The automotive repair industry, once a realm primarily defined by greasy hands, mechanical intuition, and the distinctive scent of oil and gasoline, is undergoing an astonishing metamorphosis. Today, the landscape of vehicle maintenance and repair is being irrevocably altered by a torrent of technological advancements. This isn’t just about incremental improvements; it’s a wholesale transformation that is shifting the very foundation of what it means to be a mechanic, effectively leaving behind the ‘simple mechanics’ who relied solely on traditional methods and manual prowess.

Indeed, the days when a mechanic could diagnose most issues with a keen ear and a trusty wrench are rapidly becoming a nostalgic memory. Modern vehicles are intricate, rolling computers, packed with sensors, complex systems, and sophisticated software that demand an entirely new skill set and an array of high-tech tools. This profound evolution isn’t just a trend; it’s an imperative for survival and success in an industry increasingly driven by innovation, precision, and efficiency.

This in-depth exploration will delve into the critical technological trends that are revolutionizing auto repair, highlighting how these innovations are making the industry more efficient, accurate, and customer-friendly. We will examine the crucial role technology plays in modern car repairs and underscore why staying abreast of these advancements is absolutely essential for both repair shops and vehicle owners in today’s rapidly evolving automotive world. Prepare to journey into a future where vehicles are smarter, repairs are more precise, and the expertise required is fundamentally digital.

1. **Advanced Diagnostic Tools: The New X-Ray Vision for Vehicles**Gone are the days when car repairs relied solely on manual diagnostics and the mechanic’s best guess. The advent of modern diagnostic tools has drastically improved precision and efficiency in identifying car problems, marking one of the most significant advancements in the industry. These tools provide accurate and efficient diagnostics, moving beyond time-consuming and often inaccurate manual troubleshooting methods that once defined the trade.

Today, technicians have access to a range of computerized diagnostic tools that can quickly pinpoint issues with remarkable accuracy. These sophisticated systems can plug directly into a vehicle’s onboard diagnostics system (OBD-II), allowing technicians to read trouble codes and get a detailed look into the car’s health. With scanners and software that communicate with the car’s internal systems, issues that once took hours to find can now be identified in minutes, improving efficiency and minimizing customer wait times.

These advanced tools are capable of scanning various systems and components, gathering data, and generating comprehensive reports, aiding in swift and effective repairs. They utilize advanced sensors that collect critical data from a vehicle’s systems, monitoring parameters such as engine performance, emissions, and fluid levels. This capability allows for faster and more accurate diagnoses, reducing repair times and costs, and ultimately enhancing overall customer satisfaction.

