Every time you start your car, you’re experiencing the incredible legacy of racing innovation. It’s a connection that runs far deeper than most realize, as the relentless pursuit of speed, efficiency, and driver control on the racetrack has served as the ultimate proving ground for countless automotive technologies. What begins as a groundbreaking, often extreme, solution in the crucible of competitive driving frequently finds its way into the vehicles we rely on every single day.

The demanding conditions of motorsports have pushed engineers to develop technologies that improve every facet of a vehicle, from its raw performance to its fundamental safety and even its environmental footprint. Racing teams invest billions in sophisticated data collection and rapid prototyping, constantly refining designs and systems under immense pressure. This intense, accelerated development cycle directly contributes to the advancements that make our daily drives safer, more efficient, and undeniably more enjoyable.

From cutting-edge engine components to critical safety systems and ingenious driver aids, the transfer of technology from the track to the street is a continuous, fascinating process. We often take these features for granted, unaware of their high-octane origins. Join us as we explore some of the most common and impactful car features that were originally developed for motorsports, demonstrating how racing’s ingenuity has become an integral part of modern automotive engineering.

1. **Semi-Automatic Transmissions**The concept of a transmission that allows drivers to shift gears quickly and precisely without the complexity of a clutch pedal is a true motorsport marvel that has significantly enhanced everyday driving. Race car drivers crave the control of a manual transmission, but the human element of shifting can be too slow and prone to errors. This need for speed and accuracy on the track led directly to the development of sophisticated gearboxes that now offer an engaging yet convenient driving experience in road cars.

Enter Direct-Shift Gearboxes (DSG) and clutchless manual transmissions, both born from racing technology. These systems allow drivers to engage with the gear-shifting process, giving them a sense of control over the engine’s power delivery, while simultaneously minimizing the potential for mistakes that could cost precious seconds in a race or lead to hazardous situations on the road. It’s the best of both worlds, bringing race-derived precision to the mainstream.

DSGs, for example, function almost like two transmissions working in concert. One transmission handles the odd-numbered gears, while the other takes care of the even-numbered ones. This ingenious design ensures that the next needed gear is always “on deck,” ready to be engaged instantaneously. The result is a gear change that is significantly faster than what a conventional manual transmission can achieve, and without the need for a clutch pedal, it further reduces driver error, making them a fun addition to sporty Audi and Volkswagen models today.

Similarly, clutchless manuals, often manifesting as automatic transmissions with a manual mode, directly translate the racing idea of engine control and sequential shifting into production cars. These systems are becoming increasingly common, allowing drivers to choose when the car changes gears without ever touching a clutch. Crucially, like Sequential Manual Transmissions (SMTs) in race cars, they only shift in order—from first to second, then third, and so on—preventing potentially disastrous mis-shifts that can occur with a traditional manual transmission.

