The future of the internal combustion engine, a marvel of engineering that has powered our world for over a century, is a topic of intense debate and innovation. As the global push for decarbonization accelerates, engineers and scientists are exploring every conceivable pathway to reduce greenhouse gas emissions from the transport sector.

Among the promising, yet complex, solutions being discussed are e-fuels. These so-called ‘liquid sunlight’ alternatives offer a tantalizing vision: a way to keep our existing vehicles running while significantly cutting their carbon footprint. But, like many grand solutions, the reality of e-fuels is nuanced, filled with both potential and significant challenges that demand a closer look.

This in-depth exploration will delve into 14 critical facts about e-fuels, moving beyond the headlines to reveal the practicalities, economics, and energy physics that truly define their role in our future. We’ll break down what e-fuels are, how they’re produced, and the formidable obstacles that stand in the way of them becoming a truly affordable and scalable alternative. Understanding these elements is crucial for anyone interested in the real possibilities for decarbonizing transportation without completely abandoning the familiar roar of an engine.

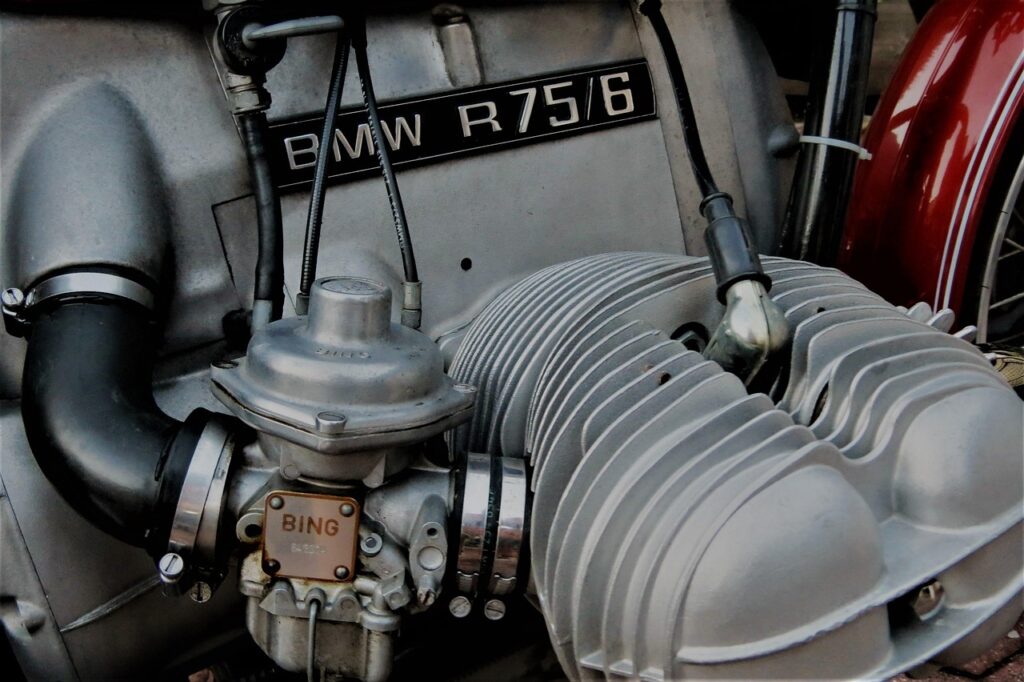

1. **Defining E-Fuels: More Than Just a Name**E-fuels represent a category of advanced fuels that are often lauded as a potential savior for internal combustion engines in a carbon-constrained world. They are fundamentally defined as “drop-in fuels made from solar and wind energy.” This means they are designed to be compatible with existing fuel infrastructure and vehicle engines, making them an appealing option for fleet transitions and legacy vehicle support.

These fuels are known by several names, reflecting the diverse approaches to their creation and application. Beyond the common term ‘e-fuels,’ you might encounter them referred to as ‘power-to-liquids,’ ‘power-to-gas,’ ‘e-gas,’ ‘electrofuels,’ or, as some industry players like Bosch prefer, ‘renewable synthetic fuels.’ Each name underscores a particular aspect of their production or end-use, but they all converge on the core principle of synthesizing fuels using renewable electricity.

The ‘drop-in’ capability is a significant draw, suggesting that a seamless transition could be possible without massive overhauls of current vehicle fleets or refueling stations. This compatibility is often highlighted as a key advantage, potentially mitigating the enormous infrastructure costs and consumer adoption challenges associated with entirely new propulsion systems. It promises a future where our cars, trucks, and planes can continue to run on familiar mechanics, albeit with a drastically cleaner fuel source.