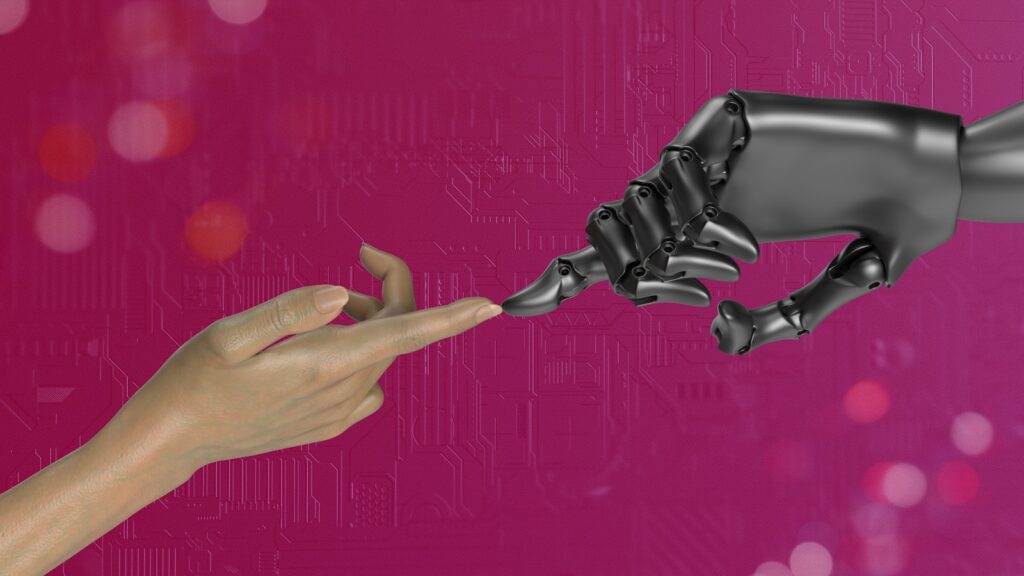

2. **The Role of Artificial Intelligence (AI): The Brain Behind the Diagnosis**Artificial Intelligence (AI) is making significant inroads into the auto repair sector, fundamentally changing how repairs are diagnosed, executed, and managed. AI-driven diagnostic systems represent a profound shift, moving beyond mere data collection to intelligent analysis. These systems are designed to analyze data patterns and predict potential issues before they become serious problems, essentially providing proactive car care.

These AI systems learn from each repair, continuously improving their accuracy by analyzing vast amounts of data quickly and efficiently. AI algorithms can detect patterns and correlations in vehicle performance, allowing mechanics to make informed decisions about repairs. This technology reduces the margin for error, ensuring that diagnoses are more precise and that technicians can quickly identify complex problems by analyzing vast amounts of data and providing recommendations based on patterns and historical information.

Additionally, AI can assist in managing inventory, scheduling maintenance, and even suggesting repair solutions, making the entire process more efficient. Predictive maintenance, driven by AI algorithms, enables proactive car care by analyzing data from various sensors and identifying potential issues before they escalate. This proactive approach not only prevents major repairs but also extends the lifespan of the vehicle, ensuring better outcomes for both mechanics and customers.

3. **Augmented Reality (AR) in Repairs: A Digital Overlay for Real-World Precision**Augmented Reality (AR) is emerging as a powerful tool in auto repair, providing a transformative experience for technicians. This cutting-edge technology overlays digital information onto the physical world, offering real-time guidance during repairs. Imagine a mechanic wearing AR glasses, seeing step-by-step instructions or having specific parts highlighted directly in their field of view.

This technology enhances precision and significantly reduces the likelihood of errors, especially in complex repairs, by enabling remote diagnostics and troubleshooting. Through AR applications, technicians can collaborate with remote experts, who can overlay instructions, diagrams, and annotations onto the technician’s field of view, facilitating accurate repairs. This collaborative aspect is a game-changer for intricate and specialized tasks.

AR technology not only accelerates the repair process but also ensures a higher degree of accuracy, minimizing rework and improving the overall quality of service. For technicians, it’s like having an expert looking over their shoulder, providing precise, context-aware information exactly when and where it’s needed. This allows for a more confident and efficient execution of tasks, even for those less familiar with a particular vehicle model.

4. **Connectivity and Remote Diagnostics: Vehicles That Talk to the Shop**The rise of connected vehicles has paved the way for remote diagnostics, marking another revolutionary stride in auto repair. Modern cars, equipped with Internet of Things (IoT) sensors, can communicate directly with repair shops, transmitting data about their condition. This means your vehicle isn’t just a machine; it’s a sophisticated data-generating hub that can ‘call home’ when something is amiss.

This connectivity allows for real-time monitoring and early detection of issues, enabling timely maintenance before a minor problem escalates into a major breakdown. Telematics systems, which collect data on how a vehicle is driven—including acceleration, braking, fuel usage, and engine performance—can share this information with auto repair centers. This helps shops understand what might be wrong with a vehicle even before it physically arrives.

Remote diagnostics further facilitate a new level of convenience, where technicians can assess problems without the vehicle being physically present at the shop. This is particularly useful for fleet services or companies managing a large number of vehicles, allowing for preventive maintenance and helping in planning repair schedules with minimal disruption. It’s a proactive approach that ensures vehicles remain safe, efficient, and reliable by addressing potential issues preemptively.

Read more about: Tech Geek’s ‘Unknown’ Code: Unlock Your Car’s Hidden Menu Instantly Without Ever Visiting the Dealership

5. **Electric and Hybrid Vehicle Challenges: A New Frontier of Expertise**The shift towards electric and hybrid vehicles (EVs) introduces entirely new challenges and, importantly, new opportunities for the auto repair industry. These environmentally friendly vehicles operate on fundamentally different systems compared to traditional combustion engines. Consequently, they require specialized knowledge and equipment for maintenance and repairs, moving far beyond the mechanical expertise of the past.

