Your vehicle’s brake pads are not just another component; they are the frontline defenders of your safety on the road. These unassuming friction materials play an absolutely crucial role in transforming kinetic energy into the controlled deceleration that allows your car to slow down and stop safely. Because they are designed to experience constant wear and tear as they perform this vital function, understanding when they need attention isn’t merely about routine upkeep—it’s about protecting your investment and, most importantly, the lives of everyone in your vehicle.

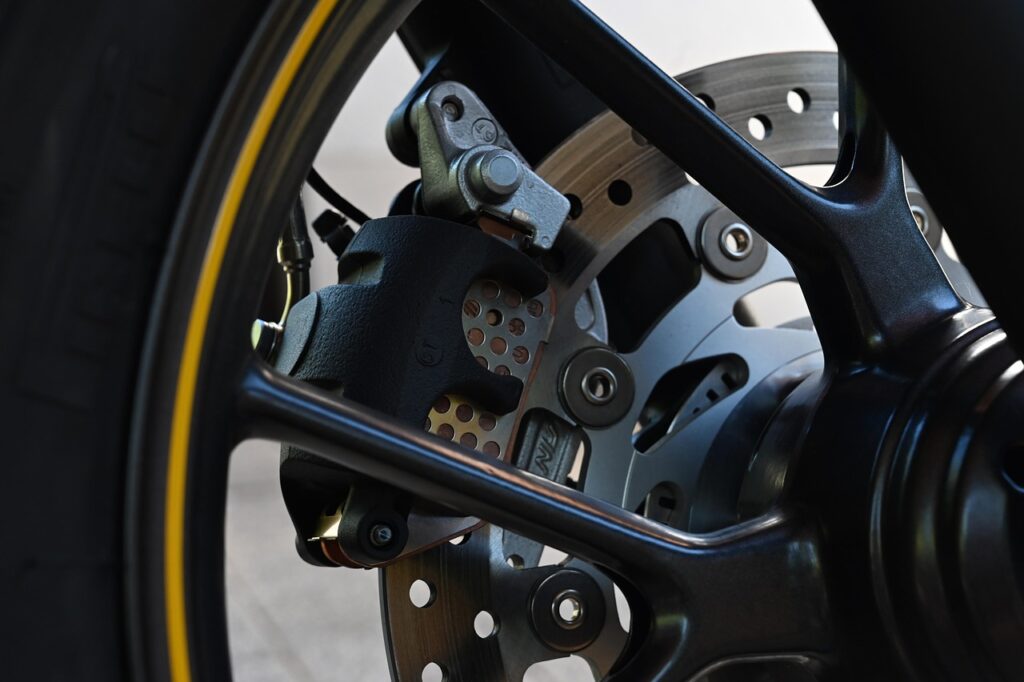

At their core, brake pads work in harmony with your vehicle’s brake rotors, or discs, to generate the friction necessary for effective stopping. When you engage the brake pedal, hydraulic pressure activates the brake calipers, which then squeeze the pads firmly against the spinning rotors. This dynamic process converts your vehicle’s momentum into heat, effectively bringing the car to a halt. It is precisely this constant contact and the resulting friction that cause brake pads to gradually wear down over time, a natural and unavoidable part of their operational cycle.

Replacing your brake pads at the opportune moment is paramount for a multitude of reasons. Severely worn-out brake pads can drastically diminish your vehicle’s stopping power, dramatically elevating the risk of accidents. Furthermore, procrastinating on their replacement can lead to more extensive and far more expensive damage to other integral components within your brake system, such as the rotors and calipers. Recognizing these warning signs early empowers you to maintain optimal vehicle safety and performance, preventing a minor repair from spiraling into a significant financial burden.

1. **Squealing or Screeching Brakes**One of the most common and often the very first indication that your brake pads are wearing thin is a distinctive high-pitched squealing or screeching sound that occurs when you apply the brakes. This isn’t just a random noise; it’s a deliberate warning signal engineered into most modern brake pads. These pads are equipped with small metal wear indicator tabs, or shims, which are strategically designed to contact the rotor when the pad material has worn down to approximately 20% of its original thickness, typically around 3mm.

When these metal tabs make contact with the spinning rotor, they produce that unmistakable metallic squeal. This sound is generally most noticeable during light braking, as the pad isn’t pressed as firmly against the rotor. Interestingly, the noise might temporarily disappear under heavy braking, simply because the increased pressure forces the pad more uniformly against the rotor, momentarily silencing the indicator. It’s also worth noting that some temporary squealing can occur after rain or a car wash as surface rust clears from the rotors, but persistent squealing is a clear call for attention.

