The crack of a bat, the pop of a ball hitting a glove – these sounds have defined America’s pastime for generations. But the equipment making these iconic sounds has undergone a remarkable transformation. Today’s players step onto the field with gear that early baseball pioneers wouldn’t recognize. This evolution hasn’t just changed how the game looks; it’s fundamentally altered how baseball is played.

Whether you’re a coach looking to understand equipment development, a player seeking performance advantages, or a baseball history enthusiast, this comprehensive guide tracks the fascinating journey of baseball equipment innovation and its impact on America’s beloved game. We’re diving deep into the tools that built the legends, from the crudest sticks to the most advanced smart gear, showcasing how each piece became a cornerstone of the sport we love.

From the rough-and-ready instruments of the 19th century to the meticulously engineered gear of today, baseball equipment has always been at the heart of the game’s progression. It’s a story of necessity, ingenuity, and a relentless pursuit of performance and safety, mirroring the very spirit of the sport itself. Join us as we break down 12 pivotal equipment innovations that defined an era and pushed baseball into new frontiers.

1. **The Primitive Bat: A Player’s Own Craft (1800s)**When baseball first emerged in the mid-19th century, the concept of a standardized bat was practically nonexistent. Players were true craftsmen, often making their own bats from whatever wood was readily available. Imagine a world where every player stepped up to the plate with a unique piece of lumber, carved to their personal specifications. These early bats varied dramatically in length, weight, and shape, sometimes even resembling modern cricket bats more than the sleek, balanced models we recognize today.

Common choices for materials included robust woods like hickory or ash, prized for their strength and availability. The individualistic approach meant that there was no uniform feel or performance across the league, making each at-bat a slightly different experience. This era truly highlighted the raw, unrefined nature of early baseball, where personal ingenuity was as crucial as skill on the field.

As the game gained traction, the 1850s marked the advent of commercially produced bats, signaling a slow shift away from purely handmade implements. However, even these initial commercial offerings retained significant variation, reflecting the lack of universal standards. It wasn’t until 1859 that the first regulations began to appear, limiting bat diameter to 2.5 inches. Intriguingly, at this point, no restrictions were placed on length, leaving players free to wield incredibly long bats if they chose. This period laid the very foundation for what would eventually become the iconic baseball bat, beginning its long journey of refinement.

2. **The “Lemon Peel” Baseball: A Glimpse into Early Play (1800s)**The baseball itself started its life as a far cry from the perfectly uniform spheres players use today. Early baseballs were distinctly handmade affairs, characterized by their unique construction and often unpredictable flight patterns. Picture a small core, which could be made of anything from rubber to yarn, and in some more bizarre cases, even “fish eyes or other bizarre materials,” as the context mentions. This core would then be meticulously wrapped in yarn and covered with several pieces of leather, painstakingly stitched together.

These early designs were frequently referred to as “lemon peel” or “rose pedal” balls due to their irregular stitching patterns, typically consisting of four sides sewn together to form an “X.” This distinctive construction meant that the ball’s flight was anything but consistent, adding an element of delightful unpredictability to every pitch and batted ball. The inconsistency certainly made for exciting, if not challenging, gameplay.

As the game grew in popularity and sophistication, the demand for a more consistent ball became apparent. By the 1850s, the familiar figure-eight stitching pattern, which we instantly recognize today, began to emerge. This innovation was a game-changer, creating more consistent flight patterns and a more predictable playing experience. Further standardization arrived in 1872, when the official weight and size specifications were established: between 5 and 5.25 ounces and 9 to 9.25 inches in circumference. Remarkably, these standards are “remarkably similar to today’s standards,” showcasing a foundational moment in baseball’s equipment evolution.

3. **The Barehanded Era & First Gloves: Protection Over Pride (1870s)**Perhaps no piece of baseball equipment has a more dramatic origin story than the fielding glove. In the earliest days of baseball, the game was played entirely barehanded. This brave approach, while perhaps a testament to players’ toughness, inevitably led to significant pain and frequent injuries from catching the hard, fast-moving ball. It was a badge of honor to play without protection, with “playing barehanded was considered the mark of a true player.”

The first tentative steps towards hand protection appeared around 1870. These weren’t the padded, webbed gloves we know, but simple leather work gloves, often with the fingertips cut off. They offered minimal protection, mainly serving to preserve some dexterity while cushioning the impact ever so slightly. Adopting these early gloves, however, was met with resistance and even ridicule. Many players viewed them as a sign of weakness, a departure from the rugged, barehanded tradition of the game.

