In the world of cycling, where performance, quality, and safety are paramount, manufacturers like Cannondale consistently affirm their commitment to meeting the highest standards. Riders demand reliability, especially when pushing their limits on challenging terrains or simply commuting. This dedication to safety, however, sometimes leads to the discovery of potential hazards in products already on the market, necessitating crucial safety notices and recalls to protect consumers.

These recalls are not just administrative formalities; they are critical measures designed to prevent serious injuries or worse, ensuring that riders can trust their equipment. While any recall can be an inconvenience, they ultimately serve the vital purpose of addressing unforeseen issues that could compromise a bicycle’s integrity. For consumers, staying informed about these notices is not merely recommended, but essential for personal safety and making informed decisions, particularly when considering a used bicycle.

As conscientious consumers, understanding the specifics of bicycle recalls—what models are affected, what the hazards are, how to identify them, and what immediate action is required—empowers us to ride with confidence or take necessary precautions. This comprehensive guide will delve into specific instances where various bicycle models and components have been identified with safety concerns, some of which could lead to structural failure, especially as they accumulate kilometers. Our aim is to provide clear, actionable insights to help you navigate these important safety considerations.

1. **Cannondale Model Year 2021-23 Dave Bicycles and Framesets**One significant safety concern recently identified by Cannondale pertains to their Model Year 2021-23 Dave bicycles and framesets. The manufacturer has pinpointed a critical issue where the bicycle’s headtube/downtube weld can become damaged. This damage carries the serious risk of the weld separating from the bicycle frame entirely, which directly poses significant fall and injury hazards to the rider.

Cannondale’s recall, conducted in cooperation with the U.S. Consumer Product Safety Commission (CPSC), underscores the severity of this structural flaw. A compromise in the headtube/downtube weld is not a minor defect; it impacts one of the most crucial stress points on a bicycle frame. Should this weld fail during a ride, it could lead to a sudden and catastrophic loss of control, resulting in severe injuries.

Identifying an impacted bicycle or frameset is relatively straightforward for consumers. Riders and Cannondale dealers alike should inspect the bicycle for the presence of the name “Dave” painted prominently on the bicycle frame’s top-tube. This distinct marking serves as the primary indicator for inclusion in this particular recall notice, simplifying the identification process for owners.

If you discover that you own a Cannondale Model Year 2021-23 Dave bicycle or frameset, the immediate and most important action is to refrain from riding it. Continued use of an affected bicycle could put you at undue risk. Consumers are advised to promptly contact their local authorized Cannondale dealer or Cannondale directly to arrange for a free replacement of the bicycle frame. This proactive step ensures your safety and restores the integrity of your cycling experience.

2. **Cannondale Cyclocross CAADX Model Year 2013-2016 Bicycles**Another serious safety recall impacting Cannondale riders involves certain Cyclocross CAADX Model Year 2013-2016 bicycles. Cannondale launched an in-depth inquiry after receiving several reports of fork fractures on these models, including a tragic incident where a rider fell and suffered injuries that ultimately led to their death. This deeply concerning situation highlights the critical importance of component integrity in high-performance cycling.

Despite extensive testing by Cannondale and independent parties that did not identify a defect in the forks, the gravity of the reported incidents prompted the company to take decisive action. They chose to inform riders of these occurrences and offer a free upgraded replacement fork. This voluntary recall, processed through the U.S. CPSC, reflects a commitment to rider safety even when a clear manufacturing defect cannot be definitively pinpointed through standard testing.

Owners of CAADX bicycles can determine if their bike is affected by inspecting it for a specific set of features. The bicycle must have a prominent “CAADX” marking on either the top tube or another tube. Additionally, it should be equipped with disc brakes, feature a large “ULTRAX” marking on the inside of the fork leg, and have a black plastic cable running to the front disc brake that is routed outside of the fork blade, rather than internally.

If your CAADX bicycle matches all these criteria, it falls under the scope of this critical recall. Riders should immediately contact their local Cannondale dealer to arrange for a free upgraded replacement fork. This replacement is a full carbon fork, designed to provide increased performance alongside enhanced safety, and offers a lower weight than the original component. Furthermore, all riders are strongly encouraged to review and heed all warnings provided in the CAADX owner’s manual, particularly the industry standard warning that a crash or impact can cause components to fatigue prematurely and fail suddenly, leading to serious injury or death.