While other minor issues like dust or road debris can sometimes cause intermittent squealing, any consistent or persistent high-pitched noise when braking should not be ignored. It’s your car’s way of telling you that the pads are nearing their service limit and it’s time to schedule an inspection. Addressing this early warning sign can prevent further damage and ensure you don’t find yourself in a more critical situation down the road.

Read more about: Why Your Car’s Brake Pads Could Be Hiding a Major Problem: 13 Critical Warning Signs Every Driver Must Know

2. **Grinding Noise**If the high-pitched squeal evolves into a harsh grinding or growling noise when you apply the brakes, you’re now dealing with a much more severe problem that demands immediate action. This ominous sound signifies that the brake pad material has completely worn away, and now the metal backing plate of the brake pad is making direct, abrasive contact with the brake rotor. This is literally metal-on-metal friction, and it’s an emergency situation that cannot be delayed.

Driving with a grinding noise is incredibly dangerous because this metal-to-metal contact rapidly destroys your brake rotors, creating deep nicks and grooves, or scores, that can render them unusable. This can quickly turn a relatively inexpensive brake pad replacement into a significantly more costly repair, potentially requiring not just new pads but also rotor resurfacing or even complete rotor and caliper replacement. The damage occurs swiftly, compounding the problem with every stop you make.

Beyond the financial implications, a grinding noise severely compromises your vehicle’s stopping power. The friction coefficient between metal and metal is much lower and less predictable than between the designed friction material and the rotor, leading to a significant reduction in braking effectiveness. You may also experience a strong vibration through the brake pedal. Continuing to drive in this condition puts you and others at extreme risk, highlighting the urgency of immediate inspection and repair.

Read more about: Your Ultimate Used Car Inspection Playbook: 12 Key Areas You CANNOT Skip

3. **Vibration in the Brake Pedal**Feeling a pulsing or vibrating sensation through your brake pedal, or even a shaking in the steering wheel, when you apply the brakes is another crucial indicator that your braking system requires attention. This tactile feedback often signals issues with your brake rotors, most commonly warped rotors, or can be a result of uneven pad deposits on the rotors. Warped rotors are typically caused by excessive heat generation, a problem that often exacerbates when brake pads are allowed to wear down too thin.

When brake pads become thin, their ability to dissipate heat efficiently diminishes. This increased thermal stress can lead to the rotors overheating and becoming warped, meaning their surfaces are no longer perfectly flat. This uneven surface then causes the calipers to grab intermittently, leading to the pulsation you feel. Uneven pad wear, where one part of the pad wears faster than another, can also contribute significantly to this vibration, creating an inconsistent braking force.

The vibration may start subtly, perhaps only noticeable during moderate to heavy braking, but it tends to worsen over time as the warpage or uneven wear progresses. Aggressive driving habits, especially frequent hard braking, towing, or carrying heavy loads, can accelerate this wear pattern and the onset of vibrations. If you feel any such shaking, it’s a clear signal for a professional inspection to diagnose the root cause and prevent more severe damage to your entire braking system.

Read more about: Your Ultimate Used Car Inspection Playbook: 12 Key Areas You CANNOT Skip

4. **Increased Stopping Distance**If you find yourself needing to press the brake pedal further than usual, or if your vehicle simply takes noticeably longer to come to a complete stop, these are strong indications that your brake pads are thinning and losing their effectiveness. As the friction material on your brake pads wears down, their ability to generate the necessary friction against the rotors diminishes significantly. This reduction in friction directly translates to reduced stopping power.

This phenomenon of increased stopping distance is particularly alarming in critical situations, such as sudden stops or emergencies, where every foot of braking distance counts. What might have once been a routine stop can become a dangerous situation, as your vehicle simply cannot decelerate as quickly or efficiently as it once could. This reduced performance is often more pronounced when braking from higher speeds, such as on the highway, or when your vehicle is carrying a heavy load, as the demand on the braking system is higher.

Beyond just the immediate safety concern, reduced stopping power can also be severely affected by weather conditions. Worn pads will perform even worse in wet or slippery conditions, further compromising your ability to maintain control and stop predictably. If you notice this elongation in your stopping distance, it’s a critical sign that your brake pads require immediate inspection. Procrastination in this instance directly correlates to increased accident risk and a compromised driving experience.

