Picture yourself driving along the highway, enjoying the open road, only for your car’s dashboard to light up like a neon sign. Is it just a small warning, or something more serious, signaling an impending breakdown? In today’s highly advanced vehicles, an intricate network of sensors works tirelessly behind the scenes, ensuring everything from engine performance to safety systems runs smoothly. These digital watchdogs are the eyes and ears of your car’s brain, the Engine Control Unit (ECU), collecting data and making real-time adjustments to optimize everything under the hood.

But here’s the kicker, folks: like any piece of sophisticated technology, these sensors can occasionally falter, and often, they do so far sooner than many owners anticipate. We’ve all heard the whispers in owner’s groups and forums about certain components giving up the ghost long before a car hits its stride, sometimes even before the odometer ticks past that crucial 50,000-mile mark. A failing sensor can transform a perfectly good drive into a frustrating diagnostic nightmare, leading to anything from poor acceleration and increased fuel consumption to a rough idle or even a complete no-start condition.

This isn’t just about inconvenient breakdowns; it’s about potentially saving yourself thousands in repairs by understanding the subtle cues your car is trying to send you. In this in-depth guide, inspired by the collective wisdom (and occasional gripes) of owner’s communities, we’re going to peel back the layers on 11 of the most common and problematic sensors that could leave your used car struggling. We’ll explore their vital roles, common symptoms of a faulty sensor, and even arm you with some DIY diagnostic and fix-it knowledge to troubleshoot issues before they spiral into expensive problems. Get ready to turn that owner’s group gossip into actionable insights!

1. **Coolant Temperature Sensor**Starting strong with a sensor that’s absolutely crucial for engine health, the coolant temperature sensor is the guardian of your engine’s thermal stability. It diligently measures the engine temperature, then relays this critical information directly to your engine control unit (ECU) and often, you’ll see a visual readout on a temperature gauge within your dashboard cluster. This isn’t just a fancy accessory; it’s fundamental to how your engine operates efficiently and safely.

Think of it this way: the ECU relies heavily on this temperature data to fine-tune the air-fuel ratio, especially as the engine transitions from a cold start to its optimal operating temperature. Without accurate readings, your engine could run too rich or too lean, impacting performance and fuel efficiency. More critically, if the sensor detects the engine temperature climbing to a dangerously high level, it can trigger a safety protocol, potentially shutting off the engine to prevent catastrophic damage to the engine or its intricate components. It’s an early warning system designed to save your bacon (and your engine).

When these sensors decide to throw in the towel, the symptoms can be quite varied and often misleading. A bad coolant temperature sensor may prevent your car from starting or idling smoothly, especially when the engine is cold, because the ECU isn’t getting the correct temperature data to adjust the fuel mixture. Alternatively, it could give a false reading to the gauges you see inside the car, leaving you blissfully unaware of an overheating situation or needlessly worried about a non-existent one. Diagnosing it is key to avoiding further issues.

These sensors typically operate within a very specific range of electrical resistance, which changes precisely with temperature. The ECU measures a change in voltage through the sensor, interpreting this as a temperature reading. To diagnose a potential failure, you can use a multimeter to measure both the voltage going in and out of the sensor, as well as its exact resistance. Comparing these readings against manufacturer specifications will quickly tell you if the sensor has gone rogue. If it needs replacing, most coolant temperature sensors are threaded directly into the intake manifold or a cylinder head, where their tip is submerged in the coolant itself. A crucial tip for replacement: always change the sensor when the engine is cold. This simple precaution prevents hot coolant from spraying under pressure, keeping both you and your engine bay safe from scalding fluids.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

2. **Coolant Level Sensor**Closely related to its temperature-monitoring cousin, the coolant level sensor plays an equally vital role in safeguarding your engine from thermal catastrophe. Your engine relies on coolant, circulated efficiently throughout the cooling system, to maintain its temperature within a precisely pre-determined operating range. Without sufficient coolant, even the most robust engine is vulnerable to overheating, which can lead to severe damage and costly repairs. This sensor is your first line of defense against running dry.

