The relentless quest for larger, more powerful aircraft engines has been a driving force in aviation history, continuously pushing the boundaries of technology and engineering. These engines are far more than mere mechanical constructs; they embody the very heart of aviation, propelling human ambition faster and further across vast distances. Their journey, from the early piston engines to the transformative jet propulsion era, is a testament to an unyielding pursuit of power, efficiency, and, crucially, unwavering reliability.

Yet, raw power alone is insufficient for the demands of modern commercial aviation. The true measure of an engine’s greatness lies in its capacity for sustained, reliable operation over an extended lifespan, often enduring tens of thousands of flight hours. This pursuit of longevity is deeply intertwined with engineering excellence, the meticulous selection of advanced materials, and rigorous testing protocols, all of which ensure that these complex systems can withstand the intense rigors of continuous flight for durations that once seemed unimaginable.

In this analytical exploration, we delve into some of the most impressive commercial aircraft engines ever conceived. These mechanical marvels exemplify not only groundbreaking technological innovation but also the industry’s profound commitment to crafting components designed for enduring performance and unparalleled operational reliability. They are the giants that facilitate global connectivity, embodying the pinnacle of aerospace engineering built to last, often operating flawlessly for incredibly long durations, reflecting the aviation industry’s impressive failure rate of less than 1 in 1 million flight hours for modern jet engines.

1. **General Electric GE9X**

The General Electric GE9X stands as the crown jewel of modern aviation engineering, serving as the formidable heart of the Boeing 777X. This colossal engine boasts an unparalleled fan diameter of 134 inches, a dimension that not only makes it the largest ever produced but also firmly establishes a new benchmark for power within the commercial aviation sector.

Beyond its sheer size, the GE9X was meticulously developed to offer unmatched efficiency and environmental performance. Its design significantly reduces both fuel consumption and carbon emissions, a critical advancement for sustainable air travel. This remarkable efficiency is achieved through the integration of cutting-edge advanced materials and sophisticated aerodynamic technologies, making it a true epitome of innovation in aircraft propulsion.

The engineering philosophy behind the GE9X underscores a profound commitment to sustained, reliable operation over extensive periods. Its components are designed to function flawlessly, having undergone a gauntlet of challenges that mimic real-world conditions, much like the rigorous manufacturing standards and testing processes that all high-performance engines endure. This meticulous attention to detail ensures that the engine can handle the continuous demands and rigors of flight, contributing to the overall high reliability statistics of modern jet engines.

Read more about: Inside the Boeing 777X Test Jet: Folding Wings, Giant Engines, and the Push Towards Certification

