Ever found yourself paused, mid-sentence, wondering whether to use “worse” or “worst”? You’re definitely not alone! These two little words, so similar in sound and spelling, carry vastly different weights when describing something truly… bad. Understanding their nuances isn’t just for grammar quizzes; it’s about precisely articulating degrees of negativity, especially in critical situations like product safety.

“Worse” is the comparative form of “bad,” meaning “more bad.” Use it when comparing two things: “Your breath is bad, but mine is worse.” It shows deterioration against one other thing. “Worst” is the superlative form, meaning “most bad.” This word comes out when comparing more than two things, or when something has hit rock bottom—the absolute lowest point. Think “Yours is bad, mine is worse, but his is the worst,” or “That was the worst meal I’ve ever eaten.” It signifies the most extreme degree of unfavorability.

In consumer products, especially automobiles, “worst” takes on a profound meaning. Recalls represent a manufacturer’s acknowledgment of something gone wrong, moving from ‘bad’ to ‘worse,’ or plunging into the ‘worst’ category. These aren’t minor inconveniences; they signal fundamental flaws in design, manufacturing, or ethical judgment. Today, we delve into significant automotive recalls, using our grammar clarity to spotlight what made these situations truly “the worst.” From mechanical defects to ethical oversights, each case serves as a powerful reminder of manufacturing challenges and the critical importance of stringent safety measures and unwavering accountability. Let’s break down these indelible incidents.

1. **Volkswagen’s Windshield Wiper Recall (1972)**Our journey into product recalls begins with an unexpected culprit for an automotive giant: Volkswagen’s iconic Beetle. In 1972, this beloved model faced a significant setback. The National Highway Traffic Safety Administration (NHTSA) received complaints about loose windshield wipers on Beetles manufactured between 1949 and 1969. This issue, though seemingly simple, profoundly impacted driver safety.

Loose wipers created a particularly “worse” driving condition in adverse weather. Impaired visibility turned a rain shower into a dangerously compromised scenario on the road. For a brand globally recognized for reliability, this widespread defect posed a considerable challenge. It demonstrated how even a small component can lead to significant safety concerns and public outcry.

Volkswagen did issue a recall, offering to replace defective parts at a nominal cost. However, the situation quickly went “from bad to worse” for many customers. They found themselves shouldering additional expenses for further repairs, beyond just the wiper mechanism. This revealed a critical need for manufacturers to ensure comprehensive customer satisfaction in the recall process, not just a basic fix.

Ultimately, the 1972 wiper recall highlighted an enduring lesson: no component, even in high-selling models like the Beetle, is too minor for stringent quality control. It showed how a mundane part, when defective, could escalate a driving experience from inconvenient to outright dangerous. This contributed to a “worst-case scenario” for driver visibility and trust, setting an early precedent for robust post-sale accountability.

