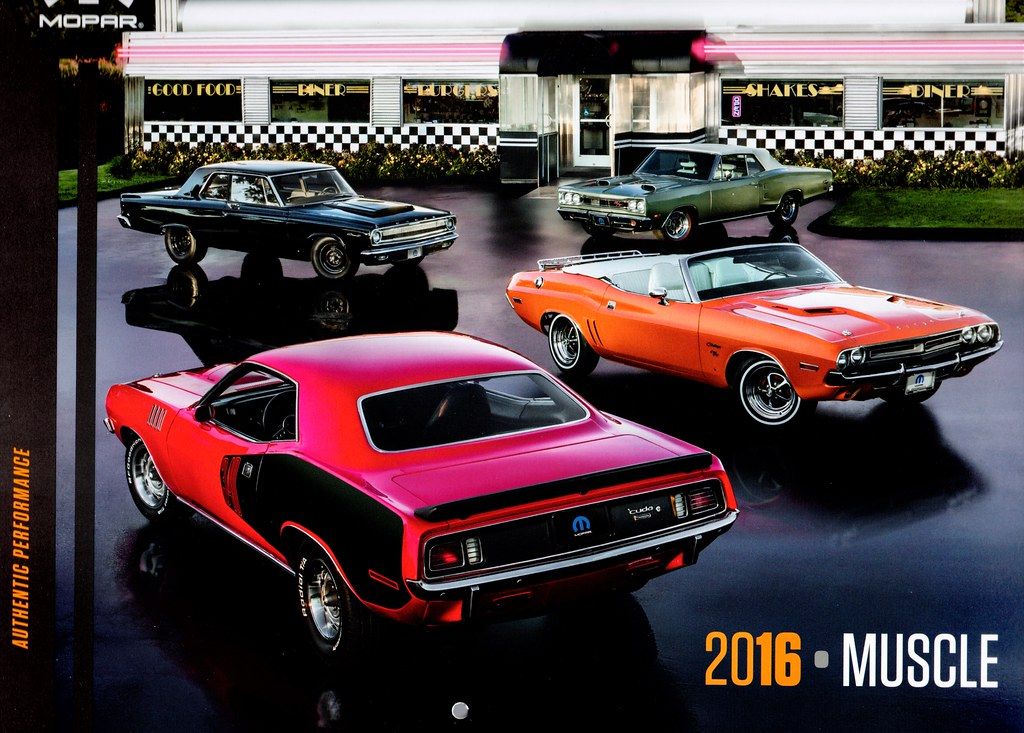

For any true gearhead, the mere mention of the 1960s and early 1970s conjures a symphony of unbridled power and a visceral connection to the road that arguably remains unmatched. This was an era where raw, mechanical might wasn’t just admired; it was the very essence of American motoring. Muscle cars, propelled by their gargantuan big block engines, didn’t just dominate the roads; they sculpted a culture, leaving an indelible mark on enthusiasts and setting benchmarks that continue to echo in conversations about automotive legacy.

It was a glorious time when Detroit, at the heart of it all, was throwing out monster V8 engines like freebies, each one capable of shaking pavements and rattling windows. From Chevrolet’s legendary 454 to Ford’s 429 Cobra Jet, and Chrysler’s monstrous 426 Hemi, these powerhouses cranked out crazy horsepower and torque figures, promising an intoxicating blend of speed, sound, and a driving experience that felt truly alive. The sheer scale and ambition of these machines fostered a passion for performance that defined a generation of drivers.

However, this golden age, rich with chrome, carbs, and compression ratios over 10:1, was not destined to last indefinitely. A confluence of legislative changes, economic pressures, and evolving consumer preferences began to reshape the automotive landscape, initiating a gradual but undeniable shift away from these magnificent, gas-guzzling behemoths. Yet, even as external forces conspired against them, the underlying philosophy of building engines with durability and raw capability in mind set a standard that, for many, modern engineering still strives to replicate.

1. **The Era of Dominant V8 Powerhouses** The automotive landscape of the 1960s and early 1970s was a vibrant testament to American ingenuity and a fervent horsepower war among manufacturers. Everywhere one looked on the road, it was all V8 powerhouses, an undisputed reign of engines designed for maximum impact. Enthusiasts of all ages could acquire vehicles with substantial power and captivating styling without requiring exorbitant sums of money, a dynamic that birthed automotive legends.

