When you’re in the market for a pickup truck, especially one intended for real work, the conversation often revolves around engine power, towing capacity, and luxurious cabin features. Yet, one of the most vital, often-overlooked aspects of a truck’s performance and longevity lies beneath its robust exterior: the suspension system. Its ability to maintain a level stance and a stable ride under significant weight is not just about comfort; it’s absolutely critical for safety, control, and the long-term durability of your vehicle.

Some trucks are meticulously engineered to shrug off heavy payloads with impressive ease, demonstrating a remarkable resilience that keeps them poised and predictable on the road. These are the workhorses that inspire confidence, regardless of whether they’re hitched to a massive trailer, loaded with construction materials, or simply carrying substantial cargo. Unfortunately, not all popular models live up to this standard, with many revealing glaring design flaws in their suspension that lead to noticeable, and often dangerous, sagging when pushed even slightly beyond light-duty tasks.

This in-depth article is designed as a crucial guide for consumers, dissecting the performance of several best-selling pickups that, once loaded with as little as 500 pounds, can transform from capable haulers into precarious “suspension sinks.” Drawing from rigorous testing data and expert observations, we aim to arm you with the precise, factual information you need to make an informed purchasing decision. Understanding which trucks might leave you literally dragging your heels—and why—can save you considerable money, frustration, and potential safety hazards down the road.

1. **Ford F-150 (2015–2020)**The Ford F-150, particularly models from 2015 to 2020, has carved out a reputation for delivering a comfortable ride and commendable fuel efficiency, appealing to a broad spectrum of drivers. However, beneath this appealing façade, its suspension system often reveals inherent weaknesses when confronted with substantial loads, particularly in its base configurations. This issue becomes strikingly apparent as the truck tends to sag noticeably, even when carrying payloads that might seem well within its advertised capabilities or when towing trailers.

Despite the innovative use of an aluminum body to reduce overall vehicle weight—a move intended to enhance both performance and efficiency—the underlying suspension components in these specific F-150 generations lack the robust stiffness and reinforcement found in more heavy-duty counterparts. This design choice, while contributing to a smoother daily driving experience, ultimately compromises the truck’s ability to handle significant weight without significant compromise. The resulting sagging is not merely a cosmetic concern; it actively degrades the truck’s ride quality, negatively impacts braking performance by altering weight distribution, and severely diminishes overall stability, a risk that escalates considerably at highway speeds.

Owners of these F-150 models frequently find themselves turning to a variety of aftermarket solutions to mitigate these suspension shortcomings, such as installing helper springs or airbags. While these modifications can certainly improve load-bearing capabilities, they represent an additional, often unexpected, investment required to bring the truck up to a standard of consistent heavy-hauling performance. In essence, while the F-150 of this era excels at daily driving and lighter-duty tasks, its stock suspension system falls short for users who demand reliable and consistent performance when carrying significant weight right off the dealership lot.

Car Model Information: 2014 Ford F-150 XLT

Name: Ford F-Series

Caption: 2022 Ford F-150 Lariat Luxury

Manufacturer: Ford Motor Company

Aka: Ford Lobo (Mexico, 1992–present)

Production: 1948–present

Class: Pickup truck#Full-size pickup truck

Layout: Front-engine, rear-wheel-drive layout,rear-wheel drive

Predecessor: 1941 Ford

Categories: All-wheel-drive vehicles, All Wikipedia articles written in American English, All articles that may contain original research, All articles with unsourced statements, Articles that may contain original research from September 2020

Summary: The Ford F-Series is a series of light-duty trucks marketed and manufactured by the Ford Motor Company since model year 1948 as a range of full-sized pickup trucks — positioned between Ford’s Ranger and Super Duty pickup trucks. Alongside the F-150 (introduced in 1975), the F-Series also includes the Super Duty series (introduced in 1999), which includes the heavier-duty F-250 through F-450 pickups, F-450/F-550 chassis cabs, and F-600/F-650/F-750 Class 6–8 commercial trucks.

The most popular version of the model line is the F-150 pickup truck, currently in its fourteenth generation (introduced for the 2021 model year). From 1953 to 1983, the entry-level F-Series pickup was the 1⁄2 ton F-100. Starting in 1984, the F-150 became the entry-level. The F-150 has a long-running high-performance off-road trim level introduced for 2010, the (SVT) Raptor currently consisting of three generations. Production of the F-150 SVT Raptor ended in 2014 and was succeeded in 2017 by a new F-150 Raptor, which is based on the thirteenth and fourteenth generation F-150.

