In a world that demands speed and efficiency, few industries have experienced as profound a transformation as the dairy industry. From the serene pastures where milk is collected to the bustling processing plants that prepare it for our tables, every step of the dairy supply chain serves as a testament to relentless innovation. This is not merely about delivering a product; it is about a dynamic evolution propelled by technology, consumer demand, and a profound understanding of market trends.

At its core, a dairy represents far more than just a physical location. As the definition specifies, it is “a place where milk is stored and where butter, cheese, and other dairy products are manufactured, or a place where those products are sold.” This comprehensive description encompasses everything from a simple room designated for milk storage to an expansive, highly sophisticated facility. In the United States, the term “dairy” can even denote an entire farm or a specific section of a mixed farm focused on milk production for human consumption, with milk sourced from a diverse range of animals such as cows, buffaloes, goats, yaks, sheep, horses, or camels.

Gaining an insight into the nuanced terminology of the dairy sector offers a captivating glimpse into its global reach. While in the U.S., an entire farm is commonly referred to as a “dairy,” the area where milk is collected from cows is often termed a “milking parlor” or simply “parlor.” Smaller dairies might still utilize “stanchion barns,” but larger operations have adopted specialized setups. After collection, milk finds its temporary abode in the “milk house” before being transported to a “dairy plant”—also known simply as a “dairy”—for processing.

This intricate process underscores a remarkable journey of adaptation. In New Zealand, for instance, milking areas are also known as “milking parlours” or, historically, “milking sheds.” These can range from a practical “herringbone shed” to an incredibly efficient “pit parlour.” The evolution of parlor design, transitioning from basic barns to large rotary structures, highlights the industry’s unwavering commitment to handling the throughput of cows with unparalleled efficiency. For some smaller operations, particularly in Europe, the farm itself may function as a processing plant, transforming its own milk into artisanal products such as butter, cheese, or yogurt—a delightful homage to traditional methods of specialist milk production.

The history of the dairy industry is as rich and enduring as milk itself. For thousands of years, milk – producing animals have been an integral part of nomadic subsistence farming. Herders moved along with their animals, establishing a symbiotic relationship centered on protection and sustenance. In more recent agricultural societies, owning dairy animals has been a common practice, with milk harvested for domestic and local village consumption—a quintessential cottage industry.

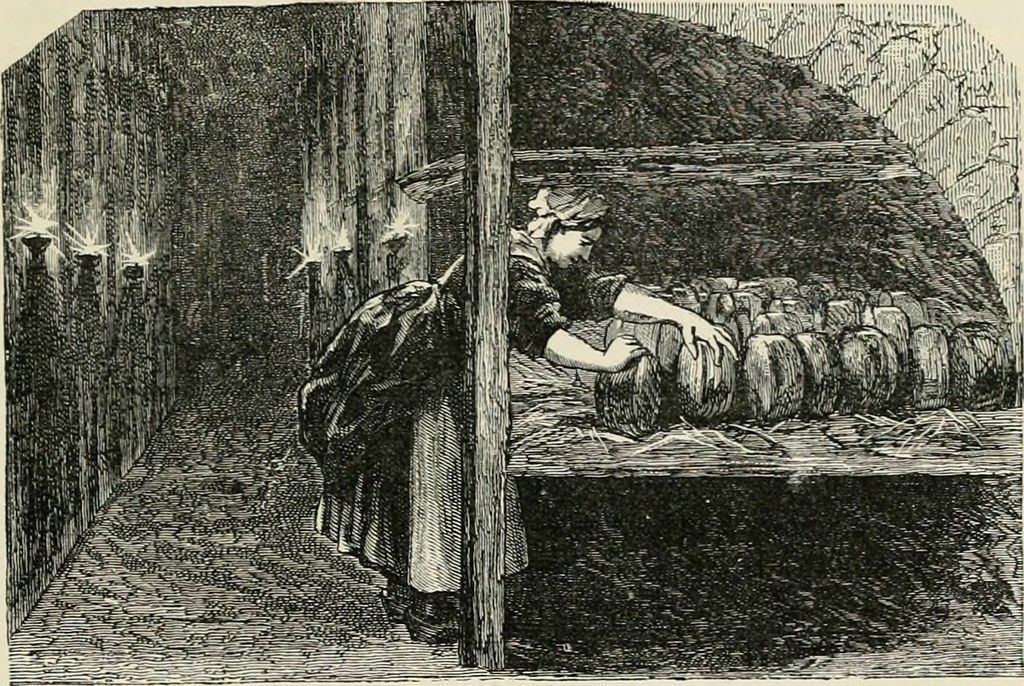

These early operations were typically small, with herds easily managed through hand – milking, usually performed by a “dairymaid” or “dairyman”. The very word “dairy” harks back to Middle English “dayerie” and Old English “dæge”, meaning “female servant” or “kneader of bread”, illustrating the deeply personal and manual nature of early milk production. The entire milking process for a small herd often took less than an hour, with about ten animals per milker.

