The term “high” permeates our language and understanding, describing a multitude of states, attributes, and conditions. From physical elevation to abstract concepts like value or importance, “high” signals a departure from the average, often implying a greater degree, intensity, or complexity. In the realm of intricate systems and demanding scenarios, understanding these various dimensions of “high” is not merely an academic exercise; it is a critical “buyer beware” primer, essential for anticipating the operational realities and potential “maintenance headaches” that accompany elevated characteristics. As seasoned analysts of performance and longevity, we recognize that what is “high” in one aspect often has ripple effects, influencing the demands placed upon an entire entity.

The automotive sector, though not explicitly detailed here, often presents vivid examples of how initial perceptions of “high” attributes – be it performance, luxury, or advanced technology – invariably lead to “high” expectations for ongoing care. The principles we explore, however, are universal, applying to any system where complexity, intensity, or value are elevated. Our objective is to dissect the multifaceted nature of “high,” providing a structured framework for identifying the inherent signals that foreshadow an increased need for vigilance, specialized attention, and potentially significant resource allocation to ensure sustained functionality and mitigate unforeseen complications.

This analytical journey will illuminate how various “high” characteristics, as defined within the comprehensive linguistic breakdown of the term, invariably point towards scenarios that are, by their very nature, more demanding to sustain. We will explore how these specific attributes act as indicators, demanding a deeper understanding and a more proactive approach to what we might colloquially term “maintenance.” By dissecting these initial six core conceptual facets, we aim to equip the discerning individual with the foresight necessary to navigate the landscape of elevated expectations and inherent challenges.

1. High Costs: The Inevitable Partner of Elevated Value

When we encounter systems or entities described by “high prices,” “high interest rate,” or generally “greater than normal in degree, intensity, or amount high prices,” we are immediately alerted to a fundamental aspect of ‘high’: its direct correlation with financial outlay. This isn’t merely about the initial acquisition cost; it extends to the ongoing financial commitments required to sustain the perceived value or function of the item. A “high” cost often signifies advanced engineering, premium materials, or specialized functionality, each of which inherently dictates a particular standard of care and expenditure for its upkeep.

Understanding the implications of “high costs” goes beyond simple budgetary allocation. It involves recognizing that components, expertise, and replacement parts associated with a “high-priced” system are likely to carry a proportional premium. This is a critical “buyer beware” insight: the initial financial barrier is often just the first in a series of elevated expenses that will define the ownership experience. The expectation that a “high-value” system will operate flawlessly without corresponding “high” investment in its maintenance is a common pitfall.

Indeed, the very definition of “high” in this context — “greater than normal in degree, intensity, or amount” — applies to the ongoing financial “drain” just as much as it does to the initial expenditure. For any system boasting “high” attributes, one must anticipate a “high” demand for resources to maintain its integrity, functionality, and, crucially, its inherent “value.” This fundamental principle underscores the importance of a holistic financial assessment, extending far beyond the point of purchase, to truly understand the long-term implications of engaging with something that is “high” in its economic dimension.

2. High Complexity: Navigating the Intricacies of Advanced Design

The concept of “high” also extends to the realm of development and intricacy, as evidenced by terms like “advanced in complexity or development high finance” or references to “high things” and “high thinking.” When a system achieves a “high” level of complexity, it inherently introduces a greater number of interdependent variables and specialized components. This elevation in design sophistication, while often delivering superior capabilities or functions, simultaneously creates an environment ripe for “maintenance headaches” if not approached with an equally “high” degree of understanding and precision.

An advanced or “highly” developed system, by its very nature, demands a more nuanced diagnostic and repair methodology. The straightforward troubleshooting applicable to simpler designs becomes inadequate when confronted with intricate networks of functionality. This is where the “buyer beware” warning resonates most strongly: the allure of “high” development often masks the underlying reality of increased susceptibility to cascading failures and the necessity for highly specialized technical expertise, which itself is often a “high” commodity.