The tide began to turn with influential figures. Albert Spalding, a star pitcher who would later found the renowned sporting goods company, played a crucial role in legitimizing the glove. When Spalding “began using a glove in 1877, the stigma gradually faded.” By the 1890s, padded gloves, though still much smaller than their modern counterparts, started to become more commonplace. The webbing between the thumb and forefinger – a feature now absolutely standard – would not make its debut until around 1920, marking another significant leap in glove design and player comfort.

4. **The Modern Wooden Bat’s Ascent: Power and Precision (1920s-1960s)**The period between the 1920s and 1960s is often considered a “golden age” for baseball equipment development, and the bat certainly experienced a renaissance. During this era, bat manufacturers meticulously experimented with various wood types, ultimately settling on ash as the standard material. Ash was preferred for its superior “strength-to-weight ratio,” offering a balance of durability and swing speed. While hickory bats were incredibly durable, they proved “too heavy for most players as the game evolved toward faster swing speeds,” indicating a shift in play style.

This vibrant period also saw the rise of signature model bats, a concept that continues to thrive today. Legendary players began collaborating directly with manufacturers, lending their names and influence to specific bat designs. Babe Ruth’s iconic partnership with Hillerich & Bradsby, the makers of the Louisville Slugger, established the blueprint for player endorsements that still resonates throughout sports marketing. The distinctive oval logo of the Louisville Slugger, which first appeared in 1930, quickly became a powerful emblem of professional quality and tradition.

Beyond endorsements, practical improvements defined the era. Bat handles became increasingly tapered, meticulously designed for a better grip and enhanced control at the plate. Manufacturing techniques advanced significantly, leading to the standardization of barrel diameters, ensuring consistency across the league. By the 1950s, a typical professional bat measured “34-35 inch, 32-34 ounce,” notably heavier than many of today’s models, reflecting the physical demands and hitting philosophies of the time.

5. **The Revolutionary Webbed Glove: A Fielding Game-Changer (1920s-1960s)**Just as bats were evolving, so too were gloves, becoming specialized instruments tailored for each defensive position. The 1920s brought the development of the “specialized catcher’s mitt with significant padding,” a crucial innovation for the demanding role behind the plate. Soon after, first basemen’s mitts emerged with their distinctive design, specifically crafted “to aid in scooping throws from the dirt,” demonstrating an understanding of position-specific needs. By the 1930s, outfielder gloves began to feature deeper pockets and longer lengths, ingeniously designed “to extend reach” and secure those crucial catches.

However, one individual stands out for a truly revolutionary contribution: Bill Doak. This spitball pitcher for the St. Louis Cardinals fundamentally altered glove design in 1920. Doak suggested the inclusion of a web between the thumb and forefinger, an idea that created a much deeper pocket. This seemingly simple innovation profoundly changed fielding techniques, allowing players to catch the ball more securely “in the webbing rather than with the palm,” significantly reducing painful impacts and improving control.

The post-World War II manufacturing boom further accelerated glove innovation. Advances allowed for the production of “lighter, more flexible gloves,” making them easier to break in and more comfortable for players during long games. The 1950s and 1960s saw the introduction of the hinged glove, which provided an even greater advantage by “making closing around the ball easier.” By the end of this golden era, gloves had expanded significantly in size and become highly specialized, transforming defensive play across all positions.

6. **The Catcher’s Protective Arsenal: Shielding the Command Center (1920s-1960s)**As the game evolved, particularly with faster pitching and harder-hit balls, the need for protective gear became paramount, especially for the catcher, who consistently faced the brunt of the action. The catcher’s equipment underwent a complete and necessary transformation during this pivotal period. While primitive forms of the catcher’s mask had existed since the 1870s, it was in this era that they became properly “reinforced and better-fitting,” offering a much-needed layer of safety against errant pitches and foul tips.

Beyond the mask, the evolution of protection extended to the entire body. Chest protectors, which began as simple padding, significantly advanced to “include shoulder protection,” providing a more comprehensive shield for the vital organs. Shin guards also became an essential part of the catcher’s ensemble, designed to “extended protection from ankle to knee,” ensuring that the lower legs were safeguarded against devastating impacts. These innovations were critical in allowing catchers to confidently perform their demanding role.

Batting helmets, though initially optional, gradually gained acceptance after the tragic 1920 death of Ray Chapman from a pitched ball. This somber event underscored the undeniable need for head protection. However, it wasn’t until much later, in 1971, that batting helmets became mandatory in the major leagues. Early versions of these helmets were often surprisingly rudimentary, sometimes just “modified construction hard hats,” before purpose-built designs specifically for baseball began to emerge. These protective advancements, though sometimes slow to be adopted, were crucial steps in prioritizing player safety and transforming baseball into a more secure sport.”

