There’s a unique dread that washes over a driver when the familiar hum of the road is suddenly interrupted by an unwelcome symphony of creaks, clunks, and rattles. You’ve just navigated what feels like twenty miles of bad road, maybe exploring some beautiful backwoods, only to hit the smooth pavement and hear your car transform into a tin can full of bolts. That sound isn’t just annoying; it’s your vehicle trying to tell you something important about its well-being.

While the immediate risk of your car losing an essential part on the highway might be low, ignoring these chassis and suspension noises is never a good idea. They are critical indicators that something is amiss, potentially impacting your safety and certainly diminishing the comfort and quiet enjoyment of your ride. Nobody wants to drive a vehicle that constantly sounds like it’s on the verge of falling apart.

Pinpointing the exact source of these mysterious noises can be a challenge. The complex dynamics of a rolling vehicle, the intricate design of modern suspensions, and the way sounds echo and travel through the chassis and body all conspire to make diagnosis difficult. But fear not, because understanding the common culprits is the first step toward restoring peace and quiet to your drive. We’re here to help you decode what your car is trying to tell you.

1. Damaged Control Arm

The control arm, often referred to as an A-arm or wishbone, is a fundamental component that links your car’s suspension system to its chassis. These vital parts incorporate bushings and ball joints, which are specifically designed to facilitate controlled movement and flexibility, playing an integral role in maintaining the precise geometry of your vehicle’s suspension. When these components are operating as they should, your ride is smooth and quiet.

However, control arms are subjected to immense stress and wear over time, making them a common source of suspension noise when compromised. Damage can manifest in several ways. You might experience issues such as loose or excessively worn-out ball joints, which are critical pivot points, or failed rubber or polyurethane bushings that are designed to absorb vibrations and cushion movements.

Furthermore, a control arm itself can become bent or twisted due to impacts, or its mounting points on the vehicle’s frame might suffer damage or rust away, especially in environments exposed to road salt. Each of these scenarios can lead to a cascade of related problems. These issues collectively contribute to a range of alarming suspension noises, signaling that immediate attention is required to prevent further complications and ensure safety.

Read more about: Master the Wild: 14 Essential Survival Gear Items for Any Outdoor Challenge