3. **2010-2012 Bad Boy and Bad Girl Bicycles**The 2010-2012 Cannondale Bad Boy and Bad Girl bicycle models have also been subject to a significant safety recall due to potential structural weaknesses. This recall stems from reports of affected bicycles developing fatigue cracks in a critical area: where the axle meets the fork leg. Such fatigue cracks are inherently dangerous because they tend to grow with continued use, eventually leading to a broken axle.

The hazard associated with a broken axle is substantial. If the axle separates from the fork leg, it directly creates a high risk of an accident or serious injury for the rider. Given the severity of this potential failure, Cannondale has issued a firm directive: riders should not use their bicycle until the fork has been thoroughly inspected or, if necessary, replaced by an authorized professional.

To determine if your Bad Boy or Bad Girl bicycle is subject to this recall, you need to examine the production date code located on the bottom of the fork leg. Look for the first character of this code. If the first character is ‘P,’ the bicycle is from Production Year 2010. If it’s ‘Q,’ it’s from 2011. For 2012 models, an ‘R’ as the first character indicates it’s subject to recall, unless it is specifically ‘RA,’ which is not subject to this particular safety notice.

Should your bicycle’s date code confirm it is subject to this recall, your immediate action is to stop riding it without delay. The next step is to bring your bicycle to your nearest authorized Cannondale Dealer. There, the fork will undergo a professional inspection, and if found necessary, a replacement will be provided at no charge. For any questions, Cannondale Customer Service in the U.S. can be reached at 203-845-8498, selecting option “1” for consumer support, available Monday through Friday, 9 am to 6 pm EST, or via email at [email protected].

4. **OPI Stem/Steering Tube Assemblies (2011-2015 Cannondale Mountain Bikes)**A critical safety concern was identified with OPI stem/steering tube assemblies used in certain Cannondale Mountain Bikes produced between Model Year 2011 and Model Year 2015. These assemblies, some of which were also sold as aftermarket stems, presented a potential safety issue related to the connection between the base of the OPI stem and the top of the steering tube. Through regular testing, it was determined that this specific connection design resulted in a reduced fatigue life, a serious flaw that could lead to fork failure.

The implication of such a failure is a high risk of a serious accident or injury for the rider, as loss of control could be sudden and unexpected. While Cannondale reported no accidents or injuries as a direct result of this issue at the time of the recall, the potential severity led them to conduct a voluntary recall in cooperation with appropriate regulatory authorities. The OPI steerer, located inside the headtube and not visible, is the specific component being recalled.

Identifying whether your bicycle is affected by this recall requires a careful inspection of your OPI stem. The words “OPI” are printed on the top of the stem, and OPI stems typically appear smooth and rounded at the bike head tube. Additionally, these stems are distinctive for having no stem bolts, relying instead on only four handlebar bolts. This recall specifically impacts Cannondale mountain bikes from 2011-2015 equipped with a Lefty front fork that incorporates an OPI stem and OPI steerer system.

If your bicycle is equipped with an OPI stem meeting these identifiers, you must immediately stop using the bicycle. The hazard is a reduced fatigue life in the OPI steerers, potentially leading to breakage of fork clamps or bolts over time and a loss of control. Consumers should contact their nearest Authorized Cannondale Dealer without delay. Dealers will inspect the OPI stem and fork for any existing damage and will then fit the OPI stem steerer system with a special wedge kit—a reinforcement part—and install new Lefty clamp bolts. This remedy is provided at no charge and is designed to restore appropriate fatigue life to the system, ensuring rider safety.

5. **GT Speed Series and Robinson Bicycle Frames (1995-1998)**Beyond recent Cannondale issues, a significant recall from the past serves as a crucial reminder of ongoing vigilance regarding bicycle frames: the GT Bicycles recall of their Speed Series and Robinson frames. Issued in cooperation with the U.S. Consumer Product Safety Commission (CPSC) in 1998, this recall involved approximately 10,000 GT Speed Series and Robinson bicycle frames due to a severe structural defect.