Read more about: Is the 2025 Audi Q5 Still the Best for Small Luxury Buyers? An In-Depth Car and Driver Review

5. **Visual Inspection: Thin Brake Pads**Fortunately, you don’t always need a mechanic to get a preliminary idea of your brake pad condition. A visual inspection can often confirm whether your brake pads are nearing their end of life, provided you know what to look for. You can frequently check your brake pads without special tools by simply looking through the spokes of your wheels.

Most new brake pads come with about 10-12mm of friction material. For reference, if you see less than 1/4 inch (approximately 6mm) of brake pad material remaining, it’s a strong indication that it’s time to consider a replacement. The generally accepted guideline suggests that pads between 3mm and 8mm thick mean you should schedule service soon, while anything under 3mm warrants immediate replacement. Many pads also feature wear grooves that become less visible or disappear entirely when the pad is worn beyond safe limits, serving as an additional visual cue.

To conduct this check effectively, use a flashlight to get a clear view of the pad pressed against the rotor. If you’re unsure about the precise thickness, comparing what you see to a photo of a new brake pad online can provide a helpful perspective, as thickness can sometimes be deceptive from certain angles. While a visual check is a great first step, remember it’s primarily an outer pad assessment; an inner pad may wear differently. Still, it provides valuable insights and empowers you to act before other symptoms become more severe.

Read more about: Unlock Your Car’s Full Potential: 14 Simple DIY Maintenance Tasks Every Driver Must Master for a Longer, Safer Ride

6. **Dashboard Warning Lights**Modern vehicles are equipped with sophisticated diagnostic systems, and your braking system is no exception. Many contemporary cars feature electronic brake wear sensors designed to alert you when your brake pads have reached a critical level of wear. These sensors are typically embedded within the brake pads themselves and are configured to complete an electrical circuit when the friction material wears down to a predetermined thickness.

When this circuit is completed, it triggers a warning light on your dashboard, often appearing as a yellow or red indicator. This light is your vehicle’s direct way of communicating that a brake system issue, quite possibly worn pads, requires your attention. Some high-end or luxury vehicles even offer more advanced systems, displaying specific messages or even the estimated remaining pad life directly in the instrument cluster, providing an even clearer heads-up.

It’s important to be aware that in some vehicles, the same dashboard warning light might illuminate for multiple brake-related issues, such as low brake fluid levels, not exclusively for worn pads. Therefore, if this light appears, it’s always wise to check your brake fluid reservoir in conjunction with considering pad wear, especially if accompanied by any other warning signs. Never ignore a dashboard warning light; it’s a prompt for inspection and a key part of your vehicle’s safety system.

Read more about: Your Ultimate Used Car Inspection Playbook: 12 Key Areas You CANNOT Skip

7. **Pulling to One Side While Braking**If you notice that your vehicle consistently pulls or veers significantly to one side—either left or right—when you apply the brakes, this is a serious warning sign that demands immediate investigation. This phenomenon indicates an uneven braking force being applied across your vehicle’s wheels, which is inherently dangerous and can severely compromise your ability to maintain control during deceleration.

The most common culprits behind this issue include a stuck brake caliper on one side, or significantly uneven brake pad wear between the left and right wheels. A stuck caliper means that one side of your braking system isn’t releasing properly, or isn’t clamping down with the same force as the other, leading to an imbalance. Similarly, if one brake pad is worn much more severely than its counterpart, it will generate less friction, causing the vehicle to pull towards the side with more effective braking.

This uneven braking force is not only unsettling but also highly dangerous. It dramatically increases your stopping distance, as the effective braking power is reduced, and it makes it exceedingly difficult to control the car, especially during emergency stops or on slick roads. Such an issue requires prompt professional attention, as it directly impacts vehicle stability and overall driving safety. Ignoring this symptom can lead to unpredictable handling and a much higher risk of an accident.

Navigating the complexities of your vehicle’s braking system goes beyond just recognizing the immediate, critical warning signs. To truly empower yourself with comprehensive knowledge for optimal vehicle care, it’s essential to delve into additional indicators of brake pad wear, understand the myriad factors influencing their lifespan, and grasp proactive maintenance strategies that can save you money and enhance safety. Let’s peel back the layers and equip you with even more vital insights.

Read more about: The Ultimate Haulers: A Deep Dive into 2025 Half-Ton Pickup Truck Towing Capacities and Features for Informed Buyers

8. **Soft or Spongy Brake Pedal**Beyond the distinct vibrations that signal rotor issues, another critical tactile indicator is a brake pedal that feels unusually soft, mushy, or spongy underfoot. This sensation suggests a decrease in the hydraulic pressure needed to effectively clamp the brake pads against the rotors. It’s a clear signal that your braking system isn’t responding with the firmness and precision it should, translating directly into reduced stopping power and a compromised sense of control.

