Engines are, without a doubt, the very heart of any vehicle, masterfully converting fuel into the formidable power needed to propel your car down the road. While the marvels of modern automotive engineering mean that today’s engines are typically built for impressive durability and efficiency, they are not immune to the relentless forces of wear and tear, the repercussions of inconsistent maintenance, or, on occasion, manufacturing anomalies. Understanding the intricate mechanics of common engine issues and knowing precisely how to address them can be the difference between a minor hiccup and a monumental, budget-breaking repair.

This comprehensive article embarks on an analytical journey, delving into some of the most frequently encountered engine problems that, if left unattended, can rapidly escalate into severe, costly repairs or even necessitate a complete engine replacement. We will dissect the tell-tale signs, unearth the underlying causes, and provide practical, expert-driven advice on the crucial steps needed to diagnose and rectify these concerns efficiently. Our aim is to equip you, the discerning automotive enthusiast, with the knowledge to safeguard your vehicle’s most vital component.

Navigating the complex world of engine maladies requires a keen eye for detail and a proactive mindset. Ignoring the subtle warnings of a struggling engine is akin to overlooking a small crack in a dam; eventually, the consequences can be catastrophic. From the silent threat of overheating to the unmistakable declaration of a misfire, recognizing these early indicators is paramount to preserving your engine’s health and, by extension, your vehicle’s overall performance and value. Let’s dive into these critical issues with the authoritative insight that any serious driver deserves.

1. **Engine Overheating**Engine overheating stands as a truly common and critically problematic issue, capable of inflicting severe, often irreparable damage if not addressed with immediate urgency. This phenomenon occurs when the engine’s temperature rises beyond its optimal operating range, threatening the integrity of various internal components. The primary culprits behind this dangerous elevation in temperature are typically multi-faceted, ranging from low coolant levels that reduce the system’s ability to dissipate heat to a faulty thermostat that fails to regulate coolant flow precisely. Further compounding factors can include a broken water pump, which is essential for circulating coolant, or a clogged radiator and coolant passages that impede heat exchange, alongside a malfunctioning cooling fan that cannot adequately draw air across the radiator fins.

The signs of an overheating engine are usually quite distinct and should never be dismissed. Drivers will often observe the temperature gauge on their dashboard creeping into the higher-than-normal red zone, a clear visual warning. More dramatically, plumes of steam may begin to emanate from under the hood, accompanied by an unsettling burning smell from the engine bay, indicating fluids or components are being subjected to excessive heat. In severe cases, the engine may even experience a noticeable loss of power, or, in a desperate attempt to protect itself, initiate a complete shutdown, leaving you stranded.

Rectifying an overheating issue demands a systematic approach. The first step involves checking the coolant levels, inspecting both the reservoir and, with the engine cool, the radiator itself. If levels are low, topping up with the manufacturer-recommended coolant is imperative. Next, one must inspect the thermostat, as a unit stuck in a closed position will prevent coolant from circulating effectively, necessitating its replacement. The water pump should also be examined for any visible leaks or unusual noises, which would signal a need for replacement. Additionally, cleaning any debris that might be blocking airflow to the radiator and flushing the cooling system if clogs are suspected are vital steps. Finally, testing the cooling fan to ensure it activates as expected when the engine reaches higher temperatures is crucial, with repair or replacement of the fan motor or relay as needed.

Preventative maintenance is undeniably the most effective defense against engine overheating. Consistent attention to your cooling system, particularly adhering to the manufacturer’s recommendations for coolant flushes—typically every 30,000 miles—can significantly reduce the likelihood of these devastating scenarios. These routine services ensure that the coolant remains effective, free of contaminants, and circulating optimally, thereby preventing the corrosion and blockages that are often precursors to an overheated engine. Proactive care ensures the heart of your vehicle continues to beat steadily, mile after exhilarating mile.

Read more about: Collectors Beware: 13 Barn Find Restoration Pitfalls That Might Just Break Your Bank (and Your Spirit)

2. **Engine Misfire**An engine misfire is a clear indication that one or more cylinders are failing to ignite the air-fuel mixture properly, consequently failing to deliver the expected power output. This can lead to a cascade of undesirable effects on vehicle performance. The potential causes of a misfire are varied and can stem from issues within the ignition, fuel, or compression systems. Common culprits include worn spark plugs or ignition coils, which directly impact the spark’s strength and timing, leading to incomplete combustion. Clogged fuel injectors can restrict the precise delivery of fuel, creating a lean mixture that won’t ignite. Vacuum leaks can introduce unmetered air, disrupting the air-fuel ratio, while faulty sensors, such as the oxygen or MAF (Mass Air Flow) sensor, can send incorrect data to the engine control unit (ECU), leading to improper fuel mapping. In more serious cases, low compression within a cylinder, often due to worn piston rings or damaged valves, can prevent proper combustion.