The core hazard with these frames was their propensity to crack and separate. Such a failure is profoundly dangerous, as it directly causes a rider to lose control of the bicycle, leading to falls and potential injuries. At the time of the recall, GT Bicycles had already received about 17 reports of frames cracking, which tragically resulted in two reported injuries involving cuts and bruises, underscoring the tangible risks involved.

The recall specifically covered 1995, 1996, 1997, and 1998 XL and XXL model GT Speed Series, Speed Series Team, and Speed Series Cruiser frames and bicycles. Additionally, 1997 and 1998 model Robinson Pro, Pro XL, Pro 24, and Amtrac frames and bicycles were included. Identifying these models is generally straightforward, as the model names are clearly found on the frames themselves, making it easier for owners to determine if their bike is affected.

These recalled bicycle frames were sold either as part of complete bicycles or separately as frame kits by GT Authorized Dealers nationwide from November 1994 through February 1998. The frame kits ranged from approximately $300 to $450, while the complete bicycles cost between $600 and $1,450. Consumers who own bicycles equipped with these frames must immediately stop using them.

To remedy this serious defect, consumers should contact their local GT Authorized Dealer to arrange for a free replacement of the frames. GT Bicycles committed to replacing these recalled frames with a stronger, redesigned frame featuring thicker tubing, thereby addressing the fundamental safety flaw. For assistance in locating the nearest dealer, consumers can call the GT Bicycles Customer Service Department at 800-743-3248.

Continuing our examination of vital bicycle recalls and critical consumer advice, this section delves into further safety notices, providing essential guidance for anyone considering a used bicycle purchase. Understanding the historical context of recalls and the nuances of product warranties, alongside performing thorough pre-purchase inspections, can significantly mitigate risks and enhance your cycling experience. These insights are designed to empower consumers to make the safest and most informed choices.

6. **2014 Cannondale Tandem Bicycles**The structural integrity of a bicycle frame is always paramount, a truth magnified when considering tandem bicycles. These unique machines are designed to carry two riders, placing significantly higher and more complex stresses on their frames compared to single-rider models. The “Tandem 2014 Tandem Bicycles Frame Recall Notice” indicates that certain models from this year were identified with issues that necessitated a recall, underscoring the vital need for exceptionally robust frame construction in these specialized bikes.

Recalls specific to tandem frames often arise from concerns about their structural stability, particularly under the dynamic and cumulative loads experienced during regular use. Given the substantial forces involved—from pedaling in unison to braking and maneuvering with a heavier load—any weakness in a tandem frame, such as at welds or critical junctions, could have serious implications for rider safety. Such defects can compromise the bicycle’s handling and lead to unforeseen accidents.

While the detailed specifics of the defect and precise identification criteria for the 2014 Cannondale Tandem Bicycles recall are not provided in the available documentation, the presence of a “Frame Recall Notice” itself signifies a severe potential hazard. Consumers who own or are considering purchasing a used 2014 Cannondale tandem should treat this information with extreme caution. The standard protocol for such recalls is to immediately cease riding the affected bicycle and to contact an authorized dealer for a professional inspection and the manufacturer-prescribed remedy, which often involves a free frame replacement or repair.

Adhering to recall directives is not merely a recommendation; it is an essential safety measure that protects not one, but two riders from potential injury. The complexity and performance demands of tandem cycling make vigilance regarding frame integrity even more critical. Prioritizing these safety notices ensures that the joy of tandem riding is not overshadowed by preventable risks.

7. **2013 Cannondale Slice RS Frame**The realm of high-performance cycling, particularly in time trial and triathlon disciplines, demands absolute precision and structural excellence from equipment. The “Slice RS 2013 Slice RS Frame Recall Notice” for Cannondale’s performance model highlights that even top-tier, aerodynamically optimized frames can be subject to safety concerns. The Slice RS is known for its cutting-edge design aimed at maximizing speed and efficiency, making any compromise in frame integrity a significant concern for competitive and enthusiast riders alike.