2. **General Electric GE90-115B**

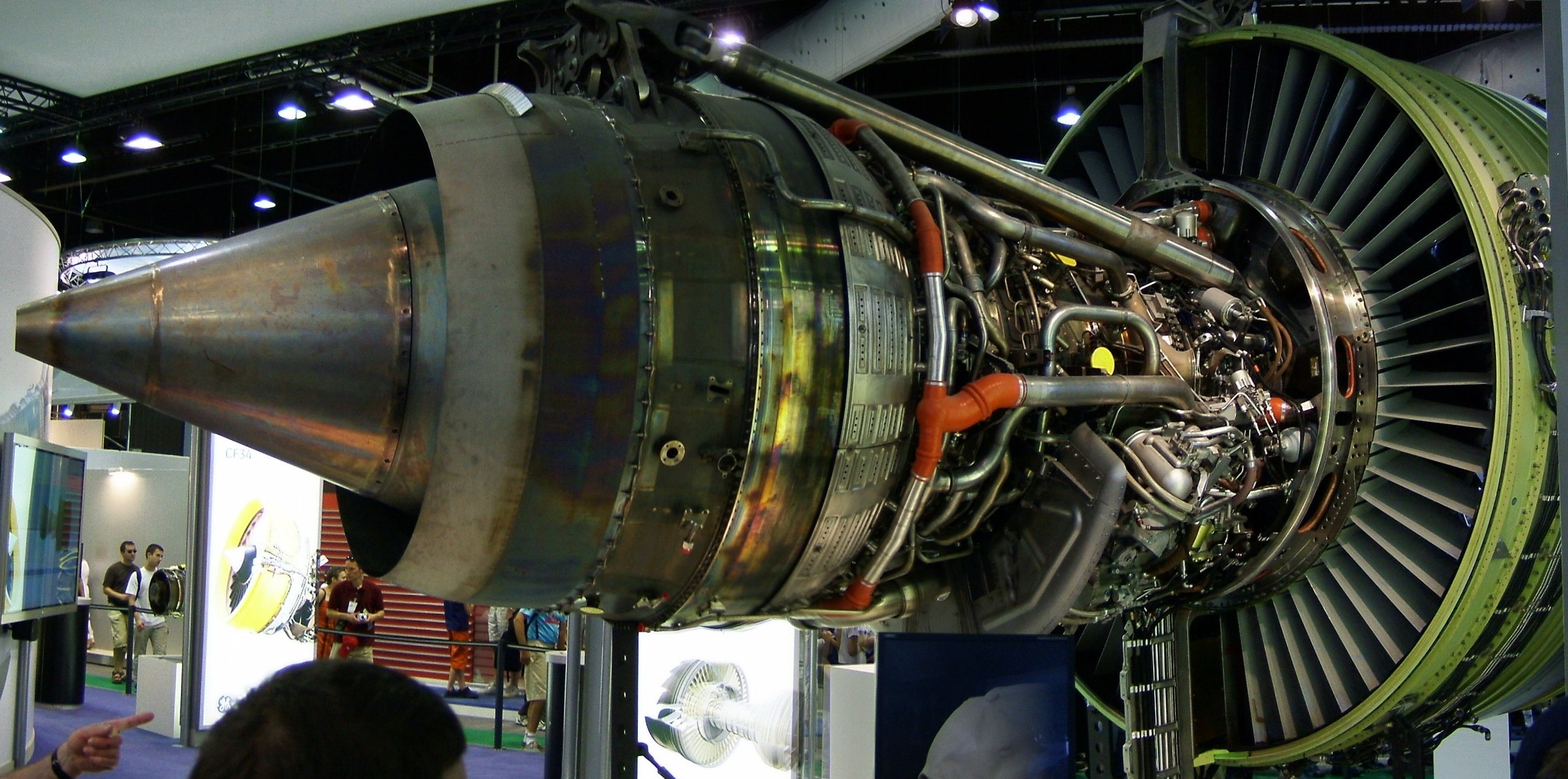

Before the advent of the GE9X, the General Electric GE90-115B reigned supreme as the pinnacle of jet engine technology. It was the powerhouse behind the iconic Boeing 777-300ER, propelling it to new heights of performance and range. With its impressive fan diameter of 128 inches and a thrust capability reaching up to an astonishing 115,300 lbf, it proudly held the title of the world’s most powerful engine for a significant period.

This engine is renowned throughout the industry for its exceptional reliability and robust performance, qualities that are crucial for long-haul operations. Its enduring success is a direct consequence of stringent quality control measures implemented during its manufacturing, coupled with extensive testing that replicates the most demanding operational scenarios. Such comprehensive processes are fundamental in producing an engine capable of delivering consistent, dependable service across tens of thousands of flight hours.

Playing a crucial role in connecting cities across the globe with its long-haul capabilities, the GE90-115B marked a significant milestone in aviation history. Its proven track record of dependability solidified its reputation, demonstrating how engineering prowess, meticulous material selection, and continuous refinement contribute to engines that not only perform powerfully but also maintain their operational integrity over an immensely prolonged service life.

3. **General Electric GEnx**

The General Electric GEnx engine represents a significant leap forward in both efficiency and eco-friendly operation within commercial aviation. Specifically designed to power the Boeing 787 Dreamliner and the Boeing 747-8, its substantial 111-inch fan diameter facilitates a remarkably quieter and significantly more fuel-efficient flight experience for both passengers and airlines.

A key aspect of the GEnx’s advanced design involves its strategic utilization of lightweight yet incredibly strong materials, such as carbon-fiber composites. These materials are instrumental in reducing the engine’s overall weight while simultaneously improving its performance metrics. This material science innovation, as emphasized in the broader context of engine reliability, directly contributes to enhanced durability and, consequently, longer operational lifespans for critical components within the engine.

