The undercarriage of your truck is perhaps the most overlooked part of your vehicle, yet it endures the harshest conditions and demands diligent care. Often out of sight, this vital area houses critical components like the frame, suspension, axles, and essential brake and fuel lines. Neglecting it invites rust, a destructive force that silently eats away at your vehicle’s integrity.

Winter, especially, transforms road salt into your truck’s formidable adversary. As salt, snow, and moisture combine, they create an ideal environment for corrosion. This damages structural components, compromising both safety and long-term value. Rust isn’t just cosmetic; it can weaken crucial parts, leading to costly repairs and compromising road safety.

The good news is that preventing rust on your truck’s undercarriage is entirely within your control. With a proactive approach, you can shield your investment, extend its lifespan, and maintain its performance. This guide outlines essential strategies, from initial preparation to ongoing maintenance, ensuring your truck remains rust-free and resilient against the elements.

1. **Initiate with a Deep Undercarriage Clean**

Before winter descends, a thorough deep clean of your truck’s undercarriage is the primary defense against rust. This critical step removes accumulated dirt, grime, and any residual road salt. A truly clean surface ensures that subsequent protective coatings will adhere properly, forming a strong barrier against corrosion.

Use a high-pressure hose or a pressure washer to blast away embedded dirt, debris, and stubborn gunk. Focus intensely on vulnerable spots like wheel wells, the exhaust system, and lower frame rails, which are notorious magnets for corrosive materials. Apply full rinsing power here.

For persistent grime or greasy residues, integrate a degreaser or specialized car wash soap into your routine. These products break down tough deposits, making them easier to rinse away. Rinse the entire undercarriage thoroughly, leaving absolutely no soap residue behind.

Allow your truck to dry completely. Trapped moisture, even after contaminants are washed away, can ironically become a catalyst for rust if protective treatments are applied to a damp surface. A short drive afterward can speed up drying for every nook and cranny.

For those in rust-prone areas, an undercarriage cleaning attachment for your hose can be a wise investment. This tool facilitates reaching deep underneath your vehicle with ease, ensuring no area is left untouched. It’s a small expenditure that yields substantial returns.

Read more about: The 13 Critical Welding Defects That Can Turn Your Weight Bench Into a Money Pit: A Guide to Avoid Structural Failure

2. **Conduct Meticulous Rust Inspections**

With your truck’s undercarriage clean and dry, the next vital action is a detailed inspection for existing rust. Catching corrosion early is paramount; it prevents a minor issue from escalating into a costly structural repair. Consider this your vehicle’s annual health check-up for foundational integrity.

Understanding rust types guides your inspection. “Surface rust” appears as flaky, reddish-brown spots, the least severe and easiest to treat. More concerning is “scale rust,” indicating deeper penetration into the metal, appearing as pitted areas, requiring aggressive remediation.

The most severe, “penetrating rust,” means corrosion has eaten entirely through the metal, creating visible holes. If you discover this damage, consult a professional mechanic. Structural integrity may be compromised, demanding expert assessment and specialized repair techniques.

For minor surface rust, immediate action is key. Address this yourself by using a wire brush or sandpaper to scrub off the affected area, working down to bare metal. Once visible rust is removed, apply a rust converter. This neutralizes any remaining oxidation, preparing the surface for protective layers.

Remember, rust isn’t always obvious. Look for tiny scratches or nicks, common entry points for corrosion. Subtle dark spots in the paint on the underside or around fenders can also signal rusting metal beneath, warranting a closer look.

Read more about: Navigating the Road Ahead: Our Expert Ranking of the 14 Best-Selling Tires of 2025 for Unrivaled Longevity and Safety

3. **Apply Robust Rust-Proofing Undercoatings**

Once your undercarriage is clean and any existing rust addressed, the next crucial step is to apply a formidable shield against future corrosion. Utilizing a high-quality rust-proofing spray or undercoating is among the most effective preventative measures. These products create a durable barrier, sealing out moisture, road salt, and other harmful contaminants, stopping rust before it ever begins.