The advent of industrialization and urbanization spurred a dramatic shift, transforming the milk supply into a commercial industry. This era witnessed the specialized breeding of cattle specifically for dairy purposes, setting them apart from animals raised for beef or as draught animals. Initially, more people were employed as milkers, but the undeniable march of progress soon led to mechanization, with machines designed to revolutionize the milking process.

Historically, the proximity of milking and processing was a given: both took place directly on the dairy farm. Hand – milking, which is still practiced on a few small farms today, involves a rhythmic, progressive squeezing of the teat, directing milk into a bucket. This traditional method, often performed with the milker seated on a low stool, highlights the intimacy of early dairy farming. Cows would stand in the field or paddock and were eventually tethered for stability as humans learned to adapt practices for greater yield.

Read more about: H-E-B’s Strategic Investment: Expanding Curbside Convenience and Redefining the Texas Grocery Experience

Today’s dairy industry is a marvel of organization and scale, though its structure varies widely across the globe. In major milk – producing nations, wholesale markets dominate the distribution. Farmers’ cooperatives play a colossal role, particularly in Ireland and Australia. In the United States, for example, in 2002, 196 farmers’ cooperatives sold an astounding 86% of the nation’s milk, a remarkable consolidation from the 2,300 cooperatives active in the 1940s, with just five accounting for half of that volume.

This concentration is not just a U.S. phenomenon; dairy processing has become increasingly centralized in major producing countries, boasting fewer but larger and significantly more efficient plants that are operated by fewer workers. This trend is especially pronounced in the United States, Europe, Australia, and New Zealand. While beneficial for manufacturing costs, this technological shift often necessitates long – distance transportation, which, as the context notes, can “increase the environmental impact”, prompting continuous innovation in logistics.

Government intervention has also shaped the market, particularly in the 20th century. Landmark legislation such as the Capper–Volstead Act of 1922 provided a limited antitrust exemption for U.S. dairy cooperatives. The 1930s witnessed the introduction of state price controls and Federal Milk Marketing Orders, which continue to operate today. Such regulations underscore the strategic importance of milk supply.

The strategic location of dairy processing plants is another fascinating aspect of industry efficiency. Plants handling liquid milk and products with a short shelf – life, such as yogurts, creams, and soft cheeses, are typically located on the outskirts of urban centers, keeping them close to consumer markets for swift delivery. Conversely, facilities manufacturing items with a longer shelf – life, like butter, milk powders, and hard cheeses, tend to be situated in rural areas, closer to the raw milk supply. While most large plants now specialize, some in Eastern Europe still produce a wide range of products, a legacy of former centralized market concepts.

Milk supply contracts are a critical cog in the global dairy machinery, which is particularly evident in the European Union. Article 148 of Regulation 1308/2013 empowers member states to mandate written contracts between farmers and raw milk processors, ensuring transparency and stability. Countries like France and Spain have adopted compulsory written milk contracts, and their impact is continually evaluated, as seen in the Scottish Government’s 2019 analysis. The UK’s voluntary code of best practice and Australia’s mandatory dairy code of conduct further underscore the global commitment to securing and streamlining milk supply.

The sheer scale of modern dairy farming is truly impressive. As herd sizes have swelled, the need for efficient milking infrastructure has become paramount. Cows are now brought to specialized sheds or barns equipped with milking stalls, a far cry from open – paddock milking. While one skilled worker could once milk up to 20 cows by hand, the objective now is to maximize grazing time for the animals, limiting the twice – daily milking routine to a maximum of one and a half hours each time. The physical milking of a cow takes only about 10 minutes per day, regardless of herd size.

The relentless pursuit of efficiency on the farm has led to sophisticated setups. Modern dairy operations require efficient milking machines, purpose – built sheds, advanced milk – storage facilities (vats), bulk – milk transport, and robust shed – cleaning capabilities. Furthermore, optimized methods for moving cows from pasture to shed and back have become crucial. Addressing animal health challenges has also been integral, with innovations such as improved veterinary medicines and the establishment of veterinary clubs, where groups of farmers collectively employ a veterinarian to focus on preventative care and year – round animal well – being.