Frame recalls in performance models typically address issues that could lead to structural failure under the high-stress conditions these bicycles are designed for. Such defects might occur in areas subjected to extreme torsional loads, like the head tube, bottom bracket, or seat tube, or in carbon layup where manufacturing inconsistencies could lead to premature fatigue. A failure in any of these critical zones could result in a sudden loss of control, especially during high-speed efforts or cornering, posing a serious risk of injury to the rider.

Without the specific details of the defect, methods for identification, or the recommended remedy explicitly provided within the current information, owners of a 2013 Cannondale Slice RS should nevertheless be acutely aware of the implications of a frame recall. The term “Frame Recall Notice” itself serves as a strong indicator that the fundamental safety and structural reliability of the bicycle could be compromised. This type of advisory from a manufacturer like Cannondale is a serious call to action for consumers.

For any rider owning a 2013 Cannondale Slice RS, or anyone considering acquiring one on the used market, the immediate and most prudent step is to confirm whether the specific frame has been inspected and remedied according to the recall. This would typically involve contacting an authorized Cannondale dealer to verify the frame’s status and to arrange for any necessary repairs or replacements. Ensuring the frame’s integrity is not just about performance, but about maintaining the highest level of safety on the road.

8. **2008 Cannondale Scalpel 100 and Scalpel Carbon 100**Mountain biking, especially cross-country riding, places immense and varied stresses on bicycle frames, particularly for full-suspension models like the Cannondale Scalpel. The “Scalpel 100 2008 Scalpel Recall 100 Frame Recall Notice” and “Scalpel Carbon 100 Recall” highlight potential structural vulnerabilities identified in these popular models. The Scalpel, renowned for its lightweight design and efficient suspension system, is pushed to its limits on trails, making frame integrity absolutely crucial for both performance and rider safety.

Frame recalls for full-suspension mountain bikes often target areas that experience concentrated stress from both rider input and terrain impact. These can include the main frame triangle, pivot points, chainstays, or seatstays, where repeated flexing and twisting can lead to fatigue cracks or failure. Given that a Scalpel frame, especially a carbon variant, is engineered for a precise balance of stiffness and compliance, any defect can significantly compromise its ability to handle rough trails and maintain predictable handling.

While the explicit details regarding the nature of the defect, the method for identification, or the precise corrective actions for the 2008 Cannondale Scalpel 100 and Scalpel Carbon 100 frames are not elaborated upon in the provided context, the issuance of a “Frame Recall Notice” demands serious attention. The potential hazard associated with a compromised frame on a mountain bike is substantial, ranging from a sudden loss of control on technical descents to complete structural collapse, leading to severe falls and injuries.

For owners of these 2008 Scalpel models, or those looking to purchase them used, it is imperative to investigate the recall status. The standard recommendation from manufacturers in such cases is to discontinue use immediately and to consult an authorized dealer. Dealers would be equipped to inspect the frame and apply any necessary remedies, such as reinforcements or frame replacements, ensuring the bicycle meets the required safety standards before it is ridden again. This proactive approach safeguards the rider against the inherent risks of a recalled component.

9. **2002-2003 Cannondale Gemini Frame**The downhill and freeride segments of mountain biking push equipment to the absolute extreme, demanding frames of unparalleled strength and durability. The “Gemini Frame (2002-2003) Certain Gemini Frame 2002 2003 Recall” for Cannondale’s Gemini model underscores that even bikes built for the most aggressive riding can present critical safety issues. The Gemini was specifically designed to withstand massive impacts and harsh terrain, making any recall related to its frame particularly alarming given the high-stakes environment in which it operates.

Recalls affecting downhill or freeride frames typically address fundamental structural weaknesses that could manifest under the intense, repeated forces of jumps, drops, and rocky descents. Potential areas of concern include heavily stressed weld areas, oversized tubing junctions, or suspension pivot points where fatigue can set in. A frame failure in such a discipline would not only lead to a complete loss of control but could also result in extremely severe injuries given the speeds and heights involved.