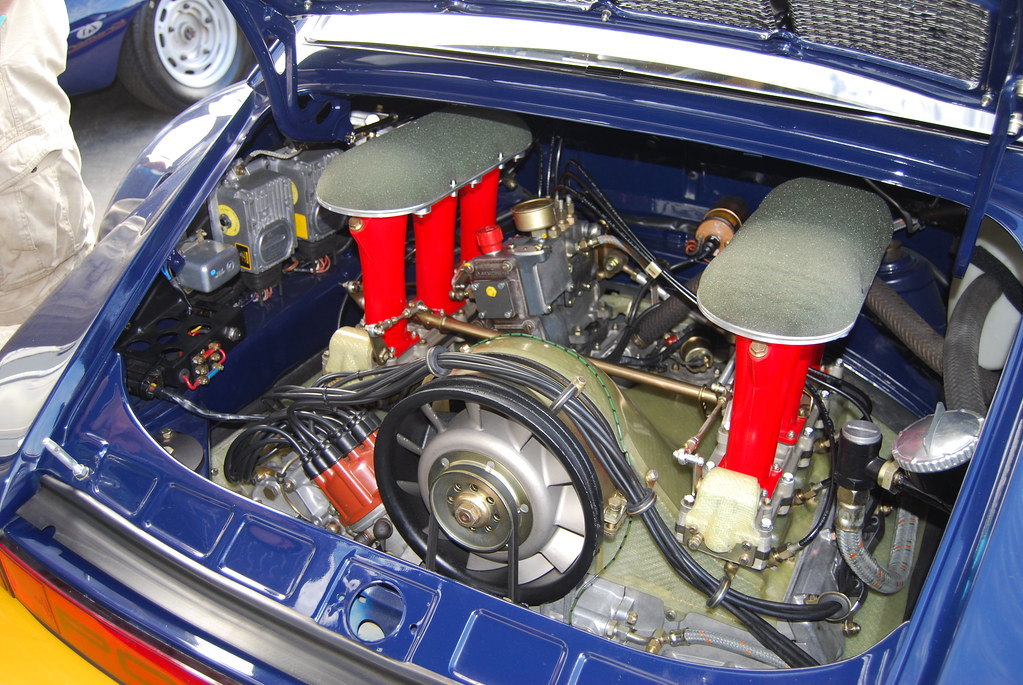

The historical roots of these systems run deep, with the most significant innovation being the dual-clutch transmission (DCT) developed for the Porsche 962 in 1984. This pioneering technology allowed gear changes without disengaging the clutch and was a direct precursor to the sophisticated semi-automatic transmissions with under-the-wheel controls used in Formula 1 to this day. While under-the-wheel clutch shifters didn’t become a universal industry standard, they remain a popular option on various performance models from Porsche, Audi, BMW, Dodge, and even Hyundai, bringing a slice of the racing cockpit to everyday commutes.

Read more about: Legends on Wheels: 15 Iconic Classic Cars Every Enthusiast Dreams of Owning

2. **Disc Brakes**The evolution of braking technology in road cars owes a significant debt to motorsports, particularly to the demands of endurance racing. Disc brakes, a now-ubiquitous feature in virtually every modern vehicle, were originally developed by Porsche specifically for the grueling 24 Hours of Le Mans. The intense heat and repeated, rapid deceleration required in such races exposed the limitations of traditional drum brakes, spurring the innovation of a superior stopping solution.

These high-performance brakes began appearing in production cars during the 1980s, marking a pivotal moment in automotive safety and efficiency. By allowing rapid braking without the wheels locking up, disc brakes dramatically improved a vehicle’s ability to stop quickly and safely. Their introduction to the market was widely heralded as a game-changer, fundamentally redefining expectations for road safety and driver control.

The influence of Formula 1 continues to push the boundaries of braking technology, even in conventional vehicles. While everyday cars still largely use cast iron brake discs, there’s a growing trend, inspired by F1, towards lighter and more heat-resistant ceramic analogs, particularly in high-performance street cars. This continuous evolution ensures that braking systems remain at the forefront of automotive innovation, constantly striving for greater safety and performance, even if F1 cars with their carbon fiber brakes remain technologically ahead.

In essence, disc brakes are a testament to how racing’s extreme demands can yield practical, life-saving advancements for the average driver. They provide superior stopping power compared to the drum brakes they largely replaced, and their continued refinement, influenced by the cutting edge of motorsports, ensures that our vehicles can halt with remarkable precision and safety, no matter the driving conditions.

Read more about: The Ultimate Guide to Used Car Hidden Gems: 12 Models Offering Unbeatable Reliability and Value

3. **Carbon Fiber Chassis**When we talk about advanced materials in automobiles, carbon fiber immediately comes to mind, and its widespread adoption today is a direct result of its proving ground in motorsports. This remarkable material is not only super lightweight but also incredibly flexible and boasts a strength approximately ten times greater than steel of the same weight. These properties made it an indispensable component for top-speed cars, from the pinnacle of Formula 1 to supersonic aircraft, where every gram and every ounce of structural integrity counts.

However, the price tag associated with carbon fiber is as astounding as its performance capabilities. The high cost of producing and pressing carbon fiber means that a future where all-carbon-fiber production cars dominate our roads remains a distant prospect. The economic realities of mass manufacturing make it challenging to implement this exotic material comprehensively in consumer vehicles, despite its clear advantages in terms of weight reduction and strength.