The introduction of the GEnx has empowered airlines to open new, more direct routes and to operate their fleets more sustainably, reflecting the evolving priorities of the aviation industry towards environmental stewardship. Its commitment to innovation, as embodied by GE, means an inherent focus on ensuring that every component functions flawlessly under the extreme rigors of flight, a foundational requirement for achieving exceptional total flight hours.

Moreover, engines like the GEnx are typically equipped with advanced real-time monitoring systems. These sophisticated sensors track engine performance data continuously, allowing for immediate corrective actions or proactive maintenance scheduling if any anomalies are detected. Such proactive approaches significantly extend the service life of the engine, ensuring its continued reliability and demonstrating a dedication to long-term operational viability, making it a prime example of an engine built for enduring service.

4. **Rolls-Royce Trent XWB**

Dedicated to the Airbus A350 XWB, an aircraft celebrated for its exceptional efficiency and expansive range, the Rolls-Royce Trent XWB stands as its indispensable driving force. Boasting an impressive fan diameter of 118 inches, the Trent XWB is meticulously tailored to meet the demanding requirements of long-haul travel, consistently offering outstanding fuel efficiency and significantly reduced emissions.

The engine’s sophisticated design and cutting-edge technology are engineered not only to achieve superior performance but also to ensure lower operating costs for airlines and a noticeably quieter cabin for enhanced passenger comfort. This blend of operational and experiential benefits is a direct result of Rolls-Royce’s unwavering dedication to engineering excellence, which frequently employs high-temperature alloys and advanced composite materials capable of withstanding the intense heat and pressure inherent within an engine’s core, thus building for endurance.

The Trent XWB exemplifies Rolls-Royce’s commitment to advancing aerospace propulsion, pushing the boundaries of what is possible in commercial jet engine technology. This continuous advancement is rigorously supported by exhaustive testing protocols, including prolonged endurance testing designed to simulate countless hours of real-world flight conditions. Such stringent evaluations ensure that engines like the Trent XWB are not merely powerful but are fundamentally built to last, providing reliable service for truly exceptional flight durations over many years of operation.

5. **Rolls-Royce Trent 900**

The Rolls-Royce Trent 900 engine has been absolutely integral to the operational success of the Airbus A380, famously known as the world’s largest passenger airliner. With a formidable fan diameter of 116 inches, this engine provides the colossal thrust necessary to lift and sustain this gargantuan aircraft, skillfully marrying immense power with essential fuel efficiency to perform its missions reliably.

This engine incorporates several innovative features, most notably its distinctive three-shaft configuration. This architectural choice is designed to optimize both performance and fuel consumption across varying flight conditions, contributing significantly to the A380’s well-earned reputation for exceptional comfort and operational excellence on its long-distance routes. This optimization, paired with the stringent manufacturing standards and meticulous assembly by skilled technicians, underpins the engine’s ability to maintain peak performance over extraordinarily long periods.

The Trent 900’s enduring presence and performance demonstrate how advanced engine architecture is absolutely key to achieving the kind of sustained, reliable service life that modern commercial aviation demands. Its design reflects an industry where daily pre-flight checks, rigorous routine inspections, and scheduled overhauls are not just protocols but fundamental practices that ensure engines deliver consistent reliability for prolonged operational periods, making the Trent 900 a testament to engineering longevity in the skies.

Read more about: Unveiling the Future: Life Aboard the USS Gerald R. Ford, the World’s Largest Aircraft Carrier

6. **Engine Alliance GP7200**

In a remarkable display of industry collaboration, the Engine Alliance GP7200 emerged as a formidable powerplant, jointly produced by two aerospace giants: General Electric and Pratt & Whitney. This engine stands proudly as an alternative to the Rolls-Royce Trent 900, also powering the majestic Airbus A380. With an imposing fan diameter of 116 inches, the GP7200 mirrors the colossal scale required to propel the world’s largest passenger airliner across continents.

What truly sets the GP7200 apart is its unique fusion of technologies, drawing expertise from both parent companies. This collaborative spirit has culminated in an engine celebrated across the industry for its intrinsic reliability, exceptional fuel efficiency, and notably lower noise levels. These attributes are not just engineering achievements; they translate directly into tangible benefits for both airlines and passengers, shaping the experience of long-haul travel.

The operational prowess of the GP7200 has made it a favorite among airlines seeking to maximize economic operation without compromising on passenger comfort. Its ability to deliver consistent performance over extended flight durations is a testament to the rigorous design and manufacturing standards inherited from its esteemed creators. Such an engine empowers carriers to maintain demanding flight schedules with confidence, knowing their powerplants are built for endurance.

