Imagine a time when building a single car took days, even weeks, of meticulous craftsmanship. Each part was individually made, and skilled workers assembled vehicles by hand—an expensive and painstakingly slow process that kept cars out of reach for the average person. This wasn’t just an inefficiency; it was the prevailing manufacturing ‘design’ of an entire era, a system fundamentally different from the rapid, synchronized processes we observe today.

Then came a monumental shift, spearheaded by visionaries who dared to challenge the status quo: why not move the product, not the worker? This radical idea, though rooted in much earlier concepts, culminated in a transformative innovation that redefined manufacturing forever. It sparked a continuous evolution, effectively causing old methods to ‘vanish’ in favor of new, more efficient ‘tooling’ and processes.

This article delves into the fascinating history and mechanical intricacies of how cars are built, piece by piece, into the marvels of engineering we see on the roads. We’ll unravel the mystery of how automotive production evolved from slow, individualized craft to the highly automated and precise assembly lines of today, tracing key American innovations and their profound impact on industry and society. Join us as we explore the foundational ‘designs’ that shaped—and continue to shape—the way vehicles come to life.

1. **Craft Production: The Vanished Era of Automotive Artistry**Before the dawn of the assembly line, the world of manufacturing was a landscape dominated by craft production. This was a system where most products were crafted individually by hand, a stark contrast to the mass-produced goods of today. A single artisan or a dedicated team would meticulously create each part of a product, relying on their individual skills and a basic set of tools like files and knives. These handmade parts would then be painstakingly assembled into the final product, often requiring adjustments until they fit together seamlessly.

This method, while allowing for bespoke quality and intricate detail, was inherently time-consuming and expensive. Craft production required years of training to become a skilled craftsperson, making the labor costly and the goods they produced prohibitively expensive for the average consumer. In the early 1900s, cars were the quintessential luxury items, symbols of status rather than practical transportation, precisely because of this manual, artisan-driven production model.

The limitations of craft production included manual labor dominance, where workers handled every aspect of production and often moved between different tools and stations. There was a distinct lack of standardization, meaning parts were made individually and components frequently needed adjustments to fit together. These inefficiencies led to limited output, where producing just one car could take weeks, driving up costs and severely restricting access for consumers. This era represents a significant ‘vanished design’ in manufacturing, replaced by the relentless pursuit of speed and efficiency.

Read more about: Dwayne ‘The Rock’ Johnson’s Iron Yard: Unveiling 13 Monster Machines Owned by the Action Titan

2. **Early Assembly Precursors: Venice and Portsmouth’s Unsung Innovations**While many immediately associate car production and assembly lines with Henry Ford, the reality of its origins is far more intricate and predates the automotive industry by centuries. The fundamental principles of assembly-line production, though not fully realized in a modern sense, trace back to remarkable historical examples of industrial ingenuity. These early precursors represent the conceptual ‘designs’ that laid the groundwork for future manufacturing revolutions.

One of the most notable examples is the Venetian Arsenal, an industrial complex that began around 1104 and became the largest in Europe before the Industrial Revolution. The Venetian Arsenal famously utilized standardized parts for shipbuilding, strikingly resembling an assembly line. Ships were moved down a canal, systematically being fitted with standardized components as they passed various stations. At its peak, this impressive operation employed approximately 16,000 people and could produce nearly one ship per day using these assembly-line principles.

Similarly, the Portsmouth Block Mills, dating to the early 19th century, are also considered one of the first instances of a continuous assembly process. While these early implementations showcased the potential for efficiency through standardized parts and sequential work, production line methods did not become widespread until the advent of the early Industrial Revolution. These historical “designs” highlight that the core idea of breaking down work and moving products sequentially for efficiency has a much longer lineage than commonly perceived.

3. **Henry Ford’s Moving Assembly Line: The Automotive Revolution Catalyst**The true revolution in assembly line technology, and arguably the most impactful American innovation in manufacturing, came with Henry Ford. While not patenting the assembly line itself, Ford undeniably perfected and implemented it in a way that transformed industry globally. On December 1, 1913, at his Highland Park plant, Henry Ford implemented the first moving assembly line for the mass production of the Model T, marking a definitive shift in production efficiency.

This innovation was nothing short of groundbreaking. Before Ford’s moving line, building a single car was a laborious, time-consuming process that often took over 12 hours. With the implementation of the moving assembly line, this time plummeted dramatically to just one hour and 33 minutes for the Model T, and later reduced to 90 minutes. This incredible leap in efficiency was achieved by eliminating unnecessary movement; instead of workers moving to the vehicle, the vehicle was brought to the workers, with each worker performing a specific task in a sequential order.