The F-Series trucks have been developed into a wide range of design configurations. Alongside medium-duty trucks and “Big Job” conventional trucks (the forerunners of the Ford L-series), the model line has been marketed as a chassis-cab truck and a panel van (a predecessor of the Ford E-Series). The F-Series has served as the platform for various full-sized Ford SUVs, including the Ford Bronco, Ford Expedition/Lincoln Navigator, and Ford Excursion. The F-Series has been marketed by its three North American brands: by Mercury as the M-Series (in Canada from 1948 to 1968), and by Lincoln in the 2000s, as the Blackwood and the later Mark LT (2010s for the latter in Mexico only).

Since 1977, the F-Series has remained the best-selling pickup truck line in the United States; it has been the best-selling vehicle overall since 1981. The F-Series has been the best-selling truck in Canada for over 50 years. As of the 2018 model year, the F-Series generated $41 billion (~$50.3 billion in 2024) in annual revenue for Ford. By January 2022, the F-Series models have sold over 40 million units. Currently, Ford manufactures the F-Series in four facilities in the United States.

Get more information about: Ford F-Series

Buying a high-performing used car >>>

Brand: Ford Model: F-150

Price: $17,745 Mileage: 131,097 mi.

Read more about: The 10 Most Dependable SUVs for Family Buyers: What Mechanics and Owner Reports Reveal About Long-Term Reliability in 2025

2. **Toyota Tundra (2007–2013)**The 2007–2013 Toyota Tundra has garnered widespread acclaim for its legendary reliability, a trait synonymous with the Toyota brand. This reputation often leads prospective buyers to assume a comparable level of robustness across all performance metrics, including load handling. Yet, for all its dependability in other areas, this generation of the Tundra struggles significantly when tasked with consistent heavy loads, often exhibiting pronounced suspension sag that can compromise both safety and handling dynamics.

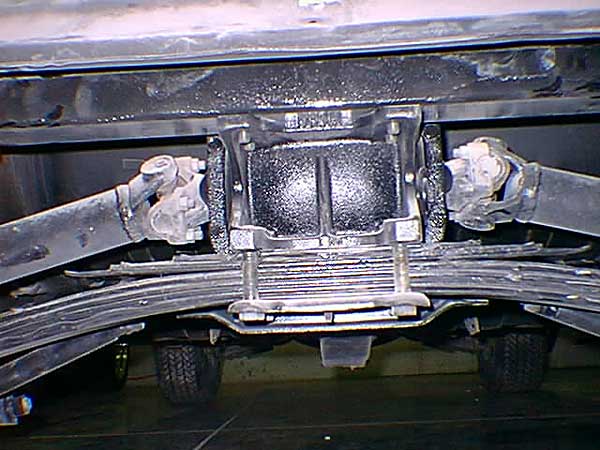

The core of this issue lies in the design of its rear leaf springs. These components, intended to provide support and absorb impacts, tend to compress quickly and excessively under pressure. This rapid compression results in a noticeable rear-end dip or “squat,” which not only looks unsettling but also profoundly affects the vehicle’s stability and control. The rear of the truck can feel less planted, leading to a diminished sense of command for the driver, particularly when navigating turns or encountering uneven road surfaces.

This problem becomes particularly acute for owners who frequently tow trailers or haul heavy cargo. Regular exposure to such stresses can lead to premature wear on various suspension components, and even frame stress over extended periods, exacerbating the long-term cost of ownership. The underlying reality is that this Tundra generation was simply not engineered with the same high load-bearing expectations that define many American heavy-duty trucks. While it serves admirably for family transport or occasional weekend tasks, its stock suspension is a notable weakness for those seeking a daily workhorse, often necessitating costly suspension upgrades or reinforcements to meet demanding usage requirements.