Chevy’s legendary 454, Ford’s 429 Cobra Jet, and Chrysler’s monstrous 426 Hemi stand as titans of this period, each cranking out horsepower and torque figures that were nothing short of crazy for their time. These engines were not merely mechanical components; they were central characters in a story of American ambition, capable of shaking pavements and rattling windows with their immense output. For any gearhead, it truly must have been a great time to be alive, offering the chance to simply sit behind such raw, untamed power.

This period fostered an unparalleled enthusiasm for performance vehicles, characterized by the visceral and emotional aspects of driving. Cars like the Dodge Charger R/T, Chevelle SS, and Plymouth ‘Cuda became instant icons, and even brands such as Buick and Mercury eagerly joined the fray, pushing the boundaries of what was possible in street-legal machines. The legacy of these vehicles and their engines continues to resonate today, with classic muscle cars from this era commanding tremendous prices on the market, a testament to their enduring specialness.

Read more about: Luka Doncic’s Epic Ride: An Inside Look at the Mavericks Superstar’s Awesome Car Collection!

2. **The Clean Air Act of 1970: The First Major Blow** Just as the horsepower war reached its peak, a significant legislative change emerged, drastically altering the trajectory of American automotive engineering. In 1970, everything took a drastic turn with Congress, through the Environmental Protection Agency (EPA), amending the Clean Air Act. This pivotal legislation aimed to tighten up emissions regulations, a necessary step given the long-standing smog problem that was clouding most U.S. cities at the time, posing serious environmental and public health concerns.

While undoubtedly necessary for public welfare, this act delivered a huge blow to Detroit’s automotive industry. Carmakers, who had been freely producing monster V8 engines renowned for their power and presence, suddenly faced a new reality. The new laws demanded significant changes, requiring automakers to cut down smog and other pollutants by an ambitious 90%. This meant radical adjustments to engine displacement, exhausts, compression ratios, and carburetors, fundamentally reshaping engine design and performance priorities.

Almost overnight, the big blocks that everyone couldn’t stop talking about, those symbols of American power and freedom, were quickly re-evaluated and seen as liabilities. The focus shifted from raw output to environmental compliance, forcing engineers to compromise on the very characteristics that had made these engines legendary. This marked the beginning of a challenging period for high-performance vehicles, as the regulatory environment began to choke out the traditional American muscle car as it was known.

3. **Rising Insurance Costs: Another Nail in the Coffin** Beyond legislative changes, another significant financial pressure contributed to the decline of big block engines well before the widely recognized Oil Crisis. Growing insurance costs became a critical factor, creating an economic barrier for many potential buyers. Insurance rates had been on a rising trend, coincidentally beginning around the same time as the muscle car craze gained traction in the 1960s and continued through the 1970s.

Insurance firms had observed a concerning rise in deadly accidents involving muscle cars during this period. This direct correlation between high-performance vehicles and increased risk led these organizations to implement substantial increases in premiums for any vehicles producing V8 displacement or those carrying a sporty badge. The financial implications for ownership were stark and immediate, making these powerful machines less accessible.

For instance, the yearly insurance premium for a 1970 Chevelle SS was approximately $300, a figure that was three times higher than the yearly cost to insure a Corolla. Some states, like New York, even took more aggressive measures, subjecting high-performance models to additional “supercharger surcharges.” These escalating costs made these vehicles unaffordable for many motorheads and potential buyers, particularly the younger drivers who were the primary fuel for the muscle car hype. As a direct consequence, sales of cars equipped with V8 engines plummeted by 55% by 1975, reflecting a significant market shift away from these once-dominant powerplants.

4. **The 1973 Oil Crisis and Changing Consumer Tastes** Just three years after the implementation of the Clean Air Act, the automotive industry was rocked by another seismic event: the 1973 Oil Crisis. This crisis was triggered when the Organization of the Petroleum Exporting Countries (OPEC) curtailed oil exports to nations that had supported Israel during the Yom Kippur War, with the United States among the affected countries. The immediate and profound consequence was that oil became a scarce commodity, leading to a dramatic and rapid increase in gas prices across the nation.

The cost of a gallon of gas, which stood at $0.36 in 1972, surged to $0.53 by 1975, representing a substantial hike that deeply impacted daily life and transportation choices. This situation was undoubtedly devastating news for muscle car owners and enthusiasts, given the notoriously high fuel consumption of high-performance muscle cars equipped with V8 engines. These vehicles, once celebrated for their power, suddenly became economically untenable for many, making big blocks increasingly unpopular.