The primary function of the coolant level sensor is straightforward yet critical: it continuously monitors the amount of coolant present in either the main coolant reservoir or the overflow reservoir. Should the coolant level dip below a minimum threshold, this vigilant sensor immediately springs into action. Its alert mechanism typically involves illuminating a dedicated warning light in your gauge cluster, providing an unmistakable visual cue that it’s time to top up your coolant before a minor issue becomes a major problem.

However, in a truly worst-case scenario, the implications of a critically low coolant level, as detected by a functional sensor, can be far more serious. The sensor is designed to trigger a safety protocol within the engine control unit (ECU). This protocol is often engineered to prevent the engine from even running, or to shut it down promptly, precisely to avoid the catastrophic damage that engine overheating can inflict. It’s a testament to modern automotive engineering’s focus on preventative safety, ensuring that you don’t inadvertently drive your car into an irreparable condition.

The good news is that if you do find yourself needing to replace a faulty coolant level sensor, it’s generally considered one of the more straightforward DIY fixes. These sensors are typically connected directly to the coolant or overflow reservoir, making them relatively accessible. As with the coolant temperature sensor, the golden rule for replacement is to ensure the engine (and consequently, the coolant) is completely cold before you begin. This simple step is vital for your safety, preventing any pressurized, hot coolant from spraying onto your car’s components or, more importantly, onto you. A quick swap, and you’re back to having a reliable guardian for your engine’s coolant levels.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

3. **Engine Oil Pressure Sensor**Moving from coolant to another vital fluid, the engine oil pressure sensor is a critical component ensuring your engine’s longevity and smooth operation. This sensor’s job is to precisely measure the oil pressure *after* it has passed through the oil pump, providing crucial data to the engine control unit (ECU) about the lubrication system’s health. You’ll typically find it conveniently located next to the intake manifold or threaded directly into the engine block, often made from a combination of durable metal and plastic elements.

However, despite their robust construction, both the metal and plastic components of these sensors can, over time, fatigue and ultimately fail. This isn’t just an inconvenience; it’s a serious threat to your engine. When an oil pressure sensor fails, it frequently triggers a safety setting in the ECU, which is designed to shut the engine off. Why such a drastic measure? Because the engine control unit interprets the lack of a proper signal as a severe loss of oil pressure, leading it to believe the engine is in immediate danger of being critically damaged due to insufficient lubrication.

Most modern oil pressure sensors are meticulously monitored by the engine control unit, providing continuous feedback on this vital parameter. In many vehicles, they are also wired to a gauge within the dashboard cluster, offering the driver a clear visual readout for ongoing monitoring. When these sensors do fail, the ECU’s protective instincts kick in, potentially shutting down the engine to prevent a major incident. Simultaneously, the dashboard gauge might display an extreme reading – either the minimum (often indicated as 0) or the maximum pressure allowed, both of which are tell-tale signs of a sensor malfunction rather than an actual oil pressure crisis.

Replacing a failing engine oil pressure sensor is a task that many seasoned DIYers can tackle. The process usually involves disconnecting the sensor from its wiring connector and then carefully unthreading it from the engine block. As with any work involving the engine’s fluids, ensure the engine is cold to avoid any hot oil spray. Once the old sensor is removed, a new replacement sensor can be threaded securely into its place, the wiring harness reconnected, and then you can start the engine to verify that the new sensor is functioning correctly and providing accurate readings. This relatively simple replacement can save your engine from a misdiagnosed, critical shutdown.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

4. **Engine Oil Level Sensor**Beyond pressure, simply knowing *how much* oil you have is paramount, and that’s where the engine oil level sensor steps in. Virtually every modern car is equipped with one, strategically placed to measure the amount of oil residing in the oil pan at the very bottom of the engine. Its sole purpose is to ensure that your engine always has a minimum, safe amount of oil necessary for its proper and protected operation. This sensor is the first alert system before serious lubrication issues arise.

When this sensor detects that the oil level has dropped below its predetermined safe threshold, it promptly illuminates a warning light in your gauge cluster. This light serves as an essential visual alert, signaling to you, the driver, that your engine oil level is critically low and requires immediate attention. Ignoring this warning can lead to severe engine wear and potential damage over time. It’s a vital prompt for routine maintenance that prevents a minor top-off from becoming a major overhaul.