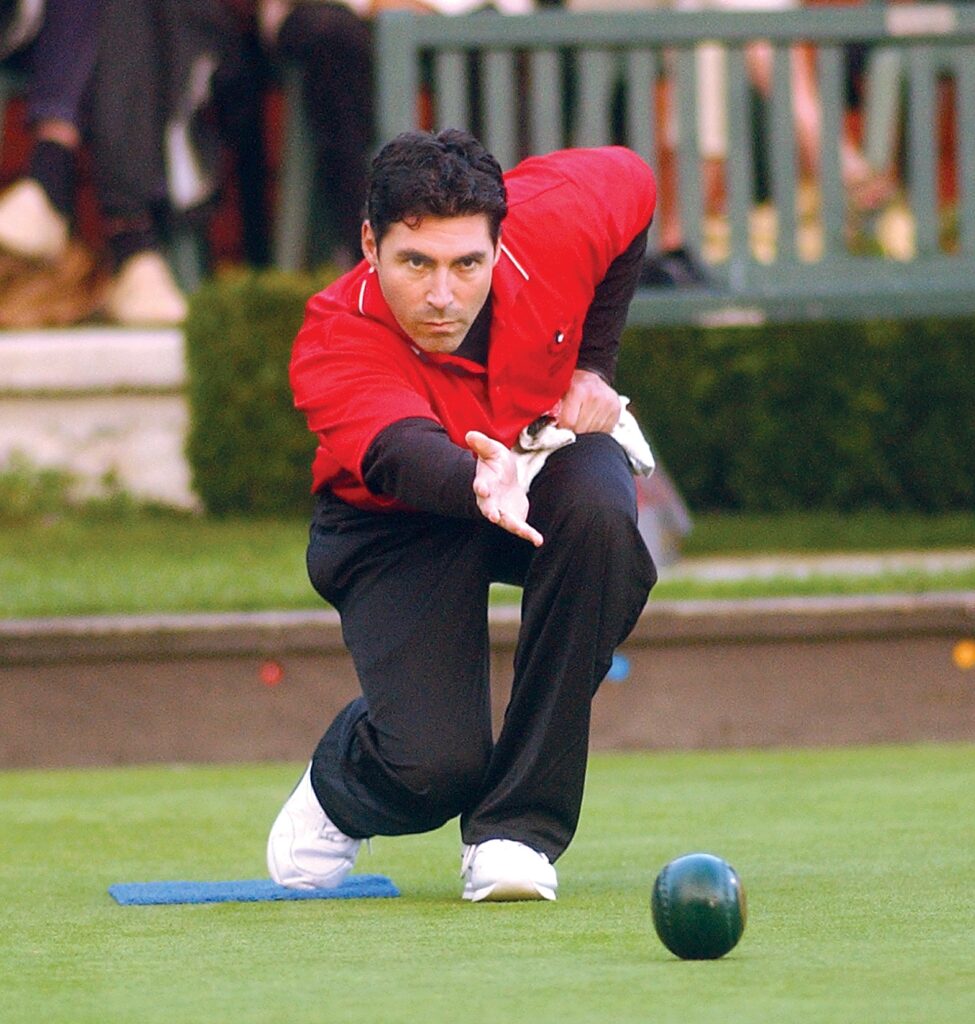

7. **The Aluminum Bat Revolution: Power for the Amateurs (1970s)**Just as professional baseball found its stride with refined wooden bats and specialized gloves, a seismic shift was happening at amateur levels. The early 1970s witnessed the introduction of the aluminum bat, a game-changer pioneered by companies like Worth Sports and Easton. These durable alternatives to traditional wooden bats quickly dominated college, high school, and youth baseball, forever altering the sound and feel of the game outside the pro ranks.

Early aluminum bats offered unparalleled durability, but their true revolution lay in performance. As designs evolved, they began to provide significant advantages over wood. Players discovered larger sweet spots, lighter swing weights, and a greater “trampoline effect” that dramatically increased batted ball velocity. This wasn’t just a slight improvement; it was a fundamental shift that empowered hitters like never before, making offensive explosions a regular sight.

However, this technological leap came with its own set of challenges. The performance gap between wood and metal bats raised serious concerns about player safety, particularly for pitchers, and the overall integrity of the game. Consequently, the burgeoning power of aluminum bats led to strict regulations in amateur play, setting the stage for ongoing debates and adjustments to ensure a level, yet exciting, playing field for all.