Concurrently with the oil crisis, automotive innovations began to pivot, focusing more intensely on increased safety, better fuel efficiency, and reduced emissions. Automakers responded by downsizing engines, strategically replacing the gas-guzzling V8s with more efficient small-block engines, and even commencing exploration into aerodynamic improvements for what were now compact models. A notable example of this shift was the 1974 Chevrolet Camaro, which featured lighter accessories such as aluminum bumpers and replaced its powerful 396-cubic-inch V8 (rated at 375 horsepower) with a 350-cubic-inch top-spec engine producing a mere 185 horsepower. This trend saw more and more efficient, compact engines rolling out from both domestic and international automakers, with imported brands capturing nearly 27% of the U.S. market by 1980, up from just 15% in 1973, cementing a permanent shift in American automotive tastes.

Read more about: Cadillac’s Golden Age: Unpacking the Sumptuous Success of the De Ville, A True Icon of 1970s American Luxury

5. **The Philosophy of “Engines Built to Last”** Many drivers frequently ponder why older cars can run smoothly for decades, often surpassing half a million or even a million kilometers, while some modern models unfortunately develop engine problems after only a few years of use. This observation points to a perceived decrease in the durability of car engines, even with the advancement of technology. There was a distinct era when the very design philosophy of the car engine prioritized longevity, ensuring that it was built to endure.

It was not uncommon to witness vehicles operating for decades, retaining their original engine and showing no signs of losing steam. Classic examples from the 1980s and 1990s, such as the Chevrolet Opala, the Toyota Bandeirante, or the Volkswagen Santana, frequently exceeded 500,000 kilometers without requiring an overhaul, a feat that is increasingly rare in today’s automotive landscape. This exceptional lifespan was a direct result of a different engineering mindset and a distinct approach to manufacturing.

The engineers of that period approached engine design with a core principle: to create components that were resistant, reliable, and inherently long-lasting. This focus was particularly crucial given the diverse and often challenging driving conditions of the time, especially in regions like Brazil, where engines had to contend with dirt roads, dust, significant temperature variations, and even fuel of questionable quality. Such an environment necessitated a design philosophy centered on robustness and unwavering dependability, ensuring the engine could withstand continuous adverse use.