Despite the prohibitive cost of full carbon fiber construction, manufacturers have ingeniously found ways to integrate its benefits into everyday cars. A common approach is the use of carbon fiber reinforced plastic, often referred to as carbon plastic. This composite material is increasingly utilized in electric cars, where reducing the weight of components is absolutely essential to compensate for the significant weight added by large battery packs, demonstrating a practical application of race-derived material science for modern efficiency challenges.

Indeed, pioneers like Ferrari and McLaren revolutionized carbon fiber chassis technology, first on the racetrack and then in their high-performance road cars. Their expertise has gradually made this once-exclusive material more accessible, contributing to advanced safety cells and crumple zones in production vehicles. This not only enhances performance through weight reduction but also significantly improves occupant protection by absorbing impact energy more effectively than traditional metals, showcasing racing’s dual impact on both speed and safety.

Read more about: The 2025 Chevy Corvette Lineup: A Deep Dive into How the New Models Elevate America’s Favorite Sports Car

4. **Dual Overhead Cam Engine**Delving under the hood reveals another fundamental automotive component with a rich racing heritage: the Dual Overhead Camshaft (DOHC) engine system. This configuration, characterized by two camshafts in the engine cylinder head and typically four valves per cylinder, is now a widely adopted standard in today’s production cars. It’s a design that speaks to efficiency, power, and precise control over the engine’s breathing.

The DOHC system’s origins trace back to the early days of motor racing, specifically to 1912. It was the result of the innovative efforts of French Peugeot engineers, who implemented it in their L76 race car. This groundbreaking vehicle immediately showcased the technology’s potential by winning its very first race that year, demonstrating a significant leap forward in engine design and performance under competitive conditions.

The primary advantages of the DOHC configuration, which made it so attractive for racing, were its ability to simplify the valve mechanism design and, crucially, to significantly increase the engine’s output. By allowing for more precise control over valve timing and lift, and by enabling the use of multiple valves per cylinder, the engine could breathe more freely, leading to greater power generation and improved efficiency, both vital for winning races.

Following its success on the track, the DOHC technology proved too beneficial to remain exclusive to racing. Its inherent advantages in performance and efficiency paved the way for its mass manufacturing and subsequent widespread adoption in civilian cars. What started as a competitive edge for a race car a century ago has evolved into a cornerstone of modern engine design, providing the smooth, powerful, and efficient performance we expect from our everyday vehicles today.

Read more about: 2025 Self-Parking Systems: An In-Depth Consumer Reports Analysis of Real-World Safety and Reliability

5. **Gasoline Fuel Injection**Today, gasoline direct injection (GDI) technology is widely used in vehicles across the globe, celebrated for its efficiency and performance. Yet, like so many other fundamental automotive advancements, its journey began in the high-stakes environment of motorsports. This precision fuel delivery system first made its debut with the FSI engine of the Le Mans Audi prototype in 2001, setting a new benchmark for engine technology.

The core innovation of GDI technology lies in its method of fuel delivery: instead of injecting fuel into the intake manifold, it injects it directly into the combustion chambers. This direct and precise control over fuel atomization and timing allows for a more efficient burn, maximizing the energy extracted from every drop of gasoline. Such an advancement was crucial for race cars seeking every possible advantage in power and endurance.

The benefits of GDI were immediately evident on the track. The technology allowed for a significant reduction in fuel consumption, a critical factor in endurance races like Le Mans where pit stops can cost precious time. Simultaneously, it led to an increase in engine efficiency and a marked improvement in throttle response, giving drivers more immediate and precise control over their vehicle’s power, which is invaluable in competitive racing.

Unsurprisingly, the Audi prototype equipped with this pioneering GDI system won the race, emphatically proving its superiority. This success on the world stage rapidly accelerated the transfer of the technology to production cars. What was once a secret weapon for a Le Mans champion has now become a standard feature in countless road vehicles, delivering better fuel economy and smoother acceleration to everyday drivers, demonstrating how racing perfects and then shares its innovations.