Car Model Information: 2024 Toyota Tundra Hybrid Limited

Name: Toyota Tundra

Manufacturer: Toyota

Production: May 1999 – present

ModelYears: 2000–present

Assembly: San Antonio,Texas

Class: Pickup truck#Full-size pickup truck

Layout: unbulleted list

Related: Toyota Sequoia

Predecessor: Toyota T100

Caption: 2022 Toyota Tundra Limited

Categories: 2000s cars, 2010s cars, 2020s cars, All-wheel-drive vehicles, All Wikipedia articles written in American English

Summary: The Toyota Tundra is a full-size pickup truck manufactured in the United States by the Japanese manufacturer Toyota since May 1999. The Tundra was the second full-size pickup to be built by a Japanese manufacturer (the first was the Toyota T100), but the Tundra was the first full-size pickup from a Japanese manufacturer to be built in North America. The Tundra was nominated for the North American Truck of the Year award and was Motor Trend magazine’s Truck of the Year in 2000 and 2008. Initially built in a new Toyota plant in Princeton, Indiana, production was consolidated in 2008 to Toyota’s San Antonio, Texas, factory.

Get more information about: Toyota Tundra

Buying a high-performing used car >>>

Brand: Toyota Model: Tundra

Price: $54,990 Mileage: 18,032 mi.

3. **Ram 1500 (2013–2018)**For the 2013–2018 Ram 1500, design priorities were heavily skewed towards delivering an exceptionally smooth and comfortable on-road experience, setting it apart from many of its competitors. A key engineering decision to achieve this unparalleled ride quality was the adoption of rear coil springs, a departure from the traditional leaf spring setups commonly found in other pickup trucks. While this innovation undoubtedly succeeded in providing a more refined and car-like ride, it introduced a significant limitation in the truck’s ability to maintain a level stance under heavy loads.

The trade-off for enhanced comfort was a severe reduction in load-bearing stability. Rear sagging is a prevalent and frequently reported issue among owners of this generation when the truck is laden with cargo or engaged in towing. This phenomenon leads to the truck feeling distinctly unbalanced, with the rear end dipping significantly. Such an imbalance can make the vehicle feel less secure, affecting steering precision and braking effectiveness, particularly when loaded closer to its maximum capacity or when navigating uneven terrain.

While aftermarket air suspension kits or helper springs offer viable solutions to counteract this tendency to sag, they represent an additional expense and a modification away from the factory configuration. For consumers who rely on their truck’s stock components for regular hauling and towing tasks, this generation of the Ram 1500 presents a major drawback. Its design ethos, prioritizing ride comfort above all else, makes it less than ideal for those whose operational demands frequently push the boundaries of its load-carrying capabilities without significant aftermarket intervention.

Car Model Information: 2017 RAM 1500 Night

Name: Dodge Ram / Ram pickup

Caption: 2017 Ram 1500 Express

Manufacturer: Dodge

ModelYears: 1981–present

Production: October 1980 – present

Class: Pickup truck#Full-size pickup truck,Pickup truck#Heavy-duty pickup truck

Layout: Front-engine, rear-wheel-drive layout,rear-wheel drive

Predecessor: Dodge D series

Categories: 1990s cars, 2000s cars, 2010s cars, 2020s cars, All-wheel-drive vehicles

Summary: The Ram pickup (marketed as the Dodge Ram until 2010 when Ram Trucks was spun-off from Dodge) is a full-size pickup truck manufactured by Stellantis North America (formerly Chrysler Group LLC and FCA US LLC) and marketed from 2010 onwards under the Ram Trucks brand. The current fifth-generation Ram debuted at the 2018 North American International Auto Show in Detroit, Michigan, in January of that year.

Previously, Ram was part of the Dodge line of light trucks. The Ram name was introduced in October 1980 for model year 1981, when the Dodge D series pickup trucks and B series vans were rebranded, though the company had used a ram’s-head hood ornament on some trucks as early as 1933.

Ram trucks have been named Motor Trend magazine’s Truck of the Year eight times; the second-generation Ram won the award in 1994, the third-generation Ram heavy-duty won the award in 2003, the fourth-generation Ram Heavy Duty won in 2010 and the fourth-generation Ram 1500 won in 2013 and 2014, and the current fifth-generation Ram pickup became the first truck in history to win the award four times, winning in 2019, 2020, 2021 and most recently, 2025.

Get more information about: Ram pickup

Buying a high-performing used car >>>

Brand: Ram Model: 1500

Price: $23,919 Mileage: 102,795 mi.