When selecting an undercoating, you’ll encounter several options. Rubberized undercoatings provide a thick, resilient layer excelling in protecting against salt and impact from road debris. They suit vehicles exposed to harsh winters and offer valuable sound-dampening qualities.

Oil-based rustproofing sprays are another popular choice, prized for their ability to penetrate deep into existing rust and effectively displace moisture. These sprays seep into tight joints, seams, and small crevices, providing a comprehensive protective film. They are often favored for ease of application and self-healing properties.

The application process is critical. Ensure the undercarriage is impeccably clean and dry, as residual moisture can compromise adhesion. Using a spray gun or aerosol can, apply the product evenly across all vulnerable areas. Prioritize crucial components like brake lines, wheel wells, and welded joints, aiming for a thorough, consistent coat.

After application, allow the undercoating to cure fully per manufacturer’s instructions, typically several hours to overnight. If DIY, always work in a well-ventilated area and wear appropriate protective gear to ensure personal safety.

4. **Equip Your Vehicle with Splash Guards and Mud Flaps**

While specialized undercoatings provide an excellent chemical barrier, physical protection is equally vital against undercarriage rust. Installing splash guards and mud flaps is a straightforward yet highly effective strategy to minimize direct impact from road salt, slush, and abrasive debris thrown up by your tires. These accessories serve as essential deflectors, safeguarding vulnerable areas like wheel wells and rocker panels.

The advantages of these additions are substantial. Splash guards and mud flaps significantly reduce corrosive elements directly striking your undercarriage. This impact is a major cause of wear, chipping away at protective layers and exposing bare metal. By intercepting these projectiles, they help preserve both your undercoating and the underlying metal structure.

Beyond rust prevention, these guards contribute to a cleaner undercarriage throughout winter. Less splashing means less accumulation of muddy, salty sludge, which traps moisture and accelerates corrosion. A cleaner undercarriage also simplifies maintenance and inspections, making routine efforts more efficient.

Furthermore, installing splash guards and mud flaps is generally an easy and cost-effective upgrade. Many truck models come with pre-drilled holes or accessible mounting points, allowing for straightforward DIY installation. This combination of low cost and high impact makes them an invaluable addition, complementing your broader rust prevention strategies.

Consider these accessories a crucial complement to your chemical rustproofing. They establish the initial physical barrier, deflecting the majority of the corrosive onslaught before it reaches areas fortified by undercoating. This comprehensive, dual-layer approach delivers superior defense, robustly safeguarding your truck’s undercarriage from winter road challenges.

Read more about: Unlock Major Savings: 15 Essential Car Maintenance Hacks That Can Save You Over $1000 Annually (Even on Brand New Models)

5. **Maintain a Regular Winter Washing Schedule**

Even with advanced undercoatings and protective accessories, road salt and grime are inevitable on your truck’s undercarriage during winter. This makes regular washing an absolute necessity for sustaining a rust-free vehicle. While washing in freezing temperatures might seem daunting, removing these corrosive elements is paramount.

The frequency of winter washes demands careful consideration. Ideally, wash your truck every one to two weeks, intensifying efforts after heavy snowfalls or when road salt trucks have been active. This consistent removal of salt and de-icers is critical because the longer these chemicals remain on metal surfaces, the greater their opportunity to initiate and accelerate oxidation.

When hand washing is hindered by adverse weather or time, opting for a touchless car wash is a smart alternative. Many modern car wash facilities feature an undercarriage rinse, incredibly beneficial for flushing away accumulated salt from hard-to-reach areas. These automated rinses offer a quick, effective way to neutralize corrosive agents before they can cause damage.

A crucial step after a winter wash is ensuring the undercarriage dries completely. Lingering moisture, even after salt is removed, can actively contribute to rust formation. After washing, consider taking your truck for a brief drive. The airflow generated during motion significantly helps evaporate residual water, leaving your undercarriage as dry as possible, diminishing new corrosion risk.

Extend meticulous cleaning to the entire vehicle’s exterior. Road salt clings to fenders, bumpers, and body panels, initiating rust in less obvious places. Employing a quality car-wash solution formulated to tackle salt and de-icers ensures your truck remains pristine and structurally sound, preserving appearance and long-term value through winter.