The symptoms associated with an engine misfire are often quite noticeable to the driver. Perhaps the most common is a rough idle, where the engine vibrates unevenly, or a noticeable hesitation during acceleration, making the vehicle feel sluggish. Drivers might also experience a significant loss of power, poor fuel economy due to inefficient combustion, and, crucially, the illumination of the engine warning light on the dashboard. This ‘check engine’ light, when accompanied by misfire symptoms, often signals a stored diagnostic trouble code that can pinpoint the problematic cylinder. Furthermore, unusual engine noises, such as popping or backfiring, particularly through the exhaust or intake, are definitive indicators of an ongoing misfire.

Addressing an engine misfire effectively requires precise diagnosis and targeted repairs. A primary fix involves replacing worn spark plugs and ignition coils, as these components are frequent causes of misfires and have specific service intervals. Cleaning fuel injectors, either through the use of fuel injector cleaner additives or professional ultrasonic cleaning, can restore proper fuel spray patterns. It is also essential to meticulously check for vacuum leaks by inspecting hoses for any cracks or disconnections, replacing damaged ones promptly. Utilizing an OBD-II scanner to test for sensor faults and replacing any malfunctioning oxygen or MAF sensors is a critical diagnostic step. Should low compression be suspected, a professional compression test is warranted, as this could indicate more significant internal issues such as a damaged head gasket or worn piston rings, potentially requiring a more extensive engine rebuild.

Consistent and routine tune-ups are the cornerstone of minimizing misfire-related issues, aligning perfectly with the ethos of proactive maintenance. Regular replacement of spark plugs and inspection of ignition components, along with periodic fuel system cleaning, ensures that these vital systems operate at peak efficiency. By staying ahead of wear and tear, vehicle owners can prevent the inconvenience, diminished performance, and potential expense associated with persistent engine misfires, ensuring their powertrain delivers consistent, reliable power and maintains optimal fuel efficiency.

Read more about: From Worse to Worst: Six Tech Products That Defined a Decade of Commercial Struggles and Surprising Comebacks

