The electric vehicle revolution is in full swing, and it’s exhilarating to witness the incredible pace of innovation. As consumers increasingly demand locally made and ecologically friendly EVs, engineers and manufacturers are stepping up to the plate, designing vehicles that are not only high-performing but also genuinely sustainable for the long haul. This next decade promises to bring some truly ‘rare’ advancements to the mainstream, changing how we think about what an EV can be and how it’s built.

One of the biggest hurdles facing the industry today revolves around crucial components for traditional permanent magnet motors: rare-earth elements. Materials like neodymium and dysprosium are imported in significant amounts from China, creating concerns about price volatility and geopolitical risks as global tensions and supply chain problems continue to plague automakers. This dependence isn’t just an economic issue; it’s a sustainability challenge, given the complex, energy-intensive, and environmentally demanding extraction processes associated with these materials. But here’s the exciting part: brilliant minds are already finding clever ways around these bottlenecks.

We’re talking about a paradigm shift in EV drivetrain design, where performance, cost, and environmental priorities converge in exciting new ways. From rethinking how electric motors generate torque without exotic materials to building lighter, stronger vehicle bodies and making maintenance a breeze, these twelve concepts are set to redefine the future of sustainable driving. Get ready to explore the cutting-edge innovations that will soon be powering your next eco-conscious ride!

1. **Rare-Earth-Free Permanent Magnet Synchronous Motors (FaSynRM)**The quest for sustainable electric vehicles has sparked incredible innovation, especially in the heart of the EV: the motor itself. One of the most promising concepts is the Ferrite-Assisted Synchronous Reluctance Motor, or FaSynRM, which cleverly combines the strengths of both reluctance and magnet torque. This design incorporates rectangular ferrite magnets inside the rotor’s flux barriers, moving away from reliance on expensive and geopolitically sensitive rare-earth magnets while still aiming for high performance.

Ferrite magnets, such as Y33H, offer a fantastic cost advantage, being roughly 60 times cheaper than NdFeB N30 magnets, costing about 1 USD per kilogram compared to 60 USD per kilogram. However, their magnetic strength is significantly weaker, typically resulting in a much lower torque output if simply swapped into an existing design. When simulating a motor using Y33H magnets, the ferrite version produces an average torque of 5.68 Nm, about half that of the NdFeB version’s 11.18 Nm.

This initial performance gap is precisely where advanced engineering steps in. Tools like Ansys optiSLang and Motor-CAD become essential, allowing for extensive optimization of the rotor geometry. By carefully fine-tuning every aspect, from magnet size to the smallest thickness variations in the rotor, engineers can maximize both the reluctance torque and the magnet torque. This rigorous optimization process, which can involve hundreds of FEA simulations and thousands of analytical iterations, allows FaSynRM designs to achieve the same performance as NdFe magnets, such as the target 11.18 Nm of torque at 3000 rpm, without changing the stator.

The real beauty of the FaSynRM concept lies not just in its performance parity, but in its dramatic cost reduction. The active material cost for the ferrite magnets is a mere 0.64 USD, bringing the total FaSynRM motor cost to approximately 68.19 USD. This makes it about 33 percent cheaper than the NdFe design, solving supply chain issues and making mass manufacturing significantly more budget-friendly. It’s a win-win for sustainability and economics, proving that high performance doesn’t have to come at a high environmental or financial cost.