This powerhouse represents a strategic choice for operators of the A380, underlining how pooled innovation can lead to superior outcomes. Its robust design and proven track record underscore the collective commitment to creating engines capable of sustained, high-performance operation over tens of thousands of flight hours, contributing significantly to the A380’s enduring legacy and demonstrating deep intrinsic reliability features essential for future flight endurance.

7. **Rolls-Royce Trent 1000**

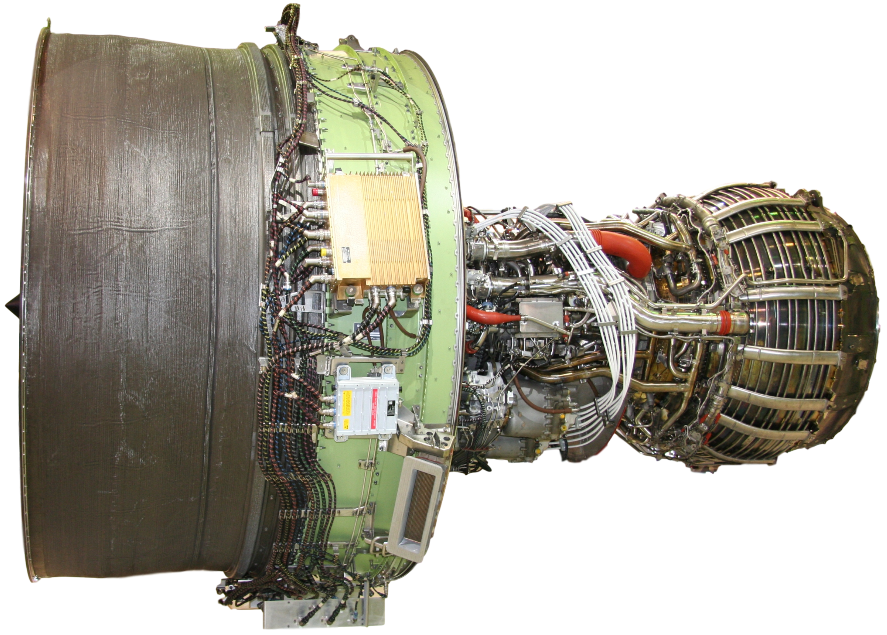

Specifically engineered to meet the ambitious demands of the Boeing 787 Dreamliner, the Rolls-Royce Trent 1000 is a marvel of efficiency and environmental consciousness. This engine features a substantial fan diameter of 112 inches, meticulously crafted to align with the Dreamliner’s revolutionary vision for air travel. It delivers unparalleled efficiency and significantly improved environmental performance, making it a cornerstone of modern, sustainable aviation.

The Trent 1000 embodies the Dreamliner’s core promise: to revolutionize air travel with greater fuel efficiency and extended range. Its design enables airlines to operate new, non-stop routes, connecting distant cities with a reduced environmental footprint. This synergy between airframe and engine has reshaped long-haul dynamics, proving that advanced engineering can deliver both performance and ecological responsibility.

Incorporating a suite of cutting-edge technologies, the Trent 1000 is not merely about thrust; it’s also about refining the passenger experience. Its innovations are specifically geared towards reducing noise and emissions, ensuring a remarkably quieter and smoother flying experience for passengers across the globe. This focus on holistic performance elevates the journey beyond mere transportation, showcasing sophisticated technological advancements.

Rolls-Royce’s unwavering commitment to the long-term reliability of the Trent 1000 is evident in every aspect of its design and manufacturing. Built to withstand continuous operation under diverse conditions, this engine exemplifies the meticulous engineering required for exceptional total flight hours. It is an intrinsic component of the Dreamliner’s vision, propelling future flight endurance with a blend of power, efficiency, and steadfast dependability.

Read more about: Unveiling the Future: Life Aboard the USS Gerald R. Ford, the World’s Largest Aircraft Carrier

8. **Pratt & Whitney PW4000**

The Pratt & Whitney PW4000 series stands as a testament to versatility and robust engineering, encompassing a comprehensive range of powerful engines designed to serve a variety of wide-body aircraft. With fan diameters stretching up to an impressive 112 inches, these engines have been meticulously tailored for demanding applications, including powering variants of the iconic Boeing 777. Their widespread adoption highlights a legacy of proven performance.