The modern dairy cow is a champion producer, typically in milk for 300 to 320 days a year. While some small herds might transition to once – a – day milking towards the end of their cycle, this practice is becoming more widespread in New Zealand for its combined benefits of profitability and lifestyle. This approach, in which a partial fall in milk yield is offset by labor and cost savings, contrasts sharply with intensive U.S. farm systems that milk cows three or more times daily to achieve higher yields per cow and lower marginal labor costs. Farmers supplying liquid milk often manage their herds to ensure year – round production, which is achieved through precise mating schedules that ensure a rotational peak production across the herd.

Northern hemisphere farmers, who often keep cows in barns for most of the year, typically manage their herds for continuous milk production to ensure a steady income. In the southern hemisphere, cooperative dairying systems often account for a two – month period of lower productivity, leveraging maximum grass and milk production during spring. This also provides cows with a crucial rest during late pregnancy. Artificial insemination (AI) has become commonplace in high – production herds, serving as a powerful tool for the genetic improvement of female offspring while also reducing the need for potentially dangerous bulls on the farm. Male calves are typically raised for beef or veal or, in some cases, culled due to a lack of profitability.

The journey of milk continues beyond the farm gate, entering the realm of industrial processing. Dairy plants receive raw milk and employ sophisticated processes to extend its marketable life and ensure safety. Two primary methods are crucial: heat treatment, which guarantees safety for human consumption and prolongs shelf – life, and dehydration, which creates storable products such as butter, hard cheese, and milk powders. These processes are vital for bringing diverse dairy products to consumers quickly and reliably.

Read more about: H-E-B’s Strategic Investment: Expanding Curbside Convenience and Redefining the Texas Grocery Experience

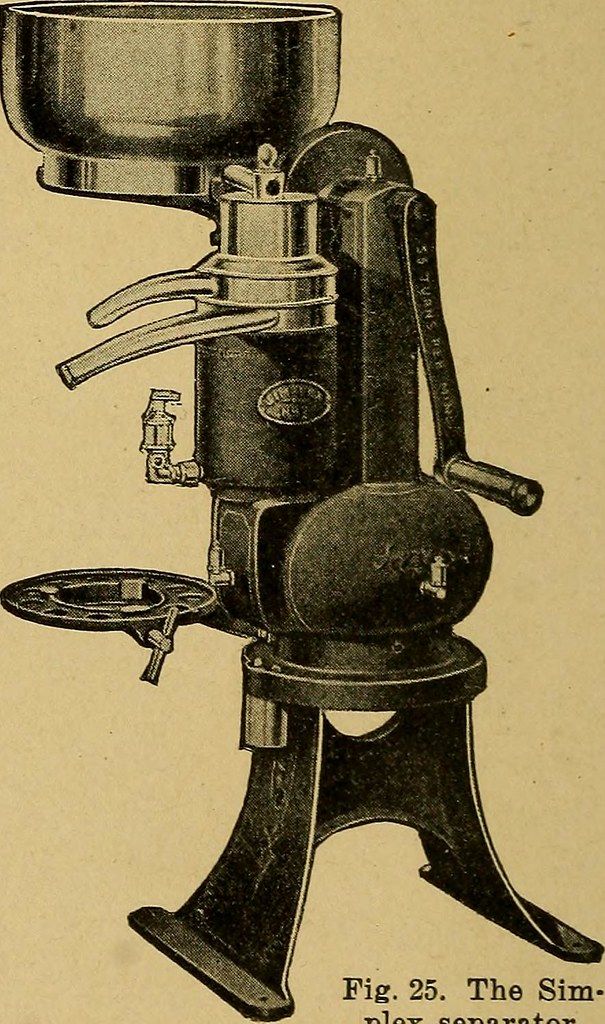

The separation of milk into cream and skim milk by colossal machines is a cornerstone of modern processing. Cream, depending on its thickness and suitability for culinary uses, is transformed into a variety of consumer products, which are tailored to local demand. A significant portion of cream, particularly that from New Zealand and Australian factories, is churned into butter. This meticulous process involves coagulating fat globules, washing the butter mass, and sometimes salting it to improve its keeping qualities. The leftover buttermilk is then directed to further processing, ensuring that no valuable resource goes to waste.