2. Worn-out Bushings

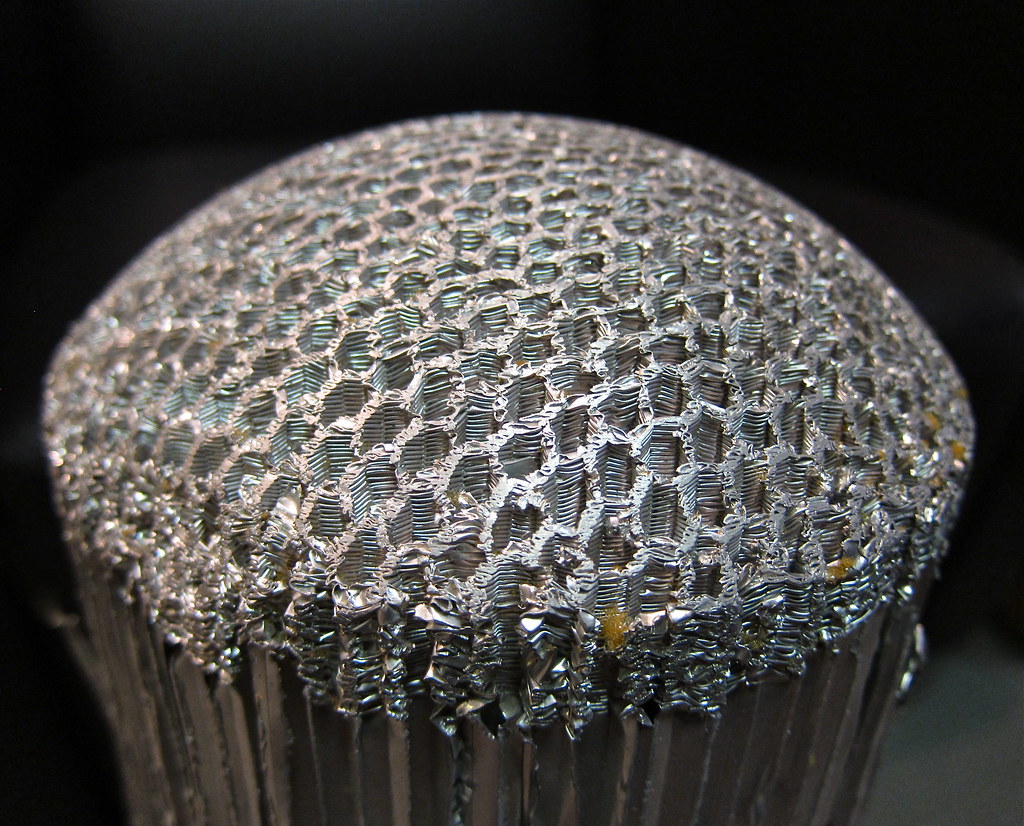

Suspension bushings are unsung heroes of your car’s ride quality, typically made from durable rubber or polyurethane. These essential components act as a crucial buffer, isolating and absorbing vibrations between various suspension parts. Beyond just cushioning, they play a vital role in preventing direct metal-to-metal contact, meticulously maintaining the precise alignment of components, and regulating overall suspension movement to ensure a smooth and controlled driving experience.

Over extended periods of use, and particularly in high-mileage vehicles, these hard-working bushings inevitably begin to wear out. The rubber can shrink and dry out, losing its flexibility and ability to perform its dampening function effectively. When this deterioration occurs, you’ll start to notice distinct noises that indicate a problem is developing within your suspension system.

A common complaint associated with worn-out bushings is a persistent creaking noise, particularly noticeable during suspension movement. While a creak might not signal an immediate, catastrophic failure, it’s a clear warning that these components are reaching the end of their service life and should be investigated. Ignoring this early sign can lead to more serious issues, such as loud clunking or thudding sounds, which suggest excessive play or slack, where components are literally banging into each other over bumps. In severe cases, complete bushing failure can compromise your car’s safety and handling significantly.

Read more about: Buyer Beware: 15 Vintage Coupes That Rarely Make It Past 120,000 Miles Without Major Overhauls

3. Faulty Ball Joints

Ball joints are pivotal connections within your car’s suspension system, serving as flexible links that connect the control arms to the steering knuckles. Their ingenious design allows for controlled movement and rotation, crucial for your wheels to steer and articulate properly. Given their strategic placement and constant workload, these components are highly stressed during every drive, making them susceptible to wear and eventual failure over time.

One of the most frequently encountered issues with ball joints is the development of excessive play or looseness. This means that the control arms and steering knuckles begin to move more freely than they should, rather than in the controlled manner they were designed for. This abnormal movement is a direct cause of noticeable suspension noise. Furthermore, ball joints can also suffer from misalignment, which affects steering precision, or develop torn rubber boots that protect the internal workings.

When a ball joint’s protective boot is compromised, dirt, debris, and moisture can infiltrate the joint, leading to corrosion and contamination of the lubricating grease. Any of these faults will typically manifest as a distinct clunking or knocking noise. These sounds are often heard when you drive over bumps, turn the steering wheel, or during changes in vehicle load, serving as an urgent signal that these critical components need professional assessment and likely replacement to maintain safe and predictable handling.

Read more about: Buyer Beware: 15 Vintage Coupes That Rarely Make It Past 120,000 Miles Without Major Overhauls

4. Deteriorated Tie Rod Ends

Tie rod ends are fascinating components, holding a crucial dual role within your vehicle’s mechanical ensemble: they are categorically part of the suspension system, yet they also serve a vital function within the steering mechanism. These components are responsible for transmitting steering wheel input to the wheels, enabling precise control and direction. While integral to suspension operation, their most immediate symptoms of deterioration often manifest in how your car steers and how its tires wear.

When tie rod ends begin to deteriorate, you’ll typically notice a range of telltale signs that impact your driving experience. These include unsettling steering vibrations, which can be felt directly through the steering wheel, indicating an issue with the link between your steering input and the wheels. Another significant symptom is front-wheel misalignment, which not only affects handling but also contributes to uneven and accelerated tire wear, requiring costly tire replacements much sooner than expected.

Interestingly, while deteriorated tie rod ends are certainly a suspension issue, noise from the suspension may not always be their primary indicator, particularly in the early stages or depending on the severity of the wear. However, as the problem progresses, you might start to hear knocking or rattling sounds, especially when turning or driving over rough surfaces, as the excessive play in the joint becomes more pronounced. Any of these symptoms warrant prompt investigation to ensure your vehicle’s steering remains precise and safe.