Read more about: The 15 Unstoppable Trucks: Engineering Excellence That Conquers 300,000 Miles and Beyond

6. **Ensure Constant Undercarriage Dryness**

Beyond cleaning and coatings, one of the most fundamental yet underestimated strategies for preventing rust is consistently minimizing moisture exposure. Rust cannot form without water and oxygen reacting with metal. By keeping your undercarriage as dry as possible, you directly interrupt the core corrosion process, making this a profoundly proactive defense.

Your parking habits play a significant role. Whenever feasible, park your truck in a dry, covered area, such as a garage or carport. This shields the undercarriage from dew, rain, and snow, preventing persistent moisture accumulation. For fleet operators, investing in enclosed storage or truck washes with heated drying systems yields substantial long-term benefits in rust control.

If you use a garage, consider a dehumidifier or moisture absorber. These devices help regulate ambient humidity, creating a drier environment that discourages condensation and lingering moisture on metal surfaces. This minor detail can make a considerable difference, particularly in regions prone to high humidity or frequent temperature fluctuations.

When your undercarriage inevitably gets wet—from a wash, puddles, or slushy roads—take steps to facilitate its drying. A short drive at moderate speeds can be remarkably effective. The airflow generated by motion helps rapidly evaporate water from all surfaces, including hidden crevices where moisture tends to linger, dramatically accelerating the drying process.

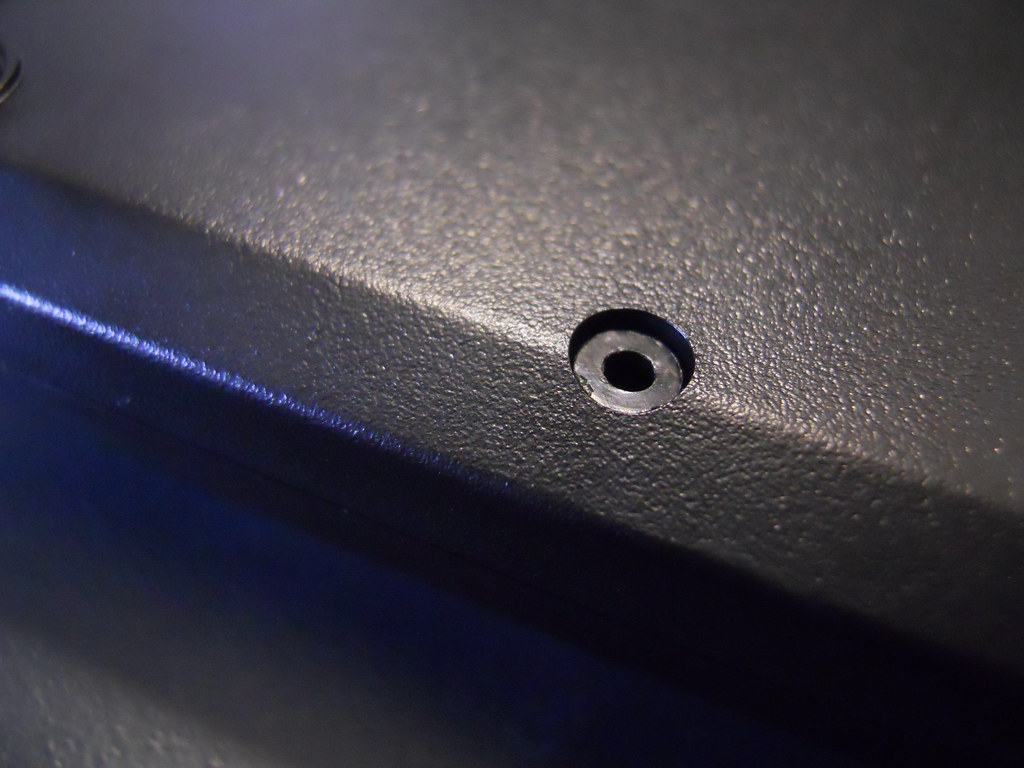

Crucially, consistently ensure all drainage holes and weep points on your undercarriage remain entirely clear and unobstructed. These apertures are designed to allow water to escape efficiently. Blockages, caused by leaves, dirt, or debris, can trap water, allowing it to pool and creating localized hotspots for accelerated oxidation. A swift check and clearing of these points with compressed air can avert significant water-related damage.

