more aggressive designs, advanced materials, and more scientific approaches to vehicle performance, safety, and efficiency, shaping the underlying philosophy of automotive development for generations.

Read more about: From Bold Concepts to Banned Relics: Unpacking 14 Bicycle Innovations That Rode the Line Between Genius and Gaffe

11. **Post-War Industrial Resurgence: Germany and Japan’s Automotive Rebirth**

The 1940s closed with a significant chapter in the global automotive narrative that is often forgotten amidst the grander events of World War II: the nascent, yet critical, industrial resurgence of Germany and Japan. These two nations, utterly devastated by war and under Allied occupation from 1945, represented not just vanquished powers but also former and future giants of the automotive industry. Their forced rebuilding and reorientation away from military production toward civilian goods laid the crucial foundation for their eventual dominance in global car manufacturing.

In both countries, the immediate post-war period was marked by immense hardship and the complete restructuring of their industrial bases. Initial occupation policies aimed at demilitarization, but the need for economic stability and reconstruction quickly led to policies supporting the revival of key industries. For automotive, this meant rebuilding bombed-out factories, retooling machinery, and painstakingly re-establishing supply chains from scratch, often under severe material and financial constraints. It was a Herculean effort that tested the resilience and ingenuity of their engineers and workforce.

Japan’s automotive sector, previously smaller and focused on commercial vehicles, saw companies like Toyota and Honda (which would soon pivot from motorcycles to cars) begin to lay groundwork for mass-producing robust, economical passenger cars for domestic and later, international markets. Similarly, in Germany, iconic brands like Volkswagen, with the enduring Beetle, and Mercedes-Benz painstakingly embarked on their post-war comebacks. These companies leveraged pre-war engineering expertise, adapting it to the new realities of scarcity and the burgeoning demand for affordable, reliable transportation.

This era of rebuilding, though fraught with challenges, was instrumental in forging the identity and future success of these automotive powerhouses. The necessity for efficiency, quality, and adaptability in a constrained environment instilled a rigorous engineering discipline and a focus on cost-effectiveness that would define German and Japanese car manufacturing for decades. The decisions and efforts made in these forgotten years of reconstruction directly enabled them to emerge as formidable, quality-driven competitors, forever altering the landscape of the global automotive industry.

12. **The Atomic Age Begins: Material Science and Engineering Foresight**

The detonation of the first nuclear bomb at the Trinity test site on July 16, 1945, ushered in the Atomic Age, a development seemingly distant from the immediate concerns of automobiles. Yet, this monumental event, alongside the subsequent development of nuclear power, had a profound, albeit often unacknowledged, indirect impact on engineering, material science, and the broader industrial mindset of the post-war era. It represented an unparalleled demonstration of human scientific and engineering capability, inspiring innovation across all sectors, including the automotive industry.

The Manhattan Project, which culminated in the atomic bomb, required unprecedented advancements in metallurgy, physics, chemical engineering, and precision manufacturing. Scientists and engineers pushed the boundaries of what was possible, developing new alloys, understanding material behavior under extreme conditions, and refining manufacturing processes to achieve extraordinary precision and reliability. This concentrated effort generated a wealth of knowledge in fields that, while initially applied to weaponry, held immense potential for civilian industrial applications.

For the automotive world, the dawn of the Atomic Age meant a new horizon for materials research and manufacturing techniques. While direct nuclear propulsion for cars remained a distant dream, the insights gained into high-strength, lightweight, and heat-resistant materials began to trickle down. Automotive engineers, always striving for better performance, fuel efficiency, and safety, started to explore advanced alloys, composites, and more sophisticated production methods, anticipating how these breakthroughs could revolutionize vehicle structures, engine components, and overall durability.

Beyond the technical specifics, the Atomic Age fostered a cultural and industrial ethos of ambitious technological exploration. It underscored the transformative power of science and large-scale R&D. This mindset encouraged investment in innovative problem-solving and a forward-looking approach to design and manufacturing across all industries. The influence might not have been visible in the sedans of the late 1940s, but the scientific and engineering framework established during this era provided the fertile ground for many of the advanced material and design innovations that would define automotive engineering in the decades that followed.

The 1940s, a decade forged in the crucible of conflict and reshaped by its aftermath, emerges not as a barren landscape for automotive development, but as a surprisingly fertile ground for innovation. From the battle-proven versatility of the Jeep to the silent revolution of the transistor, and the global economic architectures that would underpin worldwide trade, the ’40s laid the essential, often forgotten, groundwork for the sophisticated, interconnected automotive world we inhabit today. It was an era where necessity truly proved to be the mother of invention, charting a course for the future of mobility that continues to unfold.