Read more about: Olivia de Havilland: Unearthing the Darker Realities Behind a Golden Age Icon’s Glamorous Persona

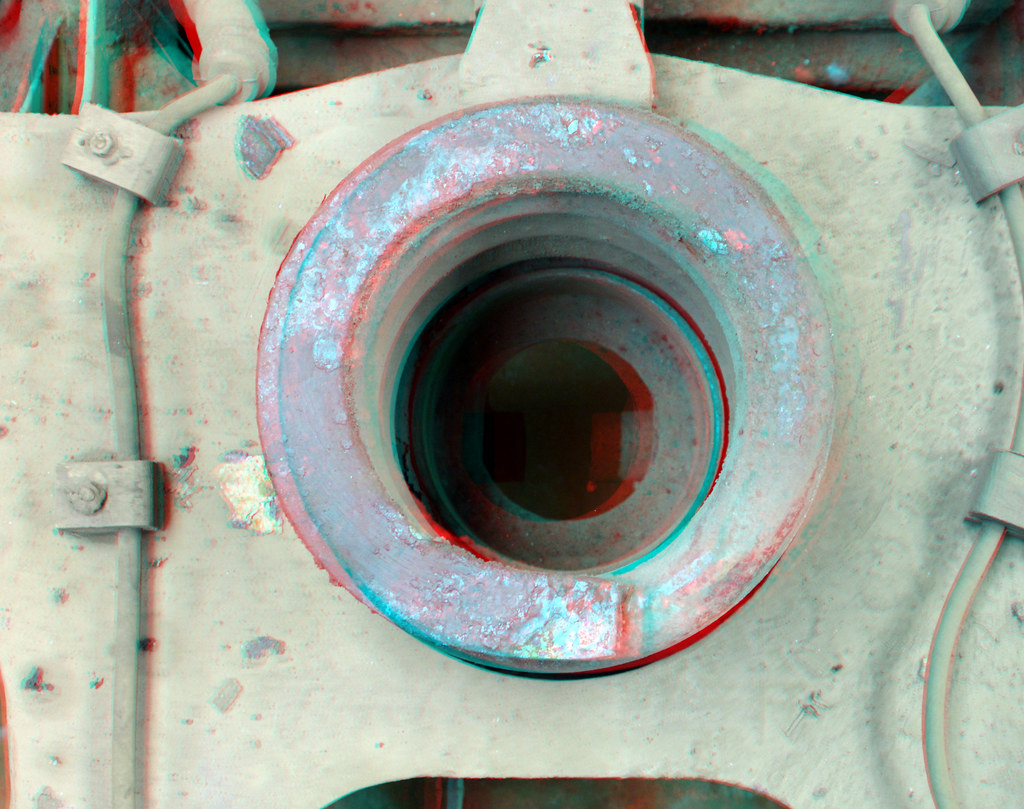

5. Compromised Struts

Struts are multifaceted components, combining the functions of a shock absorber and a spring support into a single unit. They are fundamentally engineered to support the weight of your car’s chassis, allowing for essential wheel articulation and strut rotation. Beyond simply cushioning your ride, well-functioning struts play a critical role in reducing undesirable shuddering and noise from the suspension, contributing significantly to overall ride comfort and stability.

When a strut becomes compromised, its ability to perform these essential functions is severely diminished, leading directly to a variety of unsettling noises. Damage can affect the strut assembly itself or its crucial mounting points. These mounting components, including the upper mounting plate and the upper bearing assembly, are designed to allow smooth rotational movement and absorb vibrations. If they are worn, loose, or damaged, they cannot do their job effectively.

The telltale sounds of compromised struts often include distinct squeaking, persistent creaking, or a sharp knocking noise. These sounds are particularly pronounced when driving over bumps, potholes, or whenever the suspension is actively working. If you hear these noises, especially when turning, it’s a strong signal that an inspection of the upper mounting plate and upper bearing assembly is in order. Addressing compromised struts promptly is crucial for maintaining both ride quality and the predictable handling characteristics of your vehicle.

Read more about: Buyer Beware: 15 Vintage Coupes That Rarely Make It Past 120,000 Miles Without Major Overhauls

6. Defective Shocks

Shock absorbers, commonly just called ‘shocks,’ are pivotal in ensuring your car’s smooth and controlled ride. Their primary function is to dampen the oscillations of your vehicle’s springs, preventing excessive bouncing and allowing the tires to maintain consistent contact with the road surface. Unlike struts, which also bear vehicle weight, shocks are purely dampeners, converting kinetic energy into heat to control suspension movement.