2. **The Core Production Process: Harnessing Water and Carbon**The creation of e-fuels begins with a crucial step: the generation of renewable electricity. This electricity, ideally sourced from abundant solar and wind farms, powers an electrolyzer. The primary function of this device is to perform electrolysis, a process where water is “split into hydrogen and oxygen.”

Once the hydrogen is separated, it becomes a key building block for the synthetic fuel. This hydrogen is then purposefully “combined with carbon dioxide” in a subsequent chemical reaction. The carbon dioxide used in this process can be captured from industrial emissions or even directly from the atmosphere, creating a closed-loop system that theoretically recycles carbon rather than adding new carbon to the atmosphere.

The combination of hydrogen and carbon dioxide yields various “drop-in hydrocarbons like diesel, gas (methane), or jet fuel.” This versatility means e-fuels can be tailored to replace a wide range of petroleum-derived products, from fuels for passenger cars and heavy-duty trucks to aviation and marine applications. The ability to produce different types of fuels from the same fundamental process broadens their potential market and application scope.

3. **The Low-Carbon Potential: A Conditional Green Promise**One of the most attractive aspects of e-fuels is their potential to significantly reduce carbon emissions. The pathway to achieving this low-carbon status is quite specific: e-fuels “can be very low-carbon if made from new, additional renewable electricity.” This condition is crucial and often overlooked in casual discussions about their environmental benefits.

Simply put, for e-fuels to truly be low-carbon, the electricity used in their production must not only be renewable (like solar or wind) but also ‘additional.’ This means that the renewable energy generated specifically for e-fuel production should not divert electricity that would otherwise power homes, industries, or electric vehicles. It must represent new capacity added to the grid solely for this purpose, ensuring a net reduction in carbon emissions rather than simply shifting the burden.

Without this critical ‘additionality,’ the environmental integrity of e-fuels diminishes. If the electricity for e-fuel production comes from existing renewable sources that could power electric vehicles, the overall efficiency of the energy system would be drastically reduced, and the carbon benefits diluted. Therefore, the promise of low-carbon e-fuels is inextricably linked to the rapid and significant expansion of renewable energy infrastructure.

4. **The Cost Paradox: When Green Doesn’t Mean Cheap**While the concept of low-carbon e-fuels derived from renewable electricity sounds ideal, a significant paradox emerges when cost is factored in. The underlying reality is that e-fuels “can’t be low-cost at the same time” as being very low-carbon. This is a fundamental economic challenge that separates them from the often-touted utopian vision.

The primary reason for this cost discrepancy lies in the energy conversion process itself. The journey from renewable electricity to a usable liquid or gaseous fuel involves multiple energy transformations, each incurring a loss. Even as “wind and solar electricity costs are coming down over time,” the initial cost of this power, no matter how cheap, is multiplied by the inherent inefficiencies of the e-fuel production chain.

This means that even if the raw renewable electricity becomes exceptionally inexpensive, the final price of the e-fuel will always carry the compounded cost of the energy lost during conversion. This economic principle is a critical barrier to widespread adoption, suggesting that while e-fuels can be environmentally beneficial under specific conditions, they are unlikely to compete on price with traditional fossil fuels or even directly with grid electricity powering electric vehicles in the near future.

Read more about: Paradise Found: 15 Celebrities Who Secretly Snagged Their Own Caribbean Islands (and How They Live on Them!)

5. **Inherent Inefficiency: The Energy Conversion Hurdle**One of the most significant technical and economic challenges facing e-fuels stems from their “inherently inefficient” production process. This isn’t a flaw that can be easily engineered away; it’s a fundamental aspect of converting electrical energy into chemical energy stored in liquid or gaseous fuels. The process, “at best, converts half of the energy in the electricity into liquid or gaseous fuels.”

This 50% energy conversion loss is a critical figure. It means that for every unit of renewable electricity fed into the system, at least half of that energy is dissipated, typically as waste heat, before it even becomes a fuel that can be stored or transported. This makes e-fuels a very energy-intensive product to create, requiring a disproportionately large amount of renewable electricity generation to produce a meaningful volume of fuel.

Such inefficiency has profound implications for scalability and affordability. To decarbonize a significant portion of the transport sector with e-fuels would necessitate an immense expansion of renewable energy capacity, far greater than what would be needed to directly power electric vehicles. This substantial energy overhead directly translates into higher production costs per liter or gallon, making the economic viability of e-fuels a formidable hurdle.