The assembly line stands out as one of the most significant inventions of the 20th century, often cited as one of the earliest disruptive practices. Its impact was so profound that manufacturers who failed to embrace it faced closure. More than just a method to accelerate manufacturing, the assembly line represented a powerful idea—a systematic approach aimed at enhancing efficiency and productivity that every industry swiftly adopted and adapted. The mass production facilitated by Ford’s assembly lines played a crucial role in creating the middle class, making cars more affordable and accessible to the average person, thereby democratizing the automobile and fueling unprecedented economic growth.

Car Model Information: 2023 Alfa Romeo Stelvio Ti

Caption: 1925 Ford Model T Touring Car

Manufacturer: Ford Motor Company

Production: October 1908 – May 1927

Assembly: collapsible list

Designer: Childe Harold Wills

Class: Economy car

BodyStyle: collapsible list

Layout: FMR layout

Engine: straight-4

Transmission: planetary gear

Wheelbase: 100.0 in

Abbr: on (1912 roadster)

Length: 134 in

Width: 1676 mm

Height: 1860 mm

Weight: convert

Predecessor: Ford Model N

Successor: Ford Model A (1927–1931)

Categories: 1900s cars, 1908 establishments in the United States, 1910s cars, 1920s cars, All articles needing additional references

Summary: The Ford Model T is an automobile that was produced by the Ford Motor Company from October 1, 1908, to May 26, 1927. It is generally regarded as the first mass-affordable automobile, which made car travel available to middle-class Americans. The relatively low price was partly the result of Ford’s efficient fabrication, including assembly line production instead of individual handcrafting. The savings from mass production allowed the price to decline from $780 in 1910 (equivalent to $26,322 in 2024) to $290 in 1924 ($5,321 in 2024 dollars). It was mainly designed by three engineers, Joseph A. Galamb (the main engineer), Eugene Farkas, and Childe Harold Wills. The Model T was colloquially known as the “Tin Lizzie”.

The Ford Model T was named the most influential car of the 20th century in the 1999 Car of the Century competition, ahead of the BMC Mini, Citroën DS, and Volkswagen Beetle. Ford’s Model T was successful not only because it provided inexpensive transportation on a massive scale, but also because the car signified innovation for the rising middle class and became a powerful symbol of the United States’ age of modernization. With over 15 million sold, it was the most sold car in history before being surpassed by the Volkswagen Beetle in 1972.

Get more information about: Ford Model T

Buying a high-performing used car >>>

Brand: Ford Model: Model T

Price: $31,450 Mileage: 29,946 mi.

4. **The Division of Labor: Specialization as the Engine of Efficiency**At the heart of any effective assembly line, both historically and in modern practice, lies the fundamental concept of the division of labor. This principle is a cornerstone of manufacturing, specifically designed to dramatically improve both efficiency and productivity. It involves taking complex production tasks and breaking them down into simpler, more manageable components, allowing individual workers to specialize in specific, often repetitive, operations rather than completing an entire product from start to finish.

This specialization enhances productivity by taking advantage of workers’ different skills, or by enabling workers to quickly master a singular task, leading to competitive advantages for companies. When every person is doing what they are best at, or becomes highly proficient at their assigned segment, productivity is maximized. By having workers specialize in specific operations, companies can achieve both efficiency—doing things right—and effectiveness—doing the right things—ultimately leading to increased output and success.

While early advocates of the division of labor recognized its immense benefits, such as increased efficiency and faster production, they also acknowledged potential drawbacks. These concerns included reduced worker satisfaction due to repetitive tasks and limited opportunities for advancement within a highly specialized role. Despite these acknowledged limitations, the division of labor, focusing on assigning workers to specific tasks rather than based solely on their broad skill or ability, quickly became a standard practice across a vast array of industries, from shipbuilding and general manufacturing to, most notably, car production.

5. **The 4 M’s in Manufacturing: Orchestrating the Production Symphony**The successful operation of an assembly line, whether rudimentary or highly advanced, hinges on the precise orchestration of four critical elements, often referred to as the ‘4 M’s’ in manufacturing. These are Man, Machine, Material, and Method. This concept forms the organizational ‘design’ for achieving optimal efficiency and productivity within any production system, particularly in the complex environment of car manufacturing. The assembly line is ingeniously designed to assemble components in a specific sequence, allowing for the efficient organization of these four interconnected elements.