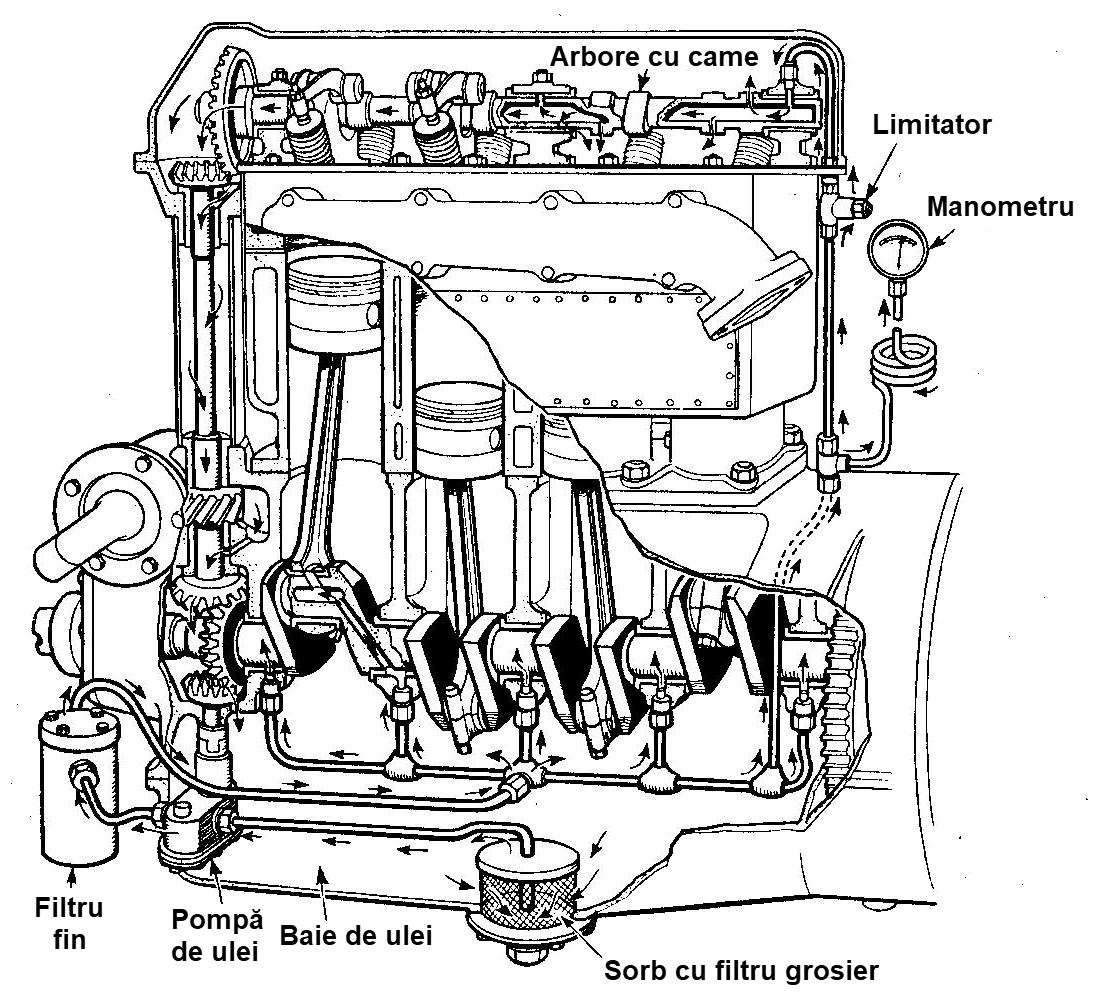

3. **Oil Leaks**Oil leaks, while sometimes appearing as a mere nuisance, are a critical indicator of underlying issues that, if neglected, can lead to severe engine damage and significantly compromise vehicle longevity. Engine oil is the lifeblood of the internal combustion engine, providing essential lubrication, cooling, and cleaning properties to myriad moving parts. A leak signifies that this vital fluid is escaping its intended circulatory path. The most prevalent sources of oil leaks often include worn gaskets and seals, such as the valve cover gasket or the oil pan gasket, which degrade over time due to heat cycling and material fatigue. Other common points of failure are a loose or damaged oil filter or drain plug, which can become compromised during routine oil changes or through physical impact. In more severe, though less frequent, scenarios, a cracked engine block or compromised oil cooler lines can be the direct cause of significant oil loss, signaling a much graver structural integrity issue.

Identifying an oil leak typically involves observing several key symptoms. Perhaps the most obvious sign is the appearance of oil spots or puddles underneath your vehicle after it has been parked, indicating where the oil is escaping. A burning oil smell, often accompanied by visible smoke emanating from the engine area, is another strong indicator, occurring when oil drips onto hot exhaust components. Furthermore, despite regular refills, a consistently low oil level in the dipstick is a clear sign that oil is being lost from the system, rather than consumed through normal engine operation. Each of these symptoms necessitates prompt investigation, as ongoing oil loss can quickly lead to insufficient lubrication, which is catastrophic for internal engine components.

Effectively addressing an oil leak begins with accurately identifying its source, a process that often involves meticulous cleaning of the engine surface to then observe fresh oil trails. Once the origin is pinpointed, common fixes include the replacement of compromised gaskets and seals, with valve cover and oil pan gasket replacements being particularly frequent and impactful repairs. Ensuring that the oil filter and drain plug are correctly installed and undamaged is also a vital, straightforward step. For vehicles equipped with oil cooler lines, a thorough inspection for cracks or leaks in these lines is necessary, leading to their replacement if compromised. These actions are fundamental to restoring the integrity of the oil containment system.

The profound importance of promptly addressing oil leaks cannot be overstated. Continuously operating a vehicle with critically low oil levels due to unchecked leaks will inevitably lead to insufficient lubrication, resulting in accelerated wear of vital engine components, potential seizing, and ultimately, severe and irreversible engine damage. This can culminate in the need for an expensive engine rebuild or a complete engine replacement. Therefore, proactive vigilance and immediate action upon detecting any signs of an oil leak are not just recommended, but absolutely essential for the long-term health and operational reliability of your engine, securing its future performance and preventing escalating repair costs.

Read more about: Collectors Beware: 13 Barn Find Restoration Pitfalls That Might Just Break Your Bank (and Your Spirit)

4. **Engine Knocking**Engine knocking, often characterized by a distinct metallic pinging or rattling noise, is a disconcerting auditory symptom that signals premature combustion of the air-fuel mixture within the engine’s cylinders. This anomaly, also known as pre-ignition or detonation, occurs when the mixture ignites spontaneously and erratically before the spark plug fires, creating competing flame fronts that collide and produce shockwaves against the piston. Such events can inflict significant stress on critical engine components. The primary causes of this detrimental phenomenon include the use of low octane fuel, which has a lower resistance to spontaneous ignition, especially under high compression. Carbon buildup inside the combustion chamber can create hot spots, acting as unintended ignition sources. A faulty knock sensor, responsible for detecting these vibrations and signaling the ECU to retard ignition timing, will fail to perform its protective role. Finally, incorrect ignition timing itself, either too advanced or improperly set, can directly contribute to conditions ripe for knocking.