This soft pedal feel often points to issues more nuanced than just thin pads, though worn pads can exacerbate the problem. It could be indicative of air trapped within your brake lines, a leaking master cylinder, or a general breakdown in the hydraulic system’s integrity. Regardless of the precise cause, a spongy pedal means your vehicle requires more distance and effort to slow down, making quick or emergency stops significantly more challenging and dangerous.

If you find yourself needing to push the brake pedal further down, or if it simply feels less firm and responsive than usual, your brake system is actively signaling for immediate attention. Addressing this particular symptom quickly is vital, as it directly impacts your ability to decelerate reliably and safely. Procrastinating on this check-up could lead to a sudden and dangerous loss of effective braking when you need it most.

Read more about: Your Ultimate Checklist: 14 Essential Things to Examine During Your Used Car Test Drive

9. **Burning Smell While Driving / Brake Fade**An alarming sensory clue that your brakes are under severe stress, particularly after extended or aggressive use, is a distinct burning odor. This pungent smell, often described as acrid or chemical, typically indicates that your brake pads are overheating, releasing gases from their friction material. It’s a sign that the pads are working beyond their optimal temperature range, rapidly accelerating their wear and compromising their performance.

This phenomenon is closely linked to ‘brake fade,’ where the braking effectiveness significantly diminishes due to excessive heat buildup. While brake pads are designed to withstand high temperatures, persistent or extreme heat causes the friction material to break down and gases to form between the pad and rotor, literally reducing the friction coefficient. This means you have to press the pedal harder and further to achieve the same stopping power, which can be terrifying and dangerous, especially on long descents or during heavy traffic.

If you detect a burning smell after a period of heavy braking, such as driving down a steep mountain road or after repeated hard stops, it’s crucial to pull over safely and allow your brakes to cool down. Ignoring this warning can lead to permanent damage to your brake pads and rotors, potentially causing complete brake failure. It’s a vivid reminder that your braking system has reached its thermal limits and needs immediate assessment.

Read more about: Why Your Car’s Brake Pads Could Be Hiding a Major Problem: 13 Critical Warning Signs Every Driver Must Know

10. **Uneven Wear, Cracks, Glazing, or Lifting on Pads**While a general visual inspection for thin pads is crucial, a more detailed look can reveal specific patterns of wear that point to underlying systemic issues. Observing uneven wear, where one part of the pad is significantly thinner than another, is a serious indicator. This could manifest as ‘tapered wear’ (a slant across the pad), ‘outer pad wear’ (excessive wear on the outer edge), or ‘inner pad wear’ (excessive wear on the side closer to the engine). These patterns typically suggest problems beyond just normal friction, such as a stuck caliper, worn guide pins, or issues with caliper bushings, leading to inconsistent pressure application.

Furthermore, inspecting for physical damage like cracks, glazing, or lifting edges on the brake pad material itself provides critical insights. Cracks can form from excessive heat or structural fatigue, compromising the pad’s integrity. Glazing, which appears as a hardened, shiny surface on the pad, occurs when extreme heat alters the friction material, reducing its effectiveness and often leading to squealing. Lifting edges indicate a separation of the friction material from its backing plate, a severe failure that renders the pad ineffective and dangerous.

These specific visual cues demand immediate attention because they not only signify a worn pad but also highlight a malfunction within other critical brake components. For instance, tapered wear often necessitates replacing the caliper along with the pads to prevent recurrence. Addressing these detailed signs early can prevent more extensive damage to your rotors and ensure that your entire braking system operates symmetrically and effectively, preventing unpredictable braking behavior and maintaining vehicle stability.

11. **Factors Influencing Brake Pad Lifespan**Understanding how various factors impact the longevity of your brake pads is key to proactive vehicle maintenance and dispelling common mileage myths. While estimates often range from 30,000 to 70,000 miles, this range can be highly misleading without considering the context of your driving habits, vehicle specifics, and even the quality of the pads themselves. Personalized assessments are essential for anticipating replacement needs and preventing safety hazards.

Your driving style is paramount. Frequent hard braking, typical in stop-and-go city driving, generates significantly more friction and heat, accelerating wear. In contrast, drivers who primarily use highways and employ smoother, more gradual deceleration often see their pads last much longer. Imagine a city driver needing replacements every 20,000 miles, while a highway driver might comfortably reach 50,000 miles or more. This variation underscores how your daily commute directly influences component life.

