The automotive landscape is buzzing with unprecedented energy, and right at the heart of this electric transformation, Ford is making a move that could very well redefine the future of electric vehicles in America. At a time when the U.S. EV market is bracing for a potential collapse, with federal tax credits poised to disappear on September 30, the iconic automaker is not just pushing forward but doubling down. With an additional $2 billion investment in battery-electric vehicles, Ford is charting a course that looks radically different from its traditional path, embracing a strategy inspired by the burgeoning Chinese EV market.

This isn’t just another incremental step; it’s a shocking pivot, a strategic masterstroke centered around a revolutionary new midsize electric pickup truck. Imagine a vehicle with a targeted base price of just $30,000, poised to arrive on the market in 2027. This ambitious project was unveiled by CEO Jim Farley himself on a recent Monday in Louisville, Kentucky, the very place where this game-changing truck will be assembled.

Farley’s vision extends far beyond merely adding another EV to the lineup. He declared, with palpable excitement, that “This new truck, based on this universal platform, is going to be more spacious inside than the RAV4, the best-selling car in the United States.” This isn’t just about matching competitors; it’s about surpassing them on their own turf, directly targeting the king of the gasoline SUV market while offering something fundamentally new. He emphasized the groundbreaking flexibility, adding, “But it will have a frunk and it will have a whole pickup truck bed behind it. No one has seen this kind of flexibility.”

Whispers and recent reports further fuel the excitement, suggesting that this groundbreaking EV pickup could bring back a familiar and beloved name: the Ranchero. According to Ford Authority, the company has even filed a new trademark for the name, specifically earmarked for electric pickup trucks. For those who remember, the Ranchero was a cult classic, a car-truck hybrid that hasn’t graced U.S. roads since 1979, known for blending sedan comfort with the practical utility of a pickup bed. This potential revival speaks volumes about Ford’s embrace of its heritage while boldly stepping into the future.

This daring move represents a radical departure for Ford, setting it apart from its American rivals, most notably Tesla. While Tesla has largely focused on premium vehicles, exemplified by the commercially struggling Cybertruck, Ford is looking in a completely different direction. It also marks a significant shift from Ford’s own highly profitable strategy of selling large, expensive pickups and SUVs, such such as the perennial favorite F-150 and the robust Expedition.

Instead, Ford is consciously adopting a strategy that bears a striking resemblance to that of the Chinese automotive powerhouse, BYD. BYD has ascended to become the world’s largest EV seller by specializing in incredibly affordable electric cars, demonstrating the immense power of accessible pricing. To put it into perspective, the cheapest BYD EV, the Seagull, starts at the equivalent of just $9,700 in China, a price point that has allowed BYD to seize massive market share from Tesla in both China and Europe.

Jim Farley readily acknowledged a fundamental truth about the current EV landscape: many existing electric vehicles simply don’t address what buyers truly want or need. In a revealing conversation with CNBC, he articulated the core of Ford’s new approach, stating, “A computer can have much lower costs—that’s why we redid this platform… to bring the costs down.” This underlines a profound understanding that affordability is not just a nice-to-have but a critical driver for widespread EV adoption and profitability.

So, the million-dollar question becomes: how exactly does Ford plan to deliver a low-cost, high-performance pickup that has eluded every other American automaker? The answer lies in a complete reinvention of its entire design and manufacturing process, a secret sauce brewed in an innovative “skunkworks” team. This visionary team has birthed the new “Ford Universal EV Platform,” a simplified architecture that represents a monumental leap forward in automotive engineering.

This new platform boasts an impressive 20% fewer parts and 25% fewer fasteners, a simplification that translates directly into reduced manufacturing complexity and cost. Perhaps even more striking is the dramatic reduction in wiring: the wiring harness alone is a staggering 4,000 feet shorter than that of the Mustang Mach-E. This isn’t merely a minor tweak; it’s a fundamental rethinking of vehicle architecture, saving precious material, weight, and assembly time.