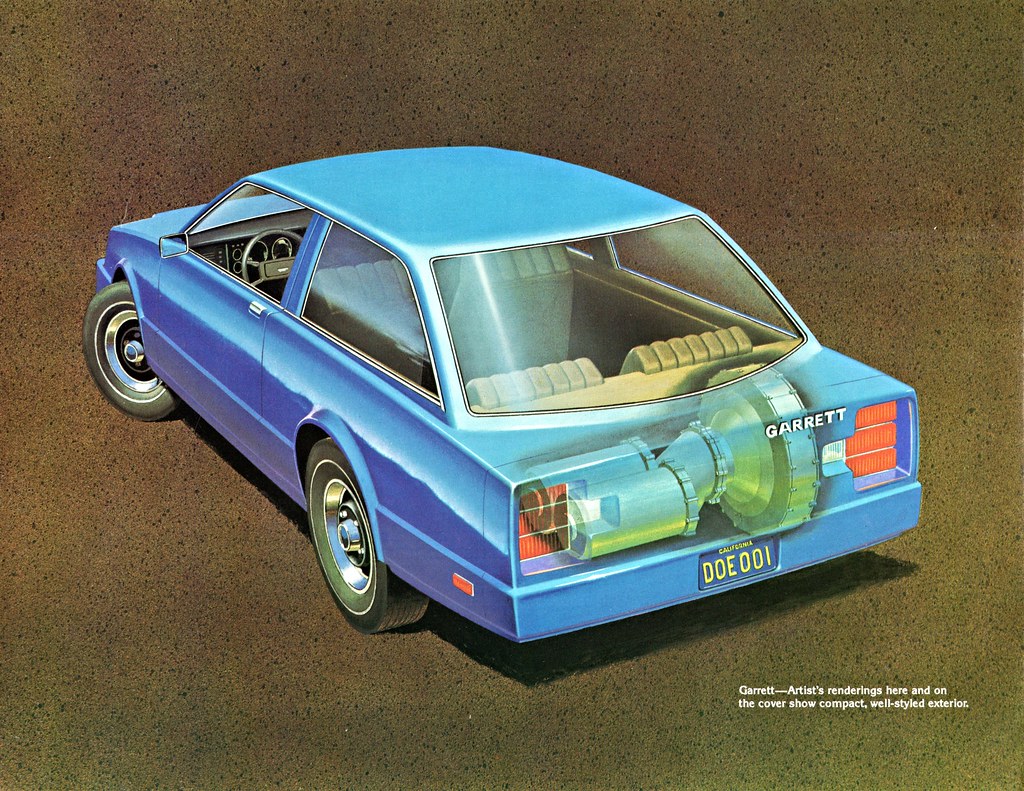

2. **Electrically Excited Synchronous Motors (EESM)**Beyond just replacing rare-earth magnets with more common alternatives, another innovative solution completely removes magnets from the motor design altogether: the Electrically Excited Synchronous Motor (EESM). This motor type operates similarly to a Permanent Magnet Synchronous Motor (PMSM), but instead of relying on permanent magnets, it generates the magnetic field in the rotor using an external excitation source. This fundamental difference makes the EESM a compelling magnet-free candidate for future EV designs.

Designing an EESM involves a distinct rotor topology, as it must include slots to accommodate wound coils that create the electromagnetic field. Critical design factors include the number of turns that can fit within these rotor slots while respecting manufacturing tolerances, and the maximum current that can be supplied to the coils without risking overheating or damage. Software like Motor CAD is instrumental in this process, helping engineers quickly and efficiently create rotor coil designs and simulate various cooling methods, such as air fan, water jacket, or oil cooling, to ensure competitive performance with NdFe PMSM systems.

Traditionally, EESMs have relied on brushes and slip rings mounted on the shaft to transfer direct current to the rotor windings. While modern brush systems use materials like carbon to minimize friction and increase durability, they are components that experience wear and typically require periodic maintenance every ten to twenty years. This has historically been a consideration for their adoption, but the ongoing advancements are making these systems more robust and reliable.

From a cost perspective, the EESM also shines. While it’s slightly more expensive than a FaSynRM due to the additional rotor windings (using AWG 16 at around 16 USD per kilogram), it still comes in at approximately 83.0096 USD for the active materials. This makes it about 20 percent cheaper than the NdFe motor’s total cost of 102.928 USD, offering another compelling, cost-effective, and rare-earth-free alternative for the next generation of electric vehicles.