Vehicle weight and the terrain you navigate also play crucial, often hidden, roles. Heavier vehicles require substantially more braking force to slow down, placing increased stress on the pads. Similarly, constantly driving in mountainous or hilly areas demands more frequent and forceful braking than flat roads, leading to accelerated wear. It’s akin to carrying a heavy load; the effort required to stop is amplified, directly impacting your brake pads.

Finally, the quality and material composition of your brake pads—be they ceramic, semi-metallic, or organic—significantly affect their lifespan and performance characteristics. Premium ceramic pads tend to last longer, produce less dust, and offer quieter, smoother braking. Economy pads, typically semi-metallic or organic, often wear faster and may generate more noise and dust. While premium options might have a higher upfront cost, their extended longevity and superior performance can make them a smarter, more cost-effective investment in the long run.

Read more about: Is a 2025 Certified Pre-Owned EV Your Smartest Move? A Comprehensive Kelley Blue Book Guide

12. **Proactive Maintenance: Extending Pad Life Through Smart Driving & Regular Checks**Extending the lifespan of your brake pads isn’t just about timely replacement; it’s fundamentally about how you drive and how diligently you monitor your vehicle. Implementing smart driving techniques can dramatically increase the life of your brake pads, potentially saving you a substantial amount on replacements and enhancing your overall safety. This proactive approach centers on minimizing unnecessary friction and heat generation.

Mastering the art of gentle deceleration is critical. Maintaining a safe following distance is paramount, providing you with ample reaction time to allow for smooth, gradual braking instead of abrupt, panic stops. This gentle approach minimizes the intense friction and heat that are primary contributors to brake pad wear. The ‘three-second rule’ serves as an excellent guideline: pick a stationary object, and when the car in front passes it, begin counting. You should reach the same object no less than three seconds later, creating a vital buffer for safer and gentler stops.

Anticipating traffic flow and utilizing engine braking are equally powerful techniques. By looking ahead and recognizing impending slowdowns, you can often simply coast and gradually reduce speed, effectively minimizing the need for hard braking. This proactive mindset not only reduces wear and tear on your brake pads but also contributes to improved fuel efficiency. For long downhill stretches, engine braking—downshifting to a lower gear—leverages the engine’s resistance to slow the vehicle, significantly reducing reliance on your friction brakes and preventing overheating.

Beyond driving habits, often-overlooked factors like vehicle loading and proper tire maintenance play a vital role. Consistently carrying heavy loads demands more braking force, accelerating pad wear. Regularly checking your tire pressure is also essential; underinflated tires increase rolling resistance, which can indirectly necessitate more braking effort. Avoiding common mistakes like ‘riding the brakes’ (even lightly resting your foot on the pedal) or unnecessary constant braking prevents continuous friction and heat buildup, which are silent brake pad killers.

13. **The Importance of Professional Inspection & Avoiding Misconceptions**While empowering yourself with DIY inspection knowledge is valuable, recognizing the limitations of a self-check and understanding the indispensable role of professional inspections is crucial for holistic brake maintenance. A common misconception is that delaying brake pad replacement saves money; in reality, this often triggers a cascade of far more expensive problems.

Ignoring worn brake pads can quickly lead to severe damage to your rotors, which, unlike pads, are significantly more costly to resurface or replace. Furthermore, prolonged neglect can strain your brake calipers, potentially causing them to seize or fail entirely—an even more expensive repair than rotors. This illustrates a vital principle: a minor repair, if ignored, can rapidly escalate into a major financial burden, highlighting why addressing issues early is always the most cost-effective solution in the long run.

A professional mechanic offers expertise and specialized tools that go beyond what most DIYers can achieve. During a comprehensive inspection, they will remove the wheels for a thorough visual check of all brake components, precisely measure pad thickness, examine rotors for warping or scoring, and inspect calipers, lines, and hoses for any signs of wear or damage. This detailed, hands-on assessment provides a complete understanding of your entire brake system’s health, catching potential problems that a simple visual glance through wheel spokes might miss.

Read more about: Your Definitive 2025 Guide: What to Check When Buying a Used Electric Vehicle

Ultimately, making informed decisions about brake pad replacement requires balancing your comfort level with DIY tasks against the benefits of professional scrutiny. While an initial DIY check can be a great first step, periodic professional inspections are non-negotiable, especially if you observe any persistent warning signs. This balanced approach ensures optimal brake performance, safeguards your vehicle’s longevity, and, most importantly, protects the safety of you and your passengers on every journey. Never underestimate the peace of mind that comes from knowing your vehicle’s most critical safety system is in peak condition.