The allure of a vintage truck is undeniable, a rolling testament to an era of craftsmanship and rugged utility. For countless enthusiasts, owning and meticulously restoring these automotive treasures isn’t just a hobby; it’s a deep-seated passion, a commitment to preserving a tangible piece of history. Yet, beneath the polished chrome and gleaming paint lies a challenge that can test the resolve of even the most dedicated restorer: the relentless hunt for elusive, sometimes seemingly impossible-to-find, original parts. This pursuit, a complex dance between dwindling supply and unwavering demand, defines much of the restoration journey.

In an industry segment valued at a staggering $1.5 billion for classic Chevy truck parts alone – and continuously growing – the stakes are incredibly high. It’s a world where authenticity commands a premium, and the tiniest details can dictate immense value. Suppliers who navigate this intricate market, understanding the nuances of scarcity and the collector’s unwavering desire for originality, become invaluable partners. But for the individual restorer, this landscape is often fraught with difficulty, transforming what should be a straightforward parts acquisition into a genuine ‘parts scramble.’

We’re about to delve into the very heart of this challenge, uncovering the 12 types of vintage truck components that frequently push restorers to their limits. From the smallest emblem to critical mechanical systems, these are the parts that demand patience, ingenuity, and often, a touch of luck to acquire. Join us as we explore why these particular components have become the holy grail for many, and how their scarcity shapes the fascinating, often frustrating, world of vintage truck restoration.

1. **Original Equipment Manufacturer (OEM) Authenticity Parts**For the serious collector, the very essence of a vintage truck’s value lies not just in its make and model, but in its historical accuracy. This intense focus on authenticity creates an extraordinary demand for Original Equipment Manufacturer (OEM) parts, components bearing the factory markings, the subtle patina of aged paint, or even the distinct scent of old rubber. These seemingly minor details are far from inconsequential; they are the threads that weave the narrative of the truck’s past, and they significantly dictate its market value.

The challenge, of course, is that the production of these original components ceased decades ago. As these vintage vehicles age, the existing stock of OEM parts naturally diminishes, making each remaining piece increasingly precious. Restorers aren’t just looking for a functional replacement; they are seeking a literal link to the truck’s history, a piece that tells a story of its origin and manufacture. This fervent desire for genuine components, or at least exceptionally accurate reproductions crafted to original blueprints, drives their prices sky-high.

Suppliers who can consistently deliver genuine OEM parts, or those with OEM-level quality, aren’t simply selling raw materials. They are providing the very foundation upon which a truck’s structural integrity and aesthetic appeal are preserved, minimizing labor costs for restoration shops and, most importantly, maintaining the vehicle’s inherent value. The ability to source these authentic pieces builds immense trust and a formidable reputation within the discerning classic truck community.

Read more about: Navigating the Scarcity: 8 Essential Ways to Unearth Parts for Your Beloved American Classics