3. **Switched Reluctance Motors (SRM)**Another significant player in the magnet-free motor arena is the Switched Reluctance Motor (SRM). These motors are gaining substantial attention, especially from Indian institutions like IIT Delhi, which are actively putting a lot of effort into developing them. The beauty of SRMs lies in their inherent simplicity and ruggedness, making them an excellent candidate for mass adoption in diverse climates and applications, including the challenging conditions often found in India.

The core appeal of SRMs stems from their basic rotor design: they don’t have any magnets or windings on the rotor. This makes them incredibly tough, less prone to overheating, and significantly cheaper to manufacture compared to traditional permanent magnet motors. Their inherent simplicity translates directly into enhanced reliability and a longer operational lifespan, crucial features for electric vehicles that need to withstand the rigors of daily use for years on end.

Prototypes developed under India’s Electric Mobility Mission Plan have already demonstrated that SRMs can compete effectively when it comes to torque density and power efficiency. This means they are not just theoretical alternatives but practical, high-performance solutions ready for real-world deployment. The potential for these processes to be extended to both passenger electric vehicles and two-wheelers is high, with key players like Mahindra Electric and Bharat Heavy Electricals Limited actively involved in their development.

Furthermore, the robustness of SRMs allows them to handle tough weather conditions, which is particularly important for India’s diverse climate areas. This makes them a highly attractive option for the expanding EV market, ensuring that electric mobility solutions are not only sustainable but also dependable and accessible to a wider population. The global scope of this initiative is also gaining traction, with prestigious companies like Mercedes-Benz, Renault, and BMW exploring similar magnet-free motor designs.

4. **Brushless Electrically Excited Synchronous Machines**While traditional Electrically Excited Synchronous Motors (EESM) offer a compelling rare-earth-free alternative, their reliance on brushes and slip rings for current transfer to the rotor windings has always presented a minor, yet persistent, maintenance challenge. However, the EV landscape is constantly evolving, and new technologies are emerging to address precisely these kinds of limitations, pushing EESM technology into an even more appealing realm: brushless operation.

Recent advancements, such as those highlighted in research by H. Chen et al., are enabling brushless DC excitation of the rotor windings in EESMs. This represents a significant leap forward, simplifying the manufacturing process by eliminating components that require physical contact and periodic replacement. The move to a brushless design inherently improves the overall reliability and reduces the maintenance burden, making these motors even more attractive for long-term operation in electric vehicles.

While this brushless approach still requires further development before it can be adopted for large-scale production and extensive long-term operation, its potential is undeniable. It aligns perfectly with the industry’s drive for systems that demand less servicing and offer greater durability. Depending on the specific application, modern brush and ring systems with extended lifespans can still be practical options, especially when combined with proper optimization to maintain motor efficiency.

Ultimately, the development of brushless electrically excited synchronous machines underscores a broader trend: the continuous pursuit of more robust, efficient, and maintenance-free motor designs for EVs. This innovation directly contributes to lower ownership costs and increased vehicle uptime, making electric mobility an even more seamless and reliable experience for consumers in the coming decade.

5. **Lightweight Materials**Weight optimization isn’t just a buzzword in EV design; it’s one of the most influential factors determining a vehicle’s performance, range, and environmental footprint. By 2025, lightweight materials have truly reached industrial maturity, offering engineers powerful tools to shed unnecessary pounds from electric vehicles. This reduction in vehicle mass directly improves handling dynamics, extends battery range, and enhances acceleration, all while lowering manufacturing emissions. It’s about getting more out of less, which is a core tenet of sustainability.

The industry is seeing widespread adoption of sophisticated materials like high-strength steel, advanced carbon fiber composites, and aluminum alloys. For example, BMW’s iX and Tesla’s Model Y are utilizing aluminum-intensive chassis platforms, which can reduce conventional frame weight by an impressive 30%. These aren’t just minor tweaks; these are fundamental structural changes that dramatically boost energy efficiency and allow for advanced structural engineering to improve crash safety. Lucid Motors’ Air Sapphire, for instance, showcases this with its monocoque cabin design, employing carbon-fiber-reinforced polymer (CFRP) to add stiffness and reduce drag, delivering luxury without compromising sustainability goals.