What remains after cream extraction is skim milk, which forms the basis for a range of popular products. A precise portion of cream is returned to create low – fat (semi – skimmed) milk, and by varying the amount of cream, producers can craft a spectrum of low – fat options. Whole milk is also standardized by adding cream back to skim milk. Furthermore, producers enhance these products with additions such as calcium, vitamin D, and various flavorings, all of which are designed to appeal to the modern consumer’s palate and nutritional needs.

Casein, the predominant phosphoprotein in fresh milk, demonstrates the remarkable versatility of dairy. Beyond being a common filler in human foods such as ice cream, casein serves as a valuable raw material for manufacturing diverse products such as fabric, adhesives, and plastics. This highlights the dairy industry’s broader impact, extending far beyond the food sector into industrial applications.

Read more about: Ever Wondered Which Foods Really Boost Your Brain Health? Prepare to Be Amazed

Cheese, a beloved dairy staple, is another testament to milk’s transformative potential. Whole milk is meticulously processed to form curds, which are then compressed, aged, and stored to create the vast array of cheeses that we enjoy. In some countries, where processing without pasteurization is legally permitted, traditional methods leverage naturally occurring bacteria to craft unique cheeses. For those with lactose intolerance, certain traditionally made hard and soft – ripened cheeses can be more digestible, as fermentation and higher fat content contribute to a significant reduction in lactose levels. Some traditionally made Emmental or Cheddar, for instance, might contain only 10% of the lactose found in whole milk, with prolonged aging further reducing the content to virtually nothing.

Whey, once largely considered a waste product and primarily fed to pigs, has seen a dramatic resurgence. Beginning around the 1950s and accelerating since the 1980s, lactose and a host of other valuable products, mainly food additives, have been extracted from both casein and cheese whey. This transformation exemplifies the industry’s commitment to maximizing resource utilization and minimizing waste. Similarly, yogurt production mirrors cheesemaking, with the process halted before the curd solidifies, creating a creamy, tangy delight.

Milk also undergoes various drying processes to be converted into powders. Whole milk, skim milk, buttermilk, and whey products are all dried into powdered forms for both human and animal consumption. Reconstituted powdered milk offers a cost – effective and long – lasting alternative to fresh milk, given that milk is approximately 88% water and powders significantly reduce transportation costs and extend shelf life for several months. Beyond these common products, specialized milk derivatives like Kumis, traditionally made from mare’s milk, are produced commercially in Central Asia, while India, a global leader in milk production, boasts a rich array of traditional milk – based products.

The efficiency of milk collection and distribution has been revolutionized. What began with milking and processing directly on the farm evolved into separating cream on the farm for butter production elsewhere, a strategy designed to reduce the high cost of transport for bulky whole milk, considering the primitive trucks and poor roads at that time. Early milk transportation methods, from lidded ‘pails’ to conical milk churns and large railway containers, showcase a relentless drive to move the product more efficiently.

Read more about: Ever Wondered Which Foods Really Boost Your Brain Health? Prepare to Be Amazed

The late 1950s marked a pivotal moment with the widespread adoption of refrigeration and improved road transport. Today, farmers temporarily store milk in large refrigerated bulk tanks, from which it is efficiently transported by truck to central processing facilities. This logistical achievement ensures freshness and quality over longer distances. In some European countries, notably the United Kingdom, milk is even delivered directly to customers’ homes by a milk float, a nod to enduring tradition combined with modern logistics. The astounding increase in milk production per cow in the U.S.—from about 5,300 pounds per year in 1950 to over 23,000 pounds per year for the average Holstein cow in 2019—is a testament to advancements in breeding, nutrition, and milking technology.

The development of milking machines has been a game – changer, extracting milk with unprecedented efficiency and hygiene. Patented as early as 1907, these machines apply a continuous vacuum to create a pressure difference across the teat canal, massaging the milk out, while also helping to keep the machine securely attached. Atmospheric air is periodically admitted into a pulsation chamber, allowing the liner to collapse and relieve tissue congestion—a sophisticated mechanism that mimics natural suckling. The entire system keeps the milk enclosed and safe from external contamination, with rigorous automated washing procedures ensuring cleanliness and compliance with food – grade material regulations.

Modern milking sheds are a marvel of engineered throughput. Bail – style sheds, an early evolution from open – paddock milking, confine cows in stalls, allowing a milker to work efficiently. These setups, with pairs of bails for machine milking, could process about 50 cows an hour with one person. While efficient, the risk of transmitting infection between cows led to innovations in disinfection.