8. **Synthetic Materials, Specialized Gloves, and High-Tech Apparel (1970s-1990s)**While aluminum bats redefined amateur hitting, the 1970s and 1980s also ushered in a new era for fielding. Glove manufacturers began integrating synthetic materials, revolutionizing design. While high-quality leather remained the core, synthetic backing, improved lacing, and specialized padding made gloves lighter, more durable, and significantly easier to break in. This meant less time wrestling with stiff leather and more time making game-changing plays.

This period also saw an acceleration of position-specific glove refinements. Outfielder gloves grew larger and deeper, specifically designed to “extend reach” and secure those crucial catches in the gaps. Middle infielders’ gloves became shallower, optimized for quicker ball transfers and lightning-fast double plays. Pitchers’ gloves evolved to better conceal their grip, while first basemen’s mitts lengthened, becoming adept at “scooping throws from the dirt” and providing a larger target area for infielders.

Beyond gloves, the material science revolution extended to footwear and uniforms. Metal cleats, which had replaced earlier leather spikes, faced competition from molded plastic cleats offering enhanced safety and comfort. Turf shoes, with specialized traction patterns, emerged as artificial playing surfaces gained popularity, giving players optimal grip regardless of the field’s surface.

Uniforms also shed their heavy wool flannel origins, transitioning to lightweight synthetic blends that vastly improved player comfort and performance. Moisture-wicking fabrics allowed players to stay cooler and drier during intense games, while stretchy materials provided better range of motion. These seemingly small advantages cumulatively made a big difference, allowing players to perform at their peak for longer.

9. **Composite Bats and Data-Driven Design (2000s-Present)**The 21st century brought another paradigm shift in bat technology with the arrival of composite materials. These complex carbon fiber designs allowed for unprecedented control over bat performance characteristics. Engineers could now precisely design specific flex patterns, weight distributions, and barrel performance zones, creating bats tailored for ultimate power and feel. This led to the implementation of the BBCOR (Bat-Ball Coefficient of Restitution) standard in 2011, ensuring composite and aluminum bats performed more like wood, addressing earlier safety and integrity concerns.

Even professional baseball’s cherished wooden bats weren’t immune to innovation. Maple surged in popularity in the early 2000s, especially after Barry Bonds’ record-breaking seasons, with players noticing its higher density and hardness could increase ball exit velocity. Unlike ash, maple tends to break with a clean snap rather than splintering. Specialized manufacturing techniques like ‘boning’ (compression), ‘cupping’ (removing wood from the barrel end), and precise weight distribution further optimized wooden bat performance, keeping tradition cutting-edge.

Perhaps the most transformative innovation across all equipment has been data-driven design. Advanced analytics, fueled by high-speed cameras, launch monitors, and motion capture technology, allow manufacturers to measure how equipment performs with unprecedented precision. This scientific approach has moved equipment development beyond guesswork, informing every curve and contour with cold, hard data.

The results of this data-driven revolution are clear: bats with engineered “sweet spots” based on actual player contact patterns, gloves designed around fielding efficiency and ball-transfer speed, and cleats with traction patterns optimized for specific movements and playing surfaces. This ensures that every piece of gear is not just a tool, but a highly specialized instrument crafted to maximize player potential.

10. **Smart Equipment and Virtual Training (2000s-Present)**The technological integration era isn’t just about materials; it’s about intelligence. The emergence of “smart” baseball equipment has revolutionized how players train and develop skills. Sensor-equipped bats now measure critical swing metrics like speed, angle, and impact, providing immediate, objective feedback. “Smart baseballs” track spin rate and velocity, while connected gloves measure reaction time and catching technique, turning every drill into a data-rich analysis session.

While current regulations typically prevent most of these technologies from appearing in official game play, their impact on training is undeniable. Coaches can now offer precise feedback based on objective measurements rather than subjective observation alone, leading to more efficient and targeted player development. It’s like having an advanced biomechanics lab right on the practice field, allowing for fine-tuning that was once unimaginable.

Adding another dimension to modern training is the rise of Virtual Reality (VR) technology. VR allows batters to experience a pitcher’s throws in a simulated environment, offering a new level of preparation and strategic insight. Defenders can simulate game situations without the physical stress, honing reaction times and decision-making in a controlled, immersive setting that bridges the gap between practice and pressure.