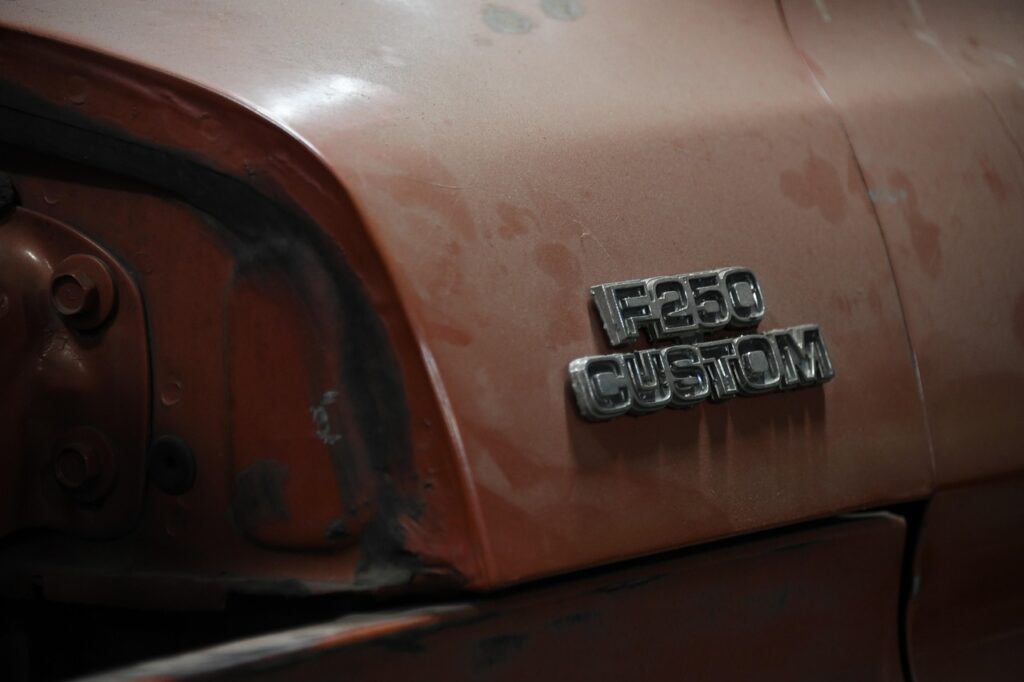

2. **Limited-Run Model Trim and Unique Emblems**Beyond the functional, there are components that define the aesthetic character and exclusivity of certain vintage trucks: the trim and unique emblems of limited-run models. These decorative elements, often subtle yet distinctive, were produced in far smaller quantities than standard components. Consequently, as the trucks themselves become rarer, so too do these specific, identifying features, escalating their scarcity to extreme levels.

Imagine the frustration of completing a near-perfect restoration, only to be held back by the absence of a unique badge or a specific piece of trim that identifies your truck as a rare variant. These are the components that, once out of production, become exceptionally valuable and difficult to locate. Their limited initial supply means that fewer were ever made, fewer survived, and even fewer are now available in a usable condition.

For a restorer, finding an original, undamaged emblem or a full set of trim unique to a specific production year or special edition model is often a monumental task. These items command premium prices not just for their material value, but for their contribution to the truck’s unique identity and historical significance. Suppliers specializing in sourcing these incredibly hard-to-find components position themselves as invaluable partners, offering a lifeline to restorers seeking to complete their historically accurate masterpieces.

Read more about: Beyond Expectations: 10 ’90s American Muscle Cars Whose Values Are Soaring, Redefining Collectible Performance

3. **Critical Everyday Wear Items**It might seem counterintuitive that commonplace items could be difficult to find, but in the realm of vintage truck restoration, even everyday wear items transform into elusive treasures. Components like brake linings, window seals, suspension bushings, and various gaskets are essential for a truck’s basic functionality and safety. Yet, once their original production runs cease, their availability quickly declines, leading to surprising scarcity.

These are not glamorous parts, but they are absolutely crucial. A classic truck cannot be safely driven without functioning brake linings, nor can its cabin be properly sealed without intact window and door seals. While generic alternatives might exist, achieving a precise fit and maintaining period-correct aesthetics often necessitates sourcing original or high-quality reproduction versions, which are often expensive to re-create accurately.

The challenge here isn’t just about rarity; it’s about the relentless march of time and material degradation. Rubber components, for instance, dry rot and crack over decades, making original pieces found in salvage yards often unusable. This forces restorers into a difficult position, where crucial, unglamorous parts become as hard to source and as valuable as more visually striking components, directly impacting the safety and comfort of the restored vehicle.

Read more about: Unsung Heroes of the Asphalt: 14 Low-Maintenance Classic Cars That Deserve a Spot in Your Garage

4. **Obsolete Mechanical Systems**The relentless march of technological progress, while beneficial for modern vehicles, casts a long shadow over the restoration of vintage trucks. Many mechanical systems from bygone eras have been rendered completely obsolete by evolving industry standards and advancements. Manufacturers naturally prioritize the production of components for contemporary vehicles, relegating the parts for older, outmoded technologies to the annals of automotive history.

Consider, for example, carburetors from the 1950s. While once standard, they have largely been supplanted by modern, efficient fuel injection systems. This means that a crucial component for a classic truck’s engine, one that defines its original performance characteristics, is simply not a priority for today’s manufacturing. Restorers are left grappling with the challenge of sourcing parts that are not only out of production but also, from a contemporary engineering perspective, fundamentally out of date.

This obsolescence extends beyond just carburetors to entire ignition systems, specialized braking components, or even unique transmission internals. The quest for these components often becomes a true treasure hunt, requiring extensive knowledge of historical part numbers and cross-referencing capabilities. It’s a stark reminder that preserving automotive history often means engaging with technologies that the modern industry has long since left behind.

Read more about: Unlocking Peak Efficiency: Engineer-Backed Strategies to Boost Your Car’s MPG by 10 Without Changing Your Route

5. **Specific Body Panels for Iconic Models**The exterior appearance of a vintage truck is its defining feature, the first element that captures attention and conveys its character. For many iconic models, like the immensely popular 1973-1979 Ford “Dentside” trucks, specific body panels such as grille shells, bumpers, and fenders are not just functional components; they are critical to achieving that instantly recognizable, classic look. Unfortunately, these large, exposed panels are also highly susceptible to damage from accidents, rust, and everyday wear, making pristine originals exceedingly difficult to find.