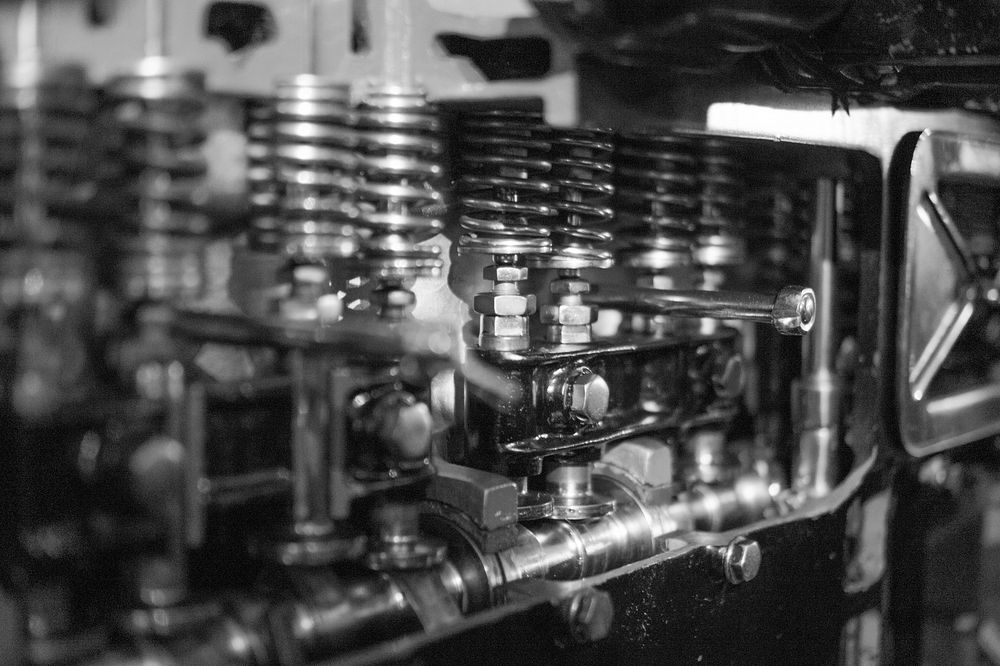

2. **General Motors’ Engine Mount Failure (1971)**General Motors faced a major recall in 1971 concerning defective engine mounts. This issue impacted an astonishing 6.68 million vehicles, creating safety hazards that could easily spiral into a “worst-case scenario” on the road. The sheer scale of potential danger elevated this beyond a simple defect into a full-blown crisis for the automotive giant.

The faulty engine mounts, designed to secure the engine, could fail, causing the engine to shift. This often led to unintended acceleration and severely compromised braking capabilities. By 1971, this critical defect was linked to 63 accidents and 18 injuries. This painted a stark picture of immediate danger, showing how mechanical failure could make a driving situation go “from bad to worse” rapidly.

Despite escalating incidents, GM initially resisted a full recall. This signaled tension between corporate cost-saving measures and imperative consumer safety. This corporate posture, driven by economic concerns, exacerbated an already “bad” situation, further tarnishing GM’s once-stellar reputation. Public and regulatory bodies viewed this reluctance as corporate interests overriding public welfare.

GM eventually acted, implementing a cost-effective solution with a cable system to stabilize the engine. However, this intervention could not entirely undo the damage to public perception. The incident served as a powerful lesson, demonstrating how critical it is for manufacturers to proactively prioritize safety. Otherwise, their brand’s standing risks plummeting to its “worst” possible state in the eyes of a concerned public, a reminder of delayed safety actions’ long-term repercussions.

Read more about: Buyer Beware: 9 Popular Used Cars That Become Money Pits Well Before 50,000 Miles

3. **The Ford Pinto Tragedy (1978)**Few automotive recalls reached the level of ethical scrutiny and public condemnation as the Ford Pinto recall in 1978. This incident became infamous specifically “for its ethical implications.” This distinction sets it apart, elevating it to a truly “worst” example not just of product failure, but of profound corporate responsibility failings.

“Ethical implications” in product safety involve difficult decisions, often balancing profitability against the highest possible safety standards. For the Pinto, this tension was starkly revealed, echoing the “tension between corporate cost-saving measures and consumer safety” seen in other cases. It suggested early design choices could have severe, morally challenging repercussions years later.

An infamous recall rooted in ethical considerations represents a “worst-case scenario” for a brand’s trust and public image. It implied that financial considerations might have outweighed human lives or safety, leading to a profound breach of trust. Such a situation is inherently “worse” than a purely accidental manufacturing defect. It points to systemic or intentional oversight with dire consequences for consumers.

The notoriety of the Ford Pinto recall underscores that accountability extends beyond fixing mechanical issues. It encompasses the moral compass guiding a company’s actions. It became a benchmark for how a product issue could transcend technical failure to become a searing indictment of corporate ethics. This firmly cemented its place as one of the “worst” episodes in automotive history in terms of moral impact.

4. **GM Ignition Switch Recall (2006–2014)**The GM Ignition Switch Recall stands as a formidable entry into major automotive safety crises. This issue spanned an alarmingly long period from 2006 to 2014. The sheer duration of this recall, indicating a deeply entrenched or complex problem, immediately marks it as a “worst” kind of scenario in terms of both manufacturing flaw and resolution challenges. It signaled years of potential risk for millions of drivers.

An ignition switch is a cornerstone component, responsible for starting the engine and powering vital electrical systems, including safety features like airbags. A malfunction in such a fundamental part can cause a swift descent from normalcy to a genuinely “worse” or even “worst-case” driving situation. The possibility of an engine shutting off unexpectedly in motion presents an extreme hazard, disabling power steering, power brakes, and potentially airbags during a collision.

The extended timeline of the recall, covering nearly a decade, further amplifies its severity and impact on public trust. Such a prolonged period before a comprehensive fix or full acknowledgment implies either a complex engineering challenge or a delayed response. This allowed the problem to go “from bad to worse” for an unacceptable length of time. This extended consumer exposure to risk unequivocally places it among the “worst” industry failings.