The first ‘M,’ **Man**, refers to the human workforce. In an assembly line, workers are strategically placed at various workstations, each performing a specialized task. This leverages the division of labor, ensuring that human effort is directed with maximum impact. The second ‘M,’ **Machine**, encompasses the tools, equipment, and automation involved. From early cutting machines to modern robots, machinery amplifies human capability, performing tasks with greater speed, precision, and consistency.

**Material**, the third ‘M,’ signifies the raw components and parts. Maintaining an efficient supply chain to ensure a reliable and uninterrupted flow of these materials to the right stations at the right time is crucial. Finally, **Method**, the fourth ‘M,’ is the sequence and procedure of operations itself. It’s the carefully planned workflow that dictates how man, machine, and material interact to create the final product. The principle is to place the man, tool (machine), and material in the sequence of the operation (method), thereby optimizing the entire workflow. This comprehensive approach was first applied in the groundbreaking production of the Model T, fundamentally revolutionizing the automotive industry and establishing a framework for modern manufacturing.

6. **Stationary Build vs. Stationary Station: The Pivotal Shift in Workflow Design**In the evolutionary journey of automotive assembly, one of the most significant shifts in workflow design involved the transition from a ‘stationary build’ approach to the ‘stationary station’ method. This comparison highlights a crucial development in production efficiency, marking another instance where an older ‘design’ essentially ‘vanished’ in favor of a superior one. Understanding this distinction is key to grasping the core mechanics of modern assembly lines.

Under the traditional ‘stationary build’ approach, the vehicle itself remained stationary. An operator, or a dedicated team, would come to the vehicle, working on it until its completion. While this allowed for focused, comprehensive work on a single unit, it suffered from significant inefficiencies. As the context explains, this method often led to duplication of efforts and wasted time, with operators moving from car to car. It was a laborious process, taking approximately 12 ½ hours to assemble each car, reflecting a less optimized use of labor and time.

Contrastingly, the ‘stationary station’ assembly method revolutionized this by doing precisely the opposite: it involves moving the car past the workers. This is achieved by adding a single line of track, often a moving line or conveyor, that pushes the vehicle along. Workers, or ‘stations,’ remain in fixed positions, each performing a specific, specialized task as the vehicle moves past them. This fundamental change results in a dramatically faster assembly process, as the car moves efficiently along the line. The increased production speed and efficiency inherent in the stationary station method directly lead to a reduction in the price of the car, making it more affordable for consumers. Today, the vast majority of automotive companies universally employ the stationary station technique in their car assembly processes, solidifying its place as the dominant and most effective workflow design.” , “_words_section1”: “1947

Having journeyed through the foundational shifts and historical milestones that brought us the assembly line, we now turn our attention to the sophisticated systems and advanced methodologies that define contemporary car manufacturing. The evolution didn’t stop with Ford; it continually adapted, integrating new technologies and philosophies to push the boundaries of efficiency, precision, and quality. Here, we unravel the intricate ‘tooling’ that keeps modern automotive production at the cutting edge, revealing the complex interplay of design, automation, workflow, and rigorous quality assurance.

7. **Lean Manufacturing: Toyota’s Legacy of Waste Reduction**Building upon the revolutionary principles laid down by the early assembly lines, the automotive industry witnessed another significant evolution with the advent of lean manufacturing. This strategy, developed by the minds behind Toyota’s Production System—Sakichi Toyoda, Kiichiro Toyoda, Eiji Toyoda, and Taiichi Ohno—represented a refined approach to efficiency, explicitly aimed at reducing waste within manufacturing systems while simultaneously boosting productivity. It’s a testament to continuous improvement, a core ‘design’ philosophy that still drives automotive excellence today.

At its heart, lean manufacturing defines “waste” as anything a customer doesn’t perceive as adding value and, crucially, wouldn’t pay for. This encompasses a broad spectrum of inefficiencies, from unnecessary motion and overproduction to defects and waiting times. By systematically identifying and eliminating these non-value-adding activities, companies can streamline their operations, ensuring that every step contributes directly to the final product’s quality and the customer’s satisfaction.