Read more about: Used Car Buyers Beware: These 7 Vehicle Brands Are Most Often Reported as ‘Lemons’ – Your Guide to Avoiding Costly Mistakes

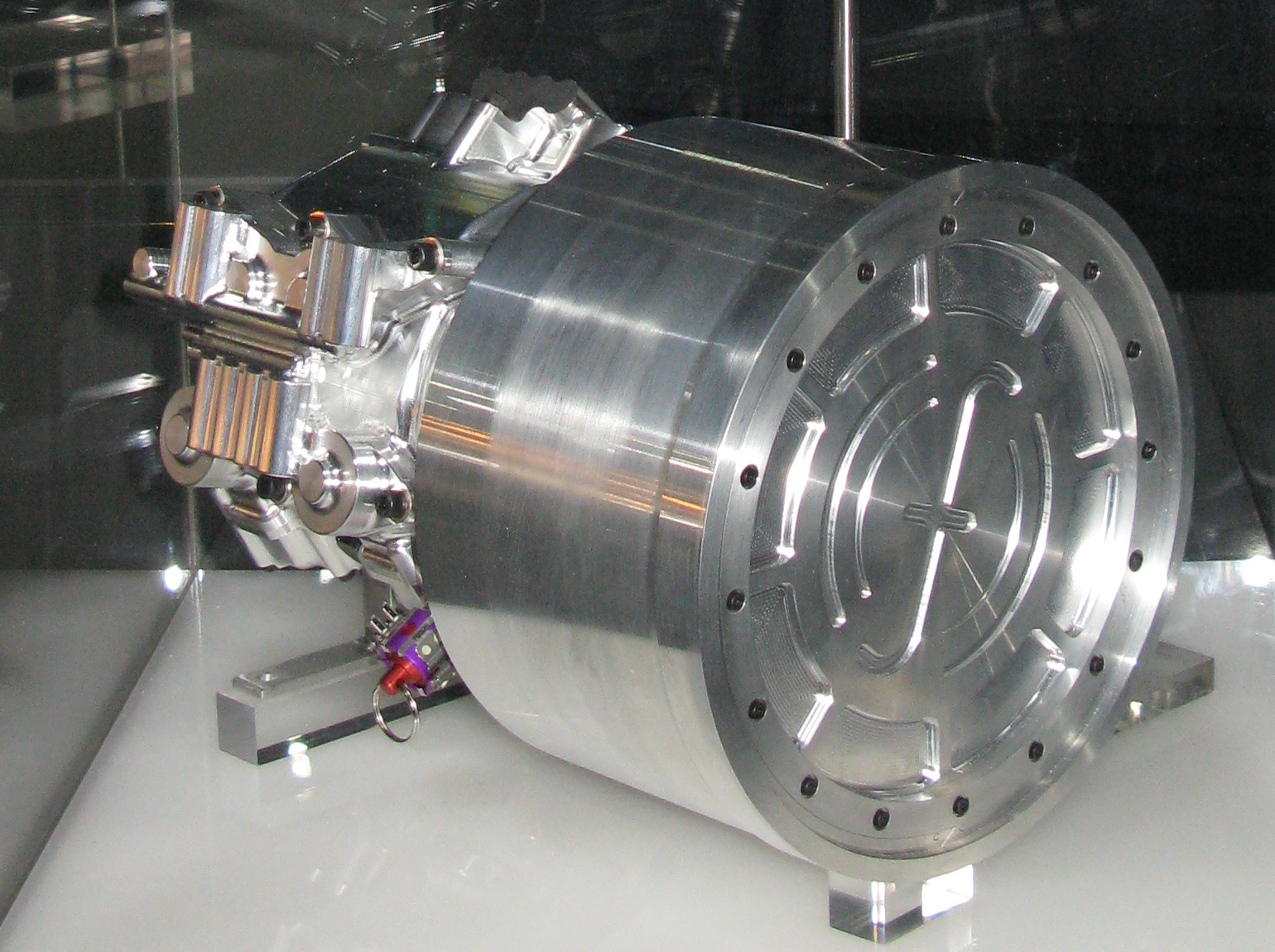

6. **Kinetic Energy Recovery System**In the relentless pursuit of the best lap times, race car creators are constantly forced to search for even the smallest reserves to increase engine output and efficiency. This intense pressure led to the development of the Kinetic Energy Recovery System, or KERS, a technology that ingeniously captures and repurposes energy that would otherwise be lost. It’s a prime example of how racing drives sustainable innovation.