Furthermore, the maintenance of “high complexity” systems often requires not just repair, but a continuous process of calibration, software updates, and precise adjustments. The “high” level of integration means that an issue in one seemingly minor component can affect multiple functions, leading to obscure symptoms and prolonged diagnostic periods. This calls for a commitment to “high” technical literacy or access to expert services, making the ongoing operational phase a significant undertaking that extends far beyond the initial procurement. The promise of advanced performance comes with the implicit contract of advanced care.

3. High Voltage/Frequency: Managing Power and Operational Rhythm

Within the lexicon of “high,” we find descriptors such as “of large or relatively large numerical value high frequency high voltage.” These terms pinpoint characteristics that speak to the fundamental operational dynamics of many systems. “High voltage” signifies a substantial electrical potential, carrying inherent risks and demanding specialized handling, insulation, and safety protocols. Similarly, “high frequency” implies rapid operational cycles or data transfer rates, putting stress on components and requiring precise timing and robust materials for sustained performance.

The presence of “high voltage” components within a system immediately signals a heightened need for safety-conscious maintenance procedures. Errors in handling or inadequate insulation can lead to dangerous failures, emphasizing a “buyer beware” for those not equipped with the appropriate training or tools. The demands of “high voltage” are not confined to safety; they also dictate the quality and durability of connecting elements and the overall electrical architecture, all of which contribute to the long-term “maintenance” profile.

“High frequency” operations, on the other hand, impose different but equally significant stresses. Rapid cycles lead to increased thermal loads, accelerated wear on moving parts, and a greater susceptibility to timing discrepancies. Systems operating at “high frequency” often require more frequent calibration and component replacement to prevent degradation of performance or outright failure. The “high” rate of activity translates directly into a “high” rate of resource consumption and component fatigue, making proactive, rather than reactive, maintenance not just advisable, but essential to avoid significant “headaches.”

4. High Standards: The Unyielding Demand for Excellence in Upkeep

The adjective “high” also conveys a sense of eminence, quality, or excellence, as seen in phrases like “exalted in style or character; elevated high drama” or “of great eminence; very important the high priestess.” When an entity or system is associated with “high standards,” it implies an inherent expectation of superior performance, meticulous finish, and enduring quality. This expectation, while desirable, often translates directly into “high” demands for its continuous maintenance and care, creating a distinctive profile of challenges.

Maintaining a system to “high standards” means that any deviation from optimal performance or aesthetic perfection becomes immediately noticeable and unacceptable. This implies a level of vigilance and precision in upkeep that far exceeds that required for more mundane items. The “buyer beware” here is a recognition that the initial promise of “high” quality necessitates a perpetual commitment to sustain that quality, which can be both time-consuming and resource-intensive.

Furthermore, the very components and materials chosen for a “high-standard” system are often selected for their superior attributes, which may also mean they are rarer, more specialized, or more costly to replace or repair. The pursuit of “high” excellence in design and function is an ongoing journey that does not end at procurement; it rather initiates a long-term relationship with “high” expectations for diligent and expert maintenance. The integrity of a “high-standard” system rests entirely on the unwavering commitment to its continuous, elevated care.

5. High Intensity: Enduring the Force of Extreme Conditions

The word “high” frequently denotes a peak state or extreme degree, as exemplified by “high (i.e. intense) heat,” “high (i.e. full or quite) noon,” or “high (i.e. deep or vivid) colour.” When a system operates under or is exposed to “high intensity” conditions—be it extreme temperatures, powerful forces, or rigorous usage—it experiences accelerated wear and tear. This inherent stress demands a corresponding “high” level of durability from its components and a more frequent, thorough “maintenance” regimen to preserve its operational integrity.

A system designed for “high intensity” applications, or one that is habitually subjected to them, inevitably faces a greater risk of component fatigue, material degradation, and structural failure. The “high” degree of operational stress means that what might be considered routine wear in a less intensive environment becomes a critical “maintenance headache” in such scenarios. “Buyer beware” applies here to the understanding that while “high intensity” can denote robust design, it equally signals a future demanding sustained and often specialized care to counteract the effects of relentless operation.