The symptoms of engine knocking extend beyond just the audible metallic sound. While the knocking noise during acceleration or under load is the most prominent indicator, it is frequently accompanied by a noticeable reduction in overall engine performance. Drivers might experience a decrease in acceleration response and a general feeling of sluggishness. Furthermore, persistent knocking can lead to diminished fuel efficiency, as the engine’s combustion process is operating inefficiently and under unnecessary stress. Ignoring these symptoms is not merely a matter of annoyance; it’s a direct pathway to potential internal engine damage, particularly affecting components like pistons, connecting rods, and bearings due to the intense and uncontrolled pressure waves.

Addressing engine knocking effectively begins with the fundamental step of always using the recommended fuel octane specified by the vehicle’s manufacturer. This ensures the fuel’s anti-knock properties are appropriate for the engine’s design. To combat carbon buildup, which is a common contributor, utilizing fuel additives specifically designed to remove these deposits can be beneficial, or a professional decarbonization service might be required for more severe cases. If a faulty knock sensor is identified through diagnostic tools, its prompt replacement is crucial to restore the engine’s ability to protect itself from detonation. Lastly, checking and, if necessary, adjusting the ignition timing is imperative; this critical task typically requires specialized professional tools and expertise to ensure precision and prevent further engine complications, as improper timing adjustments can exacerbate the problem.

It is an immutable truth in automotive maintenance that ignoring persistent engine knocking can precipitate severe internal damage over time. The continuous, uncontrolled explosions within the cylinders can lead to damaged piston crowns, worn connecting rod bearings, and even compromise the structural integrity of the cylinder walls. These issues are not merely inconvenient; they can necessitate extensive and expensive engine repairs, up to and including a full engine rebuild or replacement. Therefore, a swift and informed response to any signs of engine knocking is absolutely essential to preserve the engine’s health, maintain its performance, and avoid the substantial financial burden associated with repairing advanced damage.

Read more about: Dissecting the Disasters: 7 V8 Engines That Stumbled, Stalled, and Sank Reputations

5. **Difficulty Starting the Engine**Experiencing difficulty starting the engine can range from a minor inconvenience to a significant concern, often leaving a driver feeling helpless and stranded. This problem, which prevents the engine from cranking or firing up successfully, can be attributed to several critical systems, each playing a vital role in the ignition sequence. The most frequent culprits include a weak or entirely dead battery, which lacks the electrical power to turn the starter motor. A faulty starter motor itself or its accompanying solenoid can be the direct cause, failing to engage the engine’s flywheel. Problems within the ignition system, such as a bad ignition switch or issues with the key transponder system, can prevent the vehicle’s security protocols from allowing ignition. Lastly, fuel delivery problems, encompassing a failing fuel pump or a severely clogged fuel filter, can mean that fuel simply isn’t reaching the combustion chambers, rendering ignition impossible.

The symptoms of starting difficulties are generally quite clear and immediately apparent. The most common experience is the engine cranking slowly, with a laborious, drawn-out sound, or failing to crank at all when the key is turned. In many cases, drivers will hear only a rapid series of clicking noises emanating from the engine bay when attempting to start the vehicle. These clicks are often indicative of a battery that lacks sufficient power to fully engage the starter solenoid but still has enough residual charge to activate its internal relay. Recognizing these precise symptoms is the first critical step toward accurately diagnosing and resolving the underlying issue, preventing the frustration and potential hazards of an unreliable vehicle.

Resolving starting difficulties requires a systematic diagnostic approach to pinpoint the exact failing component. The initial step should always be to test the battery’s health; if its voltage is low or it fails a load test, replacement is the appropriate course of action. Next, inspecting the starter motor and solenoid for any signs of wear, damage, or electrical malfunction is crucial, replacing defective parts as necessary. The ignition system also warrants a thorough check, specifically addressing issues with the ignition switch, key transponder, or immobilizer that might be preventing the engine from firing. Finally, evaluating the fuel system involves testing the fuel pump pressure to ensure adequate delivery and regularly replacing the fuel filter to prevent clogs that restrict fuel flow. Each of these steps contributes to ensuring the engine receives the necessary spark, air, and fuel to initiate combustion reliably.