KERS is capable of converting braking energy, a substantial source of wasted power, into electricity. This stored energy can then be redeployed to provide a temporary boost in acceleration, giving the driver a crucial burst of power at strategic moments on the track. This capability first appeared on Formula 1 cars in 2009, instantly becoming a strategic element in competitive racing and a showcase for advanced energy management.

What’s particularly fascinating about KERS is how quickly the technology migrated to civilian cars, often with minimal adaptation. High-performance hybrid vehicles like the McLaren P1 and Ferrari LaFerrari utilize KERS systems that are almost identical to those found in their F1 counterparts, demonstrating a direct transfer of cutting-edge race engineering to the most exclusive road cars. This highlights the immediate and powerful impact of racing innovation on vehicle performance.

More broadly, the hybrid technology seen and refined in Formula 1 has significantly accelerated the development of hybrid street cars for the mass market. These energy recovery systems capture and reuse power that would otherwise be wasted during braking, not just for a performance boost, but also to enhance fuel efficiency and reduce emissions in everyday driving. KERS, therefore, represents a pivotal step in bridging the gap between extreme racing performance and the growing demand for eco-friendly consumer vehicles, proving that going fast can also mean going green.

Read more about: Navigating the Wild: The Best 2025 SUVs Packed with Off-Roading Prowess for American Adventurers

7. **Rearview Mirror**While certainly not the most amazing or technologically complex invention to emerge from the high-octane world of motor racing, the rearview mirror is undoubtedly one of the most widespread and fundamentally important. Today, it’s often the very first thing we look into after getting behind the wheel, an indispensable tool for safe navigation. Yet, its initial appearance in 1911 at the Indianapolis 500 was a gesture primarily familiar to racers rather than ordinary drivers.

At that time, racing rules and practices were quite different, and the concept of an external aid for rear visibility was revolutionary. According to Ballistic Parts, car designers quickly realized that a mirror, properly installed and adjusted, would grant the driver the ability to see rivals approaching from behind. This newfound awareness allowed racers to make strategic decisions, such as blocking opponents by choosing an optimal trajectory or facilitating easier braking around corners without having to turn their heads, thus enhancing focus on the track ahead.

Over the years, the placement of the interior rearview mirror standardized to its familiar position: typically near the top of the windshield, in the exact center and slightly above eye level for optimal visibility. However, earlier iterations saw some variation; for instance, on some race cars (especially low-slung ones) and certain Chrysler vehicles in the late 1950s and early 1960s, the mirror might be placed at the bottom of the dashboard. This approach had a significant drawback: any passengers in the backseat could practically deprive the driver of their rear view.

Further refinement, still inspired by the need for clear visibility under all conditions, led to the development of interior auto-dimming rearview mirrors. These ingenious accessories allow the driver to avoid being temporarily blinded by the glare of headlights from vehicles following at night, enhancing safety during evening drives. Consequently, this simple yet profoundly effective car accessory quickly transitioned from a competitive advantage in racing to one of the main, universally recognized safety features for conventional car drivers, becoming something we truly cannot imagine driving without.

Every time you start your car, you’re experiencing the incredible legacy of racing innovation. It’s a connection that runs far deeper than most realize, as the relentless pursuit of speed, efficiency, and driver control on the racetrack has served as the ultimate proving ground for countless automotive technologies. What begins as a groundbreaking, often extreme, solution in the crucible of competitive driving frequently finds its way into the vehicles we rely on every single day.