Doug Field, Ford’s Chief EV, digital, and design officer, shed light on this crucial innovation, explaining that the company took inspiration from the Model T to make it more than just a utility vehicle. He powerfully stated that “Compared to a generation one electrical vehicle, we can get the same range with a third less battery.” This highlights how Ford is using its intellect to reduce battery size while maintaining performance, tackling one of the most expensive components of an EV head-on.

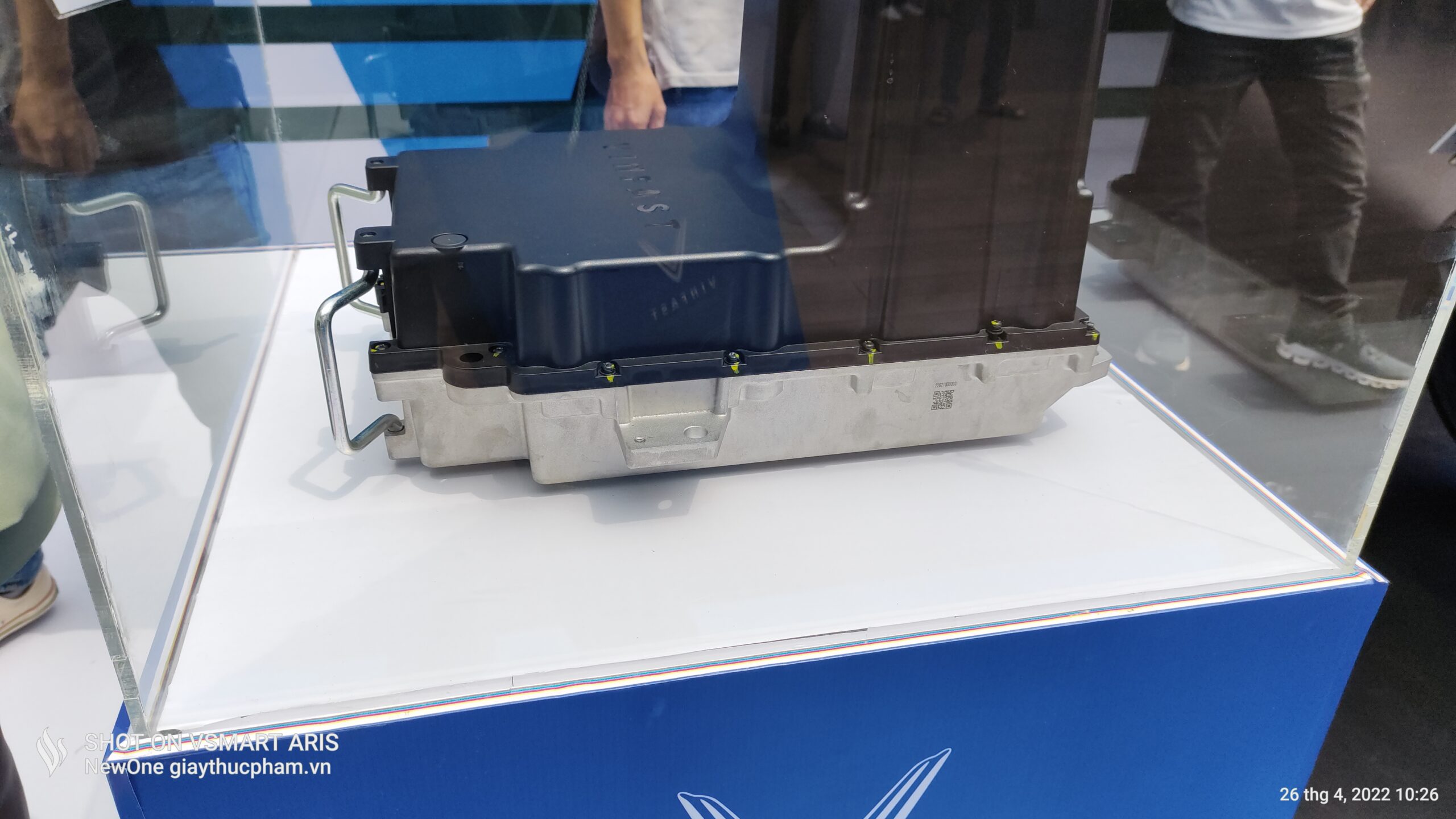

The battery itself is another cornerstone of this audacious strategy. Ford is making a significant investment in manufacturing its own cobalt-free LFP prismatic batteries right in Michigan, a move that will further bolster the domestic supply chain. This LFP (lithium-iron phosphate) chemistry is, as Ford claims, significantly cheaper than traditional battery types, offering a critical cost advantage.

Beyond cost, the design of these LFP batteries is revolutionary: they are engineered to serve as a structural part of the truck’s floor. This ingenious integration saves valuable space and further reduces overall costs, while also improving handling and creating a surprisingly quiet ride. Furthermore, the LFP batteries lie flat under the floor, which contributes to the truck’s impressive interior space, notably more passenger room than the latest Toyota RAV4, and all this without even factoring in the added frunk and truck bed.

Finally, and perhaps most dramatically, Ford has completely reinvented the factory itself. Eschewing the traditional, linear moving assembly line, the new truck will be constructed using a pioneering concept Ford calls an “assembly tree.” This revolutionary process breaks the vehicle down into three main sub-assemblies—the front, the rear, and the structural battery floor with the interior already attached—which are then joined together at the very end on a final trunk line.

Ford proudly claims that this innovative assembly tree process is 15% faster and considerably simpler than conventional manufacturing methods. While branched assembly lines aren’t entirely new in concept, Ford’s approach of building a passenger car in three discrete parts that snap together like Lego is truly novel. This radical simplification has the potential to reduce vehicle assembly times by up to 40% as automation is ramped up in the future.

