The universal frustration of a stalling car, the sudden loss of power, the unexpected silence. It’s more than just an inconvenience; it can be downright dangerous. But what if you could demystify these frustrating moments, understand the underlying causes, and even begin to diagnose the problem yourself, often with methods that get you started before you ever turn a wrench?

Engine stalling is fundamentally a symptom of your vehicle’s delicate balance of air, fuel, and electricity being disrupted. When any of these essential components falter, your engine simply shuts down. The good news is that by learning a few systematic checks and understanding common culprits, you can transform from a bewildered motorist into an empowered troubleshooter.

We’re diving deep into 14 ingenious approaches, ranging from simple visual inspections to clever diagnostic tools, that will help you pinpoint why your engine is quitting on you. While some fixes ultimately require getting your hands dirty, the ‘genius trick’ often lies in the initial, keen observation and logical deduction that saves you time, money, and a whole lot of head-scratching. Let’s get started on reclaiming control of your commute.

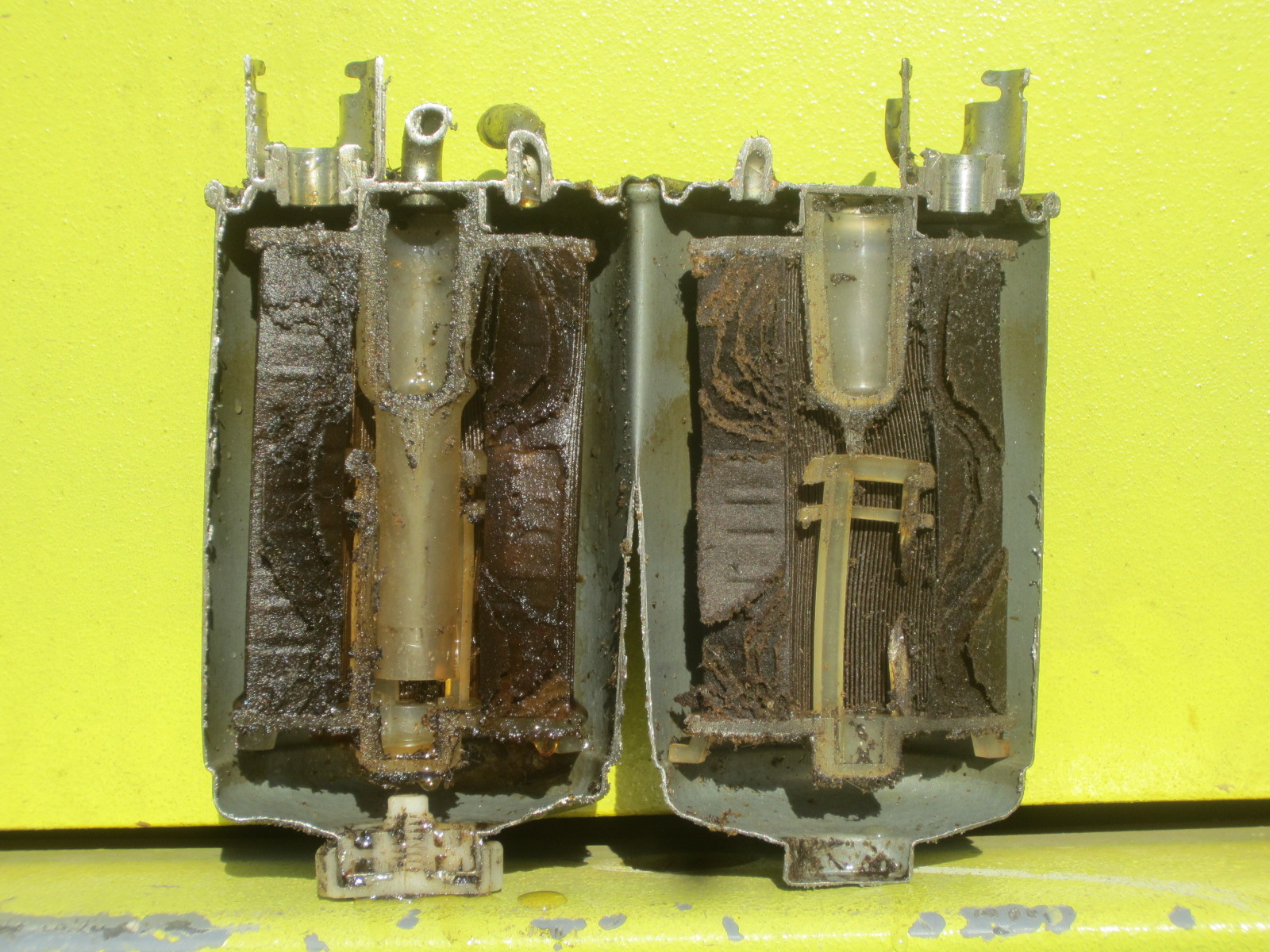

1. **Clogged Fuel Filter**A frequently overlooked culprit behind engine stalling is a clogged fuel filter, the diligent gatekeeper straining impurities from your gasoline. Located along the fuel line, often near the back of the vehicle, it’s designed to protect your engine from harmful debris. Over time, however, this filter inevitably accumulates sediment, gradually restricting the crucial flow of fuel to your engine, leading to frustrating interruptions in power.

A classic sign of a clogged fuel filter is if your vehicle stalls and refuses to restart, only to fire up without issue after sitting for a few minutes. This temporary reprieve occurs as gravity slowly allows fuel to seep past the blockage. Since replacing the fuel filter is generally straightforward and inexpensive, it’s an excellent first diagnostic step, especially given that filters typically need replacement every 40,000 miles.