The “high” degree of “intensity” also dictates the very nature of preventive maintenance. Inspections must be more rigorous, component lifecycles are often shorter, and the need for precision in replacement or repair is elevated. To maintain performance under “high intensity,” one cannot afford to be lax; every element must function optimally. This constant battle against the forces of operational wear and tear underscores a fundamental truth: the more “intense” the operational environment, the more “intensive” the required maintenance will be, posing ongoing challenges for system longevity.

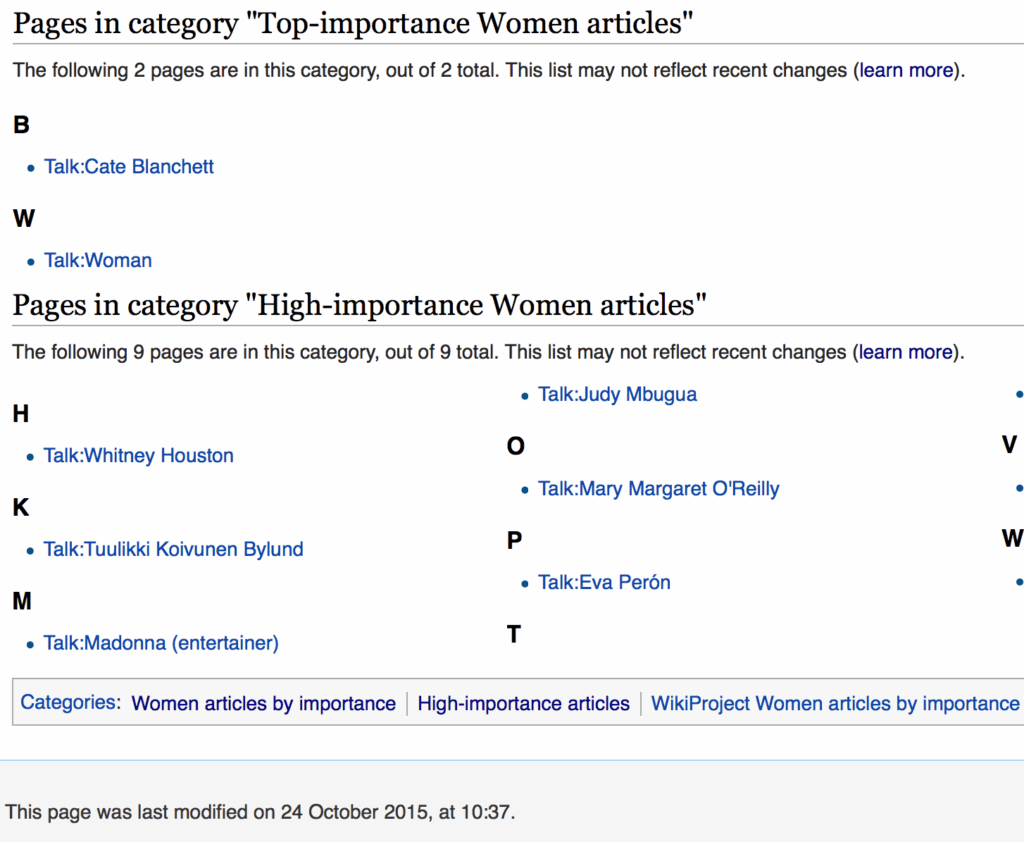

6. High Importance/Consequence: Ensuring Reliability Where Stakes Are Elevated

Finally, the term “high” signifies great importance and consequence, as in “high crimes” or “the high festival of the sun.” When a system’s function is deemed of “high importance” or its failure carries “high consequences,” the imperative for absolute reliability and flawless operation becomes paramount. This elevated significance profoundly impacts its “maintenance” profile, necessitating a proactive, rigorous, and often redundant approach to ensure uninterrupted functionality and mitigate any risk of failure-induced “headaches.”