Herringbone milking parlors have revolutionized efficiency further. Cows line up almost perpendicular to a central pit where the milker works, resembling a fishbone. Cups are applied from the rear, enabling high throughput; large herringbone sheds can efficiently milk up to 600 cows with two people. Swingover parlors, a cost – effective variant, utilize a single set of cups shared between two rows of cows, allowing for a steady flow of up to 100 cows per person.

For truly massive herds, rotary milking sheds, also known as rotary milking parlors, represent the pinnacle of efficiency. These consist of a turntable with 12 to 100 individual stalls, rotating at a rate that enables a cow to be fully milked in one turn. An operator attaches the cups as the cow steps on, and an automatic device removes them as the cow leaves, making it possible to milk over a thousand cows with remarkable speed. The advent of automatic or ‘robotic milking’ sheds in various countries has elevated this efficiency to the next level. These systems permit cows to voluntarily present themselves for milking at any time, with robot arms cleaning teats and applying equipment, all controlled by sophisticated computer software. This voluntary milking (VM) method truly obviates the need for constant human presence during the milking process.

Beyond the milking itself, supplementary accessories in sheds further optimize operations. Feed boxes linked to ear tags facilitate precise, individualized rationing of supplements, ensuring each cow receives tailored nutrition based on her production and lactation stage. Holding yards equipped with powered gates keep cows moving efficiently into the shed. Water, a vital commodity, is managed through pumps and reservoirs, with innovations even enabling heat transfer from milk to warm water, demonstrating ingenious resourcefulness.

Temporary milk storage is a critical step in preserving freshness and quality. Milk is transported by airflow or mechanical pump to a nearby vessel, then cooled by a heat exchanger before being stored in large, refrigerated bulk tanks until collection for processing. This efficient chilling system is of paramount importance in maintaining milk’s integrity.

Waste disposal and wastewater management are increasingly becoming vital considerations in the modern dairy industry, especially in countries where cows graze outdoors throughout the year. Concentrated animal waste from milking sheds is either liquefied or maintained in a solid state, often being returned to farmland as organic fertilizer, thereby emphasizing sustainable practices. In processing factories, the primary waste is washing water, which undergoes treatment, often through composting, and is subsequently spread on farm fields.

Historically, whey was simply discarded or used as feed for pigs. Today, stringent management of dairy wastewater—comprising material losses, equipment wash effluents, and sanitary wastewater—entails equalization, neutralization, and physical separation, followed by biological treatment. Cheese whey, with its high biological oxygen demand (BOD) values, is treated in anaerobic digesters or processed through membranes to recover valuable proteins. While large – scale land application of milk waste can pose problems due to soil pore blockage, other methods, such as solidification for landfill disposal or discharge into wastewater treatment plants or sanitary sewers, are also utilized, reflecting a nuanced approach to environmental stewardship.

The industry’s commitment to public health remains unwavering, with rigorous measures implemented to prevent the transmission of diseases. Unsanitary conditions heighten the risk of bacterial contamination, rendering proper sanitation practices and pasteurization indispensable. Many countries mandate government supervision and regulations to ensure that dairy products reach consumers safely. Diseases such as Leptospirosis, Cowpox, Tuberculosis, Brucellosis, and Listeria, historically associated with dairy, are now rare or have been eradicated in many regions owing to vigilant testing, culling of infected animals, and strict hygiene protocols. Although links between Crohn’s disease and M. paratuberculosis in pasteurized milk have been proposed, the industry continuously conducts research and implements safety measures.

As the dairy industry continues to progress, it encounters evolving challenges, including ethical considerations regarding animal rights. Segments of the population, including vegans and many Jains, raise objections to dairy production, citing concerns over animal welfare and environmental impact. Their perspective, often viewing dairy as part of what they term the “animal–industrial complex,” underscores the ongoing societal dialogue about the ethics of food production. The industry, while continuously striving for efficiency, also engages in these discussions, seeking to innovate responsibly and address concerns about the well – being of the animals.

The dairy industry serves as a fascinating case study in continuous improvement and adaptation. From ancient nomadic practices to the sophisticated, computer – controlled robotic milking parlors of the present day, its development journey has been characterized by an unrelenting pursuit of speed, efficiency, and accessibility. The determination to supply high – quality, safe, and diverse dairy products to consumers across the globe, ranging from the freshest liquid milk to the most complex cheeses and powders, is stronger than ever before. It is a dynamic and innovative sector that persists in optimizing its processes, demonstrating that even the most ancient food source can be ceaselessly modernized to meet the requirements of a fast – paced world, thereby ensuring that fresh, wholesome dairy products will remain a staple in our lives for generations to come.