Even though specific details of the defect, precise identification steps, or the exact remedy for the 2002-2003 Cannondale Gemini Frame recall are not detailed in the provided information, the existence of a “Recall Notice” signals a profound safety concern. For a frame designed for such extreme usage, any compromise in its integrity translates into a significant, immediate danger for the rider. Such notices are issued when a risk of severe injury is present, necessitating prompt consumer action.

Therefore, any individual owning a 2002-2003 Cannondale Gemini frame, or considering its purchase on the secondary market, must prioritize verifying its recall status. The critical action in response to a frame recall is to immediately cease all use of the bicycle. Subsequently, contact with an authorized Cannondale dealer is essential to determine if the specific frame is affected and to facilitate any required inspections, repairs, or replacements to restore the bicycle to a safe, rideable condition. This diligence is paramount for the safety of riders engaging in demanding off-road activities.

10. **Navigating the Nuances of Bicycle Warranties**When investing in a bicycle, especially a high-value mountain bike, the promise of a “Lifetime Warranty” often provides a comforting sense of security. However, as many consumers discover, these warranties frequently come with an asterisk, revealing a more intricate landscape than initially perceived. Understanding the nuanced language within manufacturer defect clauses is crucial for any consumer, particularly when faced with a broken frame and a denied claim, as highlighted by personal experiences within the cycling community.

Manufacturer warranties are designed to cover very specific issues, primarily focusing on “manufacturer defects in materials and workmanship.” This specificity provides manufacturers with significant latitude, making these phrases central to any warranty claim. The challenge for consumers lies in the inherently subjective nature of these criteria. What precisely constitutes a “defect in materials” or a “defect in workmanship”? These definitions often relate to industry standards, but proving that a broken bike is a direct result of such a defect can be incredibly gray and open to interpretation.

Experiences reveal that manufacturers often hold the final say in these situations, frequently including phrases like “at [manufacturer’s] option” in their warranty statements. This effectively means that if a claim falls into a gray area—as many do—the manufacturer determines the next steps. While a clear, undeniable defect, such as those seen in large-scale component recalls, is straightforward, many breakages occur from scenarios that don’t neatly fit into a manufacturer’s specific instances, such as a frame cracking during an uneventful dismount.

For consumers whose claims are rejected, recourse through legal processes is often impractical due to the costs involved. Attorney John Bang noted that warranty language is typically “written in a way that is incredibly favorable to the manufacturer” and has likely evolved from years of case law to standardize the definition of a “manufacturer’s defect.” This places the burden of proof, and often the cost of failure, squarely on the consumer unless the defect is unequivocally evident.

Despite the formidable legal framework, there are instances where claims are eventually covered, often influenced not by strict warranty requirements but by good business decisions. Companies may approve claims to maintain customer loyalty and uphold their reputation, especially after several rounds of communication and provided evidence. This suggests that persistence and a clear presentation of your case, even if the initial decision is negative, can sometimes lead to a favorable outcome, though it is by no means guaranteed. It’s a reminder that while warranties offer protection, their application can be complex.