For systems where “high importance” is a defining characteristic, the cost of downtime or malfunction is not merely financial; it can involve safety, critical operations, or significant reputational damage. This immediately elevates the “maintenance” strategy from reactive repairs to a sophisticated regime of preventive checks, predictive analytics, and often, scheduled overhauls. The “buyer beware” message here emphasizes that acquiring or operating such a system means inheriting a “high” degree of responsibility for its continuous, faultless operation.

The very “high” stakes involved mean that “maintenance” cannot be an afterthought; it must be a core operational pillar, integrated from design to decommissioning. This often entails “high” quality assurance, “high” levels of redundancy, and continuous monitoring to detect the slightest anomaly before it escalates. The demand for “high” reliability in “high consequence” scenarios intrinsically leads to a “high” investment in maintenance, both in terms of resources and unwavering attention, to safeguard against any potential for operational disruption.

Having laid the groundwork with the initial dimensions of ‘high,’ we now pivot to the more advanced facets, which collectively form the complete picture of what it truly means for something to be ‘high-maintenance.’ These characteristics move beyond foundational attributes, delving into nuanced implications that demand a sustained, elevated level of attention and specialized upkeep. As we explore these remaining six facets, the ‘buyer beware’ message becomes even more pronounced, guiding us toward a comprehensive understanding of the proactive management required to mitigate future operational ‘headaches.’

The evolution of technology and engineering continually pushes boundaries, and with each leap, the intrinsic demands on ownership and care also escalate. This section dissects how qualities like status, fidelity, raw performance, inherent risk, and the very concept of ‘pressure’ contribute to a system’s overall maintenance profile. Ultimately, we converge on ‘high-maintenance’ as a definitive characteristic, not merely a descriptor but a fundamental operational reality.

7. High Status/Rank: The Burden of Exalted Expectation

When a system or entity is described as possessing “high status,” or “exalted in style or character,” this isn’t merely a point of prestige; it inherently dictates an elevated expectation for its ongoing presentation and functionality. Such items, much like “the high priestess” or “high officials of the court,” carry a certain gravitas that demands meticulous preservation and often, a bespoke approach to their care. The very act of ownership or operation becomes a commitment to upholding this perceived eminence.

Maintaining something of “high status” often means that standard, off-the-shelf solutions are insufficient. Components might need to be sourced from specialized suppliers, or repairs might require artisans trained in specific, often traditional, methods. Any visible imperfection or operational lapse can be seen as a direct detraction from its inherent value, pushing maintenance routines into a realm of obsessive detail and costly intervention. This contributes significantly to the ‘high-maintenance’ reality.

For the discerning individual, the “buyer beware” in this context is paramount: the initial allure of “high status” comes with an implicit, often substantial, long-term investment. This investment is not just financial, but also in the time and effort required to ensure that the item consistently meets the exacting, sometimes unspoken, standards associated with its elevated position. The upkeep of status is a continuous, resource-intensive endeavor.