The GM Ignition Switch Recall became a stark illustration of consequences when critical components fail massively over many years. It emphasized the imperative for diligent internal safety assessments, rapid response to reported issues, and robust accountability. This incident, impacting numerous vehicles for a significant duration, stands as a definitive example of a “worst” scenario that profoundly shook public confidence in a major automotive manufacturer.

5. **Toyota’s Faulty Window Switches (2015)**Our final stop in this section of notable automotive recalls brings us to Toyota’s Faulty Window Switches, an issue highlighted in 2015. While perhaps not as immediately life-threatening as engine failures, this recall illustrates how even seemingly minor component flaws can create a significant “worst” situation for consumers. It undeniably impacts a manufacturer’s commitment to overall product quality.

A window switch, often taken for granted, is integral to a vehicle’s functionality and user experience. When these switches become faulty, they lead to frustration and inconvenience, making a simple act like opening a window a “worse” daily chore. More critically, in specific emergencies—such as escaping a submerged vehicle or venting smoke—a non-functional switch could inadvertently contribute to a hazardous, even “worst-case,” outcome for occupants.

For a brand like Toyota, globally renowned for meticulous engineering and reliability, a widespread recall over faulty window switches delivered a “worst” blow to its image of perfection. It signaled that even the smallest parts, if not manufactured to the highest standards, could trigger a massive logistical challenge and undermine consumer confidence. This incident reminded everyone that quality control must extend to every single component.

This 2015 recall served as an important reminder that “worst” in product safety isn’t always about catastrophic, immediate danger. Sometimes, it pertains to a pervasive lapse in quality affecting basic functions. This creates a broadly “worse” user experience and necessitates a costly, large-scale fix. It demonstrated that maintaining consumer trust requires consistent excellence across the board, down to every button and switch within the vehicle.

Alright, so we’ve navigated the tricky linguistic terrain of “worse” and “worst” and kicked off our tour of some seriously infamous automotive recalls. We’ve seen how everything from a loose windshield wiper to engine mount failures can turn a simple drive into a “worst-case scenario.” But buckle up, because our journey through manufacturing challenges and the pursuit of consumer trust isn’t over yet! We’re diving into the next five incidents that really hammered home what it means for things to go from bad to worse, or hit rock bottom.

These aren’t just technical glitches; they’re moments that reshaped industry practices and reminded us all that even the biggest brands can face their “worst” days. From global scandals that shook public confidence to critical safety failures that demanded widespread action, each story is a powerful lesson in what happens when things veer off course. Let’s keep exploring these unforgettable events, because when it comes to product safety, the lessons learned are truly priceless.

6. **Volkswagen’s “Dieselgate” Scandal (2016)**Remember how we talked about “worst” taking on a profound meaning in consumer products? Well, if ethical judgment is part of the equation, then Volkswagen’s “Dieselgate” scandal from 2016 certainly qualifies as an undeniable “worst-case scenario” for corporate integrity. This wasn’t just a defect; it was a bombshell that hit the automotive world, illustrating how profound ethical failings can dwarf mere mechanical issues.

When a company faces a scandal of this magnitude, the situation goes “from bad to worse” in a flash, not just for the affected vehicles but for the entire brand reputation. It suggests a systemic or intentional oversight that cuts deeper than an accidental flaw, causing public trust to plummet. It transforms a product problem into a searing indictment of a company’s moral compass, something inherently “worse” than a simple manufacturing misstep.

The fallout from such a widely publicized event resonates deeply with consumers, who expect transparency and honesty from the brands they support. For Volkswagen, a company long associated with reliable engineering, this incident pushed its public image into the “worst” possible state regarding trust and credibility. It served as a stark, global reminder that accountability extends far beyond just fixing what’s broken—it’s about the very principles guiding a company’s actions.

7. **Toyota’s Unintended Acceleration Recalls (2009–2010)**Now, picture this: you’re driving, everything’s normal, and suddenly your car decides to accelerate on its own. Talk about a “worst nightmare” scenario, right? Toyota faced exactly this terrifying issue with its unintended acceleration recalls between 2009 and 2010. This wasn’t a minor hiccup; it was a fundamental safety concern that elevated driving from routine to genuinely dangerous for countless owners.

When a problem impacts the very control you have over your vehicle, the situation can rapidly go “from bad to worse,” creating immediate and profound hazards on the road. The sheer scale of these recalls, affecting millions of vehicles globally, meant widespread fear and uncertainty among drivers. It highlighted how critical it is for manufacturers to address such life-threatening defects with utmost urgency to prevent even “worse” outcomes.