Renowned throughout the industry for its exceptional durability and outstanding operational efficiency, the PW4000 series leverages advanced aerodynamic design and meticulously selected materials. This sophisticated approach maximizes fuel economy while simultaneously minimizing the maintenance costs that airlines face, directly supporting their efforts to provide cost-effective and reliable service to a global clientele.

The commitment to engineering excellence within the PW4000 line ensures that each engine can withstand the rigors of continuous flight, contributing to its remarkable longevity. Its design principles are deeply rooted in the pursuit of sustained performance, reflecting an industry-wide dedication to components that not only perform powerfully but also maintain operational integrity over immensely prolonged service lives, enduring tens of thousands of flight hours.

This series has cemented Pratt & Whitney’s reputation for delivering engines that are not just powerful, but inherently reliable for the long haul. The PW4000’s enduring presence across a diverse fleet of wide-body aircraft underscores its intrinsic reliability features and its profound impact on ensuring future flight endurance, continuing to serve as a workhorse in global aviation for decades.

9. **Rolls-Royce Trent 800**

The Rolls-Royce Trent 800, a significant contributor to the success of the Boeing 777 program, commands attention with its substantial 110-inch fan diameter. This engine was specifically developed to power several variants of the Boeing 777, offering substantial improvements in fuel efficiency and a welcome reduction in noise levels. It quickly became a vital component in the evolution of twin-aisle aircraft, enhancing their operational viability.

Its exceptional performance characteristics were instrumental in enabling the Boeing 777 to emerge as one of the most successful twin-aisle aircraft in history. By facilitating long-range, direct flights that seamlessly connect cities across continents, the Trent 800 played a critical role in expanding global connectivity. This engine truly embodied the spirit of modern long-haul travel, making previously challenging routes economically feasible.

The Trent 800’s consistent performance and unwavering reliability have profoundly solidified Rolls-Royce’s esteemed reputation as a leader in wide-body aircraft engines. Its engineering, meticulously refined through exhaustive testing protocols and continuous operational feedback, demonstrates an enduring commitment to quality. Such diligence ensures the engine’s capability to perform under the most demanding flight conditions, contributing to its sustained operation.

For years, the Trent 800 served as a cornerstone of the 777 fleet, demonstrating how thoughtful design and robust construction translate into remarkable operational longevity. It represents a powerful example of an engine engineered for future flight endurance, continually delivering powerful, dependable service across a vast number of flight hours and upholding the highest standards of aerospace engineering for decades.

Read more about: Unveiling the Future: Life Aboard the USS Gerald R. Ford, the World’s Largest Aircraft Carrier

10. **Pratt & Whitney PW1000G**

Marking a truly revolutionary stride in jet engine design, the Pratt & Whitney PW1000G, affectionately known as the Geared Turbofan (GTF), represents a paradigm shift for commercial aviation. While its fan diameters, up to 81 inches, might appear smaller compared to its wide-body counterparts, its impact on efficiency and environmental performance is anything but. This engine series is predominantly utilized on various narrow-body aircraft, most notably the Airbus A320neo family.

The brilliance of the GTF lies in its innovative geared fan technology. This ingenious mechanism allows the fan and the low-pressure compressor/turbine to spin at different, optimized speeds, leading to significant reductions in fuel consumption, noise output, and CO2 emissions. This technological leap has set new and ambitious standards for the sustainability of commercial aviation, aligning perfectly with evolving global environmental priorities.

The introduction of the PW1000G has empowered airlines operating narrow-body fleets to achieve unprecedented levels of efficiency and environmental stewardship. Its design doesn’t just promise; it delivers substantial operational savings and a quieter footprint, making air travel more sustainable for passengers and surrounding communities alike. This engine is a powerful statement about how innovation can drive both economic and ecological benefits.

The PW1000G is not merely an engine; it is a vision for the future of flight, showcasing intrinsic reliability features adapted for a new class of aircraft. Its ability to redefine efficiency for narrow-body operations highlights its profound impact on future flight endurance. This revolutionary geared turbofan technology ensures not only impressive flight hours but also a greener, more sustainable trajectory for aviation for decades to come.