4. **Chevrolet Colorado (2015–2020)**The Chevrolet Colorado, specifically models produced between 2015 and 2020, stands as a popular choice in the midsize truck segment, offering a more maneuverable and fuel-efficient alternative to full-size pickups. While it boasts a decent payload rating on paper, suggesting a reasonable capability for carrying weight, its rear suspension system is demonstrably not built for frequent or heavy-duty use. Owners often discover that pushing this truck beyond its comfort zone quickly exposes its limitations.

Under load, the Colorado’s rear suspension visibly sags, a clear indicator that it struggles to maintain its intended ride height and structural integrity. This sagging has direct and detrimental consequences for the truck’s handling stability, making it feel less secure and predictable, especially when navigating turns or encountering sudden movements. The compromised stability is a significant safety concern, particularly when the vehicle is operating near its payload limits or towing.

Reports from owners frequently highlight poor ride quality during towing operations, with the truck exhibiting excessive bouncing or wallowing. Furthermore, the persistent rear-end droop can contribute to issues with uneven tire wear, such as cupping or feathering, accelerating the need for tire replacements and impacting overall operating costs. It becomes evident that the suspension of this Colorado generation was not engineered with the rigorous demands of heavy-duty hauling in mind, making it best suited for lighter, urban, or recreational use. For those who consistently require more robust performance from their midsize truck, aftermarket upgrades or a complete switch to a larger, more capable truck often become necessary.

Car Model Information: 2022 Chevrolet Colorado ZR2

Name: Chevrolet Colorado

Caption: 2024 Chevrolet Colorado Z71

Manufacturer: General Motors

Production: 2003–2012, 2014–present (US),2004–2020

(Thailand),2011–present (Brazil)

Class: Pickup truck,Pickup truck

Layout: Front-engine, rear-wheel-drive layout

Predecessor: Chevrolet S-10,Chevrolet D-Max,Holden Rodeo,Holden Ute

Aka: GMC Canyon,Holden Colorado

Categories: 2010s cars, 2020s cars, All-wheel-drive vehicles, All articles with dead external links, Articles with dead external links from November 2016

Summary: The Chevrolet Colorado (sharing mechanical commonality with the GMC Canyon) is a series of compact pickup trucks (mid-size since second generation) marketed by American automaker General Motors. They were introduced in 2004 to replace the Chevrolet S-10 and GMC S-15/Sonoma compact pickups. The Colorado is named after the U.S. state of Colorado, while the Canyon took its name from the deep chasm between cliffs.

Get more information about: Chevrolet Colorado

Buying a high-performing used car >>>

Brand: Chevrolet Model: Colorado

Price: $33,991 Mileage: 40,794 mi.

5. **Honda Ridgeline (2005–2014)**The first-generation Honda Ridgeline, produced from 2005 to 2014, was a vehicle that bravely charted its own course, prioritizing innovative features, SUV-like comfort, and a unique unibody construction. This design approach, a stark contrast to the traditional body-on-frame setups of conventional trucks, delivered a smooth and refined driving experience reminiscent of an SUV. However, this very unibody architecture inherently limited its ability to support substantial weight without encountering significant structural and suspension challenges.

The Ridgeline’s suspension system quickly bottoms out when the bed is fully loaded, leading to a pronounced and often dramatic rear sag. Unlike a robust body-on-frame truck designed to flex and distribute heavy loads across a reinforced chassis, the unibody construction struggles to absorb and manage the same level of stress. This makes the truck feel less capable and more cumbersome when carrying heavy items, diminishing confidence in its utility as a true work vehicle.

While the Ridgeline excelled as a versatile companion for weekend warriors, offering impressive cargo flexibility and a comfortable ride for everyday errands, it unequivocally falls short when confronted with serious work demands such as regular towing or heavy hauling. Owners who acquire this vehicle with expectations of robust load-bearing capability often find themselves disappointed, frequently resorting to aftermarket air suspension kits to bolster its performance. Despite its commendable reliability and unique versatility in other aspects, the first-generation Ridgeline simply does not measure up when it comes to the rugged and consistent load-bearing capability expected from a pickup truck in demanding situations.

Car Model Information: 2023 Honda Ridgeline Black

Name: Honda Ridgeline

Manufacturer: Honda

Caption: 2022 Honda Ridgeline

Production: 2005–early 2015,2016–present

ModelYears: 2006–2014,2017–present

Assembly: Alliston, Ontario

Class: Pickup truck#Mid-size pickup truck

BodyStyle: 4-door pickup truck

Layout: ubl

Categories: 2010s cars, All-wheel-drive vehicles, All Wikipedia articles written in American English, Articles with short description, CS1 maint: multiple names: authors list

Summary: The Honda Ridgeline is a mid-size pickup truck manufactured and marketed by Honda since the 2006 model year, over two generations in a unibody, crew–cab, short-box configuration with a transverse-mounted engine.