Early diagnosis is profoundly crucial to avoid being unexpectedly stranded due to a failure to start, making proactive maintenance and awareness invaluable. Regular battery checks, adherence to scheduled fuel filter replacements, and prompt attention to any initial signs of starting hesitation can prevent a minor component failure from escalating into a debilitating roadside emergency. By ensuring all elements of the starting and fuel delivery systems are in optimal working order, vehicle owners can significantly enhance their vehicle’s reliability, providing peace of mind and ensuring the engine is always ready to spring to life when called upon, a testament to proper care and informed action.

Read more about: Beyond the Launchpad: An Analytical Look at The Challenger Disaster’s Technical Flaws from Faulty O-Rings to Explosive Failure

6. **Excessive Exhaust Smoke**Excessive exhaust smoke, regardless of its color, is a potent visual diagnostic clue that unequivocally signals a significant internal engine problem requiring immediate attention. The color of the smoke provides a roadmap, guiding mechanics and informed vehicle owners toward the specific nature of the malfunction. This phenomenon indicates that something other than clean exhaust gases—be it oil, coolant, or an overly rich fuel mixture—is being combusted or vaporized within the engine or exhaust system. Ignoring this visible symptom is a direct invitation to further, potentially catastrophic, internal damage, as it points to fundamental issues affecting the engine’s core operational integrity and its long-term health.

Blue smoke is a definitive indicator that oil is being burned inside the combustion chambers. This typically occurs due to the degradation or failure of components designed to keep oil confined to the crankcase and cylinder head. Common causes include severely worn piston rings, which allow oil to seep past the pistons into the combustion area, or compromised valve seals, which permit oil to leak down the valve stems. In turbocharged engines, issues with the turbocharger itself, such as worn bearings or seals, can also cause oil to enter the exhaust stream and burn. Rectifying blue smoke usually involves conducting a compression test to assess piston ring integrity, followed by replacing worn rings or valve seals, or repairing/replacing the turbocharger if it is identified as the source.

White smoke, particularly when thick and persistent, often signifies that coolant is entering the cylinders and being burned, a highly alarming sign. The most common and severe cause is a blown head gasket, which allows coolant from the cooling passages to breach the combustion chamber. Other serious structural issues, such as a cracked cylinder head or engine block, can also facilitate coolant ingress. This burning of coolant produces steam that exits as white exhaust smoke. The fix for white smoke typically involves performing a leak-down test to pinpoint the exact location of the leak, followed by the replacement of the head gasket. In more severe cases, inspecting for cracks that may require cylinder head machining or even a complete engine replacement becomes necessary to prevent further, irreversible damage from coolant contamination and overheating.

Black smoke, in contrast to blue or white, is generally indicative of an excessively rich fuel mixture, meaning too much fuel is being injected into the cylinders relative to the air available for combustion. This inefficiency often results from a dirty air filter that restricts adequate airflow, clogged or faulty fuel injectors that deliver an overabundance of fuel, or malfunctioning sensors, such as the MAF (Mass Air Flow) or MAP (Manifold Absolute Pressure) sensor, which provide incorrect data to the ECU, leading it to command more fuel. The solutions for black smoke are typically less invasive but equally important: replacing the air filter to ensure proper airflow, cleaning or replacing faulty fuel injectors, and testing and replacing sensors like the MAF/MAP for errors. Promptly addressing these smoke issues is paramount, as they prevent not only poor performance and fuel economy but also avert further internal engine damage, ensuring the engine operates cleanly and efficiently.

Navigating the complexities of modern performance engines demands a keen understanding of their potential vulnerabilities, especially as they age. While our journey through the initial six common engine issues provided a robust foundation, several other severe maladies demand equal, if not greater, vigilance. These problems, often insidious in their development, can just as rapidly escalate into scenarios where a full engine rebuild becomes an unfortunate reality, particularly in high-performance vehicles where tolerances are tighter and demands are higher.

Our focus now shifts to these additional critical concerns, dissecting issues that range from the meticulous timing mechanisms that govern an engine’s rhythm to the structural integrity of its internal seals and the sophisticated forced-induction systems that boost power. Each presents its own unique set of warning signs, underlying causes, and, most importantly, crucial preventative measures and professional interventions necessary to preserve the heart of your high-performance machine.

Read more about: The Road to Ruin: 15 Major Engine Models That Crumbled Before 50,000 Miles

7. **Timing Belt and Chain Failures**The timing belt or chain stands as a truly indispensable component within your engine, serving the critical function of synchronizing the rotational movements of the crankshaft and camshafts. This precise orchestration ensures that the engine’s valves open and close at the exact right moment relative to the pistons’ travel. Should this vital link falter or break, the consequences are nothing short of catastrophic, often leading to severe engine problems ranging from bent valves—where pistons collide with open valves—to a total engine lock-up, rendering the vehicle immobile.