Even in emerging markets, the drive for lightweighting is strong. Indian startups such as Pravaig Dynamics and Ola Electric are actively exploring fiber-reinforced polymer panels for scooters and EV taxis. Their objective is to strike a delicate balance between cost-efficiency, recyclability, and, most importantly, passenger safety. This local innovation is crucial for making sustainable mobility accessible. To support this growth, companies like Tata Elxsi and JBM Auto are partnering with global composites manufacturers, localizing advanced material production and indicating the growing maturity of India’s EV materials supply chain.

This concerted effort across the globe to integrate lightweight materials into EV structures signifies a collective commitment to pushing the boundaries of what electric vehicles can achieve. It’s a clear signal that the future of mobility will be lighter, more efficient, and inherently more sustainable, paving the way for vehicles that perform better and tread lighter on our planet.

Read more about: Unleash Your Inner Gearhead: 14 Classic Car Restoration Projects Under $10K That Promise High Returns

6. **Multi-Material Joining Technologies**As manufacturers embrace the extensive use of lightweight materials like aluminum, carbon fiber, and high-strength steel, a new challenge arises: how do you effectively join these disparate materials without compromising strength or adding excessive weight? This is where multi-material joining technologies become absolutely indispensable, acting as the silent enablers of advanced EV structural design. These innovations are crucial for incorporating lightweight components seamlessly and safely.

Engineers are deploying a suite of sophisticated joining methods to tackle this challenge. Friction stir welding, for instance, is a solid-state joining process that creates high-quality, low-distortion welds in aluminum and other metals. Ultrasonic metal welding uses high-frequency vibrations to create metallic bonds between similar or dissimilar materials, ideal for delicate components. Structural adhesives are also playing a huge role, providing strong, lightweight bonds across large surfaces, often complementing mechanical fasteners or welds.

These advanced joining methods are not just about strength; they dramatically improve design flexibility. This is particularly vital when combining various structural elements, such as suspension systems, crash structures, and battery enclosures, especially in the confined spaces of an EV chassis. By allowing engineers to mix and match materials optimally, these technologies facilitate the creation of robust, safe, and incredibly efficient vehicle architectures that would be impossible with traditional joining techniques.

The integration of multi-material joining technologies is a testament to the ongoing innovation in EV manufacturing. It ensures that the benefits of lightweight materials are fully realized, without sacrificing the structural integrity or safety that modern vehicles demand. This intricate dance between materials and joining methods is propelling the industry forward, making future EVs stronger, lighter, and ultimately, more sustainable for everyone.

7. **Ultra-Fast Charging Systems: From 30 Minutes to 10**The age of waiting hours for your electric vehicle to charge is rapidly becoming a relic of the past, thanks to incredible advancements in ultra-fast charging technology. By 2025, leading battery innovators like CATL and BYD are truly revolutionizing how we power up our EVs, making ‘filling up’ an electric car almost as quick as a traditional gas vehicle. It’s a game-changer for daily convenience and long-distance travel, effectively eliminating range anxiety for good.

One of the most impressive breakthroughs comes from CATL, whose Shenxing Superfast Charging LFP battery was unveiled in 2023 and is already making its way into several 2025 EV models. This cutting-edge battery promises an astounding 400 km of range from just a 10-minute charge, under ideal circumstances. This phenomenal performance is achieved through a combination of brilliant engineering, including a low-resistance electrolyte design, integrated intelligent thermal management, and a nano-crystal coating that together push the boundaries of charging speed.

India is also rapidly accelerating its charging capabilities, with companies like Exide and Tata Motors actively testing high-voltage platforms that can accommodate an 800V charging architecture. These powerful systems are specifically designed to dramatically reduce battery replenishment times for commercial EV fleets, proving particularly impactful for e-buses and critical last-mile delivery applications. Additionally, there are strong rumors that Ola Electric’s much-anticipated four-wheeler will integrate 350kW charging support, signaling a broader market shift towards ultra-rapid energy transfer across various vehicle segments.