Get more information about: Honda Ridgeline

Buying a high-performing used car >>>

Brand: Honda Model: Ridgeline

Price: $33,830 Mileage: 46,675 mi.

6. **Overloaded Trucks**Among the myriad factors contributing to suspension failure in heavy-duty trucks, the single most egregious and direct cause is consistently overloading the vehicle beyond its specified Gross Vehicle Weight Rating (GVWR) or its suspension’s design limits. This is not merely a matter of pushing the envelope; it is, in plain terms, a terrible and profoundly dangerous practice that invites catastrophic consequences. When a truck is made to carry more weight than its suspension system is engineered to handle, the ensuing stress is not distributed harmlessly; rather, it propagates through every single component of the suspension—from the robust springs and crucial shock absorbers to the delicate airbags and essential bushings.

This excessive and unrelenting stress acts as a potent accelerant for wear and tear, forcing components to operate outside their intended parameters. Springs are deformed, shocks are overwhelmed, airbags are pushed to their breaking point, and bushings are prematurely degraded. The repeated imposition of such loads, especially if it becomes a regular occurrence, creates a ticking time bomb within the vehicle’s infrastructure, making it a surefire recipe for catastrophic failure. This can manifest as anything from sudden spring collapses and ruptured airbags to fractured axles and compromised steering components, all of which pose severe risks to the driver, cargo, and other road users.

The temptation to overload, even with the rationale of “just this once,” can inflict real and lasting damage that subtly, or sometimes overtly, compromises the entire suspension system. It’s a false economy, as the immediate gratification of hauling a little extra weight is often dwarfed by the long-term costs of accelerated component degradation, unexpected repairs, and potential safety incidents. Adhering strictly to the manufacturer’s payload specifications is not just a recommendation; it is a fundamental principle of vehicle safety and mechanical longevity. Prioritizing correct load management is paramount to preserving the integrity and performance of your truck’s suspension, ensuring it remains a reliable and safe asset for its intended lifespan.

Read more about: Owner’s Watch List: The Luxury SUVs That Become Costly Repair Nightmares After Seven Years

7. **Worn-Out Leaf Springs or Airbags**Beyond simply overloading, the natural degradation of key suspension components like leaf springs and airbags significantly contributes to failure. These crucial elements are constantly under stress, flexing and absorbing impacts to support the vehicle’s weight and ensure a stable ride. Over time, their ability to perform these essential functions diminishes, leading to compromised structural integrity and ride quality.

The integrity of leaf springs, the curved metal stacks that flex to absorb weight and impact, is particularly susceptible to wear. Years of carrying oversized loads or suffering poor weight distribution can cause these springs to sag, crack, or even snap outright. Factors such as the heat and humidity prevalent in regions like Memphis can accelerate metal fatigue, causing rubber and metal components to degrade faster than anticipated.

Similarly, air suspension systems, which utilize airbags to absorb shock and maintain load balance, are not immune to degradation. Over an extended period of use, these airbags can develop microscopic cracks, larger holes, or valve leaks, leading to a loss of internal pressure. Once these components begin to degrade, the entire ride height and load distribution of the vehicle are thrown out of alignment, manifesting as a noticeable drop in the truck’s stance.

The consequences of worn-out leaf springs or failing airbags extend beyond just an aesthetic sag. An ofilter ride height or excessive creaking while hauling are clear indicators of trouble, and if left unaddressed, these issues can lead to more severe problems such as frame damage and uneven tire wear. The uneven suspension stress resulting from these failures can also damage axles, shocks, and control arms, compromising both safety and the truck’s overall longevity.

8. **Improper Load Distribution**Even when a heavy-duty truck is operated within its specified Gross Vehicle Weight Rating (GVWR), an improper distribution of the cargo can still lead to significant suspension problems. It is not merely about the total weight, but rather how that weight is balanced across the truck’s chassis and axles. An unbalanced load creates disproportionate stress on different parts of the suspension system, negating the benefits of staying within the overall weight limits.