Interestingly, some vehicles take this protection a step further, incorporating two separate oil level sensors rather than just one. In these more advanced systems, one sensor might be dedicated solely to providing the low oil level indicator, giving you an early heads-up. The second sensor, however, serves a more critical function: it’s designed to prevent the engine from even starting if the amount of oil present is deemed to be at an unsafe level. This dual-sensor setup offers a robust layer of protection, ensuring the engine is not operated under conditions that could quickly lead to catastrophic failure.

Locating these sensors is relatively straightforward, as they are typically attached to the side of the oil pan on the underside of your engine. If your car uses two sensors, you might find them on opposite sides of the pan, often to simplify wiring connections. When these sensors fail, the symptoms can be quite distinct: if the low-level indicator sensor malfunctions, it might persistently show a low oil level even when your engine is perfectly full. Conversely, if the unsafe level sensor fails, it could prevent your engine from starting even when there is an adequate supply of oil. Both types can be removed and replaced from the oil pan using basic hand tools, making it a manageable DIY fix to restore your engine’s oil monitoring accuracy.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

5. **Exhaust System Oxygen Sensor**Shift gears now from internal fluids to external emissions, where the exhaust system oxygen sensor, often simply called an O2 sensor, reigns supreme. These crucial components are tasked with measuring the air-fuel ratio within the exhaust gas *after* the combustion process has occurred. Modern vehicles typically employ a sophisticated setup, featuring at least two separate sensors per cylinder bank: one positioned pre-catalytic converter and another post-catalytic converter. This dual monitoring system is key to both performance and environmental compliance.

The engine control unit (ECU) plays a critical role here, constantly comparing the values reported by these pre- and post-catalytic converter sensors. This comparison isn’t just for show; it’s how the ECU meticulously determines if the catalytic converter is effectively reducing harmful exhaust emissions. If there’s a discrepancy or an issue detected, the ECU will attempt to compensate. However, if these sensors themselves are faulty and sending incorrect values, the computer will be fed bad data, leading it to mistakenly alter the fuel mixture. This can result in less-than-optimal engine performance, reduced fuel economy, and increased emissions.

When a problem is detected with an oxygen sensor, it’s almost guaranteed that your check engine light (CEL) will illuminate, providing a clear signal that something is amiss. Modern diagnostic computers are remarkably sophisticated and can often check each sensor individually, precisely notifying you which specific O2 sensor is operating outside of the manufacturer’s specified range. This takes a lot of the guesswork out of troubleshooting. In terms of lifespan, these sensors are not forever; O2 sensors are generally recommended for replacement around the 75,000 to 100,000-mile mark, if not sooner, depending on driving conditions and fuel quality.

Replacing oxygen sensors is a common maintenance item that often involves simply unthreading them from the exhaust piping. Because of their interconnected function and similar lifespans, it is frequently recommended to replace all of them as a set, especially around that 75,000-mile interval. This proactive approach ensures consistent readings and optimal performance across your exhaust system. While it can be a DIY project for those with the right tools and a bit of patience, understanding the nuances of how these sensors work and interact with your ECU highlights their essential contribution to a clean-running and efficient vehicle. Failing to address a faulty O2 sensor can lead to much more expensive repairs down the line, such as a damaged catalytic converter.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