When shock absorbers become defective or worn out, their internal hydraulics degrade. This means the piston inside the shock moves without the proper resistance, often stopping abruptly when hitting a bump, leading to uncontrolled suspension motion. Another common issue can be loose or dried-out mounting bushings, which are meant to provide a secure and quiet connection point. Both scenarios spell trouble for your ride.

Defective shocks are a frequent source of knocking or rattling sounds, which are often most noticeable from the rear suspension, especially when driving over bumps or uneven surfaces. Beyond the annoyance of the noise, worn or damaged shock absorbers pose significant safety risks. They can lead to reduced maneuverability, making your car harder to control in emergency situations, and dramatically diminish on-road safety, all while subjecting you to a persistently uncomfortable and jarring ride.

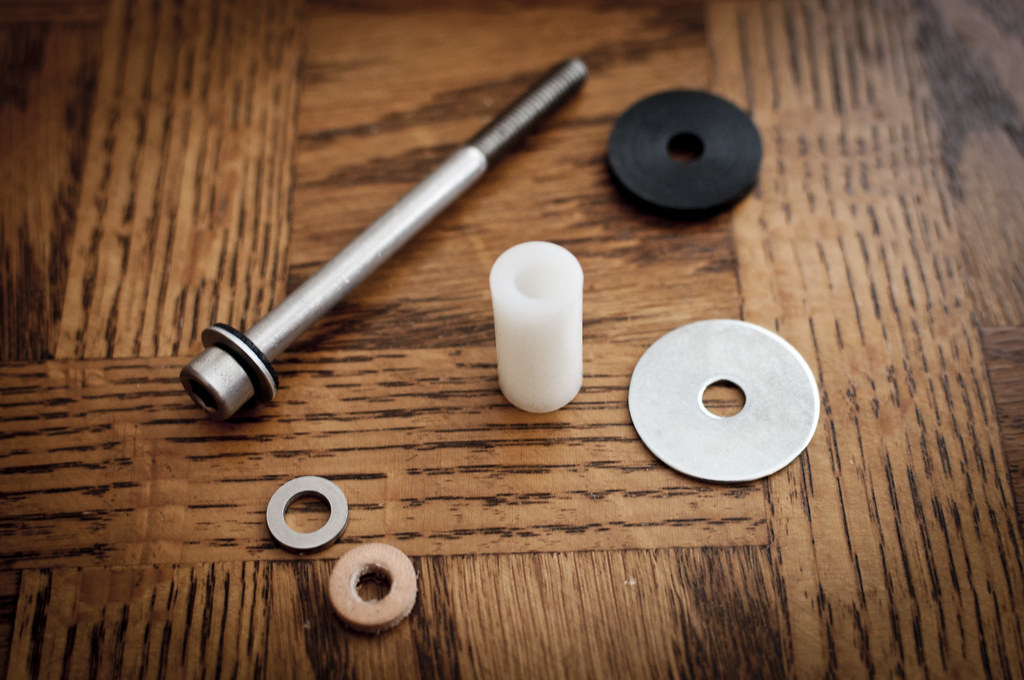

7. Flawed Mounting Hardware

The unsung heroes that bind your entire suspension system together are its mounting hardware. This category encompasses a variety of critical components such as bolts, nuts, washers, and specialized brackets, all meticulously designed to securely fasten the suspension’s various parts to your vehicle’s sturdy chassis. When this hardware is in optimal condition, it ensures a tight, vibration-free connection, allowing the suspension to perform its duties quietly and effectively.

However, even the toughest hardware can become flawed over time. Common issues include bolts that have simply backed out and become loose due to constant vibration and road forces, or hardware that has become damaged, worn, or fatigued from years of stress. Misalignment during a previous repair, or even the presence of insufficient hardware if components were not properly reinstalled, can also lead to significant problems, compromising the integrity of the suspension attachment points.

When mounting hardware is loose or otherwise compromised, it creates a direct pathway for undesirable noises to develop. You’ll typically hear distinct rattling sounds, particularly noticeable over rough roads or during sudden movements, as components are no longer held firmly in place. More serious issues can result in a sharp, metallic clunking noise, signaling metal-on-metal contact where it shouldn’t occur. Such noises are a clear indicator that the structural integrity of your suspension’s attachment points needs immediate inspection and repair.