Owners of discerning performance vehicles should be acutely aware of the symptoms that signal impending timing belt or chain issues. A persistent ticking sound emanating from the engine is often one of the earliest and most common indications that the timing chain might be stretching or its tensioners failing. Additionally, difficulties in starting the vehicle, or the engine misfiring or stalling altogether, can point to issues with incorrect timing belt alignment, disrupting the engine’s combustion cycle. Another strong sign of potential damage or wear is oil leaking from the front of the engine, which can indicate a compromised timing cover seal.

The vast majority of timing chain issues, approximately 90%, are attributed to the inevitable march of general wear and tear, rather than specific inherent faults. However, premature failures are notably more prevalent in high-performance engines, such as those found in BMWs, particularly when routine oil changes are neglected or if the specified synthetic oil is not consistently used. The precise lubrication of the timing chain and its associated components is paramount, making regular, high-quality oil maintenance an absolute non-negotiable for these sophisticated powerplants.

Preventative maintenance is the ultimate bulwark against the devastating costs associated with timing belt and chain failures. While timing belts typically have specific replacement intervals, often every 60,000–100,000 miles, timing chains are generally designed to last the life of the engine. Nevertheless, routine visual inspections during other services can help detect early signs of wear or leaks. When replacement becomes necessary, engaging a qualified mechanic is crucial, as they possess the expertise to ensure all components are meticulously aligned correctly, safeguarding your engine’s intricate internal rhythm.

Read more about: Immediate Regret Behind the Wheel: 15 Vehicles Owners Wished They Never Financed at the Dealership

8. **Blown Head Gasket Problems**A blown head gasket represents far more than a mere inconvenience; it signals a major engine problem with the potential to inflict severe engine issues, including persistent engine stalling and dangerous overheating, if its presence is ignored. This critical component forms the seal between the engine block and the cylinder head, designed to contain the immense pressures of combustion and prevent the mixing of vital fluids like coolant and engine oil. When this seal fails, the integrity of the engine’s internal environment is fundamentally compromised.

Fortunately, a failing head gasket often announces its predicament through several clear and unmistakable indicators. A critical symptom is the loss of engine compression, which occurs when combustion gases escape between cylinders or leak into the intake system, leading to very high-performance regressions and noticeable power reduction. Coolant leaks are another tell-tale sign, usually evidenced by consistently low levels of coolant in the reservoir or actual puddling of coolant beneath the car. Moreover, persistent overheating, particularly if the vehicle struggles to maintain normal operating temperatures (typically 200 to 225 °F) for more than 15 minutes, is a frequent and alarming symptom, often accompanied by the destruction of the cooling system, including radiator failure and hose erosion.

Numerous factors can conspire to cause a head gasket to fail, with overheating standing out as one of the most significant contributors, accounting for a substantial percentage of failures. Modern engines rely heavily on the accurate and continuous flow of coolant through intricate cylinder head passages to maintain precise cooling. When this cooling system falters, extreme temperatures can cause the delicate gasket material to degrade and fail over time. Furthermore, a lack of consistent maintenance, such as skipping routine checks on coolant levels, significantly amplifies this risk. High engine pressure, whether due to improper tuning or simply the natural wear in a high-mileage engine, can also push the gasket beyond its intended capabilities, precipitating leaks and eventual failure.

Read more about: Expert Warning: 13 Critical Transmission Problems to Spot in Your SUV Before Costly Failure