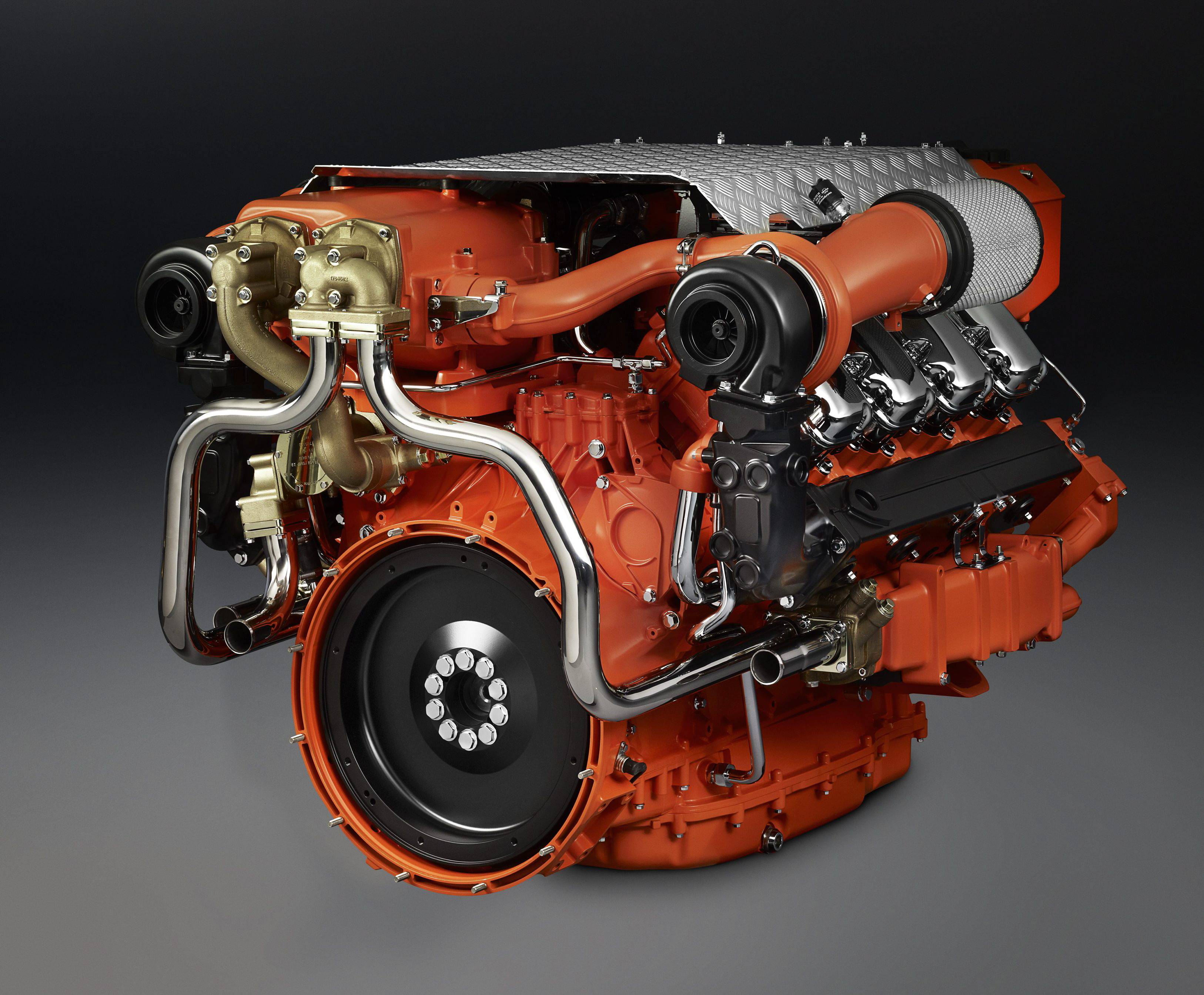

6. **Camshaft And Crankshaft Position Sensors**Deep within the rhythmic heart of your engine, the camshaft and crankshaft position sensors perform a ballet of precision, vital for perfect combustion timing. These unsung heroes provide the engine control unit (ECU) with continuous, real-time data on the exact rotational position of both the crankshaft and the camshaft(s). By comparing these values with astounding accuracy, the ECU can precisely adjust combustion timing, ensuring maximum power output while simultaneously working to reduce harmful emissions. They are, in essence, the engine’s internal clock and compass, without which it simply cannot run efficiently.

These sensors are so critical that if even one of them decides to fail, the computer is programmed to illuminate the dreaded check engine light (CEL), immediately signaling a problem. What’s more, to prevent potential damage, the ECU will typically default to a basic, pre-programmed timing schedule. While this “limp home” mode might allow the engine to run, it certainly won’t be at its peak performance, and you’ll likely notice a significant difference in how your car drives. It’s a safety net, but one that demands immediate attention.