To tackle this, you’ll need to carefully disconnect the fuel lines secured by plastic clips on either end, then unscrew the bracket holding the cylindrical filter in place. Always position a container beneath to catch any residual fuel and exercise extreme caution when handling gasoline due to its flammability. Installing the new filter simply involves reversing these steps, ensuring all connections are snug and secure to restore optimal fuel flow.

Read more about: Beyond the Battery: 12 Smart Ways to Slash Your Car’s Emissions (No EV Needed!)

2. **Cracked Fuel Line**The fuel line, a critical conduit from your gas tank to the engine, ensures a constant supply of gasoline. Any damage to this line, perhaps from running over road debris, can lead to leaks that starve your engine and cause it to stall. Beyond the obvious performance issues, a compromised fuel line presents a serious safety hazard due to the potential for highly flammable fuel leaks.

The most undeniable symptom of a cracked fuel line is the distinct, unmistakable smell of gasoline, particularly noticeable around the vehicle. A visual inspection, which may involve safely getting underneath your car, is essential to pinpoint any visible cracks, punctures, or wet spots along the line. It’s imperative not to ignore this; never drive a vehicle with a leaking fuel line as it poses an immediate and severe fire risk.

Depending on the material, repairs can be DIY-friendly. If the rupture occurs in a rubber section, you can often remedy it by simply removing the hose clamps and replacing that segment of the line. However, for leaks in steel lines, professional assistance from a mechanic is usually necessary, as these repairs demand specialized tools and expertise to ensure a safe, long-lasting fix that maintains fuel system integrity.

Read more about: Decoding Your Car’s Cries: A Popular Mechanics Guide to Diagnosing Strange Noises, From Squeaks to Knocks