At the heart of this revolution is analytics, which has become an integral part of baseball. The incorporation of sensors in equipment provides teams with invaluable data that can be used to enhance player performance, refine game strategy, and even prevent injuries by identifying biomechanical flaws. The modern game isn’t just about talent; it’s about intelligently leveraging every piece of data available to gain a competitive edge.

11. **Modern Field Equipment, Training Gear, and Advanced Player Protection**It’s not just the players’ personal gear that has gone high-tech; the very fields they play on have seen incredible advancements. Field maintenance equipment has transformed from simple rakes and brooms to sophisticated machinery. Today’s groundskeepers utilize specialized infield groomers for consistent surface texture, automated irrigation systems for optimal moisture, and laser-guided grading equipment that maintains precise field contours, ensuring a flawless playing surface every game.

Field protection equipment has also evolved dramatically. Early rain tarps required massive crews for deployment; now, modern systems include lightweight materials that can be quickly deployed by smaller teams. Some professional facilities even boast automated tarp systems that unfurl at the push of a button, turning a race against the clock into a streamlined operation. These innovations protect million-dollar investments and keep the game moving.

Player protection continued its relentless march forward with significant innovations beyond personal gear. Batting practice safety, for instance, has moved from simple screens to engineered systems like batting turtles, L-screens with specific visibility cutouts, and portable pitching mounds constructed from advanced materials that mimic permanent mounds. Furthermore, the 1990s saw the groundbreaking introduction of the hockey-style catcher’s helmet, which provided integrated head and face protection far superior to the traditional mask/cap combination, solidifying player safety behind the plate.

Training equipment, too, has seen a complete transformation. Batting cages now feature specialized netting, pitching machines with programmable pitch types and sequences, and video capture systems for instant swing analysis. For pitchers, development equipment includes radar guns for velocity, high-speed cameras for spin analysis, and weighted training implements designed to refine specific pitching mechanics. The practice field of today is truly a state-of-the-art laboratory for developing future stars.

Read more about: The Future of Work: 16 Careers Experts Predict Will Vanish by 2035 Amidst AI and Automation

12. **Standardization, Customization, and a Sustainable Future**As equipment capabilities advanced at an astonishing pace, governing bodies quickly realized the need for comprehensive standards to balance performance with safety. Key regulatory milestones, like the NCAA limits on composite bat performance in 2003, the BBCOR standard in 2011, and USA Baseball youth bat standards in 2018, were implemented to prevent “offensive explosions” and maintain competitive balance. These rules are crucial for ensuring fair play and protecting all participants.

Modern baseball equipment undergoes rigorous testing and certification before it ever sees a game. Bats must meet specific performance standards in laboratory settings, and helmets are subjected to stringent impact resistance tests. Even the baseballs themselves are meticulously tested for consistency in bounce, hardness, and flight characteristics. This commitment to quality assurance means players can trust their gear, and fans can trust the integrity of the game.

The future of baseball equipment is undeniably centered on personalization. Advanced manufacturing techniques, including 3D printing, already allow for custom-fitted equipment components. Imagine bats with handle shapes precisely molded to individual players’ grip patterns, gloves designed around a player’s unique hand anatomy, or cleats with traction patterns customized to a player’s running and fielding movements. This level of bespoke gear promises to unlock unprecedented levels of performance and comfort.

Beyond performance, environmental considerations are increasingly driving future equipment development. Manufacturers are actively exploring sustainable alternatives to traditional ash and maple for wooden bats, alongside recycled and biodegradable materials for protective equipment. Innovations in manufacturing processes are also focused on reducing environmental impact, ensuring that America’s pastime not only looks to the future of play but also the future of our planet.

**Conclusion: Equipment’s Ongoing Impact on America’s Game**

The evolution of baseball equipment is a powerful reflection of American innovation itself. From the rudimentary, handcrafted bats and bare hands of its infancy to the precision-engineered composite materials and specialized smart designs of today, baseball gear has relentlessly pushed boundaries while respectfully honoring its deep traditions. This dynamic interplay between innovation and respect for the past continues to define the sport’s development.

Read more about: Navigating the Future: 14 Top New SUVs and Crossovers to Watch in 2025 for Savvy Buyers

This continuous journey ensures that while professional play maintains its cherished connection to wooden bats and time-honored designs, technological advancements are constantly improving safety, durability, and performance across every level of the game. For coaches, players, and fans alike, understanding this fascinating history provides invaluable context for appreciating the modern game, where every crack of the bat and pop of the glove tells a story of relentless progress and an enduring love for America’s beloved pastime.