Today, we continue our journey into the fascinating world where track-tested ingenuity meets daily commutes. We’ll delve into seven more advanced technologies and design philosophies, including sophisticated electronic systems, aerodynamic principles, and cutting-edge material science, that have seamlessly transitioned from the competitive edge of racing to become indispensable in modern production vehicles. Prepare to see how the world’s most intense races continue to shape the cars of tomorrow, one innovation at a time.

Read more about: The Ultimate Off-Road Showdown: 2025 Ford Bronco vs. Land Rover Defender Face-Off

8. **Backup Camera**Many of us now rely on the humble backup camera to maneuver into tight parking spots or simply to ensure safety when reversing. This seemingly modern standard actually has its roots firmly planted in the unique challenges of endurance racing, specifically at the Le Mans 24 Hours. Automotive designers faced a peculiar problem with the Audi R18 LMP1: its mid-engine layout completely obstructed any traditional rearward visibility.

To overcome this, engineers had to equip the R18 LMP1 with a rear-view camera system paired with an AMOLED display, effectively replacing the non-existent rearview mirror. This ingenious solution, born out of a race car’s design necessity, allowed the driver to maintain crucial situational awareness despite the car’s configuration. It was a direct response to a very practical problem on the racetrack.

The success and reliability of this system in the demanding environment of Le Mans quickly paved the way for its migration to production vehicles. A notable example is the electric version of the Audi R8 E-Tron, which also integrated a similar setup where a 7.7-inch LED display replaced the traditional mirror, with the camera mounted on the roof’s top. This demonstrates a direct lineage from race-specific solutions to high-performance road cars.

The widespread adoption of this technology culminates in a significant safety mandate: as of 2018, every new car sold in the United States must include a backup camera as a standard feature. This makes the backup camera a perfect illustration of how a solution for an elite racing challenge can evolve into a universal, essential safety component for millions of drivers, making our roads safer for everyone.

Read more about: Unleashing the Soul of Driving: What the 2025 Mazda MX-5 Miata Offers True Purists

9. **Laser Headlights**While LED headlights have become commonplace, a more advanced form of automotive illumination also emerged from the crucible of motorsport: laser headlights. These revolutionary lighting systems were first utilized by Audi in 2014 on their R18 E-Tron Quattro race car, once again demonstrating the 24 Hours of Le Mans as a proving ground for cutting-edge technology.

The unique demands of the Le Mans race, which runs for 24 hours and includes significant nighttime driving, necessitated exceptionally powerful headlights. To meet this challenge, engineers developed a system using four-module LEDs that generated a potent blue light beam. A special converter then transformed this intense blue light into a spectrum more suitable and comfortable for the human eye, providing unparalleled visibility during the darkest hours of the race.

The performance advantages of laser headlights—their incredible brightness and long-range illumination—were immediately apparent on the track. This rapid success led to their almost immediate implementation in a limited-production road car, the Audi R8 LMX. This swift transfer from the race-proven R18 E-Tron Quattro to a street-legal performance vehicle underscores how quickly racing innovation can influence mainstream automotive design, offering a glimpse into the future of nighttime driving safety and performance.

Read more about: The Ultimate 12-Step Guide to Inspecting a Used Heavy-Duty Truck for Frame Damage

10. **All Wheel Drive**The concept of all-wheel drive (AWD) has transformed how vehicles handle diverse road conditions, and its widespread popularity today owes a great deal to its pioneering application in motorsports. Audi first introduced its now-legendary AWD system, known as “Quattro,” in 1980, marking a pivotal moment in automotive history. This technology was swiftly integrated into the revolutionary four-wheel-drive Audi Quattro model, immediately showcasing its capabilities.

The Quattro system was designed to allow cars to easily conquer both smooth, flat sections and rough, bumpy areas of a race track. Its brilliance lies in its ability to improve upon the brutal simplicity of earlier all-wheel-drive systems by precisely changing the torque transmitted to each wheel. This advanced control made race cars exceptionally agile, allowing them to handle with the nimbleness of a Mini while still harnessing more than 300 horsepower under the hood, a remarkable feat of engineering.