This series of incidents became a pivotal moment for Toyota, a brand usually synonymous with impeccable quality. It underscored the immense pressure on automakers to ensure that every system, especially one as crucial as acceleration, functions flawlessly. Ultimately, the unintended acceleration recalls demonstrated how swiftly consumer confidence can erode when core safety features are compromised, pushing a brand into one of its “worst” public relations challenges.

8. **Ford’s Ignition Switch Fires (1996)**Just when you thought an ignition switch couldn’t get any “worse” than the GM debacle, Ford entered the chat in 1996 with its own chilling problem: ignition switch fires. Yes, you read that right – fires! The possibility of your vehicle spontaneously combusting due to a faulty component is, without a doubt, a “worst-case scenario” that no driver ever wants to contemplate. This issue was not just inconvenient; it was terrifying and life-threatening.

An ignition switch, seemingly a small part, holds incredible power over a vehicle’s electrical system. When it malfunctions to the point of causing a fire, it takes a driving experience from merely “bad” to unfathomably “worse” in an instant, posing extreme risks to occupants. This highlighted a grave engineering oversight, reminding us that every single component, no matter how small, can have massive, catastrophic implications if it’s not up to snuff.

The lessons from Ford’s ignition switch fires were profound, forcing the industry to confront the imperative of rigorous quality control for *every* part, from bumper to bumper. It served as a grim reminder of the “worst” potential consequences when critical electrical components fail. The incident cemented its place in automotive history as a stark warning about the need for unyielding vigilance in vehicle safety.

9. **Ford Transmission Disaster (1980)**Speaking of monumental automotive headaches, let’s rewind to 1980 for the Ford Transmission Disaster. The very word “disaster” in the title tells you this wasn’t just a minor recall; it was a widespread, fundamental flaw that left a huge mark. When a vehicle’s transmission, a core component, goes rogue, it quickly escalates from a “bad” situation to a truly “worst” operational state, potentially leaving drivers stranded or in precarious situations.

This issue involved a design defect that allowed vehicles to slip from ‘Park’ into ‘Reverse’ if the driver wasn’t pressing the brake, or if the parking brake wasn’t fully engaged. Imagine the chaos, the danger! This kind of pervasive problem, affecting a fundamental aspect of vehicle operation, undoubtedly made the driving experience “worse” for legions of Ford owners, demanding a massive, costly, and complex recall effort.

The Ford Transmission Disaster underscored the intricate challenges manufacturers face in ensuring absolute reliability in complex mechanical systems. It became a significant lesson in product liability and consumer protection, demonstrating how crucial it is to meticulously design and test every core component. This incident remains a powerful example of how a widespread mechanical failure can plummet a brand’s standing to its “worst” in the public eye, impacting trust for years to come.

Read more about: 18 Notorious Car Flops That Defined the 1970s

10. **Takata Airbag Recall (Ongoing)**And finally, we arrive at what is arguably one of the most widespread and protracted automotive safety crises in history: the Takata Airbag Recall. The fact that this recall is “ongoing” tells you everything you need to know about its complexity, scale, and the sheer challenge it represents. It’s a textbook example of a “worst-case scenario” that just keeps on giving, affecting tens of millions of vehicles from nearly two dozen different automakers globally.

Airbags are supposed to be the ultimate safety net, deploying to protect occupants in a collision. But when these critical devices contain a defect that can cause them to explode violently, spraying shrapnel, they transform a life-saving feature into a potentially fatal hazard. This horrifying reality takes the concept of a product flaw “from bad to worse” in the most tragic way, leading to injuries and fatalities and turning an accident’s outcome into the absolute “worst.”

The sheer scope of the Takata recall, impacting so many manufacturers and stretching over so many years, highlights the immense global interdependence in the automotive supply chain. It’s a stark, enduring lesson in the absolute imperative for diligent, meticulous component testing and quality assurance at every level. This colossal, industry-wide crisis cemented its place as a definitive “worst” failure, profoundly shaking public confidence and forever changing how the world views occupant safety.

So there you have it: a deep dive into some of the most impactful (and frankly, “worst”) automotive recalls in history. From ethical scandals to fundamental safety flaws, each of these incidents serves as a powerful, often sobering, reminder of the constant vigilance required in manufacturing. They teach us that precise communication—whether through words like “worse” and “worst” or through rigorous safety standards—is absolutely essential. Because in the end, protecting consumers and maintaining trust is always the goal, ensuring that our journeys on the road are as safe as possible, and never, ever, a worst-case scenario. Now, if you’ll excuse us, we’re off to check our car’s recall status… just in case! You never know when you might dodge a bullet, or a faulty airbag, that is. Stay safe out there, folks!