Continuing our deep dive into the symphony of unusual sounds your car’s suspension might be composing, we now turn our attention to additional critical components that, when compromised, can spell trouble for your ride quality and safety. Understanding these often-overlooked culprits is key to effective diagnosis and a quieter, more confident driving experience. Armed with this knowledge, you’ll be better prepared to interpret what your vehicle is trying to communicate, transforming frustrating noises into actionable insights.

Read more about: The Dragon’s Ascent: Unpacking China’s Modern Military and Expanding Global Reach by 2025

8. Damaged Strut or Shock Pistons

Deep within your car’s struts and shock absorbers lie pistons, components just as vital as the housing they operate within. These pistons are engineered to move through a viscous fluid, providing the necessary resistance to dampen suspension oscillations and ensure a smooth ride. Their integrity is paramount for effective damping, as any damage here can directly compromise the entire strut or shock performance, creating unsettling noises.

Central to the piston’s function are its seals. When these seals are damaged, they can no longer contain the fluid effectively, leading to leakage around the piston. This loss of fluid immediately impacts the strut or shock’s ability to provide consistent resistance, diminishing its damping capabilities significantly. As a direct consequence, you might start hearing distinct squelching, hissing, or gurgling noises as the piston struggles to move through an inadequately filled or compromised chamber.

Further compounding potential issues, the rods that the pistons ride on, found within both shocks and struts, are typically treated with chromium to prevent corrosion. However, over time and exposure to harsh conditions, these rods can become pitted. This surface pitting can directly abrade and damage the internal seals as the piston moves, accelerating fluid loss and increasing internal friction. Such degradation means the component loses its capacity to absorb bumps effectively, and in most cases, these units are sealed and not serviceable, necessitating a full replacement.

Ignoring noises stemming from damaged strut or shock pistons is a recipe for a rapidly deteriorating ride quality. Not only do the squelching and gurgling sounds indicate a loss of damping, but the uncontrolled suspension movement can also lead to premature wear on other components, compromised handling, and a significant reduction in vehicle control, particularly over uneven terrain or during emergency maneuvers.

9. Weakened Suspension Spring

Suspension springs are the backbone of your car’s ability to absorb impacts and maintain ride height, supporting the vehicle’s weight and allowing for controlled wheel articulation. When these vital components become compromised, whether through cracking, breaking, or simply weakening over time, they lose their ability to perform their primary function effectively. This degradation often leads to a variety of disturbing noises that signal deeper structural problems within the suspension.

One of the clearest indicators of weakened or damaged springs is the onset of banging, clunking, rattling, or scraping sounds. These noises typically arise when a broken section of a spring moves independently or comes into contact with other suspension components. While sudden damage can be driver-induced, such as hitting a severe pothole, springs can also naturally weaken and bind over extended periods of use due to fatigue and constant stress, slowly losing their original load-bearing capacity.

Beyond the audible complaints, fatigued springs will also manifest in noticeable changes in your vehicle’s driving dynamics. You might experience excessive body lean when braking hard, where the front of the car dives disproportionately, or a pronounced squatting of the rear under rapid acceleration. These exaggerated weight transfers are direct consequences of springs that can no longer adequately resist movement and support the vehicle’s mass, impacting both comfort and stability.

Addressing weakened or damaged suspension springs is crucial for restoring your car’s intended handling and ride characteristics. Fatigued springs that cannot properly support the vehicle’s weight must be repaired or replaced. While some springs might be capable of being re-shaped back to their OEM specifications, in most cases, a full replacement with new units is necessary to ensure proper support and maintain the predictable, safe handling your vehicle was designed for. This prevents further strain on other suspension parts and re-establishes ride integrity.