When cargo is not evenly distributed, one side of the suspension is forced to bear a greater share of the workload than the other. This asymmetrical loading can cause components on the overstressed side to compress excessively, leading to a noticeable tilt or sag. Over time, this consistent uneven pressure results in accelerated and asymmetrical wear across the suspension, impacting leaf springs, airbags, shock absorbers, and bushings on the affected side.

This phenomenon significantly increases the chances of component misalignment and eventual failure. An imbalanced truck can feel distinctly unstable and unpredictable on the road, with impaired steering precision and reduced braking effectiveness. The vehicle’s handling dynamics are compromised, making it more challenging to control, especially when navigating turns, encountering sudden maneuvers, or driving on uneven terrain.

Ensuring that cargo is properly secured and evenly distributed across the truck bed or trailer is a fundamental principle of vehicle safety and mechanical longevity. Adhering to manufacturer guidelines for load placement and weight distribution is crucial. This proactive approach prevents premature wear and tear, maintains the truck’s stability and control, and helps avoid dangerous situations that arise from an unbalanced vehicle.

Read more about: Your Empowerment Guide: Navigating Simple Estate Planning Without a Lawyer to Secure Your Future

9. **Shock Absorber Failure**Shock absorbers play a vital, often understated, role in a heavy-duty truck’s suspension system, acting as its first line of defense against the constant assault of potholes, bumps, and road vibrations. These critical components are responsible for regulating rebound movement and controlling how the suspension handles impacts, effectively dampening oscillations to maintain tire contact with the road and ensure a smooth, controlled ride.

However, like all mechanical parts, shock absorbers do not last forever. They are subject to wear and tear, and over time, their internal mechanisms can degrade, or their seals can fail, leading to leaks of hydraulic fluid. When shocks wear out or leak, they lose their ability to effectively control the suspension’s movement. This manifests as a noticeable decrease in damping capability, allowing the vehicle to bounce excessively or sway uncontrollably.

The consequences of worn-out shocks are immediate and severe. A truck with failing shock absorbers may exhibit pronounced bouncing, unsettling swaying, or even nosediving during braking, severely impacting its handling. This reduced control directly translates into poor steering response and overall instability, which poses a significant safety hazard, particularly at highway speeds or when the vehicle is towing a loaded trailer.

Beyond the immediate safety concerns, failing shock absorbers also place additional strain on other suspension components. The uncontrolled movement and increased impact forces accelerate the demise of leaf springs, airbags, bushings, and control arms, fast-tracking their premature wear. Regular inspection and timely replacement of worn shocks are therefore not just about comfort; they are essential for preserving the integrity of the entire suspension system and ensuring safe vehicle operation.

Read more about: Ready to Mod? The 12 Critical Aftermarket Parts to Skip for Uncompromised Reliability and Value

10. **Corrosion and Environmental Wear**Heavy-duty trucks are built to withstand challenging conditions, but the relentless exposure to various environmental elements can take a severe toll on their suspension systems. Factors such as road salt used in icy winter conditions, corrosive chemicals, and abrasive mud from off-road detours are persistent threats that accelerate the degradation of critical metal components. This constant environmental assault makes corrosion a major concern for truck owners, particularly for steel suspension parts.

Rust and corrosion do not merely affect the appearance of a truck; they gradually eat away at the structural integrity of essential components. Metal brackets, leaf springs, U-bolts, air suspension fittings, and various hangers are all vulnerable to this insidious process. Over time, this relentless decay weakens these parts, significantly reducing their ability to withstand the stresses of heavy loads and demanding road conditions.

Left unchecked, this weakening can lead to catastrophic failures. A severely corroded spring mount, an oxidized hanger, or a rusted bolt can unexpectedly give way under operational stress, causing breakdowns and creating serious safety issues mid-route. For example, operating out of regions like Pittsburgh, PA, where winters are notoriously harsh, makes rust prevention an absolutely indispensable part of any regular maintenance checklist for heavy-duty truck owners.

Proactive measures against corrosion are therefore not optional but essential for preserving the lifespan and safety of a truck’s suspension. Regular cleaning, applying protective coatings, and routine inspections to identify and address early signs of rust are crucial. Prioritizing rust prevention helps maintain the structural integrity of the suspension, ensuring reliable and safe performance even in the most adverse environmental conditions.