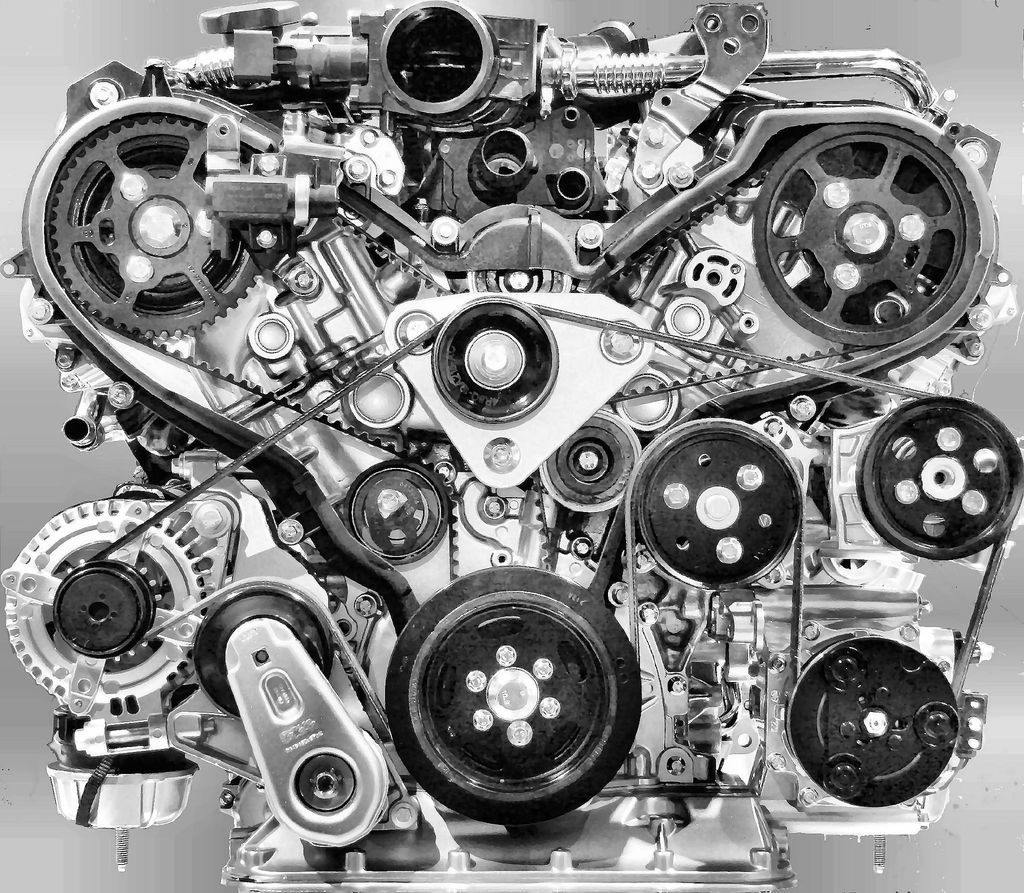

6. **Oversizing and Simplicity in Classic Engine Design** The remarkable resistance and enduring nature of older car engines can be largely attributed to several key design and construction factors that contrast sharply with modern approaches. One paramount factor was the practice of “oversizing” internal parts. Components such as connecting rods, pistons, crankshafts, and valves were meticulously crafted with more material and larger clearances, a design choice that inherently made them less susceptible to premature breakage and wear. In this era, no expense was spared in the fundamental construction of the engine, prioritizing strength and longevity above all else.

Another critical aspect contributing to their legendary durability was simplicity. These engines relied significantly less on intricate electronics, an array of multiple sensors, or sophisticated components like variable geometry turbines or high-precision direct injection systems that are commonplace today. The fewer complex parts inherent in their design meant fewer potential points of failure, which in turn translated into simpler, more accessible, and often cheaper maintenance – epitomizing the famous sentiment of a car engine that “any local mechanic can fix.”

Furthermore, many of these classic engines were designed to operate at lower rotational speeds, a characteristic that naturally reduced internal stress and, consequently, minimized wear over time, significantly extending their useful life. Their physical structure was inherently robust, often featuring thick cast iron blocks, engineered to withstand high temperatures and continuous, demanding use. This foundational strength was complemented by the superior quality of the materials employed, including forged crankshafts and high-strength steels, further enhancing their resilience. This inherent robustness even allowed many of these engines, such as the well-known AP engines from Volkswagen or GM Família 2, to receive performance enhancements like turbo or supercharger additions without necessitating major internal modifications, a testament to their exceptional build quality.

For any genuine automotive enthusiast, the roaring symphony of a ’60s or ’70s V8 engine often evokes a profound sense of nostalgia, a yearning for an era of unbridled power and mechanical purity. Indeed, the first section celebrated these giants and the robust engineering philosophy that made many classic engines incredibly durable. However, to truly appreciate the automotive landscape of that period, we must also confront a less glamorous truth: the muscle car era, despite its legendary status, wasn’t always a smooth ride of thunder and glory. Beneath the dazzling chrome and the promise of burnouts often lurked significant engineering challenges and outright mechanical disasters.

It’s crucial to understand that even during this supposed golden age, not every engine was a masterpiece of reliability or street performance. As one seasoned automotive expert put it, “Disaster. After. Disaster.” Many powerplants, while impressive on paper or at the drag strip, proved to be temperamental, expensive to maintain, or fundamentally flawed for daily driving. This second section will pull back the curtain on some of these iconic, yet often problematic, V8 engines from the ’60s and ’70s that, for better or worse, defined the era’s engineering struggles. We’ll also cast an eye forward, exploring how the historical pressures that shaped these designs continue to echo in today’s automotive landscape.

7. **Chrysler’s 426 Wedge: Paper Tiger Muscle** When discussing the legendary engines of the 1960s, Chrysler’s 426 Wedge often comes up with a reputation for raw power. It had displacement, massive heads, and the promise of a street terror. Yet, for many who experienced it firsthand, the reality fell short of the hype. Despite its imposing specifications, it was frequently described as slower than a 440 Six Pack in real-world scenarios, proving harder to keep running than a “watch full of sand,” a truly telling description from those who wrestled with it.

The reason for this perceived underperformance often lay in Chrysler’s own detuning efforts. Instead of unleashing its full potential, the factory-installed a restrictive intake, diminishing its street credibility. Owners, having invested in what they expected to be a dominant machine, were understandably furious. An old-school gearhead from Detroit lamented, “All that money, and my neighbor’s 454 Buick ate my dust. Should’ve used it as a boat anchor,” perfectly encapsulating the frustration of a powerful engine held back by its own design compromises. It often lacked off-the-line punch and crisp throttle response, demanding high-octane fuel and expert tuning that most drivers simply didn’t provide.