Kevin Young, Ford’s advanced manufacturing program chief, underscored the urgency and necessity of this transformation. He candidly remarked, “Wiring is the nemesis. If you don’t change that input, then nothing else is ever going to change.” This reflects a deep understanding of the systemic challenges in traditional automotive manufacturing and Ford’s unwavering commitment to dismantling them. He also added a powerful statement on the company’s resolve: “Change is necessary. Back’s against the wall, so you have to make it happen.”

The ultimate goal behind streamlining the wiring and embracing a simpler, more capable zonal architecture is multifaceted. It aims to improve packaging, significantly reduce weight, and rely on fewer, yet more powerful, ECUs (electronic control units) to manage vehicle functions. This software-first approach is an area where pure EV makers like Tesla and Rivian have excelled, while legacy automakers like Toyota and Volvo have historically struggled, highlighting Ford’s deliberate effort to catch up and innovate.

Ford’s commitment extends to ensuring this affordability translates directly to the consumer. Jim Farley articulated this aspiration beautifully, stating, “Our idea is that the people working here in Louisville will be able to buy this car and spend money on other things they love, like vacations, their home, and their children’s education.” This isn’t just about a vehicle; it’s about empowering communities and improving lives, a true testament to the company’s human-centric approach.

This audacious new truck is a direct challenge, not just to its immediate competitors but to the entire auto industry’s long-standing assumptions about EV pricing and production. It’s a bold declaration that affordable, desirable electric vehicles are not just a dream but a tangible reality for the near future. Ford claims that this new midsize EV pickup will boast a lower cost of ownership over five years than a three-year-old used Tesla Model Y, an incredibly specific and powerful competitive claim.

This aggressive strategy comes at a critical juncture for Ford’s own EV division, which has faced significant headwinds. In the second quarter of 2025, the unit recorded an operating loss of a staggering $1.3 billion, part of a larger $2.2 billion loss in the first half of 2025 and a total of $12 billion over the last two and a half years. The company is betting that this radical new approach, ingeniously borrowed from China’s successful affordability model and powered by American innovation, is the only viable path to finally make EVs profitable for the company and truly accessible for everyone else.