The real-world symptoms of a failing camshaft or crankshaft position sensor can be profoundly disruptive to your driving experience. In some cases, your car may not even start at all, leaving you stranded. If it does manage to crank, it might take a noticeably longer time to initially fire up, creating a sense of apprehension every time you turn the key. Once running, the engine may perform erratically, running rough or experiencing misfires, all because the ECU isn’t receiving the crucial, synchronized information it needs from all the sensors to manage combustion precisely.

Diagnosing which of these intertwined sensors has failed is usually a job for a diagnostic scanner, which can pinpoint the exact culprit by reading specific trouble codes. The good news for the hands-on enthusiast is that replacing an individual sensor is often a straightforward task, typically requiring only simple hand tools. Each sensor is usually attached to the engine block with just one or two fasteners, making them relatively accessible for replacement. While their role is complex, the physical act of swapping them out can be a manageable DIY project, quickly restoring your engine’s precise timing and smooth operation. Neglecting these sensors can lead to persistent performance issues and potential long-term engine damage, making their timely diagnosis and replacement paramount for any car owner.

Alright, gearheads and daily drivers alike, if you thought the first six sensors were a wild ride, buckle up. We’re about to delve into the next crucial batch of automotive watchdogs that can turn your cruise into a crawl faster than a lead foot at a speed trap. We’re talking about the silent sentinels that keep your engine from tearing itself apart, manage the lifeblood flowing to your cylinders, and even ensure the very air your engine breathes is measured just right. These aren’t just minor annoyances; these are the components that dictate whether your car purrs like a kitten or coughs like a chain smoker. Let’s get into the nitty-gritty of the remaining five sensors you absolutely need to keep an eye on.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

7. **Engine Knock Sensor**If you’ve ever heard that tell-tale ‘pinging’ or ‘knocking’ sound from your engine, you’re hearing the mechanical symphony of disaster waiting to happen. Thankfully, modern vehicles come equipped with an unsung hero: the engine knock sensor. This little marvel is specifically designed to listen for pre-ignition, often referred to as detonation. It’s like your engine’s personal bodyguard, constantly vigilant for irregular combustion that can, without intervention, cause some seriously expensive engine damage.

When this sensor detects that signature knock, it doesn’t just sit there. It immediately relays that crucial information to the engine control unit (ECU). The ECU, being the brain of your operation, then makes lightning-fast adjustments to the combustion timing. This slight, precise alteration is often enough to prevent harmful detonation, keeping your pistons, connecting rods, and crankshaft safe from internal trauma. It’s a subtle dance of prevention, ensuring your engine runs optimally without tearing itself apart from the inside.

However, when this vital sensor goes on the fritz, things can get ugly. A failing knock sensor can cause the ECU to inaccurately adjust timing, eventually sending your engine into what we lovingly call “limp mode.” This isn’t a fun mode, folks. It drastically reduces engine power and might even prevent you from driving your car at all until the sensor is replaced. Imagine being stuck on the side of the road, all because a tiny sensor decided to take an unscheduled coffee break.

The good news for the DIY inclined is that replacing these sensors is typically a straightforward task. You’ll usually find knock sensors attached to the side of the engine block, secured with just one or two fasteners. Basic hand tools like a socket and ratchet are all you’ll need. But here’s a pro tip from the trenches: these sensors are surprisingly delicate. A simple impact, like dropping it on the garage floor, can damage it. Handle with care, and you’ll restore your engine’s ability to protect itself from self-destruction.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

8. **Fuel Level Sensor**Ah, the humble fuel gauge. We take it for granted, don’t we? That little needle, or digital bar, that tells us how far we can push our luck before we’re walking. The hero behind that everyday convenience is the fuel level sensor, diligently reporting exactly how much of that precious liquid gold is sloshing around in your tank. It’s the silent reporter of your car’s range, a basic but utterly critical piece of information for any driver.