The impact of lean manufacturing has been profound, extending far beyond the automotive plant floor. Its principles—focused on optimizing resources, minimizing errors, and maximizing output through a relentless pursuit of efficiency—have become aspirational qualities for virtually every business today. From software development to healthcare, organizations globally seek to adopt lean methodologies, proving that Toyota’s innovative ‘tooling’ for production optimization has an enduring, universal appeal.

To truly grasp the depth and significance of this manufacturing paradigm, a recommended deep dive into “The Machine That Changed the World: Based on the Massachusetts Institute of Technology 5-Million-Dollar 5-Year Study on the Future of the Automobile” offers unparalleled insights. It illuminates how lean principles not only transformed car production but also fundamentally altered the competitive landscape of global industry, cementing its place as an indispensable modern manufacturing ‘design’.

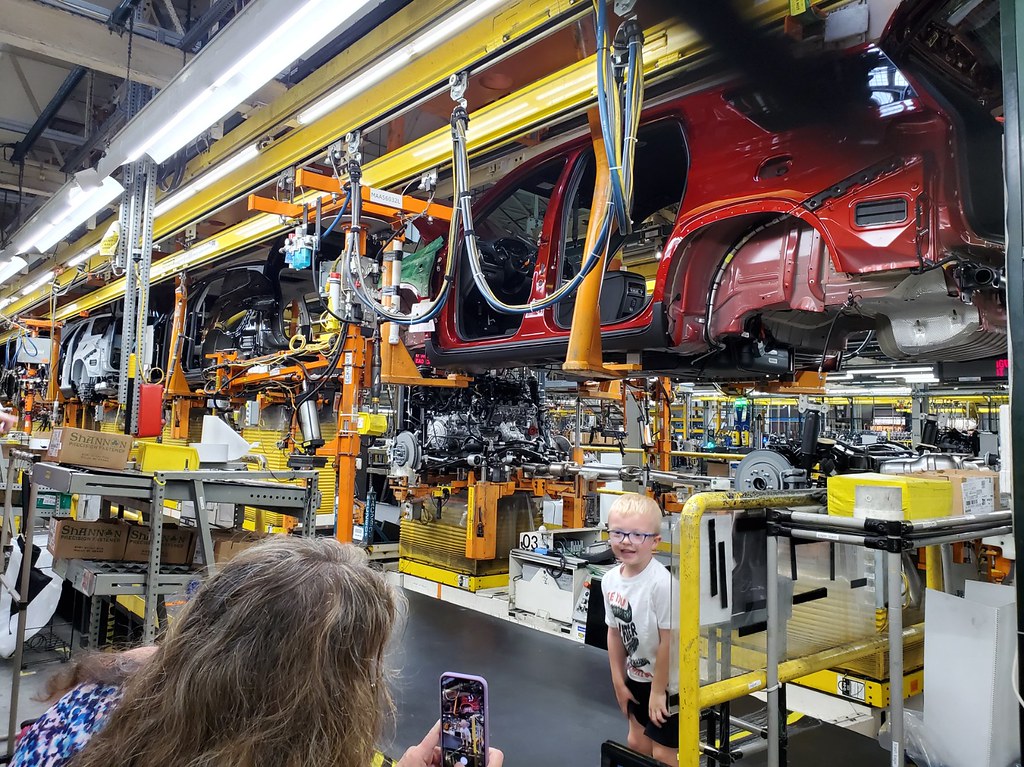

8. **Automotive Plant Workflow: The Symphony of Major Departments**The transformation of raw materials into a finished automobile is a meticulously choreographed dance, executed across several specialized departments within an automotive production plant. Each department plays a distinct, critical role in the overall workflow, representing a highly organized ‘design’ for sequential manufacturing. This intricate coordination ensures that parts are fabricated, assembled, and finished with precision, propelling the vehicle through its journey down the line.

The process typically begins in the Stamping department, where colossal presses transform flat sheets of metal into the intricate shapes of the car’s body-in-white components. These stamped parts then move to the Body Shop, a hive of activity where robots and human workers collaboratively weld, solder, screw, and glue these elements into the basic skeletal structure of the vehicle. It’s here that the car truly begins to take its form, creating the robust shell that will house all subsequent systems.

Following the body’s completion, the vehicle progresses to Trim, often referred to as general assembly. This stage focuses on the interior, where components such as seats, dashboards, and complex electronic systems are carefully installed. Simultaneously, the Chassis & Final assembly department is responsible for integrating the vehicle’s core mechanical systems, adding the engine, transmission, axles, and wheels—finally enabling the car to support its own weight and become a mobile unit.