Beyond the racetrack, the benefits of the AWD system quickly became apparent to everyday drivers. It has evolved into a “must-have” feature for many car owners, especially those who frequently encounter challenging driving conditions. When available traction is low, such as on snow, ice, dirt, gravel, or wet pavement, the extra grip provided by an AWD vehicle is invaluable, offering not only a more stable feel but also superior acceleration.

Today, manufacturers like Subaru and Audi are widely recognized as leaders in AWD technology, constantly refining these systems. However, the influence is so profound that most car manufacturers now offer all-wheel drive in at least one model within their lineup. This widespread adoption highlights how a racing innovation designed for competitive advantage has become a fundamental feature for enhancing safety, control, and confidence in civilian vehicles across the globe.

Read more about: Used Car Buyers Beware: These 7 Vehicle Brands Are Most Often Reported as ‘Lemons’ – Your Guide to Avoiding Costly Mistakes

11. **Steering Wheel Buttons**The modern car steering wheel, often adorned with a myriad of buttons, is a testament to another practical innovation that migrated from the intense environment of Formula 1 racing. F1 steering wheels are far from simple, featuring approximately 25 buttons, each meticulously designed to control specific functions critical for improving driving performance during a race. These buttons allow drivers to make rapid adjustments without ever taking their hands off the wheel or their eyes off the track, offering a crucial competitive edge.

The functions controlled by these buttons vary significantly between a race car and a production vehicle. For instance, while F1 buttons manage complex car controls like engine mapping, brake bias, and energy recovery systems, those on a Honda Civic’s steering wheel are typically less focused on direct car control. Instead, they are primarily designed for convenience, allowing drivers to manage the sound system, answer phone calls, or activate cruise control with ease.

Despite the difference in specific functions, the core benefit remains the same: the ability to control these features using buttons located directly before the driver’s eyes has a profoundly positive impact on both safety and convenience. Drivers can adjust settings or answer a call without fumbling for controls elsewhere in the cabin, thereby reducing distractions and keeping their focus on the road ahead. This direct access enhances overall driving experience and safety.

The evolution of steering wheel controls in production cars began with simple buttons on car stereos. This quickly expanded to a comprehensive array of buttons, switches, and levers directly integrated into the steering wheel itself. This allows for seamless control of various vehicle systems, such as cruise control, enabling drivers to set their speed and momentarily forget about the gas pedal, directly translating a race-derived ergonomic principle into everyday comfort and safety.

Read more about: Beyond the Hype: A Consumer Reports Deep Dive into Why the Subaru Forester and Honda CR-V Consistently Top the Sales Charts

12. **Traction Control System**The widely used traction control system (TCS), a secondary function of electronic stability control (ESC), represents a crucial safety innovation that originated and was perfected in the high-stakes world of motorsports. Its first notable application was by the Scuderia Ferrari S.p.A division in 1990, where it immediately demonstrated a profound impact on vehicle dynamics and driver capability. The system was so effective that it was subsequently banned from racing for being “too good,” as it was perceived to excessively compensate for driving mistakes made by Scuderia racers.

The primary design purpose of TCS in racing was to enhance performance by ensuring maximum traction under acceleration without allowing wheel spin. This was particularly vital when accelerating out of turns on a race track, where maintaining optimal grip is paramount for achieving the fastest lap times. By managing power delivery to the wheels, the system kept the tires at an optimal slip ratio, preventing power from being wasted as uncontrolled wheelspin.

Although technical inspections ultimately deemed the system “quite inappropriate” for competitive racing due to its performance-leveling capabilities, its value for civilian cars cannot be overstated. The ability of TCS to prevent loss of control during acceleration, especially on slippery surfaces, translates directly to enhanced safety for everyday drivers. It intervenes automatically to restore traction, significantly reducing the risk of skids and accidents.

Indeed, the importance of this electronic assistant for road safety is underscored by regulatory actions. For example, since 2004, the electronic assistant, including features like traction control, has been made mandatory for all cars produced in the European Union. This mandates the integration of race-derived technology into every new vehicle, making an elite performance enhancement a universal standard for driver safety on public roads.