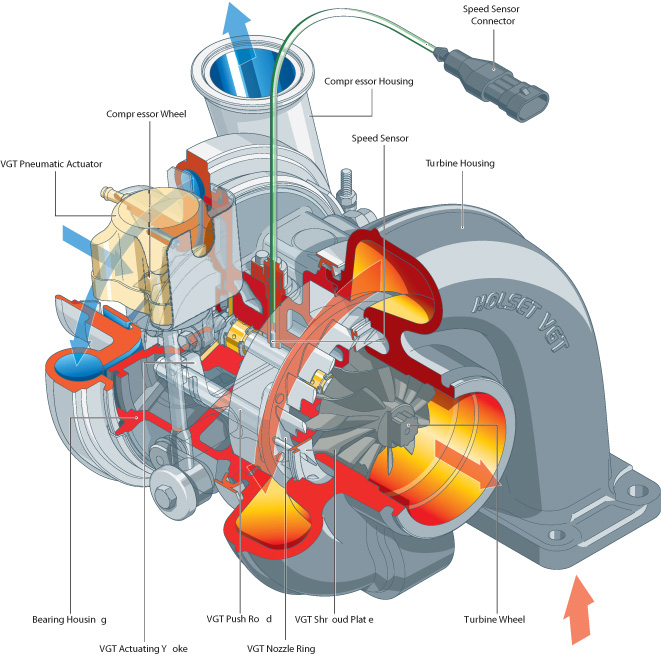

9. **Turbocharger Failures**As an essential component specifically engineered to maximize car engine performance by forcing more air into the combustion chambers, turbocharger failures are unfortunately common and present challenges not unlike other severe engine problems. For drivers who cherish the enhanced power delivery and efficiency that a turbo provides, understanding how to swiftly identify common symptoms and what precisely causes these malfunctions is paramount. This knowledge can proactively prevent expensive auto repair fix-ups, ensuring these intricate components continue to keep your engine performing at its peak efficiency.

When a turbocharger begins to fail, it typically makes its distress known through a series of increasingly obvious symptoms. A significant loss of performance is almost always the first and most noticeable indicator, as the turbocharger’s primary role is to deliver additional horsepower across the entire RPM range; its failure directly translates to a sluggish, underpowered vehicle. Furthermore, changes in exhaust smoke can often signal underlying issues: while a small amount of white smoke upon a cold startup might be normal, persistent plumes of black or blue smoke are definitive indicators of oil leaking into the engine or internal combustion problems. Additionally, any unusual whining or other strange sounds emanating from the turbo unit itself should be regarded as a critical warning sign that demands immediate investigation.

While the intricacies of turbo failures can often be complex, the majority—a staggering 80%—are directly attributable to oil contamination. Contaminated or degraded engine oil, or even genetically altered oil (referring to oil that has lost its intended properties), can cause accelerated wear on the turbine bearings, which rotate at speeds exceeding 300,000 RPM, eventually leading to the wheels tearing themselves apart. Beyond lubrication issues, other factors can also lead to malfunctions, including clogged air filters restricting vital airflow, collapsed inlet hoses, blocked oil supply lines that starve the turbo of lubrication, or even the incorrect use of gaskets during installation. Faulty ECU calibration or poorly calibrated boost control systems can also significantly impact the turbocharger’s intended performance and longevity.

Preventing turbo failures effectively begins with precise diagnosis and, more importantly, a rigorous maintenance regimen. Regularly replacing oil pumps and incorporating inline filter/regulator combinations, such as Turbosmart’s OPR, can profoundly reduce the risk of oil contamination, ensuring the turbo receives the cleanest possible lubricant. It is absolutely crucial to consistently use clean, high-quality engine oil and to meticulously ensure that your oil supply and drain lines are in impeccable condition and routed precisely as intended. Moreover, a simple yet highly effective practice post-turbo operation is allowing the engine to idle for 30–60 seconds before shutting down; this allows the turbo to cool down, greatly reducing the chances of thermal damage to its bearings. Whether the solution involves rebuilding or completely replacing a turbo, taking the necessary time to properly calibrate the system and utilize the correct, high-quality components will provide enduring long-term reliability and performance.

Read more about: Dissecting the Disasters: 7 V8 Engines That Stumbled, Stalled, and Sank Reputations

10. **Cracked Engine Block Concerns**A cracked engine block represents a potentially catastrophic issue that can precipitate an array of severe engine problems, fundamentally compromising the very core structure of the vehicle’s powertrain. Understanding the common symptoms that manifest when a block is compromised, alongside the various possible causes such as poor lubrication or a faulty radiator, is crucial for car owners. This knowledge empowers them to navigate their repair options, which can range from complex and costly to surprisingly effective interventions, before a complete engine replacement becomes the only recourse.

The presence of a cracked engine block almost invariably reveals itself through a series of undeniable symptoms. The most obvious and alarming signs are consistent coolant or oil leaks, frequently evidenced by visible puddles of fluid appearing underneath the parked vehicle. Beyond these direct fluid losses, drivers may experience a noticeable loss or decrease of engine power, an engine that persistently overheats, or the alarming sight of white smoke emanating from the exhaust – a clear indicator of coolant being burned in the combustion process. Often, these issues are accompanied by a sudden, inexplicable loss of fluid from reservoirs or the persistent illumination of the check engine light. A safe and effective quick identification of these symptoms can prevent further, more extensive damage to the engine.