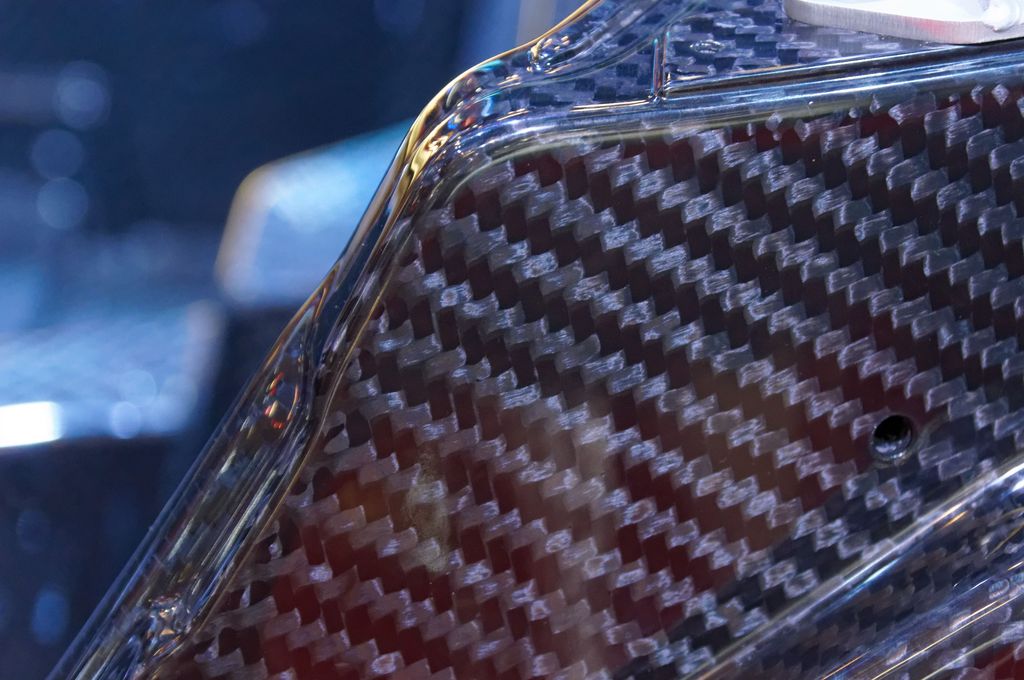

11. **Comprehensive Pre-Purchase Inspection for Used Carbon Bicycles**Buying a used bicycle, especially one with a carbon frame, can offer excellent value, but it also demands a meticulous approach to inspection. Carbon frames, while incredibly strong and light, have unique characteristics that make assessing potential damage trickier than with other materials. Unlike steel or aluminum, where damage is often overtly apparent, carbon can harbor hidden structural issues from severe impacts that are invisible to the eye, potentially leading to sudden and catastrophic failure during a ride.

Before even delving into specific checks, a general inspection is paramount. First, ensure the bike is the correct size for you; an ill-fitting bike, no matter the deal, is a poor investment. Then, lift the bike a few inches and drop it, listening for any unusual rattles or clunking sounds that might indicate internal issues beyond normal chain and cable slap. A bit of detective work can also reveal past incidents: mismatched wheels, for example, could signal a prior crash. Always ask the seller for their reason for selling, as this can provide valuable context.

When examining the carbon frame itself, a bright torch in good direct light is your best friend. Closely inspect the entire surface for ripples, gouges, or any signs of paint damage that might mask underlying carbon compromise. Pay particular attention to the top and down tubes, which are susceptible to crush injuries from roof or boot rack clamps. Critically, scrutinize the seatpost clamp area and the slot for cracks; while some small cracks might be repairable, like those Rob Granville of Carbon Bike Repair UK mentions, others can signify deeper problems like “carbon creep” that will spread over time. Do not purchase a bike if you see evident cracks.

Further critical points of inspection include the front derailleur mounting plate, especially if it’s riveted or bonded; bluish-white powdery deposits can indicate corrosion, leading to mount failure. CBR advises walking away if you see cracks originating from this area. For the fork, if possible, remove it to check the steerer tube for damage at the stem clamping point. If removal isn’t feasible, straddle the top tube, lock the front brake, and apply downward pressure on the front wheel, watching for flex and listening for rasping noises from inside the head tube. This test, often the first CBR performs, can reveal fractured steerers, a dangerous hidden problem.

Finally, check the headset bearings for wear or poor adjustment by lifting the front wheel and swinging the bars. If it feels notchy or rough, the headset may be worn. If there’s excessive play, inspect the bearing seats. Remember, a seized seatpost, indicated by difficulty twisting the saddle after loosening the clamp, is not only a major hassle but also a strong indicator of poor maintenance. If you’re ever in doubt about a carbon bike’s integrity, the most prudent step is to have it professionally assessed by a carbon repair specialist, who possesses the expertise to detect hidden damage that could lead to sudden failure.

In the intricate world of cycling, where the allure of performance meets the practicalities of safety and reliability, informed choices are your most valuable asset. Whether navigating the complexities of a bicycle recall, deciphering the fine print of a warranty, or meticulously inspecting a used carbon frame, empowering yourself with knowledge ensures that every ride is not just exhilarating, but genuinely safe. Stay vigilant, stay informed, and enjoy the ride with confidence.