The demand for unblemished body panels is consistently high, especially for highly sought-after models. A dented fender or a rusted tailgate can undermine an otherwise perfect restoration, and while crash repair using junkyard fenders under $100 might be an option, finding one in genuinely good, repairable condition is a significant challenge. Restorers often spend countless hours hunting for grilles with intact headlight buckets and bezels or doors and tailgates that are complete assemblies, as these can save hundreds in restoration costs if found in decent shape.

Unlike smaller mechanical parts, body panels are large, difficult to ship, and often require extensive bodywork even when “found.” Their scarcity in good condition, combined with their importance to the truck’s overall aesthetic, makes them a prime candidate for the “impossible-to-find” list. Their authenticity maintains the truck’s character and, crucially, often makes them a better long-term investment than reproduction alternatives that may not match original specifications perfectly.

Read more about: Unsung Heroes of the Asphalt: 14 Low-Maintenance Classic Cars That Deserve a Spot in Your Garage

6. **Specialized Performance Drivetrain Upgrades**While some restorers seek strict originality, others aim to enhance their vintage trucks with performance upgrades that were either available in limited numbers during the vehicle’s era or have become highly desirable modern adaptations. This pursuit of specialized engine and drivetrain components introduces another layer of scarcity, as these items are often specific, highly sought after, and not readily available in the aftermarket.

Consider the quest for a 351 Windsor roller motor, particularly cherished by enthusiasts for its performance potential, or a Ford T5 manual 5-speed transmission, a popular upgrade for classic trucks seeking a more modern driving experience. Another example is the Ford 8.8 rear end with disc brakes, which offers a superior stopping power upgrade over original drum brakes. These components represent specific desirable enhancements that elevate a truck’s capabilities.

However, precisely because these components are so desirable and often pulled from other specific donor vehicles, they become incredibly difficult to source in good, complete, and functional condition. Their rarity stems from a combination of their original specialized nature, the passage of time, and the intense demand from a community eager to improve their classic trucks while retaining a vintage feel. The search for these specialized performance parts often requires a deep dive into specific model years and a keen eye for compatible upgrades from other Ford vehicles, transforming the hunt into an engineering challenge as much as a sourcing one.

Read more about: Unlocking Peak Efficiency: Engineer-Backed Strategies to Boost Your Car’s MPG by 10 Without Changing Your Route

7. **The Elusive Interior: Complete Cabin Components**Once the exterior and drivetrain are sorted, the restorer’s gaze inevitably turns inward, toward the cabin where the vintage truck’s character truly comes alive. Sourcing complete interior components presents its own unique set of obstacles, often proving just as challenging as finding an unblemished body panel. These parts are not merely functional; they contribute directly to the authentic look and feel that reproduction pieces frequently struggle to match, preserving the vehicle’s historical integrity.

Dashboard pads, often cracked and faded by decades of sun exposure, are a prime example. While some can be repaired or refinished, finding an original in pristine or even restorable condition can save hundreds of dollars and countless hours of labor. Equally critical are the bucket seat tracks, which are essential for both seat functionality and, crucially, safety. Their absence or severe degradation can stall an otherwise complete interior assembly, leaving a vital aspect of the truck’s usability in limbo.

Door panels and associated trim pieces are another category of interior components that maintain the cabin’s authenticity. These often bespoke elements, with their specific patterns and material textures, are difficult and costly to reproduce accurately to OEM standards. Even seemingly minor details, like horn rings and other steering column components, become significant finds, as they complete the tactile experience and visual accuracy of the period-correct interior. The subtle patina of aged materials and the original scent of old rubber, as some collectors note, are details that dictate true value.

The meticulous scrutiny of these interior parts is not just about aesthetics; it’s about ensuring the vehicle performs reliably and safely. Every component, from the largest dash pad to the smallest trim piece, must be evaluated for quality and condition. Striking the delicate balance between maintaining authenticity and ensuring robust functionality is a constant tightrope walk for classic truck enthusiasts, especially when considering the intricate details that define a period-correct cabin.

Read more about: Beyond the Wash: 14 Pro Secrets to Making Your Car’s Interior Look Brand New Again

8. **Unseen Complexity: Rare Electrical Systems**Beneath the surface of every vintage truck lies a labyrinth of electrical systems, often overlooked but absolutely vital to its operation. While they may not boast the visual appeal of chrome accents or polished paint, rare electrical components can prove surprisingly durable and, when located, incredibly valuable. These are the systems that manage everything from ignition to illumination, and their scarcity can halt a restoration as surely as a missing engine block.