6. **The Magnified Cost of Electricity: A Compounding Factor**Building on the inherent inefficiency of e-fuel production, the cost of electricity, even if it’s cheap renewable power, becomes a magnified factor in the final price. The core issue is that “power still costs something, and that cost is essentially magnified by the low yield of e-fuels production.”

Consider a scenario where renewable electricity is available at a very competitive price. Due to the less-than-50% conversion efficiency, to produce a specific amount of e-fuel, you would need more than double the equivalent energy input in electricity. This means that the initial cost of that electricity effectively doubles (or more) per unit of usable fuel produced, just to cover the conversion losses.

This compounding effect of cost and inefficiency creates a powerful economic disincentive. Even if the price of wind and solar energy continues its impressive decline, the basic physics of e-fuel synthesis ensures that the ‘fuel’ itself will always be significantly more expensive than the electricity used to create it, making it difficult to compete with more direct electrification pathways.

7. **The Equipment Hurdle: Expensive Electrolyzers and Unproven Cost Reductions**Beyond the cost of electricity and the inefficiencies of the process, the actual manufacturing equipment for e-fuels also presents a significant financial barrier. Specifically, “the electrolyzers used to break water into hydrogen and oxygen are notoriously expensive.” These are not simple devices; they involve complex materials and engineering to operate efficiently and reliably at scale.

There’s been a degree of optimism from some analysts, who “believe electrolyzer prices will go through the floor in the coming decades.” This perspective suggests that technological advancements and mass production could dramatically reduce the capital expenditure required for e-fuel plants, thereby lowering overall production costs. However, this optimistic view lacks concrete evidence according to recent, thorough investigations.

“Our recent and very thorough literature review found no evidence for these claims.” This absence of substantiating data is critical. Without a clear path to significantly cheaper electrolyzers, the capital costs associated with building e-fuel production facilities remain a formidable obstacle. This means that, for the foreseeable future, the high upfront investment in equipment will continue to contribute substantially to the overall cost of e-fuels, dampening expectations for rapid cost reductions.

8. **Setting Realistic Cost Expectations: Debunking the €1.20/Liter Myth**Among the boldest projections for e-fuels has been a claim from Bosch, suggesting these synthetic alternatives would be available at the pump for an incredibly low “1.20 Euro per liter… by 2030.” On its surface, such a figure would make e-fuels economically competitive and a clear game-changer for the internal combustion engine. However, as we’ve explored the intricate realities of e-fuel production, a much more grounded picture emerges, one that strongly contradicts such optimistic pricing.

This seemingly enticing price point simply doesn’t align with the fundamental energy physics and economic hurdles inherent in e-fuel creation. As previously discussed, the process is notoriously inefficient, losing a significant portion of energy in conversion. This inefficiency, combined with the non-negotiable cost of even cheap renewable electricity and the expensive electrolyzer technology, makes a €1.20 per liter price tag in the near future highly improbable.

In fact, our own extensive economic modeling, based on middle-of-the-road assumptions and a thorough literature review, paints a starkly different scenario. We’ve found that it is far more realistic to expect that “significant volumes of renewable e-fuels won’t be made for less than 3 or 4 Euros per liter in 2030.” This substantial difference of 3 to 4 times the projected cost underscores the need for realistic planning and a critical assessment of future energy strategies.

9. **The Crossroads of Decarbonization: E-Fuels or Electrification?**With the urgent need to decarbonize the transport sector, humanity stands at a critical juncture, facing fundamental decisions about how we power our future. It has become abundantly clear that existing low-carbon biofuels or biogas will not be nearly enough to decarbonize all the cars, trucks, ships, and airplanes that keep our global economy moving. This realization forces a clear choice for passenger cars: either transition to electric motors, powered by a charging plug, or strive to keep the internal combustion engine alive by filling it with these new “liquid sunlight” e-fuels.

One pathway champions the familiar roar of an engine, adapting it to a new, cleaner fuel source. This approach seeks to leverage existing infrastructure and a deeply ingrained cultural relationship with internal combustion technology. It offers a vision of continuity, where the form factor and operational mechanics of vehicles remain largely unchanged, but the environmental impact is dramatically reduced.

The alternative, electrification, represents a more fundamental shift in propulsion technology. It calls for widespread adoption of electric motors, supported by a burgeoning network of charging infrastructure. This path promises higher efficiency, direct utilization of renewable electricity, and a cleaner operating experience, but it demands a significant transformation in manufacturing, infrastructure, and consumer habits.