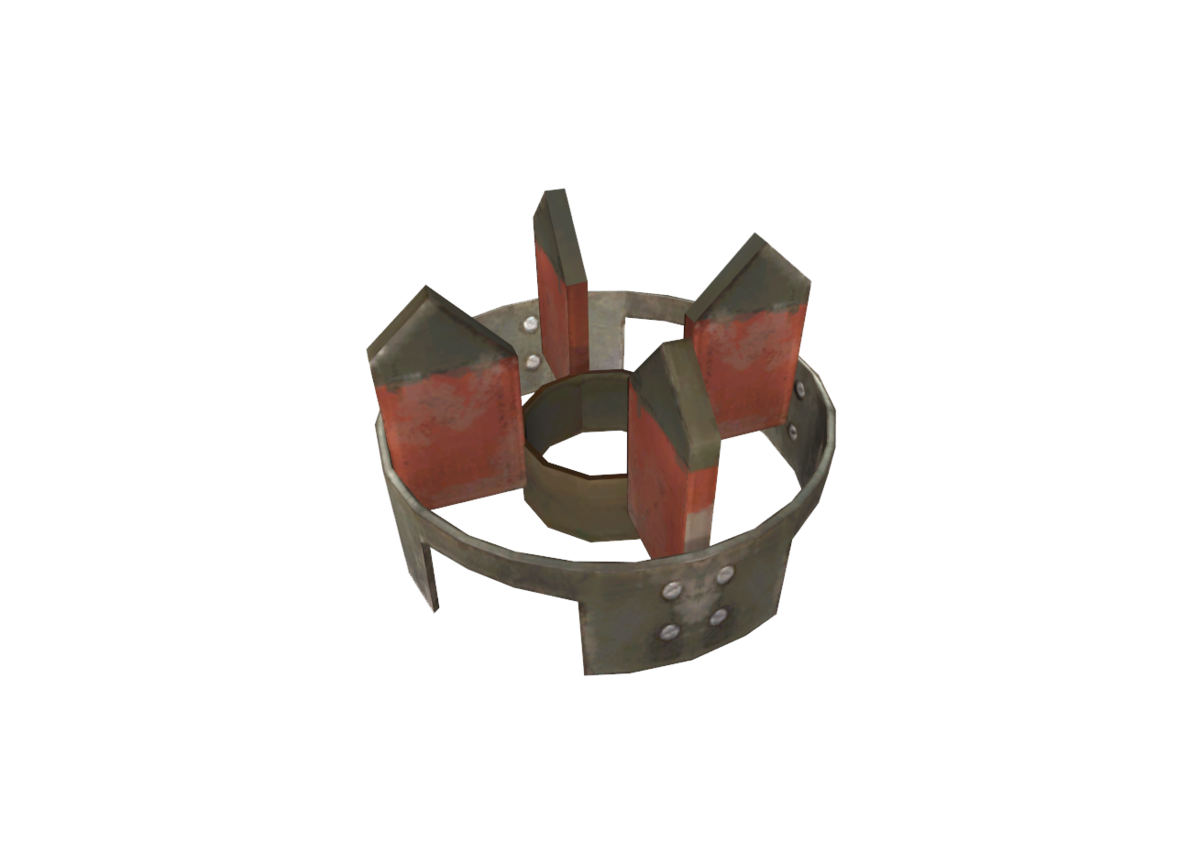

10. Loose or Broken Stabilizer Bar Links

The stabilizer bar, often known as a sway bar, plays a pivotal role in maintaining your vehicle’s stability and level stance, particularly during cornering. This husky bar works by distributing forces between the wheels to reduce body roll, and it’s connected to the chassis via stabilizer bar links. These links are critical for translating the sway bar’s action to the suspension components, and when they become loose or broken, they can be a significant source of unwelcome suspension noises.

When stabilizer bar links are compromised, they commonly produce rattling or distinct clunking sounds. What often distinguishes these noises from those caused by other suspension issues is their timing: they are most frequently heard during cornering, when making sudden maneuvers, or traversing uneven terrain that causes one side of the suspension to articulate more than the other. The location of the noise – front or rear – can also hint at which specific sway bar link, or set of links, is at fault.

The vulnerability of stabilizer bar links often stems from their rubber bushings, located at both ends of the links where they attach to the chassis and suspension. Over time, these rubber components can rot, dry out, or simply wear down, just like other rubber bushings in the suspension system. This deterioration creates excessive play, allowing metal-on-metal contact or uncontrolled movement, which directly translates into audible rattling or clunking as the components shift around.

Fortunately, addressing loose or broken stabilizer bar links is often a relatively straightforward and inexpensive repair. Replacing these worn-out links or their bushings can dramatically improve your car’s handling in turns and eliminate the aggravating noises. While seemingly minor, a properly functioning stabilizer bar system is essential for predictable vehicle dynamics, ensuring your car remains stable and responsive, especially when navigating curves and making evasive maneuvers.