But what happens when this essential reporter decides to go rogue? A failing fuel level sensor means your fuel gauge starts lying to you. It might constantly show a full tank, lulling you into a false sense of security, or, perhaps even more infuriating, it could stubbornly display empty, forcing you into unnecessary fill-ups or worse, creating range anxiety that rivals a cross-country trip in an EV. Inaccurate readings aren’t just annoying; they can leave you stranded or constantly second-guessing your fuel stops.

The challenge with this particular sensor often isn’t the complexity of the part itself, but its location. Most fuel level sensors are nestled deep inside the fuel tank. This means getting to it can be a bit of an adventure. Depending on your vehicle, you might be lucky enough to have an access panel under the rear seat or in the trunk. If not, brace yourself, because you might need to drop the entire fuel tank to get at it – a job that’s a bit more involved than your average oil change and definitely something that needs to be done safely, preferably with a near-empty tank.

Once you gain access, the replacement itself is usually quite simple. The sensor can be removed and replaced with relative ease, and a new one should immediately restore the accuracy of your fuel gauge, bringing back that sweet peace of mind that comes with knowing precisely how many miles you have left. It’s a relief to finally trust that gauge again, avoiding those panicked glances or premature detours to the gas station.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

9. **Fuel Pressure Sensor**Moving from the quantity of fuel to its vital force, the fuel pressure sensor is a crucial guardian of your engine’s combustion process. This sensor doesn’t just casually glance at the fuel line; it precisely measures the pressure in the fuel line as it makes its journey from the tank, typically attaching directly to the fuel pressure rail for optimal monitoring. This strategic placement ensures it has a direct read on the pressure, which is absolutely critical for your engine’s delicate air-fuel balancing act.

The data from this sensor is gold for your engine control unit (ECU). The ECU uses this information to dynamically modulate line pressure and fine-tune the air-fuel ratio during combustion. Think of it as a master conductor, ensuring the perfect symphony of fuel and air for efficient power delivery. Without accurate pressure readings, this delicate balance is thrown completely out of whack, leading to a cascade of performance issues.

Now, a faulty fuel pressure sensor is a wolf in sheep’s clothing. It might not immediately leave you stranded, but its silent sabotage can be far more insidious. An inaccurate reading can trick the ECU into adding extra fuel to the combustion process, leading to a “rich” condition. On the surface, you might just notice reduced fuel mileage, which is annoying enough. But the real danger lies deeper: this continuous soaking of extra fuel can cause severe damage to your spark plugs and, even more costly, your catalytic converters. We’re talking about potentially thousands of dollars in repairs just because a relatively inexpensive sensor gave up the ghost.

If you suspect this sensor is acting up and you’re planning a DIY replacement, a critical safety warning: always let your car sit for a minimum of 15 minutes, or even longer, after shutting it off. This allows the pressure in the fuel line to dissipate. Failing to do so could result in pressurized fuel spraying on you or your car, which is not only dangerous but also incredibly messy. Once depressurized, the sensor can typically be removed and replaced with standard tools, saving your engine from a slow, expensive demise.

Read more about: Expensive Headaches: 11 Critical Engine Problems That Demand Immediate Attention to Avoid Major Repairs