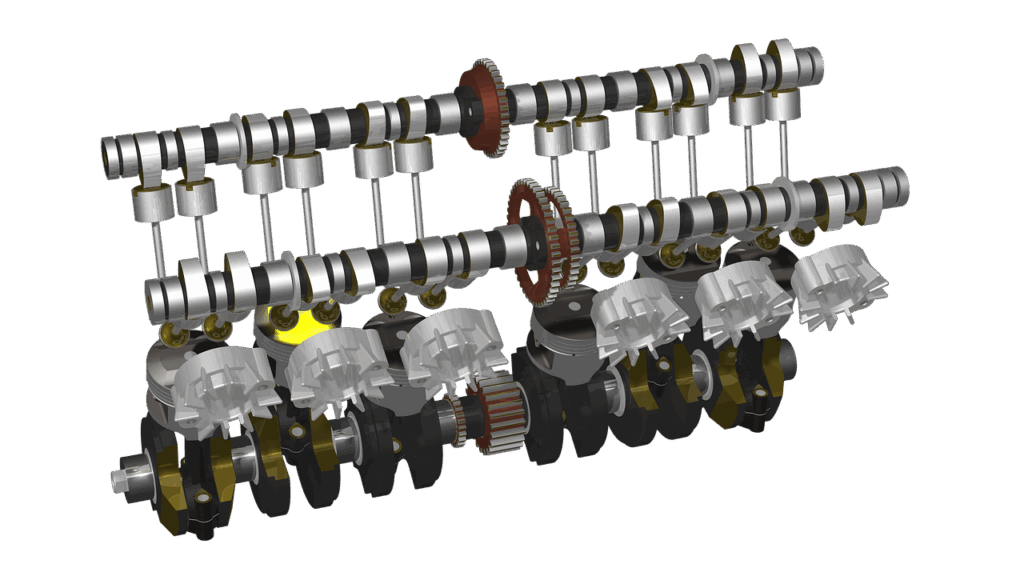

10. **The Efficiency Chasm: Unpacking E-Fuels’ Energy Losses**The most compelling argument against widespread e-fuel adoption for road transport lies in a brutal fact of energy physics: the profound inefficiency of the entire e-fuel pathway compared to direct electrification. When examining how much original renewable electricity actually reaches the wheels of a vehicle, “one of these pathways is over 4 times more efficient than the other.” The e-fuels route is, unequivocally, the less efficient one.

The journey from green electricity to a usable liquid fuel is fraught with energy losses. Our previous economic modeling work, specifically for drop-in diesel technologies, reveals that a staggering “48% of the energy from renewable electricity [is] lost in conversion to liquid fuels.” Imagine generating clean power, only to have nearly half of it dissipate before you even have a fuel ready to use. This makes the production of e-fuels an incredibly energy-intensive process, requiring disproportionate amounts of renewable energy capacity.

Compounding this initial loss is the inherent inefficiency of the internal combustion engine itself. Once the e-fuel is produced, a further “70% of the energy in those fuels will be lost when they are combusted in internal combustion engines.” This figure represents the well-known thermodynamic limits of ICEs, where much of the fuel’s chemical energy is converted into waste heat rather than mechanical motion. The combination of these two significant losses—48% during production and 70% during combustion—culminates in a dismal “total efficiency of 16% for the e-fuels pathway.” This means that “the vast majority of the energy from the sun or wind is lost” before it ever propels a vehicle, making e-fuels a very expensive way to move a car.

11. **The Electrification Advantage: Maximizing Energy from Renewables**In stark contrast to the energy-intensive e-fuel pathway, electric vehicles (EVs) offer a dramatically more efficient method for converting renewable electricity into motive power. The difference in overall system efficiency is not just significant; it is transformative, making electrification a clear front-runner for practical decarbonization efforts in the transport sector.

The path from a renewable power plant to an EV’s wheels involves far fewer energy transformations and considerably less waste. For an electric vehicle, energy losses are contained primarily within two stages: “losing only 10% in charging and 20% by the motor.” The charging loss accounts for the energy dissipated as electricity moves from the grid into the battery, while the motor loss covers the energy converted to heat during the motor’s operation. These are relatively small percentages when compared to the e-fuel chain.

When these efficiencies are combined, the results are compelling: an electric vehicle boasts an impressive “total efficiency of 72%.” This figure represents how much of the original renewable energy actually contributes to powering the vehicle. This striking contrast with the 16% efficiency of the e-fuel pathway highlights an undeniable advantage for EVs, translating directly into “a lot of savings in fuel costs!” While acknowledging that there’s a 6% efficiency loss in electricity transmission and distribution (which we similarly omit when discussing e-fuel transport losses), the overall energy economy of EVs remains vastly superior, ensuring that more clean energy goes precisely where it’s needed.