7. **Annual Reapplication of Rust Protection**

Rust-proofing is not a one-and-done solution; it necessitates ongoing vigilance. To ensure continuous, peak protection for your truck’s undercarriage, reapplying undercoating or rust-proofing spray annually is a non-negotiable step. Like any protective barrier, these coatings are subjected to constant wear from road debris, chemical exposure, and environmental factors, causing their effectiveness to gradually diminish.

It is vital to recognize indicators signaling the need for a fresh application. If you observe your existing undercoating appears visibly worn, thinned, or flaking in specific areas, its protective integrity is compromised. Similarly, the appearance of any new rust spots, even minor ones, signals that your current defense system is failing and requires immediate reinforcement.

Even without obvious signs of wear, a reliable guideline is to reapply protective coatings at least once annually. Consider this an annual “booster shot” for your vehicle’s immunity against corrosion. This consistent, routine maintenance guarantees a continuous, unbroken barrier against the onslaught of harsh winter road conditions and other corrosive agents your truck encounters throughout the year.

The most opportune time to schedule reapplication is in the fall, ideally just prior to the first snowfall or when local road crews begin applying de-icing agents. This strategic, proactive timing ensures your truck is fully armored before it confronts its most challenging environmental threats. Being adequately prepared provides your undercarriage with the strongest possible defense when critically needed.

Certain rust-proofing products, particularly many oil-based sprays, are formulated with the expectation of annual reapplication for sustained, optimal performance. These products often possess inherent “self-healing” properties, meaning they can actively creep into newly formed micro-fissures and continuously displace moisture. Regular reapplication ensures these crucial benefits remain consistently active, creating a dynamic shield that adapts effectively to ongoing exposure and significantly extends your truck’s functional lifespan.

Now that we’ve covered the foundational steps to safeguard your truck’s undercarriage, it’s time to delve into more advanced defense strategies. These proactive measures and long-term solutions are designed to ensure optimal longevity for your vehicle, moving beyond basic protection to comprehensive resilience against corrosion.

Read more about: Navigating the Latest CDC and Health Guidelines: Your Essential Guide to Flu and COVID-19 Vaccines This Season

8. **Proactively Address Common Rust-Prone Areas**

Even with consistent maintenance, certain parts of your truck’s undercarriage are inherently more vulnerable to rust. Keeping a keen eye on these critical spots and understanding their unique susceptibilities allows for targeted prevention and early intervention, saving you from more significant repairs down the line.

The exhaust system, including pipes and mufflers, is particularly susceptible to rust. Constant exposure to varying temperatures, water, and road salt makes these components highly prone to corrosion. Regular cleaning and inspection of these parts can significantly extend their lifespan and prevent premature failure.

Thin metal lines, such as brake lines and fuel lines, are another major area of concern. These vital conduits can corrode quickly if not adequately protected, leading to serious safety hazards. Compromised brake lines can result in fluid leaks and brake failure, while rusted fuel lines increase the risk of hazardous fuel leaks. Ensuring these lines are coated and frequently inspected is paramount.

Wheel wells and fenders are notorious hotspots where road salt and moisture accumulate heavily. The constant kicking up of debris and corrosive elements by your tires makes these areas prime targets for rust. Additionally, essential structural components like frame rails and rocker panels can weaken significantly if allowed to rust, compromising the vehicle’s overall integrity and safety.

Read more about: The 15 Unstoppable Trucks: Engineering Excellence That Conquers 300,000 Miles and Beyond

9. **Implement Specialized Rust-Proofing Technologies**

While traditional undercoatings provide an excellent barrier, the evolution of rust prevention offers even more sophisticated options. Beyond the widely used rubberized and oil-based sprays, you might consider newer technologies that offer enhanced protection, moving from a passive shield to an active defense.