Beyond these primary stages, other critical departments contribute to the vehicle’s perfection. The Foundry Department meticulously casts metal parts like engine blocks and cylinder heads. After the structural and interior elements are in place, the Painting department applies the vehicle’s final protective and aesthetic finish. Lastly, the Engine build shop meticulously assembles the engine components, preparing them for seamless installation into the vehicle. This multi-departmental approach, with each ‘tooling’ its specific process, is a testament to the scale and precision of modern car manufacturing.

The seamless synchronization and coordination between all these departments are absolutely essential to maintain a smooth workflow and ensure the timely completion of each vehicle. Any disruption in one area can cascade through the entire production line, highlighting the immense importance of this integrated and highly specialized operational ‘design’.

9. **Car Design and Prototyping: The Blueprint for Innovation**In the fiercely competitive automotive market, success hinges on a manufacturer’s ability to innovate and consistently introduce new, appealing design features. This drive for distinctiveness necessitates a crucial preliminary stage: car design and prototyping, which serves as the foundational ‘tooling’ for validating new concepts before committing to full-scale production. It’s where ideas take tangible form and are rigorously tested under real-world conditions.

Prototyping involves the creation of a ‘primitive form’ or an original iteration of a product, part, or even a specialized tool. In the automotive industry, these prototypes are not merely models; they are carefully constructed physical representations used to validate the design, evaluate innovations, and confirm the functionality of new car parts. This meticulous process helps to mitigate risks and ensures that the final product will meet stringent performance and aesthetic standards.

Various types of prototypes serve specific purposes in this validation stage. Visual prototypes focus on representing the product’s appearance, while proof-of-principle prototypes confirm a concept’s feasibility. Working prototypes capture both function and appearance, and user experience prototypes assess how drivers and passengers interact with the vehicle. Each type is a vital component of the design validation stage, where tangible vehicle models are crafted as foundational blueprints for refinement.

Manufacturers leverage diverse tools and techniques to bring these designs to life. Computer Numerical Control (CNC) machining is widely adopted for creating high-precision components, offering accuracy and repeatability. For rapid model creation, 3D printing has become indispensable, while vacuum casting allows for detailed replicas. Even simpler techniques like plastic injection molding are employed for basic physical objects, fostering collaboration during the design process. This comprehensive prototyping ‘design’ is critical for proactively identifying and addressing design discrepancies, ensuring peak efficiency, and safeguarding valuable resources before mass production begins.

10. **The Modern Assembly Line: Robots and Humans in Harmony**Today’s car assembly lines represent the pinnacle of manufacturing evolution, a sophisticated blend of automation and human expertise, all driven by the foundational principles of acceleration, efficiency, and increased output. These modern marvels are a far cry from Ford’s initial 150-foot line; they can stretch more than 8 miles in length, showcasing the immense scale and complexity involved in producing contemporary vehicles. While the average car assembly takes about 17 to 18 hours, specialized vehicles like Ferraris can still command up to three months due to meticulous handcrafting.

At the forefront of this advanced ‘tooling’ are robots, integral to the manufacturing process due to their unparalleled precision and speed, which drastically reduce the risk of human error. Robots are adept at a myriad of tasks, from creating and stamping sheet metal parts like side frames, doors, hoods, and roofs, to performing intricate operations like welding, soldering, screwing, and gluing parts onto the vehicle. Their unwavering consistency is vital in maintaining the tight tolerances required in modern car construction.

However, the human element remains irreplaceable. While robots handle the heavy, repetitive, and precise tasks, human workers excel at fitment, delicate electrical installations, and other precision work that requires fine motor skills and adaptive judgment. This collaborative model, where human workers sometimes partner with robotic work cells for specific tasks, optimizes the assembly process, leveraging the strengths of both.

The assembly sequence itself is a carefully choreographed ballet of components. After the body-in-white is painted, the car is placed onto a moving production line. Doors are often removed to create space, allowing window glass and other parts to be installed on them separately. Electrical wiring and the ceiling liner are meticulously integrated, followed by the engine, brakes, and other undercarriage components. Bumpers and tires are attached, then the windshield, rear glass, and seats. Finally, the doors are reattached. For Battery-powered Electric Vehicles (BEVs), a battery pack is installed, while Fuel-cell Electric Vehicles (FCEVs) receive hydrogen tanks and fuel cells.