Read more about: Why Your Next Car Should Be an EV: A Die-Hard Gas Fan’s Unfiltered Take on the Electric Revolution

12. **The Race to Parity: Battery Costs Versus Electrolyzer Costs**The economic viability of any new technology is often determined by its ability to reach cost parity with established alternatives. In the race to decarbonize transport, both e-fuels and electric vehicles are on a trajectory to reduce costs, but the evidence points to vastly different timelines and certainties for each pathway. For electric vehicles, the outlook for cost reduction is particularly strong and well-documented.

There is compelling and extensive evidence that “declining battery costs will bring electric vehicles to cost parity with conventional cars in the near-term.” This phenomenon, driven by technological advancements, economies of scale in manufacturing, and increasing demand, has been observed for years. It suggests that the initial purchase price of an EV will soon no longer be a significant barrier for many consumers, making the transition to electric a financially sensible choice without compromising performance.

Conversely, the optimistic claims surrounding the plummeting costs of e-fuel production equipment, particularly electrolyzers, lack this same foundation of evidence. While some analysts ‘believe’ electrolyzer prices will drop dramatically, our comprehensive literature review “found no evidence for these claims.” This means that the high capital expenditure for e-fuel plants, already a significant hurdle, is unlikely to see the rapid reductions necessary to make e-fuels genuinely affordable or competitive with direct electrification any time soon.

13. **Quantifying the Economic Burden: The Staggering Cost of E-Fuel Decarbonization**The implications of choosing the less efficient e-fuel pathway extend far beyond theoretical energy losses; they translate into tangible, monumental economic costs. To put the financial burden of relying on e-fuels into sharp perspective, consider a direct comparison with existing regulatory frameworks designed to promote greener transportation.

Calculations reveal a sobering truth: “using e-fuels to reduce GHG emissions from vehicles would cost 3 times as much as the penalty for not complying with Europe’s fuel economy standards for passenger cars.” This is not a marginal difference; it represents a colossal additional expenditure for a pathway that, as demonstrated, is inherently less efficient and more complex to scale. Such a premium would place immense strain on economies and consumers alike, making widespread adoption a financially daunting proposition.

This disproportionate cost stems directly from the inefficiencies in e-fuel production and use, coupled with the current and projected high costs of production equipment and renewable electricity magnified by the low yield. It signifies that pursuing e-fuels as a primary decarbonization strategy for light-duty vehicles would essentially be an expensive workaround, incurring penalties far greater than those designed to incentivize cleaner technologies. The financial prudence of such a decision is, therefore, seriously questionable when more efficient alternatives exist.

14. **The Urgency of Climate Action: Why Strategic Choices Matter Now**Ultimately, the discussion around e-fuels is not just about engineering marvels or economic projections; it is deeply intertwined with the urgent global imperative to address the climate crisis. The choices we make now regarding decarbonizing the transport sector will have profound, irreversible consequences for our planet’s future, and therefore, strategic decisions must be based on the most efficient and scalable solutions available.

Choosing the “less efficient pathway – e-fuels – to decarbonize cars will cost a lot.” This cost isn’t merely financial; it encompasses precious resources and, critically, time. Every decision that diverts focus or investment from the most effective solutions is a delay that we, as a global society, can ill afford. The clock is ticking, and half-measures or inefficient detours only push us further behind in the race against climate change.

More than just money, “it will cost us a lot more than money; it will cost us the time we urgently need to roll out electric vehicles and charging infrastructure.” The monumental task of transforming our energy and transportation systems requires rapid deployment, massive infrastructure investments, and broad societal buy-in. Opting for a pathway that demands significantly more renewable energy per kilometer traveled, or relies on uncertain cost reductions, jeopardizes our ability to achieve these critical objectives within the necessary timeframe.

Therefore, a clear-eyed understanding of the facts surrounding e-fuels versus direct electrification is not just academic; it is essential. The evidence strongly suggests that accelerating the rollout of electric vehicles and their supporting infrastructure is the most direct, efficient, and economically sensible path forward. This strategic choice is paramount “if we want to have any chance of containing the climate crisis.” The future of mobility and the health of our planet depend on embracing the most practical and efficient solutions available, moving beyond theoretical possibilities to implement real, impactful change.

As we look ahead, the vision for sustainable transport is becoming clearer. It is a future where innovation is guided not by wishful thinking or the allure of continuity, but by the hard facts of physics and economics. The internal combustion engine has powered generations, but as we navigate the complexities of decarbonization, the path of least resistance—and greatest impact—lies in harnessing renewable electricity directly. The time for decisive action, grounded in efficiency and realism, is now, ensuring a vibrant, clean future for mobility across the globe.