To unlock its true potential, owners often resorted to aftermarket solutions, such as Edelbrock intake manifolds, headers and exhaust systems, and distributor upgrades, costing hundreds of dollars in the ’70s, which translates to thousands today. These modifications were essential just to make the 426 Wedge perform as expected. For many, a Buick 430 or Cadillac 472 offered a better, more forgiving street experience with superior torque and smooth power delivery, highlighting the Wedge’s problematic nature despite its theoretical prowess.

Car Model Information: 2023 Alfa Romeo Stelvio Veloce AWD

Categories: All Wikipedia articles needing clarification, All articles needing additional references, All articles to be expanded, All articles with specifically marked weasel-worded phrases, All articles with unsourced statements

Summary: The Chrysler Hemi engine, known by the trademark Hemi or HEMI, is a series of high-performance American overhead valve V8 engines built by Chrysler with hemispherical combustion chambers. Three generations have been produced: the FirePower series (with displacements from 241 cu in (3.9 L) to 392 cu in (6.4 L)) from 1951 to 1958; a famed 426 cu in (7.0 L) race and street engine from 1964-1971; and family of advanced Hemis (displacing between 5.7 L (348 cu in) 6.4 L (391 cu in) since 2003.

Although Chrysler is most identified with the use of “Hemi” as a marketing term, many other auto manufacturers have incorporated similar cylinder head designs. The engine block and cylinder heads were cast and manufactured at Indianapolis Foundry.

During the 1970s and 1980s, Chrysler also applied the term Hemi to their Australian-made Hemi-6 Engine, and a 4-cylinder Mitsubishi 2.6L engine installed in various North American market vehicles.

Get more information about: Chrysler Hemi engine

Buying a high-performing used car >>>

Brand: Chrysler Model: 426 Wedge

Price: $32,281 Mileage: 30,239 mi.

8. **Chrysler’s Street Hemi: Glorious… and Gloriously Picky** The 426 Hemi is, without question, the undisputed king of the muscle car era, a name that still commands reverence among enthusiasts. Its glorious reputation is well-earned, delivering immense power and an unforgettable driving experience. However, the secret often left out of the legend is its demanding nature. Living with a Street Hemi was, for many, a significant commitment, requiring constant attention and a deep understanding of its intricacies.

This was not merely a street engine; it was a thinly disguised race engine, and it demanded sacrifice from its owners. Featuring dual carburetors and solid lifters, it ran exclusively on high-octane fuel and necessitated frequent, meticulous tuning. As one V8 Buick forum contributor succinctly put it, “There’s nothing overrated about a Hemi… [but] it’s not the most desirable as far as keeping [it] tuned for the street.” This meant owners needed to be constantly aware of lash settings and keep the timing perfectly dialed in, or risk the engine blowing smoke with a distinct lack of refinement.

Maintenance for the Hemi was an ongoing affair, with common fixes including carburetor synchronization every few months and valve adjustments every 6 to 12 thousand miles. For those unable to reliably source high-octane fuel, dropping the compression was a necessary, though power-sapping, modification. Today, maintaining a Hemi can cost up to $500 per adjustment, a substantial sum, particularly if one can even find a technician knowledgeable enough to perform the work. For a more street-friendly, yet still potent, alternative, many pointed to the Mopar 440 Six Pack or the Ford 428 Cobra Jet, offering comparable excitement with significantly less fuss.

Car Model Information: 2023 Alfa Romeo Stelvio Veloce AWD

Categories: All Wikipedia articles needing clarification, All articles needing additional references, All articles to be expanded, All articles with specifically marked weasel-worded phrases, All articles with unsourced statements

Summary: The Chrysler Hemi engine, known by the trademark Hemi or HEMI, is a series of high-performance American overhead valve V8 engines built by Chrysler with hemispherical combustion chambers. Three generations have been produced: the FirePower series (with displacements from 241 cu in (3.9 L) to 392 cu in (6.4 L)) from 1951 to 1958; a famed 426 cu in (7.0 L) race and street engine from 1964-1971; and family of advanced Hemis (displacing between 5.7 L (348 cu in) 6.4 L (391 cu in) since 2003.