**Future Outlook: Charting a Course for Infinite Horizons**

Our journey through these ten colossal commercial airline engines underscores a relentless human drive for innovation and endurance. From the unparalleled thrust of the GE9X to the revolutionary efficiency of the PW1000G, each engine represents a pivotal chapter in the quest for superior air travel. Yet, as impressive as these achievements are, the aviation industry remains firmly fixed on the horizon, eagerly exploring what comes next in propulsion technology.

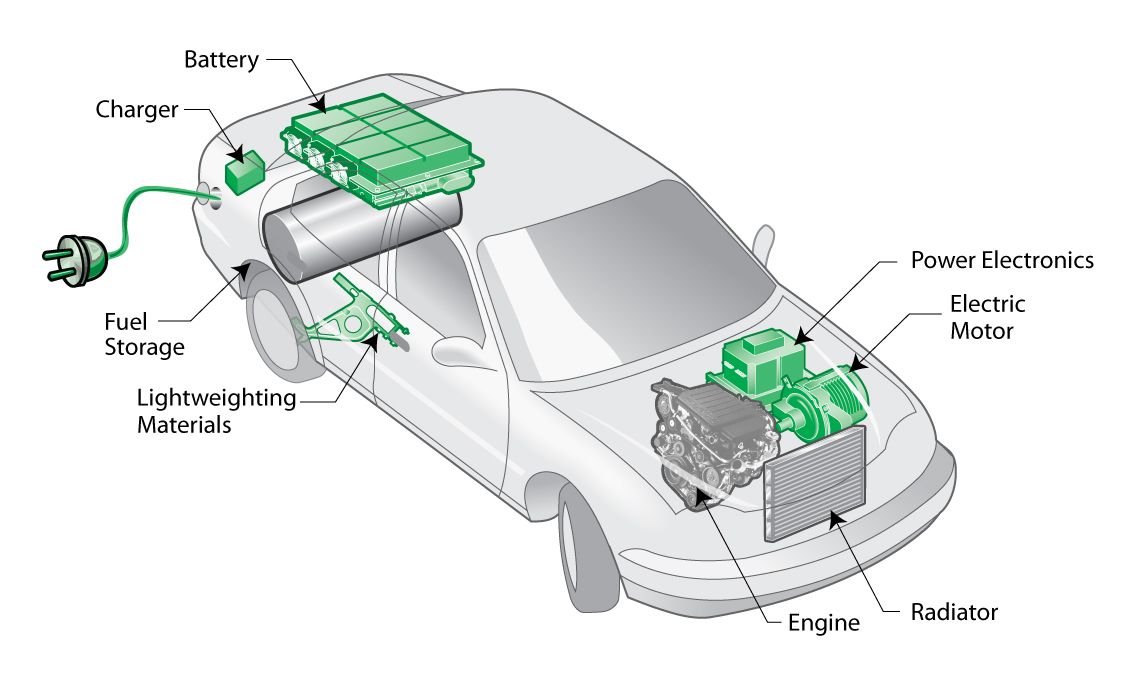

The future of aircraft engines is an electrifying prospect, with engineers and visionary designers pushing the boundaries further than ever before. The current trajectory points towards groundbreaking innovations such as electric and hybrid propulsion systems, promising not only the potential for even larger and more powerful engines but also a commitment to greener, more sustainable solutions for air travel. Imagine a future where noise and emissions are drastically cut, enhancing global connectivity with minimal environmental impact.

The development of engines capable of harnessing alternative fuels is already well underway, alongside the integration of advanced materials designed to drastically reduce weight and significantly enhance efficiency. These ongoing advancements hint at the dawn of an entirely new era in aviation technology, one where operational longevity is coupled with ecological responsibility. The goal remains constant: to propel humanity faster, further, and with an ever-lighter touch on our planet, ensuring future flight endurance beyond our current imaginings.

This continuous pursuit of excellence in engine design, manufacturing, and maintenance ensures that the giants of the sky will continue to operate with unparalleled reliability for countless flight hours. It is a testament to the fact that in aviation, innovation is not just about power, but about the profound, enduring impact on our world, continually setting new benchmarks for what is possible in the skies above. The unwavering commitment to pushing these technological frontiers promises an exciting and sustainable future for global air travel.