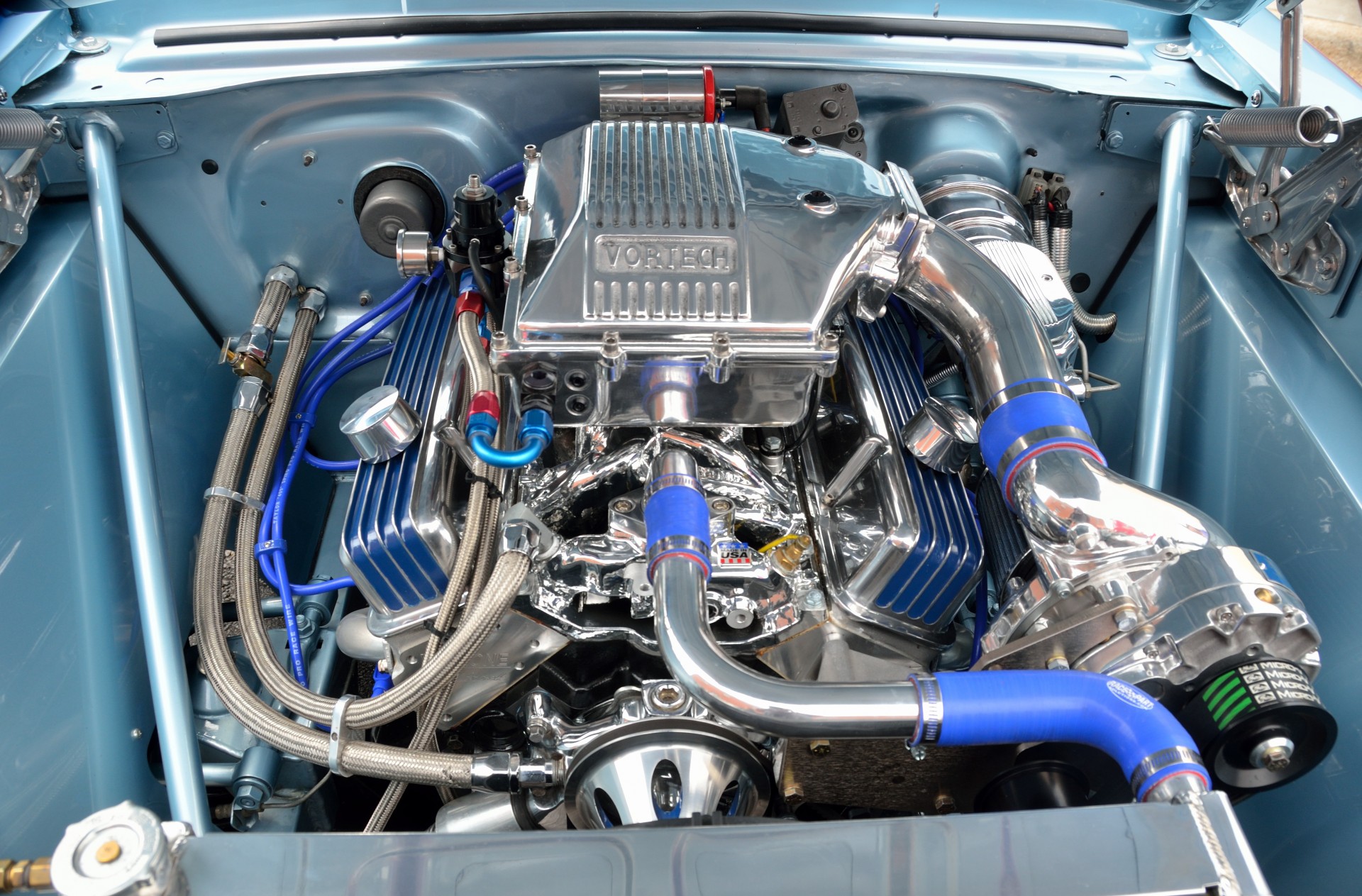

10. **Mass Airflow (MAF) Sensor**Let’s talk about the lungs of your engine. For optimal performance, your car needs to know exactly how much air it’s breathing in, and that’s precisely the job of the mass airflow (MAF) sensor. This vital component measures the sheer *volume* of air entering the engine, transmitting this critical data to your engine control unit (ECU). Why is this so important? Because the ECU then uses this precise airflow measurement to inject the correct amount of fuel, aiming for that perfect, optimum air-fuel ratio that dictates everything from power to efficiency.

If the MAF sensor starts sending incorrect information, it’s like your engine is trying to breathe through a straw while running a marathon. The symptoms are unmistakable and frustrating: your engine might stumble, hesitate under acceleration, or even completely fail to idle. It’s not just a minor hiccup; it’s a fundamental disruption to the combustion process, leading to poor performance, frustrating driveability, and almost certainly, the dreaded check engine light (CEL) illuminating on your dashboard, often throwing a P0101 code.