Technicians now need to be extensively trained to handle high-voltage systems, understand battery management, and diagnose the intricacies of electric drivetrains and regenerative braking systems. This is not merely an extension of existing skills but an acquisition of entirely new ones, often involving safety protocols for working with high-voltage components. Repair shops are adapting by investing in the necessary tools, such as specialized diagnostic equipment for EV batteries, and robust training programs to service these vehicles effectively.

Embracing this growing segment of the automotive market is crucial for any repair shop aiming for long-term success. As EVs gain popularity, the demand for EV-specific repair expertise will only grow. Shops that invest in this knowledge and technology are setting themselves apart, positioning themselves to attract a new customer base and remain relevant in an evolving automotive landscape that champions sustainability.

Read more about: Consumer Alert: 12 SUVs Prone to Expensive Mechanical Issues Early in Their Lifespan

6. **The Importance of Software Updates: Keeping Vehicles Current and Secure**As vehicles become more akin to computers on wheels, software updates play an increasingly crucial role in their maintenance and performance. Manufacturers regularly release updates to improve performance, fix bugs, enhance safety features, and even introduce new functionalities. Just like your smartphone or computer, your car’s operating system needs routine attention.

Keeping the vehicle’s software up-to-date is absolutely essential for optimal functioning, security, and sometimes, even recall compliance. These updates can address everything from engine management and infotainment system glitches to crucial safety system enhancements. Neglecting software updates can lead to suboptimal performance, vulnerabilities, or even malfunctions that were not present in the original design.

This trend emphasizes the need for repair shops to stay current with the latest software tools and protocols. Technicians must be capable of performing these updates accurately, often requiring specialized diagnostic equipment and manufacturer-specific software interfaces. The ability to manage and implement software updates effectively is now a fundamental skill, transforming the auto repair shop into a vital nexus for vehicle digital health.

Read more about: Drive Safer and Smarter: The 12 Essential Car Software Updates for Enhanced Security and Performance

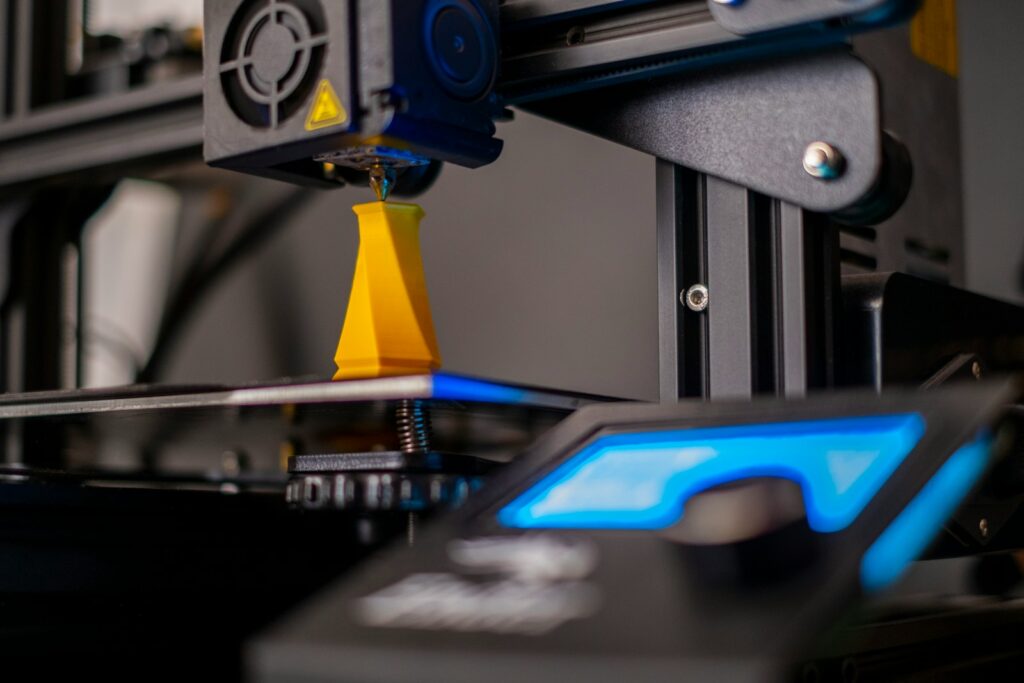

7. **3D Printing for Parts Replacement: Manufacturing on Demand**3D printing technology is starting to make significant waves in the auto repair industry by enabling the quick and often custom production of parts. This innovation addresses a common pain point: the availability of specific or rare components. If a specific part is hard to find, out of production, or would take an extended time to ship, mechanics can now 3D-print the required component right in the shop.