Although Chrysler is most identified with the use of “Hemi” as a marketing term, many other auto manufacturers have incorporated similar cylinder head designs. The engine block and cylinder heads were cast and manufactured at Indianapolis Foundry.

During the 1970s and 1980s, Chrysler also applied the term Hemi to their Australian-made Hemi-6 Engine, and a 4-cylinder Mitsubishi 2.6L engine installed in various North American market vehicles.

Get more information about: Chrysler Hemi engine

Buying a high-performing used car >>>

Brand: Chrysler Model: Street Hemi

Price: $32,281 Mileage: 30,239 mi.

9. **Chevy Vega 2.3L: Aluminum Annihilation** As the 1970s dawned, a shift in consumer focus towards smaller, more efficient cars began to emerge, prompting American manufacturers to venture into new territory. In 1971, GM introduced the Chevy Vega, aiming to conquer the small car market with what they hoped would be a “world-beater.” What they delivered, however, was an engine that became synonymous with self-destruction, wrapped in a car often plagued by rust. The Vega’s 2.3L aluminum-block inline-4 engine was an ill-fated experiment in design.

GM decided against using traditional cylinder liners, opting instead for a high-silicon alloy where the piston was supposed to “wear into” the bore. This innovative approach worked as poorly as it sounded in practice. The moment the engine overheated—a common occurrence due to its design flaws—the cylinder walls scuffed, warped, and effectively gave up, leading to soaring oil consumption and a rapid loss of compression. Engines often failed catastrophically between 30,000 and 40,000 miles, making reliability a constant concern for owners.

A CarTalk user, “texases,” bluntly summarized the Vega’s plight: “The engine burned oil quickly… overheated… resulting in worn aluminum cylinders and blown head gaskets.” The irony was palpable when GM awarded the Vega “Car of the Year” in 1971, a title that would later seem like a cruel joke to countless owners. Fixing these issues often involved costly re-sleeving of the block or adding coolant overflow tanks, turning the car into a money pit. Many suggested that “anything” was a better option, highlighting the Vega’s unenviable legacy as one of GM’s most embarrassing moments.

10. **Ford’s 460 V8 & Variable Venturi Carb: Big Block, Bigger Joke** The Ford 460 V8, once a formidable 365-horsepower brute, faced a significant challenge in 1975 when it was subjected to the rapidly evolving emissions regulations of the era. The result was a stark transformation: the powerful engine was effectively neutered, becoming a 200-horsepower “paperweight” smothered in a spaghetti of vacuum hoses and rudimentary emissions technology. This stark reduction in power, without a fundamental redesign, turned a once-respected engine into a source of frustration for many Ford owners.

Compounding the issue, Ford equipped the detuned 460 with the infamous Variable Venturi (VV) carburetor. This “smart” carb, intended to improve fuel efficiency and emissions, proved to be incredibly temperamental and notoriously difficult to tune. It struggled to maintain a stable idle, often stalling unexpectedly, especially when accessories like the air conditioning engaged. Dealership mechanics openly expressed their disdain for the VV carb, with one directly stating, “You could spend three hours tuning it, and it’d still stall when the A/C kicked on,” reflecting the widespread exasperation it caused.

Many owners resorted to drastic measures to improve their vehicles’ drivability, often performing “de-smog” tune-ups that involved ripping off the problematic VV carb and replacing it with a more reliable Holley unit. Disabling EGR and AIR systems and recurving the distributor were also common modifications, all aimed at restoring some semblance of performance and reliability to the strangled engine. These fixes, while costly, were a testament to the lengths owners would go to escape the misery caused by the 1975 460. For a truly potent big block, many looked to the pre-’72 460 or even GM’s Cadillac 472/500 motors, which offered powerful alternatives with far fewer operational headaches.