Electronic rust inhibitors, for example, represent a modern approach to corrosion control, utilizing an electrical current to prevent rust formation. While their effectiveness can be a topic of debate among experts, they showcase an innovative effort to tackle the problem from a different angle, complementing physical barriers rather than replacing them entirely.

A highly effective and proactive solution comes in the form of specialized oil undercoatings, such as NH Oil Undercoating®. This unique blend of highly refined petroleum and rust inhibitors is engineered to guard against rust and corrosion on all metal surfaces. It actively works to eliminate moisture that carries salt, dirt, and other pollutants from the metal, providing long-lasting protection for your vehicle.

NH Oil Undercoating protects metals by displacing moisture and treating surfaces with highly effective corrosion inhibitors. These inhibitors form an adsorbed (bonded) layer on the metal, acting like tiny umbrellas that shield surfaces from water molecules. This creates a non-conductive material, preventing the external circuit needed for electrolysis and stopping corrosion in its tracks, even protecting electrical connections from “greening.”

After application, this undercoating is designed to lift and remove contaminants, moisture, and even some surface rust, penetrating to the good metal beneath. It establishes an ultra-thin, molecularly bonded protective film that creeps deep into cracks, crevices, spot welds, seams, and folds, areas where moisture often pools and is otherwise unprotected. For an added bonus, products like NH Oil Undercoating® Back N Black not only protect but also improve the appearance of any metal surface, giving your undercarriage a refreshed look while ensuring robust defense.

10. **Master Advanced Undercarriage Cleaning Methods**

Regular cleaning is the cornerstone of rust prevention, but employing advanced cleaning techniques can dramatically enhance its effectiveness, especially for those managing larger vehicles or fleets. Moving beyond a simple hose, these methods offer a more thorough and efficient way to combat stubborn grime and corrosive buildup.

The “touchless” cleaning method is a highly efficient and effective way to clean the entire vehicle, including the undercarriage. This involves a two-step process: first, spraying a low pH pre-soak with a pressure washer, which excels at neutralizing minerals like road salt and breaking down surface rusting. After a short dwell time, a high pH soap is applied directly onto the low pH solution. This second step neutralizes the low pH and targets oils and grease, completing the process before a final rinse.

Utilizing touchless detergents for undercarriage washing allows for targeted cleaning. A low pH detergent effectively neutralizes road salts and de-icing solutions, while an alkaline high pH detergent is more effective at removing heavy greases and oils. This dual-action approach can simplify inspections and parts replacement by ensuring a truly clean surface, though it’s important to have equipment that can reach all angles of the undercarriage.

Dedicated undercarriage cleaners offer another excellent solution, particularly because they can be used without needing to drive your truck onto a platform. These tools are designed to spray water and detergents upward, directly targeting the underside of your vehicle. While they provide a convenient way to keep the undercarriage clean, they might require switching between equipment if you’re also cleaning the rest of the vehicle, though quick-connect parts can streamline this process.

Read more about: Beyond the Shine: Unmasking the Realities of Vintage Convertible Ownership and How to Conquer Common Maintenance Headaches

11. **Strategic Driving Habits to Minimize Exposure**

Sometimes, the simplest changes in your driving routine can offer significant protection against rust. Being mindful of where and when you drive can substantially reduce your truck’s exposure to the most aggressive corrosive agents, particularly during challenging winter months.

One crucial habit to adopt is avoiding large puddles in winter. Puddle water is not just dirty; it’s a potent cocktail of road salt and grime that splashes up into the undercarriage. This salty water then clings to metal surfaces, accelerating the formation of rust in hidden crevices and vulnerable areas. Steering clear of standing water helps keep your undercarriage drier and cleaner.

Limiting your driving immediately before, during, and after winter storms is another highly effective strategy. During these periods, road de-icers are at their highest concentrations, blanketing roadways with corrosive chemicals. By minimizing exposure to these peak concentrations, you reduce the opportunity for salt brine to adhere to and begin corroding your truck’s vital components.