This capability can be a game-changer, particularly for vintage vehicles, unique models that require rare parts, or even custom modifications. It significantly reduces wait times for parts that may be difficult to source, improving turnaround times for repairs. The ability to quickly design and print components enhances service offerings and dramatically cuts down on the logistical headaches associated with traditional parts sourcing.

Not only does 3D printing cut down on wait times for shipping, but it can also reduce the overall cost of repairs by minimizing inventory management expenses and shipping fees. As 3D printing technology becomes more accessible, sophisticated, and cost-effective, it has the potential to revolutionize how parts are sourced, produced, and used in auto repair, streamlining operations and improving customer satisfaction through faster and more flexible solutions.

Now, let’s continue our journey into the digital revolution of auto repair, exploring how these powerful technological shifts are not just changing the tools mechanics use, but fundamentally reshaping shop operations, elevating the customer experience, and transforming how technicians are trained. The focus here is on the intricate ways digital solutions integrate into the daily fabric of the automotive service world, making it smarter, more responsive, and more future-proof. These advancements underscore why staying abreast of technological trends is absolutely essential for both repair shops and vehicle owners in today’s rapidly evolving automotive landscape, ensuring better outcomes for all involved.

8. **The Rise of Mobile and On-Demand Services: Bringing the Shop to Your Driveway**Convenience is undoubtedly one of the most significant drivers of change across many industries, and auto repair is no exception. Modern life often leaves little room for time-consuming trips to the repair shop, which is why the rise of mobile repair units and on-demand services has become a game-changer. These innovative services are designed to bring the repair shop directly to the customer, offering unparalleled flexibility and time-saving solutions. For residents seeking auto repair in locations like Salt Lake City, UT, such services offer the convenience of professional repairs without the need to visit a physical shop.

Imagine the ease of having routine maintenance, minor repairs, or even a diagnostic check performed right in your driveway, office parking lot, or wherever your vehicle may be experiencing an issue. This model eliminates the need for customers to arrange transportation or spend hours in a waiting room. It’s a paradigm shift from the traditional brick-and-mortar approach, catering to the demands of a fast-paced world and significantly enhancing the customer experience by minimizing disruption to their day.

For auto repair shops, embracing mobile and on-demand services offers a unique competitive advantage. It allows them to extend their reach beyond their physical location, tap into new customer segments, and provide a truly customer-centric service. Equipping mobile units with advanced diagnostic tools, essential repair equipment, and skilled technicians transforms the concept of the repair shop into a flexible, adaptable entity that meets customers where they are, when they need it most.

9. **Automated Inventory and Parts Management: The Digital Backbone of Efficiency**Managing an extensive inventory of automotive parts has historically been one of the more intricate and time-consuming aspects of running a successful auto repair business. The challenge lies in balancing the need to have critical parts readily available with the costs associated with stocking a wide array of components. Thankfully, cloud-based systems and sophisticated automated inventory management tools are revolutionizing this critical operational area.

These advanced systems provide real-time visibility into stock levels, track parts usage, and can even trigger automatic reorders when supplies begin to run low. This proactive approach ensures that essential components are always in stock, minimizing delays in repairs due to unavailable parts. By optimizing inventory, shops can reduce carrying costs, prevent waste from obsolete stock, and ultimately improve their bottom line through more efficient resource allocation.

The ability to accurately track the availability of specific components in real-time dramatically improves workflow efficiency. Technicians can quickly confirm if a needed part is on hand or if it needs to be ordered, streamlining the repair process from diagnosis to completion. This digital backbone not only saves countless hours typically spent on manual inventory checks but also ensures that repair jobs don’t get held up due to missing or misplaced components, enhancing overall productivity and customer satisfaction.