Finding a complete, unmolested wiring harness, for instance, is a triumph for any restorer. Decades of exposure to the elements, rodents, and haphazard modifications often leave original harnesses in disarray, making a functional, intact unit a prized possession. Such a find can save immeasurable time and effort compared to repairing or reverse-engineering a damaged loom, ensuring all necessary hardware is included for a secure attachment and proper operation.

Beyond the fundamental wiring, specific electrical accessories from certain model years or optional packages become truly rare. Factory fog light switches, complete with their original wiring harnesses, are exemplary finds that can significantly boost a truck’s historical accuracy and overall value. Furthermore, some restorers look to intelligent electrical upgrades, such as sourcing electric fans from a Lincoln Mark VIII or Ford Contour for enhanced cooling, or transmission coolers from F-250s and Super Duties for performance applications, blending vintage aesthetics with modern reliability.

This convergence also extends to lighting technology, where suppliers are now offering retro-style halogen headlights or LED kits that meticulously mimic original appearances while delivering dramatically brighter illumination and extended lifespans. Custom lens designs ensure a perfect fit and maintain the classic light pattern, with increasing emphasis on compliance with international safety standards like those set by the United Nations Economic Commission for Europe (UNECE). Sourcing these rare and robust electrical components, or their period-appropriate modern equivalents, is fundamental to a vintage truck’s safety, functionality, and enduring appeal.

Read more about: The Platinum Pain: 15 Luxury Vehicles That Secretly Punish Their Owners with Sky-High Costs

9. **The Restomod Revolution: Blending Eras of Performance**While some purists steadfastly pursue absolute originality, a powerful and increasingly popular trend known as “restomod” is reshaping the vintage truck landscape. This movement skillfully merges classic aesthetics with modern engines and components, driving a unique demand for “mixed parts bundles” that bridge decades of automotive engineering. The goal is to retain the iconic lines and character of a classic truck while elevating its performance, reliability, and everyday drivability to contemporary standards.

The essence of a restomod lies in carefully selected performance upgrades that were either limited-run during the truck’s original era or represent highly desirable modern adaptations. For example, enthusiasts might embark on a quest for a 351 Windsor roller motor, revered for its performance potential, or integrate a Ford T5 manual 5-speed transmission to achieve a more modern driving experience. Another popular modification involves upgrading to a Ford 8.8 rear end equipped with disc brakes, offering a significant improvement in stopping power over original drum setups.

This blend of old and new extends beyond the powertrain to other critical systems. The demand for lightweight body panels, often crafted from advanced materials, or high-performance braking systems is growing, as restorers seek to enhance dynamic capabilities without sacrificing visual authenticity. The beauty of the restomod approach is its creativity: it embraces sourcing components from unexpected donor vehicles or adapting parts from later models to achieve a bespoke, elevated vintage machine.

The restomod revolution highlights the evolving nature of vintage truck appreciation. It underscores that preserving automotive history isn’t solely about recreating the past, but also about reimagining it. Suppliers who can offer advanced solutions and cater to these specific, often engineering-intensive, demands for blended parts are those poised to thrive. The convergence of classic charm and modern performance is a thrilling frontier, continually pushing the boundaries of what a vintage truck can be.

10. **The Artisan’s Last Resort: Custom Fabrication**When the relentless hunt for a specific vintage truck part reaches an unequivocal dead end, and all conventional avenues have been exhausted, restorers often turn to an ultimate, albeit costly, solution: custom fabrication. This isn’t merely a backup plan; it’s a testament to unwavering dedication, requiring exceptional craftsmanship and specialized knowledge to bring a missing component into existence from scratch. It is the final recourse when no original, reproduction, or salvaged part can fulfill the need.

Custom fabrication empowers restorers to meticulously recreate or replace parts that are simply no longer available anywhere else. This bespoke approach allows them to breathe new life into their classic vehicles, ensuring that a restoration project isn’t derailed by the absence of a single, crucial element. Whether it’s a unique bracket, an intricate piece of trim, or even a complex mechanical component, skilled artisans can reverse-engineer and manufacture components to original specifications, sometimes even improving upon them with modern materials and techniques.

The process often involves advanced manufacturing techniques, including the increasingly sophisticated realm of 3D printing for specific components, particularly intricate ones or those with complex geometries. This technological advancement allows for precision and repeatability that was once impossible, making previously “unobtainable” parts a reality. However, this level of specialized work comes with a significant investment; the cost of custom fabrication varies considerably based on the complexity of the part, the materials required, and the expertise of the craftsman.