11. Malfunctioning Wheel Bearings

Often overlooked as a source of suspension noise, malfunctioning wheel bearings can produce a surprising array of unsettling sounds, indicating significant wear or damage. These critical components facilitate the smooth rotation of your wheels, allowing for efficient movement while supporting the vehicle’s weight. When they begin to fail, the resulting noises are not just annoying; they are a clear warning sign that demands immediate attention for safety and performance.

Malfunctioning wheel bearings are notorious for generating a diverse repertoire of sounds, including grinding, growling, humming, whirring, clicking, and even snapping. These distinct noises arise from the internal damage within the bearing, causing increased friction as the bearing components grind against the rotating hub or spindle. A key characteristic of wheel bearing noise is its speed dependency: the sound often intensifies as the car speeds up and may change in pitch or volume during turns or corners, providing crucial diagnostic clues.

Pinpointing a faulty wheel bearing often requires a hands-on approach. You might detect a problem by listening for a whining noise during driving, noting if one wheel hub feels significantly hotter than the others after a drive, which points to excessive friction. A “dry park check” can also be useful; with the car safely lifted, try jiggling the wheel side-to-side and up-and-down. Any excessive play or roughness, accompanied by grinding or rumbling sounds when rotating the wheel by hand, strongly suggests a failing wheel bearing.

Driving with a malfunctioning wheel bearing is not recommended, as it poses substantial safety risks. Beyond the incessant noise, a severely damaged bearing can lead to wheel detachment, sudden loss of control, or failure of other interconnected components. While replacing a wheel bearing can be a moderately involved repair, the peace of mind that comes from knowing your wheels are securely and smoothly rotating is invaluable, restoring both quiet and safety to your journeys.

Read more about: Mechanics’ Top Frustrations: 14 Bad Car Habits You Need to Stop Now to Save Money and Your Vehicle’s Life

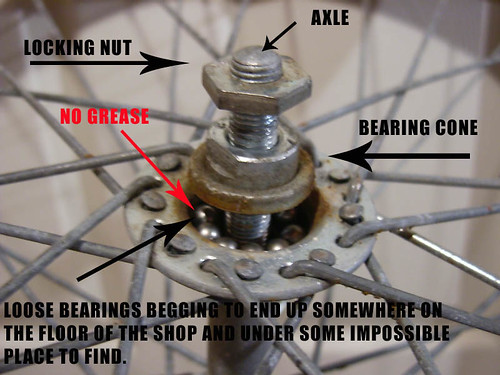

12. Insufficient Lubrication

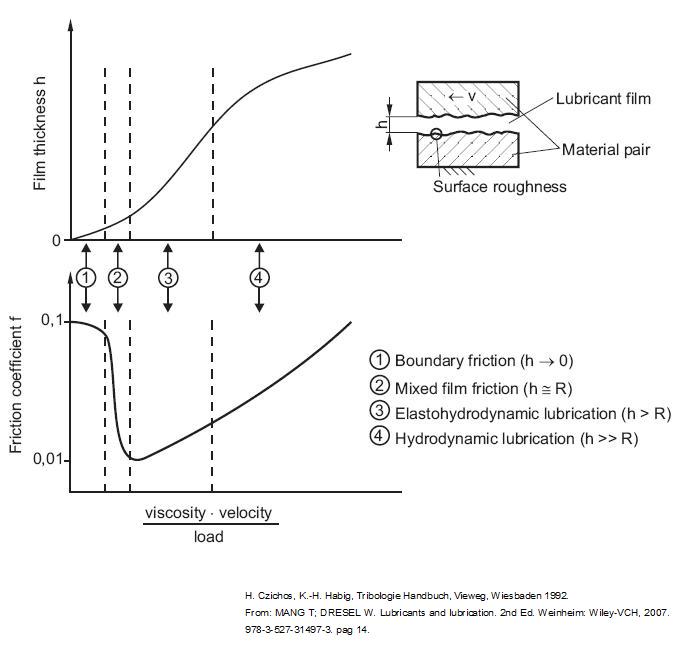

Lubrication is the silent guardian of many moving parts in your vehicle’s suspension system, reducing friction and preventing premature wear. When critical suspension joints, such as ball joints or control arm bushings, suffer from a lack of proper lubrication, the consequences are often immediately audible. This seemingly minor issue can rapidly escalate from an irritating sound to accelerated wear and eventual component failure, highlighting the importance of basic maintenance.