Farley didn’t mince words when addressing the broader competitive landscape. He articulated, “We saw this coming for years. We knew that the Chinese would be the major player for us globally, companies like BYD, new startups from around the world.” He also acknowledged the encroaching ambition of “Big technology” in the auto space, emphasizing, “They’re all coming for us, legacy automotive companies.” This is Ford’s response to an undeniable global challenge.

Farley also made it clear that Ford is drawing a line in the sand, rejecting the notion of “good college tries” by Detroit automakers that often result in “idled plants, layoffs and uncertainty.” He proudly declared, “We empowered a tiny skunkworks team. We reinvented the moving assembly line. And we are on a path to be the first automaker to make prismatic LFP batteries in the U.S. We will not rely on imports.” This unwavering commitment to self-reliance and fundamental change is truly inspiring.

Beyond its affordability, the new electric pickup promises thrilling performance. Ford is targeting a 0 to 60 mph time as fast as the Mustang EcoBoost, which completes the sprint in around five seconds, and even promises more downforce for an engaging driving experience. This ensures that affordability doesn’t come at the expense of exhilaration, making the truck not just practical but genuinely fun to drive.

Farley also boasted about the truck’s impressive utility features, including the capacity to power a house for up to six days thanks to its bidirectional charging capabilities. This eliminates the need for a separate generator, as Farley quipped, “You don’t need a generator. You just buy this truck.” This feature alone could be a massive draw for homeowners seeking energy independence and emergency preparedness.

The new $30,000 electric truck also stands in stark contrast to bare-bones offerings like the Slate truck, which aims for a mid-$20,000s price point but comes with a blank interior and no features like power windows or an infotainment screen. Ford is promising a truck a size and segment above the popular compact Maverick, which starts at about $30,000, and it will likely not be stripped-out at that price, offering a full suite of tech and creature comforts and supporting over-the-air updates.

This monumental undertaking involves a colossal investment from Ford Motor Company, totaling $5 billion into the development of the new platform and vehicles, as well as into its manufacturing facilities. A significant $2 billion is specifically earmarked for overhauling the Louisville Assembly Plant, where the new electric truck will be built, creating nearly 4,000 jobs in the process. The remainder will be strategically split between research and development and Ford’s BlueOval Battery Park Plant in Michigan, solidifying the domestic production of LFP batteries.

Ford’s high-stakes electric bet is unfolding at a time when the very future of electric vehicles in the U.S. seems fraught with uncertainty, particularly with policies impacting incentives for customers. Yet, amidst these challenges, Jim Farley frames this investment as Ford’s “most radical change” since the Model T, an era-defining moment that revolutionized the industry and established Ford as the bedrock of Detroit’s Big 3. He acknowledges, “It is a bet. There is risk.”

But Farley’s conviction is unshakeable: “The automotive industry has a graveyard littered with affordable vehicles that were launched in our country with all good intentions… At Ford, we set out to break that cycle. No more compliance cars. No more loss-leaders.” He envisions “a vehicle that can sustain itself, have strong profits, so all of our workers have an actually sustainable future,” a powerful declaration of intent.

While the midsize electric pickup is the first vehicle confirmed for this new platform, a graphic shared by Ford with the press hinted at the platform’s modularity, showcasing the potential for a family of next-generation EVs. This included a three-row SUV, a cargo van, and a small crossover, though it’s worth noting Ford last year cancelled its three-row electric SUV. This forward-looking modularity speaks to the vast potential of the Universal EV Platform to spawn a diverse range of affordable electric vehicles.

As the industry hurtles towards an electrified future, Ford is not merely adapting; it is actively shaping that future with audacious innovation and a clear focus on affordability. This isn’t just about building cars; it’s about building an ecosystem, creating jobs, and delivering on the promise of accessible, sustainable transportation for everyone. With the $30,000 electric truck leading the charge, Ford is ushering in what it calls the “Model T moment” of the electric vehicle era, signaling a thrilling new chapter for American ingenuity and the global auto industry. Get ready, because the road ahead just got a whole lot more exciting!