Globally, this push for speed is evident in existing EV models like the XPeng G9 and BYD Yangwang U8, which already offer impressive 10–15 minute partial top-ups, leveraging their advanced 800V and even 1000V high-voltage platforms. To support this demand, infrastructure companies such as ABB, Siemens, and Tata Power are diligently installing next-generation chargers with maximum outputs reaching 480 kW, drastically cutting down wait times at public stations and making genuine long-distance EV travel a seamless reality.

This rapid expansion and adoption of ultra-fast charging systems are not just about speed; they’re about transforming the entire EV ecosystem. India’s Ministry of Power, under its updated FAME III guidelines, is prioritizing the development of urban fast-charging corridors, particularly along key national highways like NH44, NH48, and NH16. This crucial infrastructure upgrade is absolutely essential for supporting the burgeoning next generation of electric logistics and intercity mobility, ensuring that EVs are not only performant but also incredibly practical for every journey.

8. **Smart Thermal Management: The Silent Enabler of EV Longevity**Often overlooked but absolutely critical to an electric vehicle’s performance and lifespan are smart thermal management systems (TMS). In 2025, as EVs grow exponentially more powerful and embrace ultra-fast charging capabilities, the necessity for highly effective heat regulation across batteries, inverters, and even the passenger cabin has intensified dramatically. A well-designed TMS isn’t just about comfort; it’s about safeguarding the entire vehicle and ensuring optimal operation.

Industry leaders such as Mahle, Valeo, and Modine are at the forefront of this innovation, ingeniously combining advanced phase-change materials, sophisticated heat pumps, and intricate liquid cooling loops to guarantee even temperature distribution throughout the EV. These integrated solutions are vital for managing the complex thermal loads generated by high-performance components, ensuring that every part operates within its ideal temperature range for peak efficiency and safety.

System-level optimization is where the true brilliance of modern TMS shines. Tesla’s acclaimed “Octovalve” and Hyundai’s “Integrated Thermal Module” stand out as prime examples, coordinating motor cooling, battery cooling, and the vehicle’s HVAC system through a single, intelligent loop. This integrated approach maximizes energy efficiency in both scorching hot and freezing cold climates, ensuring that the vehicle maintains optimal conditions without wasting precious battery power.

Furthermore, the innovation extends to specialized applications, with companies like Ather Energy and SUN Mobility utilizing latent heat storage conductors within electric vehicle removable battery packs. This clever strategy ensures optimal thermal energy exchange, especially crucial for densely populated urban environments where vehicles frequently stop and start. These advancements not only augment overall performance but also significantly mitigate the potential hazards of fires and thermal runaway, offering enhanced safety and peace of mind.

Ultimately, comprehensive thermal management is also a foundational pillar for the success of V2G (vehicle-to-grid) applications. It plays a critical role in managing the heat cycling associated with bi-directional fast charging and providing vital signals about cell life degradation. With the aid of efficient TMS, battery resilience is substantially increased, granting them an extended useful lifespan and, in turn, allowing car manufacturers to provide better warranties and improve the overall lifecycle economics for consumers.

9. **Advanced Power Electronics: Precision at the Core of Efficiency**At the very heart of an EV’s efficiency and dynamic performance lie its power electronics, particularly inverters and DC-DC converters, which are currently undergoing immense innovation in 2025. The industry is witnessing a revolutionary shift from traditional silicon-based components to cutting-edge silicon carbide (SiC) and gallium nitride (GaN) semiconductors. This transition is not merely incremental; it’s enabling electrical appliances to switch currents much faster, making them significantly more thermally tolerant and profoundly energy-efficient.

Major Original Equipment Manufacturers (OEMs) such as Hyundai, Toyota, and Tata are already enthusiastically equipping their high-performance EVs with SiC inverters. This strategic move aims to achieve a faster rise time for current, directly contributing to more responsive power delivery and, crucially, a substantial reduction in overall electricity consumption. These advanced inverters are pivotal in harnessing every watt of energy with unparalleled precision.