Read more about: Investor Alert: Unmasking the 15 High-Mileage Maintenance Traps That Can Sink Your Savings

11. **Neglected Maintenance**A heavy-duty truck’s suspension system is far from a ‘set it and forget it’ component; it demands diligent and routine maintenance to ensure its optimal performance and longevity. Skipping regular inspections, ignoring grease points, and overlooking minor signs of wear on components such as bushings or cracked mounts can swiftly snowball into system-wide failure, transforming small, manageable issues into costly and dangerous problems.

Preventive maintenance is truly your best defense against unexpected breakdowns and accelerated component degradation. This crucial regimen involves inspecting, lubricating, and replacing various parts regularly. For instance, U-bolts and other suspension fasteners can loosen over time due to constant vibrations and operational stress. Regularly retorquing these fasteners is vital for maintaining proper alignment and preventing premature wear on associated components.

Furthermore, a comprehensive maintenance schedule should include diligent checks of shock absorbers, regular pressure tests for airbag systems, and thorough inspections of leaf springs for any signs of damage or fatigue. Greasing pivot points consistently and replacing worn hardware, such as bushings and shock mounts, might seem like minor investments, but they pay off significantly in terms of increased uptime, improved safety, and reduced long-term repair costs.

Ignoring these seemingly small parts can have severe consequences; a busted bushing, for example, can quickly escalate to a busted axle if left unattended. Establishing a rigorous preventive maintenance schedule is paramount, regardless of whether your truck utilizes a leaf spring or air suspension system. If there’s any doubt about the proper maintenance practices, reaching out to a professional repair shop that specializes in heavy-duty suspension repairs can provide invaluable guidance and a tailored maintenance plan.

Read more about: Driver’s Guide: Debunking the 5-Year EV Battery Anxiety – New Research Shows Longevity and Lasting Value

12. **Air System Failures**For heavy-duty trucks equipped with sophisticated air ride suspension systems, optimal performance is entirely dependent on the flawless operation of its integrated air system. While the airbags themselves are critical, issues can originate from other vital components within the air supply network, including the air compressor, air lines, air tanks, and the air dryer. Failures in any of these parts can lead to immediate and significant suspension problems.

The air compressor is the heart of the system, responsible for generating the compressed air needed to inflate the airbags and maintain proper ride height. Should this component fail or become inefficient, the system will be unable to generate sufficient pressure, leading to a noticeable drop in suspension performance. Similarly, the air lines, which transport compressed air throughout the system, are vulnerable to leaks, cracks, or blockages, disrupting the precise delivery of air to the airbags.

One particularly insidious issue is a failing air dryer. This component is designed to remove moisture from the compressed air before it enters the system. If the air dryer malfunctions, moisture can infiltrate the air lines and tanks, leading to internal rust and corrosion, which can then damage other components, including rendering the airbags useless. This compromises the entire system’s integrity, leading to inconsistent air pressure and potential collapse.

The consequences of air system failures are severe: ranging from a sagging suspension, where the truck rides noticeably lower, to a complete and sudden collapse of the suspension on one or more corners. This loss of stability and ride height profoundly impacts vehicle control, handling, and safety, especially when the truck is under load. Regular checks for air leaks, ensuring the air compressor functions efficiently, and maintaining a dry and clean air system are essential for safeguarding the performance and reliability of air ride suspension.

**Final Thoughts**

In the demanding world of heavy-duty trucking, your suspension system is far more than just a comfort feature; it is the cornerstone of your vehicle’s safety, stability, and operational efficiency. The insights presented in this guide underscore a critical reality: whether it’s through inherent design weaknesses in popular pickup models or the pervasive impact of component degradation, environmental factors, improper load management, and neglected maintenance, suspension integrity directly dictates your rig’s ability to perform.

Read more about: The Costly Truth: 15 Vehicles Owners Deeply Regretted Driving Off the Lot

Understanding these common pitfalls is the first step toward proactive vehicle care. From ensuring balanced loads and adhering to strict weight ratings to implementing a rigorous preventive maintenance schedule that includes inspecting crucial components and guarding against corrosion, every action contributes to extending the lifespan and reliability of your truck. Don’t wait for a breakdown to realize the importance of a healthy suspension. By staying vigilant for warning signs and making informed choices, you empower yourself to keep your heavy-duty truck operating safely and smoothly, mile after demanding mile, transforming potential budget-busters and safety hazards into confident, controlled journeys.