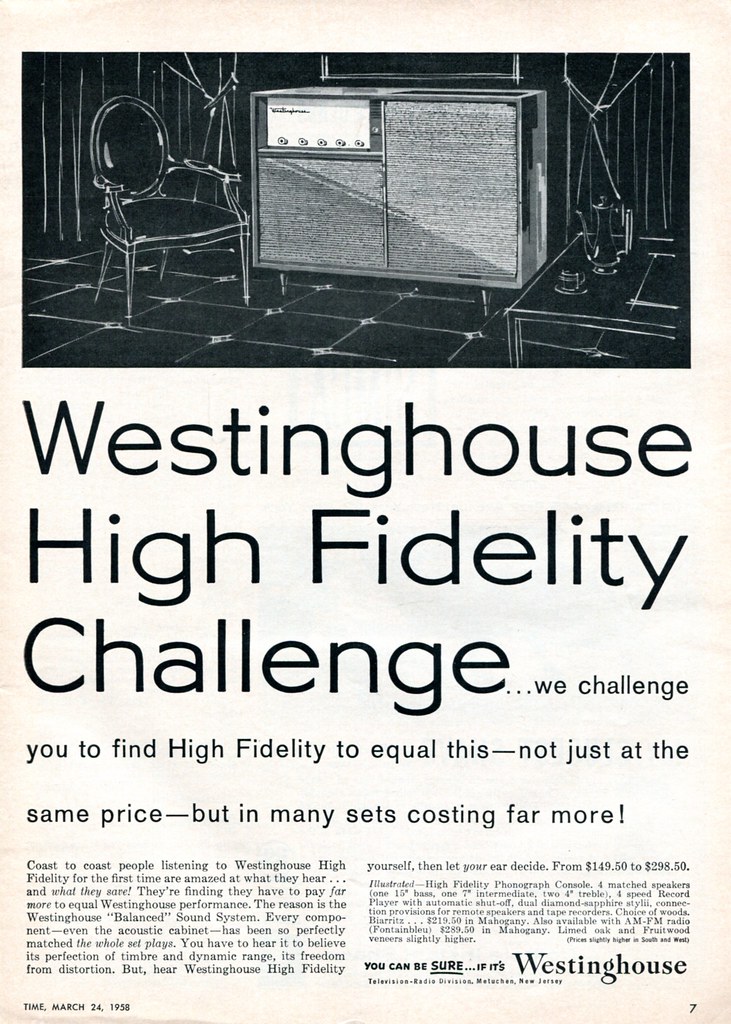

8. High Fidelity: Precision as an Operational Imperative

The concept of “high fidelity,” derived from ‘high’ indicating a supreme degree or culmination of quality, speaks to the exactness and faithfulness with which a system performs its intended function. It implies an adherence to precise standards, where any deviation from optimal output is immediately noticeable and, more often than not, unacceptable. This pursuit of accuracy and purity in function intrinsically elevates the maintenance requirements.

In systems designed for “high fidelity,” components are often engineered to extremely tight tolerances, and their interaction is precisely calibrated. Sustaining this level of exactness demands continuous monitoring, frequent calibration, and the immediate correction of even minor discrepancies. The wear and tear that might be negligible in a lower-fidelity system can severely compromise the output of a high-fidelity one, making proactive and precise interventions critical.

The “buyer beware” aspect for “high fidelity” is twofold: first, the initial cost reflects this engineering precision, and second, the ongoing cost reflects the continuous effort to preserve it. Repairs or replacements must match the original exactness, often requiring specialized tools, diagnostic equipment, and highly skilled technicians. Compromising on this continuous quest for accuracy directly undermines the very essence of its “high fidelity” design.

9. High Performance: The Demands of Sustained Peak Output

When we speak of “high performance,” we refer to systems operating at the “utmost extent or culmination” of their capabilities, designed to deliver exceptional output, speed, or efficiency. While incredibly desirable, this inherent characteristic inevitably places extraordinary stress on all constituent parts. Achieving and, more critically, *sustaining* such elevated levels of performance is a perpetual challenge that directly translates into a “high-maintenance” profile.

Systems engineered for “high performance” often push materials and components to their operational limits. This leads to accelerated rates of wear, increased thermal loads, and greater susceptibility to fatigue. The margins for error are significantly reduced; even minor degradation in a component can have a cascading effect, jeopardizing the entire system’s ability to maintain its “high” output. This mandates a robust schedule of inspections and preventative replacements.

For those seeking “high performance,” the “buyer beware” is a recognition that the initial thrill of superior capability comes with a contract for continuous, demanding care. This includes using premium-grade consumables, adhering to strict service intervals, and immediately addressing any indicators of declining efficiency. The unwavering commitment to maintain optimal tuning and component integrity is essential, making proactive diligence the cornerstone of ownership.

Read more about: Unleash the Beasts: 14 Legendary American Cars That Roared Through the 1960s, Forging an Unforgettable Automotive Decade

10. High Risk: Mitigating the Potential for Catastrophic Failure

The descriptor “high risk” signifies situations where the probability or severity of adverse outcomes is elevated, making the consequences of system failure particularly dire. When a system’s operation is intrinsically linked to such scenarios, its maintenance profile shifts from routine upkeep to a mission-critical imperative. The stakes involved are “of great importance and consequence,” compelling an exhaustive approach to ensure uninterrupted functionality.