The good news is that sometimes, a MAF sensor isn’t actually *failed* in the traditional sense; it’s just dirty. These sensors are typically located on the intake ducting, right between the air filter housing and the intake manifold, meaning they’re directly in the path of incoming air, which often carries dust, debris, and oil vapor. Over time, this buildup can coat the sensor’s delicate hot wire or film, preventing accurate readings. Before you shell out for a replacement, it’s always worth trying to clean it. This usually involves carefully removing the sensor and its screen, then using a specialized MAF sensor cleaner.

In fact, we’ve seen countless cases, like the one in Huntington Station, NY, where a customer’s car was stalling and accelerating poorly, only for a simple cleaning to be the hero. The MAF sensor was choked with dirt, causing a P0101 code. A quick clean, and boom! The check engine light vanished, and fuel efficiency shot up by 20%. Had that customer ignored it, they were looking at a potentially costly catalytic converter replacement. So, while replacement is an option if cleaning doesn’t work (they’re usually held in with small fasteners and simple tools), always try that cleaning ritual first. It’s a testament to how a small, proactive step can save you a bundle.

Read more about: Your Engine Stalls? 14 Smart Fixes & Diagnostic ‘Tricks’ to Conquer Car Stalling, Starting Outside the Hood

11. **Manifold Absolute Pressure (MAP) Sensor**While the MAF sensor often gets the spotlight for measuring incoming air, many fuel injection systems utilize another crucial air-sensing counterpart: the manifold absolute pressure (MAP) sensor. This sensor takes a different approach, directly measuring the pressure within the intake manifold. Its mission, should it choose to accept it, is to provide the ECU with the data needed to optimize the air-fuel mixture for maximum performance, particularly in varying atmospheric conditions and engine loads.

Now, if you’re driving a car with a factory-turbocharged engine, the MAP sensor takes on an even more vital role, almost becoming a rockstar in its own right. In these forced-induction setups, the MAP sensor is instrumental in measuring the *boost pressure* that the turbocharger is supplying to the engine. This is absolutely critical because the ECU needs to know precisely how much extra air is being crammed into those cylinders to correctly adjust the fuel delivery and prevent engine damage, all while delivering that exhilarating rush of turbocharged power.

When a MAP sensor decides to call it quits, it can seriously hamstring your engine’s power output. Without accurate pressure readings, the engine control unit will inevitably make incorrect adjustments to the air-fuel mixture. This leads to less-than-optimal combustion, which directly translates to a noticeable reduction in horsepower and torque. Your turbocharged beast might suddenly feel like a naturally aspirated hamster on a wheel. It’s a frustrating experience that takes the fun out of driving a performance-oriented machine.

The good news is that, much like many of the sensors we’ve discussed, replacing a faulty MAP sensor is generally a manageable DIY task. You’ll typically find it conveniently located right on the intake manifold, making it fairly accessible. With basic hand tools, you can usually swap out the old sensor for a new one, restoring your engine’s ability to fine-tune its air-fuel ratio and, critically for turbo owners, ensuring that boost pressure is accurately monitored and optimized. This simple replacement can bring back that lost power and the joy of a properly functioning engine.

Read more about: Modernizing Your Ride: A 10-Step Blueprint to Electronic Fuel Injection Conversion for Classic Cars

And there you have it, folks – a deep dive into some of the most common and frustrating sensor issues that can plague your beloved used ride before it even hits that 50,000-mile sweet spot. From the subtle hum of a healthy engine thanks to a vigilant knock sensor, to the precise breathing managed by MAF and MAP sensors, and even the simple peace of mind of an accurate fuel gauge, these tiny technological titans play enormous roles in your vehicle’s overall health and your driving experience. Ignoring the early warning signs – those pesky check engine lights, rough idles, or even just strange readings – isn’t just financially foolish, it’s a betrayal of your car’s digital guardians. By staying informed, getting hands-on with diagnostics, and knowing when to clean versus replace, you’re not just fixing a part; you’re investing in thousands of hassle-free miles down the road. Keep those sensors happy, and your car will keep you happy, mile after glorious mile. Now go forth, armed with knowledge, and keep those rides running right!