Car Model Information: 2023 Alfa Romeo Stelvio Veloce AWD

Name: Ford 385 V8

Aka: Lima

Caption: Boss 429 Mustang#Engine

Manufacturer: Ford Motor Company

Production: 1968–1998

Predecessor: Ford FE engine,Ford MEL engine

Successor: Ford small block engine#351W

Configuration: Naturally aspirated,V8 engine

Head: Cast iron

Valvetrain: Pushrod engine

Fueltype: Gasoline

Fuelsystem: Carburetor

Coolingsystem: Radiator (engine cooling)

Bore: cvt,cvt

Stroke: cvt,cvt

Block: Cast iron

Displacement: cvt,cvt,cvt

Power: cvt,cvt

Torque: cvt,cvt

Specpower: cvt

Compression: 8.0:1, 8.5:1, 11.0:1, 11.3:1

Categories: All articles with unsourced statements, Articles with short description, Articles with unsourced statements from April 2021, Articles with unsourced statements from January 2020, Ford engines

Summary: The Ford 385 engine family is a series of “big block” overhead valve (OHV) V8 engines designed and manufactured by Ford Motor Company. The family derives its 385 name from the 3.85-inch (98 mm) stroke of the 460 cubic-inch V8 introduced in 1968. A 429 cu in (7.0 L) version was also introduced the same year, with a 370 cu in (6.1 L) variant appearing in 1977.

Produced until 1998, the 385 engines replaced the MEL engine entirely, along with multiple engines of the medium-block FE engine family. The engines saw use by all three Ford divisions in full-size cars, intermediates, personal luxury cars, pony cars, and muscle cars. In trucks, the engine family succeeded the much larger Super Duty family, and was used in full-size trucks and vans, along with medium-duty and heavy-duty trucks.

Produced in Lima, Ohio at the Lima engine plant, the engine family was the final big-block V8 designed and produced by Ford during the 20th century.

Last used in intermediate cars in 1976, the engines were phased out of all Ford cars after 1978 as its full-size cars underwent downsizing. Following its shift to truck use, the 385 engines were joined by multiple diesel-powered engines.

In 1997, Ford introduced the overhead-cam Triton V10, which replaced the 385 V8 engine family after the 1998 model year; the next overhead-valve big-block V8 produced by Ford is the 7.3 L “Godzilla” V8 introduced for 2020.

Get more information about: Ford 385 engine

Buying a high-performing used car >>>

Brand: Ford Model: 460 V8

Price: $32,281 Mileage: 30,239 mi.

11. **Ford 255 V8: The Engine That Should’ve Stayed in the Trash** By 1980, the automotive industry was still grappling with the fallout from the oil crisis and stricter regulations, leading manufacturers to pursue efficiency, sometimes at the expense of performance. Ford’s contribution to this trend was the 255 cubic inch V8, a deeply flawed experiment born from the decision to shrink the revered 302 Windsor engine. This “destroked” 302 was an undeniable step backward, delivering the anemic power of a four-cylinder while retaining the fuel consumption characteristics of a V8, and the torque of a mere sewing machine.

Wheezing out a paltry 120 horsepower, the 255 V8 was an instant punchline in the Blue Oval’s history. It even struggled with premium fuel, often pinging despite its low output. A high school friend who owned an LTD equipped with this engine recounted how they used to joke that it was the “only V8 that could get outrun by a riding mower,” perfectly illustrating its profound lack of performance. The 255 embodied the compromises of an era where regulatory pressures often overshadowed the driving experience.

The common fix for the 255 V8 was not to repair or tune it, but simply to replace it. Enthusiasts and mechanics alike recognized its inherent limitations, leading to widespread engine swaps for more capable powerplants like a proper 302 or 351. The 255 V8 serves as a stark reminder of how rapidly changing automotive priorities could lead to truly uninspired engineering, resulting in an engine that was effectively canceled by the market and remains a certified punchline in Ford’s legacy.

12. **Oldsmobile 5.7L Diesel (1978–1985): The Lawsuit Engine** Perhaps one of the most infamous engines of the late 1970s, and indeed one of the worst ever built, was the Oldsmobile 5.7L Diesel. This ill-conceived attempt to convert a gasoline 350 V8 block into a diesel engine became a catastrophic failure that not only plagued its owners but also, for decades, severely damaged the reputation of diesel passenger cars in America. Oldsmobile made insufficient modifications, primarily changing the heads and only slightly beefing up a few other parts, setting the stage for disaster.

The fundamental flaws were numerous and critical. The head bolts were too small for the increased compression of a diesel, the crankshaft was weak, and the injection system was notoriously unreliable. These deficiencies led to alarmingly high rates of catastrophic failure. The Environmental Protection Agency (EPA) bought a test fleet, and every single vehicle broke down before testing could even be completed—a documented failure, not mere anecdote. Farmers, cab drivers, and ordinary families who purchased these vehicles found themselves ensnared in a cycle of expensive repairs and profound disappointment.