Read more about: Unearthing the Untamed: 2025’s Premier Factory Off-Road Vehicles Engineered for American Terrain

13. **Active Suspension**While a regular, or passive, suspension system merely reacts to the road’s dictates, an active suspension system represents a significant leap forward, initially pioneered and refined in motorsports. This advanced technology doesn’t passively absorb impacts; instead, it proactively raises and lowers the chassis for each wheel independently. This dynamic adjustment provides superior handling, enhanced traction, and a remarkably smoother ride by isolating the vehicle’s body from unstable road surfaces.

Early iterations of active suspension primarily focused on adjusting the rigidity of the shock absorbers to improve ride quality and control. However, Formula 1 racing pushed this technology to new, unprecedented heights. In modern active suspension systems, all relevant road surface data is continuously transferred to an onboard computer with the help of specialized sensors strategically installed in different parts of the vehicle. This real-time data allows the system to make instantaneous, precise adjustments, optimizing the car’s attitude and grip over varying terrain.

The practicality and benefits of active suspension were too great to remain confined to the racetrack. Toyota was one of the first manufacturers to bring this cutting-edge technology to mass production, with the 1983 Toyota Soarer being a pioneering example of a production car featuring the system. Following this, models like the Citroen Xantia and Volvo S60R further marked its ascent into the consumer market, demonstrating its versatility and desirability.

Today, the active suspension system found in an Audi A8 serves as a prime example of the sophisticated capabilities possible with this technology. It dynamically adjusts to ensure optimal comfort, stability, and handling, showcasing how a complex racing innovation designed for competitive advantage has evolved into a luxurious and performance-enhancing feature for high-end production vehicles. This journey illustrates motorsport’s enduring impact on advancing ride quality and vehicle control for all drivers.

Read more about: From Garage Gems to Gold Mines: 8 Muscle Cars Poised to Skyrocket in Value

14. **High-Quality Tires**For many car owners, the ritual of swapping out winter and summer tires twice a year is a common one, driven by the continuous evolution of rubber compounds and tread patterns on the market. This constant innovation in tire technology owes an invaluable debt to motorsports, where the extreme demands of racing provide the ultimate proving ground for tire manufacturers.

The best tire manufacturers gain crucial experience by participating in a diverse range of competitions, pushing the boundaries of what is possible. The key knowledge derived from this intense R&D is in the rubber composition itself, which directly influences a tire’s wear resistance, grip, and performance characteristics under various conditions. Crafting the perfect compound for specific racing scenarios yields insights that are directly applicable to consumer tires.

Only after the ideal rubber composition is perfected does the intricate design of the tread pattern come into play. This pattern allows car tires to “dig” into the ground’s surface for better grip, shedding water or finding purchase on loose terrain. Racing provides an accelerated environment for testing countless tread designs, identifying which patterns offer optimal performance and safety, lessons that are then adapted for everyday driving challenges.

Of course, race options must be significantly adapted for civilian use. While a race car might use “slicks” (tires with no tread) that need to be changed every week or even after a single race for maximum performance, such frequent replacement is impractical and unnecessary for the average driver. The challenge for manufacturers is to translate race-derived knowledge into high-quality, durable tires that offer excellent grip, wear resistance, and safety for millions of miles of daily commutes, marrying performance with practicality.

Read more about: Amazon’s Secret Stash Revealed: Unbelievable Deals on Home Essentials You Need Right Now!

As we’ve explored, the connection between the roar of the racetrack and the quiet hum of your daily commute is undeniably profound. Every innovation, every refinement, and every technological leap made in the high-stakes world of motorsports contributes directly to the cars we drive, making them safer, more efficient, and undeniably more exciting. From the precision of a semi-automatic gearbox to the life-saving capabilities of a backup camera, these features remind us that the relentless pursuit of victory on the track continues to shape the future of automotive engineering for everyone. So, the next time you get behind the wheel, take a moment to appreciate the incredible legacy of racing innovation that makes your ride possible.