In a “high-risk” environment, maintenance is not merely about extending lifespan; it is fundamentally about preventing catastrophic events. This necessitates not only robust design and engineering but also a comprehensive strategy for redundancy, fail-safes, and continuous, real-time monitoring. Every potential point of failure must be identified, assessed, and proactively mitigated, transforming maintenance into a highly analytical and preventative science.

The “buyer beware” message for “high-risk” systems emphasizes that the cost of failure far outweighs the cost of prevention. This translates into substantial investments in specialized diagnostics, stringent quality control for replacement parts, and the training of highly skilled personnel who can operate and maintain the system under the most demanding conditions. The commitment to meticulous, often over-engineered, maintenance is a non-negotiable aspect of managing high risk.

11. High Pressure: The Stress of Demanding Operational Environments

The term “high pressure” can denote a demanding operational environment or significant internal system pressures, aligning with ‘high’ meaning “greater than normal in degree, intensity, or amount.” Whether referring to extreme external forces, rigorous deadlines, or internal system dynamics like “high-pressure liquid chromatography,” this characteristic inherently places intense stress on components, demanding specialized design and an equally intense maintenance approach.

Systems operating under “high pressure” conditions are continually subjected to forces that can lead to accelerated material fatigue, deformation, or structural failure. Gaskets, seals, and structural elements are particularly vulnerable, necessitating materials with exceptional durability and design tolerances far exceeding those of conventional systems. This relentless operational stress demands a proactive maintenance regimen focused on integrity and early detection of wear.

The “buyer beware” for “high pressure” applications underscores that small compromises can lead to dramatic failures. Maintenance involves not just routine checks but often requires specialized non-destructive testing, precise component replacement, and strict adherence to manufacturer specifications. The vigilance required to sustain integrity under constant pressure is significant, making consistent, expert attention crucial for long-term reliability and safety.

Read more about: Are Electric Trucks Worth It? A Driver’s Honest Review of the Electrifying Road Ahead

12. ‘High-Maintenance’ as a Definitive Characteristic: Embracing the Demands

Finally, we arrive at “high-maintenance” itself—a derived term that encapsulates the culmination of all the preceding “high” facets. This isn’t a pejorative label, but rather a definitive characteristic signaling an inherent reality: the system requires a continuous, significant investment of time, expertise, and resources to sustain its intended performance, value, or state. It is a design choice, an operational necessity, and a testament to its inherent elevated nature.

A system deemed “high-maintenance” is one whose design, function, or operational context inherently demands more than average attention. This could be due to its complexity, the precision required for its fidelity, the intensity of its operation, or the consequences of its failure. Understanding this characteristic from the outset allows for informed decision-making, shifting the perspective from unexpected burden to anticipated operational reality.

For any discerning individual, the ultimate “buyer beware” concerning “high-maintenance” is to fully acknowledge and prepare for this commitment. It means budgeting not just for acquisition, but for a lifecycle of specialized care, expert intervention, and often, continuous upgrades. Embracing this characteristic is about adopting a proactive management philosophy, ensuring that the elevated demands are met with equally elevated dedication to preserve the system’s integrity and extend its functional life.

Ultimately, the journey through these various dimensions of ‘high’ reveals a singular, overarching truth: elevated attributes, while offering superior capabilities or prestige, are intrinsically linked to an elevated requirement for sustained care. Whether it’s the sheer cost, the intricate design, the operational rhythm, or the very stakes involved, each facet of ‘high’ serves as a clear indicator, a red flag not of fault, but of an inherent demand. Approaching any purchase or operational scenario with this comprehensive understanding of ‘high’ transforms potential ‘headaches’ into manageable, albeit significant, responsibilities, ensuring longevity and sustained value in a world that increasingly values the extraordinary.