Read more about: Unlock Maximum Range: 15 Essential Hacks for Your EV in Freezing Winter Conditions

12. **Ensure Unobstructed Drainage Points**

While it might seem like a minor detail, maintaining clear drainage holes and weep points on your truck’s undercarriage is a surprisingly impactful rust prevention strategy. These small apertures are specifically designed to allow water to escape efficiently, preventing corrosive pooling.

Blockages, often caused by accumulated leaves, dirt, mud, or other road debris, can turn these drainage points into traps. When water cannot escape, it collects in pockets, creating localized hotspots where moisture is constantly present. This stagnant water then accelerates oxidation, leading to rust formation in areas that should otherwise remain relatively dry.

Make it a routine to check these drainage holes, typically found around the edges of the hood and trunk, along the bottoms of doors, and on frame rails and behind rocker panels. Using compressed air to blow out any obstructions is a quick and effective way to ensure proper water flow. This simple, proactive step can avert significant water-related damage and contribute greatly to your undercarriage’s longevity.

Read more about: Decoding the Drips: Your Essential Guide to Diagnosing, Fixing, and Preventing Coffee Maker Leaks

13. **Understand and Mitigate Specific System Vulnerabilities**

Beyond the general undercarriage, certain critical systems have unique vulnerabilities to rust that demand specific attention. Recognizing these susceptible components and implementing targeted preventative measures is essential for maintaining your truck’s operational integrity and safety.

The air suspension system, along with leaf spring hangers and slack adjusters, are all highly prone to corrosion. Rust buildup on these components can lead to serious issues: springs can crack, airbags can chafe, and air tanks can corrode from the inside out, particularly if moisture isn’t properly drained from the air system. Such failures can compromise ride quality and safety.

A vital actionable tip for preventing this internal corrosion, especially in air systems, is to bleed your air tanks daily. This simple practice removes accumulated moisture, which is a major contributor to rust inside these critical components. This is particularly important during humid summers or cold mornings, as temperature fluctuations can lead to condensation.

Brake components, including S-cam bushings and pushrods, are also highly susceptible to rust. When exposed to corrosive elements, these parts can seize, leading to brake lag or, in severe cases, complete brake failure. Regular inspection, cleaning, and protection of these specific brake system parts are crucial for reliable and safe operation.

Read more about: Understanding the Unraveling: 14 Critical Mistakes Behind the Collapse of Historical Empires

14. **Leverage Professional Inspections and Long-Term Strategies**

Even with diligent DIY efforts, there comes a point where professional expertise or advanced planning becomes indispensable for optimal undercarriage longevity. Integrating professional insights and long-term strategic choices can fortify your truck against the most aggressive forms of corrosion.

For early-stage, minor corrosion, immediate action can often prevent escalation. You can sand the rusted area down to bare metal using a wire brush or grinder, then apply a rust converter to neutralize any remaining oxidation. Crucially, always seal the treated area with primer and repaint it using a durable enamel or industrial coating. Remember, it’s a golden rule to never cover active rust with paint or undercoating; it will only mask the problem until the metal beneath inevitably fails.

When rust reaches the stage of “penetrating rust,” creating visible holes, it’s time to consult a professional mechanic. This level of damage often compromises structural integrity and demands expert assessment and specialized repair techniques. Professionals can also assist in implementing long-term strategies, such as retrofitting or replacing components with rust-resistant materials like galvanized or rust-resistant alloys, which offer superior protection.

Read more about: Unlocking Dealership Gold: 15 Proven Strategies Car Dealers Use to Maximize Profit on Every Sale and Secure Their Future

Ultimately, a structured preventive maintenance (PM) schedule, including full undercarriage inspections, especially in the first and fourth quarters when road conditions are harshest, is a cornerstone of long-term defense. Coupled with leveraging professional help when needed and choosing rust-resistant parts, these proactive measures, from initial cleaning to advanced coatings and smart driving habits, ensure your truck remains a reliable, rust-free workhorse for years to come. Protecting your undercarriage today is truly the smartest investment for avoiding costly repairs and ensuring your vehicle’s enduring value tomorrow.