Numerous factors contribute to the unfortunate event of an engine block cracking, with overheating identified as the culprit responsible for approximately 70% of all such failures. Prolonged exposure to extreme heat cycles relentlessly stresses the metal, eventually making it brittle and highly susceptible to cracking. Beyond thermal stress, other significant causes include exposure to extreme cold temperatures, which can lead to the expansion of fluids if the cooling system is improperly maintained or filled with water instead of antifreeze. Manufacturing errors, though less common in modern production, can also introduce weak points, as can physical trauma to the engine bay. Routine preventative checks, such such as diligently keeping an eye on coolant levels, and taking swift action to address any overheating problems sooner rather than later, can significantly mitigate these inherent dangers.

Fortunately, repairing a cracked engine block is indeed possible in a majority of cases, offering viable alternatives to a complete engine replacement. Advanced methods, such as cold metal stitching, provide a permanent repair solution that often negates the need for complete engine disassembly, a process that saves both time and labor. Furthermore, specialized automotive products, like those offered by Bar’s Leaks, are designed to provide permanent fixes by sealing small cracks, thereby allowing your engine to continue running reliably for years. For owners of classic cars, professional repairs might be preferred to meticulously preserve the vehicle’s original value and integrity, whereas modern vehicles, due to the intricate nature of their construction and potentially higher labor costs for repair, often benefit more practically from a complete replacement. Repair costs for a cracked block can fluctuate significantly, ranging from hundreds to many thousands of dollars, with the most complex repairs naturally incurring greater expense. It is always a wise strategy to obtain a second opinion from a trusted specialist to gain a comprehensive understanding of the necessary next steps and to avoid any unwelcome surprises.

Read more about: Beyond Snow Tires: Your Ultimate Lifehacker Guide to Winter Driving Essentials

11. **Seized Engine Issues**A seized engine represents arguably the gravest mechanical ailment a vehicle can endure, an almost irreparable condition that effectively brings the engine’s operational life to an abrupt halt. This catastrophic failure typically stems from either profoundly poor lubrication or severe, prolonged overheating. When an engine seizes, its internal moving parts, such as pistons, connecting rods, and crankshaft, literally bind or lock up, preventing any further movement and rendering the engine completely unusable.

One of the most frequent pathways to a seized engine is through critically insufficient lubrication. As discussed previously, continuously operating a vehicle with critically low oil levels due to unchecked leaks will inevitably lead to an accelerated wear of vital engine components. Without the protective film of oil to reduce friction, metal parts grind against each other, generating immense heat and causing them to weld together, ultimately culminating in engine seizure. This underscores the profound importance of promptly addressing any oil leaks and ensuring regular oil level checks and changes.

Severe overheating is the other primary antagonist leading to engine seizure. When an engine’s temperature spirals out of control, beyond its designed operating limits, the intense heat can cause internal components to expand excessively. This expansion distorts cylinder bores, warps crucial components like piston rings and connecting rods, and degrades the vital clearances between moving parts. Eventually, these components bind against each other, leading to a complete mechanical lock-up. This highlights the absolute necessity of maintaining a healthy cooling system, ensuring adequate coolant levels, and immediately addressing any signs of overheating.

Preventative maintenance stands as the most formidable defense against the ultimate tragedy of a seized engine. Diligent adherence to the manufacturer’s recommended service intervals, particularly for oil changes and cooling system flushes, is paramount. Regularly monitoring fluid levels—engine oil, coolant—and promptly investigating any unusual noises, smells, or warning lights can catch potential issues before they cascade into irreversible damage. Investing in preventative care is not merely about avoiding inconvenience; it is about safeguarding the very heart of your vehicle and precluding the need for an immensely expensive engine replacement or rebuild. For a performance machine, this meticulous attention to detail is not just recommended, it is absolutely essential to ensure its continued exhilaration on the road.

Read more about: Collectors Beware: 13 Barn Find Restoration Pitfalls That Might Just Break Your Bank (and Your Spirit)

In the high-stakes world of performance vehicles, where engineering precision meets raw power, the heart of the machine—its engine—demands unwavering respect and vigilant care. Our journey through these eleven critical engine problems serves not as a deterrent, but as an empowerment, arming you with the knowledge to recognize the subtle whispers and overt shouts of an engine in distress. From the synchronized dance of timing belts to the intricate thermal management of turbochargers, each component plays a pivotal role in the symphony of speed and reliability. Embracing a proactive stance, coupled with the wisdom to seek professional expertise when necessary, is the true hallmark of a responsible automotive enthusiast. By doing so, you don’t just maintain a car; you preserve a legacy of performance, ensuring countless more miles of exhilarating, trouble-free driving, keeping those expensive headaches squarely in the rearview mirror.