Crucial to this entire intricate process is an exceptionally efficient supply chain. Automotive manufacturers frequently purchase specialized parts from external vendors, rather than producing everything in-house. These incoming components undergo rigorous quality checks to ensure they meet specified dimensions, designs, and tolerance limits. This meticulous approach to managing materials and components is a key part of the modern ‘tooling’ that saves time and streamlines the entire production flow.

11. **Rigorous Quality Assurance: Testing and Inspection Protocols**The journey of a car from raw material to finished product is punctuated by a series of rigorous quality assurance stages, forming an indispensable ‘design’ to prevent defects and ensure peak performance. These testing and inspection protocols are not merely checks; they are critical interventions designed to identify and resolve issues promptly, safeguarding the manufacturer’s reputation and the consumer’s safety.

Early in the manufacturing process, in-line inspections are crucial. Quality engineers employ visual inspections, for instance, to detect subtle paint imperfections, anomalies, or deviations from design specifications. Catching issues at these initial stages is paramount, as it significantly reduces the likelihood of costly reworks and potentially expensive recalls down the line, exemplifying proactive problem-solving.

As a vehicle nears completion, end-of-line inspections serve as the ultimate checkpoint before it enters the market. This meticulous process ensures that every single vehicle adheres to stringent quality standards and predefined criteria. Manufacturers now deploy advanced technologies, such as Real-Time Location Systems (RTLS), which provide continuous tracking and monitoring of vehicles. This enables swift identification of affected units should a defect be discovered, demonstrating a sophisticated ‘tooling’ for oversight.

Further enhancing these efforts are automated inspection systems, augmented with artificial intelligence (AI) and machine vision. These cutting-edge systems surpass the limitations of traditional manual methods, offering unparalleled speed, precision, and efficiency in identifying even the smallest flaws. They not only improve the accuracy of inspections but also enhance the overall employee experience by offloading repetitive visual tasks. Only after passing a final release testing, including an Outgoing QA check where all assembly and test plan processes are confirmed, is a vehicle truly deemed ready for packaging and shipping, solidifying its quality ‘design’.

12. **From Factory to Driveway: The Delivery and Dealership Network**The final, often overlooked, chapter in a car’s journey from assembly line to owner is its intricate delivery and dealership process. Once a vehicle has been meticulously manufactured and rigorously tested, it embarks on a complex logistical voyage, a critical ‘tooling’ that ensures it reaches its ultimate destination: the customer. This stage involves numerous steps and specialized logistics, carefully orchestrating the movement of vehicles across vast distances.

The process begins with meticulous preparation and documentation, ensuring every detail is accounted for before shipment. Depending on the distance and destination, the car will then be transported via rail, truck, or even by ship. For vehicles manufactured outside of North America, the majestic sight of ocean liners carrying up to 8,500 vehicles at once is common, transporting them to US ports on either coast.

Upon arrival at a US port, these vehicles are efficiently unloaded and placed in secure storage lots, awaiting pickup by specialized car haulers. These large trailers or semi-trailers, capable of transporting up to nine cars simultaneously, are the workhorses of short-to-medium distance ground transport, delivering vehicles directly to dealerships. For dealerships located a significant distance from the plant or port, cars are often delivered to an auto ramp for long-distance hauls via rail, showcasing a robust and adaptive distribution ‘design’.

Once at the dealership, each vehicle undergoes verification and a thorough condition inspection to confirm its pristine state. Dealerships often sanitize vehicles upon receipt and again before customer delivery, a commitment to cleanliness and customer satisfaction. The car is then proudly displayed on the sales floor or lot, frequently featured on the dealer’s website to attract buyers. Modern advancements also offer touchless interactions, from live video calls to electronic signatures, and the convenience of direct home delivery, reflecting an evolving ‘tooling’ for consumer engagement.

Read more about: Drive with Peace of Mind: The Top 12 Car Brands Offering the Best Long-Term Warranties for Over 7 Years

The journey of an automobile, from initial design concepts to the moment it leaves the dealership lot, is a magnificent testament to human ingenuity and technological progress. What began as individual craftsmanship, slowly and painstakingly creating vehicles for the elite, has transformed into a highly synchronized, lean, and automated process, democratizing personal mobility on an unprecedented scale. The vanishing ‘designs’ of old have paved the way for advanced ‘tooling’ that continues to evolve, promising even faster, more precise, and sustainable assembly methods that will undoubtedly shape the future of travel. The mystery isn’t just solved; it’s a living, breathing evolution of mechanical and logistical mastery.