The most common auditory signals of insufficient lubrication are distinct squeaking or creaking noises. These sounds occur as metal components rub against each other or against dried-out rubber/polyurethane without the necessary fluid barrier. Similarly, you might encounter a persistent groaning noise, particularly noticeable when turning the steering wheel, which often indicates a dry joint, commonly found in components like the idler or pitman arm. Without adequate grease, these movements become abrasive, leading to friction and noise.

This grating or rubbing sound during suspension movement is not merely a nuisance; it’s a warning. The absence of proper lubrication allows components to wear down at an accelerated rate, compromising their structural integrity and potentially leading to excessive play. What might start as a simple creak can, if ignored, turn into a louder clunk as the worn components develop greater clearances and begin to bang against each other.

The solution for insufficient lubrication is often straightforward and cost-effective: re-lubrication. For greasable joints, a simple application of the correct grease can restore quiet operation and extend component life. For sealed joints where re-lubrication isn’t an option, the noise signals that the seal has likely failed, allowing the lubricant to escape and contaminants to enter, indicating that component replacement is the only viable long-term fix to prevent more serious damage and maintain the suspension’s intended performance.

Read more about: Watch Out: 12 Compact Cars Prone to Major Engine Issues Before 80,000 Miles – A Consumer Guide

13. Improper Torque Settings and Misalignment

At the foundation of a quiet and reliable suspension system lies the precise installation and adjustment of its components. Improper torque settings and misalignment are foundational culprits behind many suspension noises, often stemming from either negligence during maintenance or poor installation practices. These issues create instability within the suspension, leading to excessive play where none should exist, and manifesting as a variety of unsettling sounds.

When fasteners—the bolts, nuts, and washers that secure suspension components—are not tightened to manufacturer specifications, they can gradually back out due to constant vibration and road forces. This looseness creates excessive play, allowing components like control arms, sway bar links, or strut mounts to rattle or clunk against their mounting points. Even a slightly under-torqued nut can be enough to introduce an audible complaint and compromise the integrity of the suspension attachment.

Misalignment, on the other hand, refers to incorrect angles or positioning of suspension components relative to each other or the vehicle chassis. This can arise from improper installation, such as components not seating correctly, or after a repair where alignment was neglected. Misalignment not only contributes to uneven and accelerated tire wear but can also induce stresses on joints and bushings, leading to creaking, groaning, or rubbing noises as components operate outside their intended parameters.

Addressing issues of improper torque and misalignment is paramount for both vehicle safety and longevity. Adhering strictly to Original Equipment Manufacturer (OEM) recommended tightening torque specifications during any repair or component replacement is non-negotiable. Furthermore, using new, high-quality locking nuts and mounting hardware ensures a secure and lasting connection. Simple actions, like tightening a strut gland nut that has backed out and applying a drop of anaerobic thread locker, can prevent recurrence and restore peace to your ride.

**Restoring the Peace: Your Next Steps for a Quieter Ride**

The array of noises your car’s suspension can make might seem daunting, each sound a cryptic message about its underlying health. From the gentle creak of a dry bushing to the alarming clunk of a failing ball joint or the persistent hum of a worn wheel bearing, your vehicle is always communicating. Ignoring these signals is never advisable; they are not just minor annoyances but critical indicators that something is amiss, potentially impacting your safety, handling, and the long-term health of your car.

While this guide has empowered you with detailed insights into common causes, diagnosing suspension noises can still be a tricky endeavor. The echoing nature of sounds through the chassis, the intricate design of modern suspension systems, and the dynamic environment of a rolling vehicle all conspire to make pinpointing the exact source a challenge. However, by understanding the symptoms associated with each component, you’re well on your way to narrowing down the possibilities.

Read more about: The Hidden Costs of Customization: 15 DIY Truck Upgrades That Can Plummet Your Resale Value

Whether you’re a seasoned DIY mechanic or prefer to entrust your vehicle to professionals, providing as much specific information as possible—the type of noise, when it occurs (over bumps, turning, braking), and its approximate location—will significantly aid in an accurate diagnosis. Remember, your suspension is a vital safety system. What might start as a minor issue can quickly escalate into a far more serious problem if left unattended. Don’t hesitate to investigate or seek expert help. A quiet, smooth, and safe ride is within your reach.