The groundbreaking nature of these new wide band-gap semiconductors extends far beyond just speed and efficiency. They are fundamentally designed to ensure certain electronic devices last considerably longer, primarily because there is significantly less heat production during operation. In turn, this translates to tangible benefits such as energy savings and a more compact, space-saving design, even when operating at very high frequencies, showcasing a paradigm shift in power model innovation.

Excitingly, startups like Chara Technologies and Log9 Materials are actively engaged in revolutionizing the electric vehicle industry with their powertrain-integrated controllers. These innovative systems seamlessly collaborate with the inverter, motor controller, and the battery management system (BMS), providing real-time information and cohesive control. This integrated approach optimizes every aspect of the powertrain, from energy flow to overall system responsiveness.

Beyond basic control, this new system architecture unlocks a suite of sophisticated functionalities. It’s not only incredibly beneficial for energy regeneration in scenarios where motors aren’t actively driving but also provides precise torque vectoring for all-wheel-drive EVs. What’s more, these systems can dynamically alter performance profiles based on ever-changing traffic or terrain conditions, and even feature adaptive drive control units that can adjust torque distribution across motors to maintain vehicle stability during critical traction loss—a feature of immense significance in the evolving landscape of autonomous and semi-autonomous driving.

Read more about: Understanding Electricity: Key Concepts for the Informed Consumer

10. **Next-Gen Battery Packs: Modularity and Sustainability**While battery chemistry continues to evolve, a parallel and equally crucial transformation is occurring in battery pack architecture. By 2025, the trend of modular and repairable battery packs has gained significant momentum in the market, marking a pivotal step towards greater sustainability and improved lifecycle management for electric vehicles. This shift acknowledges that batteries are long-term assets, and their design should reflect that.

Leading the charge in this innovative space are Indian companies such as Log9 Materials and Matter Energy, who are actively encouraging and developing modular battery solutions specifically tailored for electric two-wheelers and three-wheelers. These pioneering packs are engineered with the foresight that individual cells or entire modules can be exchanged as needed, crucially eliminating the requirement for the entire battery to be discarded when only a portion degrades or fails. This design philosophy promises substantial benefits in maintenance costs and resource conservation.

This modular approach is a game-changer for several reasons; by allowing for targeted repairs and replacements, it significantly decreases long-term maintenance costs for vehicle owners and operators. Furthermore, it dramatically extends the useful life of the battery pack as a whole, thereby reducing waste and lessening the environmental impact associated with frequent battery disposal. This commitment to repairability aligns perfectly with the broader sustainability goals of the EV industry.

Simultaneously, a distinct but complementary trend is seeing automakers developing innovative battery casings that transcend their traditional role, functioning seamlessly as structural parts for the vehicle chassis itself. This cutting-edge approach, known as “cell-to-pack” (CTP) or “cell-to-chassis” (CTC) configurations, represents a fundamental rethinking of how batteries are integrated into a vehicle’s design, moving beyond a simple enclosure.

The inherent advantages of CTP/CTC configurations are manifold and impactful. By directly integrating battery cells into the vehicle’s frame, these designs are associated with less excessive material use, as dedicated casings and support structures can be minimized or eliminated. This innovative integration also creates more opportunities for advanced thermal management and enhanced space effectiveness, optimizing both the performance and packaging of the entire electric vehicle architecture, making future EVs lighter, stronger, and more efficient.

The path ahead for sustainable electric mobility is incredibly dynamic, with innovations unfolding at every turn. From the heart of their motors to the swift flow of their charging currents, and the intelligent management of their thermal systems, EVs are constantly being refined. These advancements, coupled with smarter battery designs that emphasize modularity and structural integration, are collectively shaping a future where electric vehicles are not just efficient and powerful, but also genuinely eco-conscious and accessible for everyone. It’s an exciting journey, and these rare concepts are lighting the way to a greener, more sustainable decade on our roads.