The widespread failures of the Oldsmobile 5.7L Diesel were so severe that they played a direct role in the genesis of consumer protection laws, including the Lemon Law. Owners often found themselves with no viable option other than to pull the diesel engine entirely and drop in a gasoline 350 V8, or, for those who dared to retain it, invest heavily in ARP studs and thicker head gaskets. The cost to fix it “right” was astronomical, often leading most owners to simply give up on the engine. For genuine diesel reliability, the prevailing wisdom was to skip GM entirely and opt for a Mercedes diesel, a stark commentary on Oldsmobile’s costly blunder.

The stories of these problematic engines from the 1960s and 1970s serve as potent reminders that even during periods celebrated for their automotive prowess, engineering challenges and market pressures could lead to significant missteps. These weren’t just isolated incidents; they were products of an evolving automotive landscape, shaped by new regulations on emissions, the rising costs of insurance, and the seismic shock of the 1973 Oil Crisis. The struggle to adapt while maintaining performance and reliability was a constant battle for engineers of the era.

Interestingly, many of these historical pressures resonate deeply with the challenges facing the automotive industry today. We are once again in an era where government regulations, this time driven by environmental concerns over carbon emissions and a push towards electrification, are threatening to redefine performance vehicles and, some argue, even “kill American muscle” once more. Just as automakers in the ’70s were forced to compromise on power, today’s engineers are navigating a complex landscape of fuel efficiency, ever-increasing safety features, and the pursuit of new technologies like turbocharging, hybrid powertrains, and electric vehicles.

Car Model Information: 2023 Alfa Romeo Stelvio Veloce AWD

Name: Oldsmobile Diesel engine

Caption: Badge of the Oldsmobile Diesel on a Buick

Manufacturer: Oldsmobile

Production: 1978–1985

Successor: Detroit Diesel V8 engine

Configuration: V6 engine,V8 engine

Displacement: V6:,{{convert,262.55,cuin,cc,0,abbr=on

Abbr: on

Bore: {{convert,3+1/2,in,mm,1,abbr=on

Stroke: 3.385 in

Block: Cast iron

Head: Cast iron

Valvetrain: Overhead valve

Compression: 22.5:1, 21.6:1

Fuelsystem: Indirect injection

Fueltype: Diesel engine

Oilsystem: Wet sump

Coolingsystem: Radiator (engine cooling)

Power: convert

Torque: convert

Categories: Articles with short description, CS1 maint: ignored ISBN errors, Oldsmobile engines, Short description is different from Wikidata, V6 engines

Summary: The Oldsmobile Diesel engine is a series of V6 and V8 diesel engines produced by General Motors from 1978 to 1985. Their design was based on the Olds 350 gasoline engine architecture.

A 350 cu in (5.7 L) V8 was introduced in 1978, followed by a 261 cu in (4.3 L) V8 only for the 1979 model year. In 1982, a 263 cu in (4.3 L) V6 became available for both front front-wheel drive and rear-wheel drive vehicles.

Sales peaked in 1981 at approximately 310,000 units, which represented 60% of the total U.S. passenger vehicle diesel market. This success was short-lived as the V8 version suffered severe reliability issues. Although GM carried out several redesigns, by the time the engine was trouble-free, the damage to its reputation had been done, and it was discontinued after the 1985 model year. The later design V6 diesel did not have the problems of the V8.

The shortcomings of the engine, and the publicity around it, negatively affected American light diesel engine sales for years to come.

The 5.7L Oldsmobile V8 is often confused with and tarnishes the reputation of its immediate successor, the reliable and economical 6.2L Detroit Diesel V8 engine, put into numerous GMC C/K light truck and G van applications from 1982 to the early 90’s, and also the military HMMWV.

Get more information about: Oldsmobile Diesel engine

Buying a high-performing used car >>>

Brand: Oldsmobile Model: 5.7L Diesel

Price: $32,281 Mileage: 30,239 mi.

The modern automotive industry, while technologically advanced, increasingly focuses on cost reduction and efficiency, sometimes at the expense of the long-term durability seen in those “built to last” classic engines. The complexity of today’s systems, with a multitude of sensors and electronic modules, introduces new potential points of failure. Furthermore, the very concept of “planned obsolescence”—designing components with a limited useful life to encourage vehicle replacement or continuous spending on parts—raises questions about whether the legendary longevity of classic engines can ever truly be replicated. History, it seems, has a peculiar way of repeating its lessons, forcing us to constantly re-evaluate what we value most in the sound and speed of our machines.