10. **Cloud-Based Repair Management Systems: The Central Nervous System for Modern Shops**The modern auto repair business demands more than just mechanical prowess; it requires sophisticated operational management. Many forward-thinking auto repair businesses are making a strategic transition to cloud-based software platforms that serve as the central nervous system for their entire operation. These comprehensive systems are designed to streamline a vast array of tasks, moving beyond simple invoicing to encompass customer relationship management, work order tracking, and detailed performance analysis.

The beauty of a cloud-based system lies in its accessibility and flexibility. Shop owners, service managers, and technicians can access crucial information from virtually anywhere, whether it’s on a desktop computer, a tablet on the shop floor, or even a smartphone. This real-time data tracking and management capability allows for unprecedented oversight and control, enabling agile decision-making and fostering a more responsive and efficient work environment.

These intelligent platforms integrate various facets of the business, from initial customer inquiry and appointment scheduling to repair completion and payment processing. They centralize customer data, vehicle history, and service records, providing a holistic view that enhances personalized service and long-term customer relationships. By connecting every part of the repair process, cloud-based systems significantly reduce administrative burdens, allowing staff to focus more on vehicle service and less on paperwork.

Furthermore, cloud systems provide invaluable insights into business performance, technician productivity, and customer satisfaction metrics. The data gathered can be analyzed to identify trends, pinpoint areas for improvement, and inform strategic growth initiatives. This data-driven approach empowers repair shops to continuously refine their services, optimize their operational efficiency, and ultimately drive sustainable growth in a highly competitive market, earning them the respect and repeat business they seek.

11. **Augmented Reality and Virtual Training for Technicians: Mastering the Future of Repair**While Augmented Reality (AR) is already proving its worth in guiding real-time repairs, its impact on technician training and education is equally, if not more, transformative. The complexities of modern vehicles, with their constantly evolving technologies and intricate systems, necessitate a continuous learning curve for automotive service technicians. This is where AR and Virtual Reality (VR) are truly revolutionizing how mechanics acquire and refine their skills.

These cutting-edge technologies offer immersive, hands-on learning experiences without the need for a physical vehicle, or even specific parts, in every training scenario. Imagine a technician donning AR glasses or a VR headset and stepping into a virtual workshop. They can practice disassembling and reassembling complex engines, diagnosing intricate electrical faults, or learning the layout of a brand-new car model, all within a safe, simulated environment.

Through AR, digital overlays can provide step-by-step guides directly in a technician’s field of vision during training, highlighting components, showing torque specifications, or displaying procedural animations in real-time. This interactive and context-aware instruction significantly speeds up the learning curve for new technicians and ensures a higher degree of consistency and accuracy in repair practices across the entire team. It’s like having an expert instructor constantly by their side, providing precise, context-aware information exactly when and where it’s needed.

For workshops, the adoption of AR/VR training tools translates directly into fewer errors, better-trained and more confident staff, and ultimately, improved customer outcomes. It allows for cost-effective training on a wider range of vehicle models and technologies, ensuring that the workforce is always up-to-date with the latest advancements. This commitment to advanced training not only elevates the skill set of individual mechanics but also enhances the overall reputation and service quality of the repair shop in a rapidly changing automotive landscape.

Final Thoughts

The journey through the evolving landscape of auto repair reveals an industry not just adapting, but actively embracing the digital age. From the surgical precision of advanced diagnostic tools to the immersive training offered by augmented reality, and from the seamless efficiency of cloud-based management systems to the transparent communication facilitated by mobile apps, technology is redefining every facet of vehicle maintenance and repair. The ‘simple mechanics’ of yesteryear are being replaced by highly skilled technicians fluent in complex software, data analysis, and digital collaboration, showcasing that the future of auto repair promises to be exciting and filled with opportunities.

This transformation is more than just a trend; it’s an imperative for survival and success. Repair shops that invest in these innovations are not only boosting their efficiency and accuracy but are also significantly enhancing the customer experience, fostering trust, and building lasting relationships. As vehicles continue their rapid evolution, becoming smarter, more connected, and increasingly electric, the symbiotic relationship between human expertise and cutting-edge technology will remain the bedrock of a thriving auto repair industry. The future of auto care is undoubtedly digital, promising a path forward that is faster, more reliable, and ultimately, more satisfying for everyone on the road. Whether in Salt Lake City, UT, or anywhere else, staying informed about these changes ensures you’re better prepared for the road ahead.