Despite the financial outlay, the value of custom fabrication is immense. It allows a project to move forward where it would otherwise stagnate, preserving the historical narrative of the truck and satisfying the restorer’s vision. It transforms a seemingly insurmountable obstacle into an opportunity for true automotive artistry, showcasing how innovation and skilled hands are essential partners in the enduring passion for vintage truck restoration.

11. **The Reproduction Predicament: Quality, Authenticity, and Value**In response to the ever-declining supply of genuine Original Equipment Manufacturer (OEM) vintage truck parts, the market for reproduction and aftermarket components has flourished, offering modern solutions to a pervasive restoration challenge. However, this burgeoning industry introduces its own complex dynamic, requiring restorers to critically assess the quality, authenticity, and ultimate value of these alternatives. The balance between period-correct integrity and practical availability is a delicate tightrope walk.

While many reproduction parts are meticulously crafted to original blueprints, striving for OEM-level quality and precise fitment, others may only loosely replicate the original designs. The spectrum of replicas ranges from near-identical, high-quality replacements that seamlessly integrate into a restoration, to those that may fall short in material, finish, or dimensional accuracy. This variability necessitates a careful evaluation by restorers, as a subpar reproduction can compromise both the structural integrity and the aesthetic appeal of the vehicle.

The ultimate goal for many is not just a functional part, but one that preserves the truck’s inherent value and historical accuracy. Suppliers who commit to genuine components or exceptionally accurate reproductions are not merely selling raw materials; they are selling a piece of the truck’s story, minimizing labor costs for restoration shops and maintaining market worth. Remanufactured parts often strike an appealing balance between quality and affordability, making them popular choices, yet factory original parts, while authentic, may be expensive and not always in pristine condition.

Therefore, restorers must scrutinize each reproduction part to ensure it aligns with their vision for authenticity and reliability. It’s a pragmatic approach to preservation, recognizing that while an original piece is ideal, a high-quality reproduction can be an invaluable asset, allowing cherished vintage trucks to not only retain their historical accuracy but also to perform reliably and safely on the road for years to come.

12. **Salvage Yard Gold: Assessing Used Components for Longevity**For many vintage truck enthusiasts and professional restorers alike, the humble salvage yard represents a veritable goldmine of authentic, often cost-effective, components. The prospect of unearthing original equipment manufacturer (OEM) parts from a forgotten donor vehicle offers immense appeal, providing a tangible link to the truck’s history that reproduction parts, however good, cannot fully replicate. Yet, navigating these automotive graveyards requires a discerning eye and a critical assessment of condition to avoid unforeseen pitfalls.

Successfully finding quality parts at U-Pull-It facilities or specialized salvage yards demands thorough inspection techniques. Critical assessment points include rust and corrosion, determining if any damage is repairable without compromising structural integrity. The integrity of mounting points must be verified to ensure secure attachment, while moving parts—such as doors, windows, and other mechanical components—must be tested for functionality. Furthermore, restorers should verify completeness, ensuring all necessary hardware is included, which can save hundreds in subsequent restoration costs.

While junkyard finds can dramatically reduce restoration expenses, it’s crucial to understand that not all used parts are created equal, and some components should never be bought used for safety and reliability reasons. For example, while body panels like fenders for a 1973-1979 Ford “Dentside” truck can be found for under $100 and offer an excellent, affordable path to crash repair, their condition can vary significantly. The “parts scramble” often leads to subjective pricing in the collector’s market, influenced more by rarity than by an item’s actual condition.

Ultimately, the judicious use of salvaged components requires both expertise and patience. When selected wisely and thoroughly inspected, junkyard parts can provide authentic, high-quality solutions, contributing significantly to a successful restoration project. They allow enthusiasts to maintain their truck’s character and historical accuracy, often making them a better long-term investment than reproduction alternatives that may not match original specifications perfectly, all while staying within a realistic budget.

The journey of vintage truck restoration, whether driven by a desire for pristine originality or the innovative spirit of a restomod, is an ongoing testament to passion, perseverance, and mechanical artistry. As we’ve explored the myriad challenges of sourcing everything from the smallest interior knob to complex drivetrain upgrades, it becomes clear that this isn’t just about turning wrenches; it’s about connecting with a tangible piece of history, understanding intricate engineering, and fostering a vibrant community. The future of these rolling legacies will undoubtedly be shaped by innovation, global collaboration, and the enduring dedication of enthusiasts committed to keeping these magnificent machines on the road, echoing the spirit of craftsmanship from decades past.