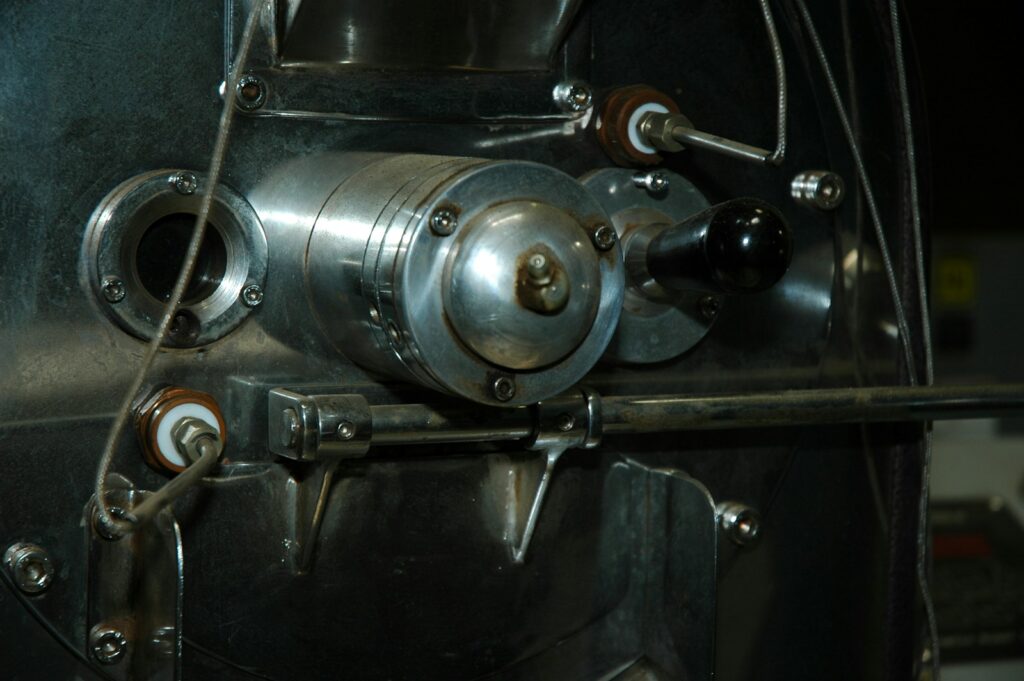

3. **Faulty Fuel Pump**When fuel filter and line integrity checks yield no answers, your attention should turn to the fuel pump, the unsung hero responsible for delivering gasoline from the tank to the engine under consistent pressure. A malfunctioning fuel pump, whether due to a blown fuse or mechanical failure, can fail to provide the consistent supply of fuel your engine demands, inevitably leading to frustrating stalling.

Beyond checking the simple fuse that powers it, diagnosing a faulty pump typically requires connecting a fuel pressure gauge to the test fitting on your engine’s fuel rail. With a friend assisting by revving the engine, you can observe the gauge readings. It’s crucial to compare these against your vehicle’s specific pressure specifications found in the manufacturer’s manual. If the readings don’t match, your fuel pump is likely the problem and will require replacement.

This diagnostic step is incredibly precise: if the fuel pressure readings align perfectly with your vehicle’s specifications, you can confidently rule out both the fuel pump and the filter. This clarity prevents wasted effort and unnecessary part replacements, efficiently guiding you towards other potential causes of your engine’s stalling issues. It’s a smart way to systematically eliminate possibilities and focus your troubleshooting.

Read more about: Beyond the Battery: 12 Smart Ways to Slash Your Car’s Emissions (No EV Needed!)

4. **Water in Fuel**Water in your fuel tank is a surprisingly common, yet often overlooked, cause of engine stalling. Because water is heavier than gasoline, it sinks and pools at the bottom of the tank, right where your fuel pump draws its supply. When the pump ingests water instead of fuel, the engine starves, leading to inconsistent performance, sudden lurches, feeling underpowered, and ultimately, stalling.

This issue can arise if your car has sat idle for extended periods, allowing condensation to form within the tank, or from inadvertently filling up with contaminated fuel. For minor amounts of water, an accessible, hood-free solution is to add a bottle of alcohol fuel drier to a full tank of gas. The alcohol mixes with and disperses the water, allowing it to safely pass through the system and be combusted.

However, for significant water contamination, a fuel drier won’t cut it. In such cases, the tank will require complete draining to remove all the water and prevent extensive damage to the fuel system. This more involved procedure is best performed by a professional mechanic to ensure safe and thorough removal of the contaminated fuel, safeguarding your engine from further costly issues.

Read more about: Rust Never Sleeps: 14 Truck Platforms That Battled Early Corrosion (And Some That Lost)

5. **Engine Error Codes**Modern vehicles communicate issues through their sophisticated onboard diagnostic (OBDII) systems, often illuminating the “check engine” light when a problem arises. This light is not a mere suggestion but a direct command to investigate. Understanding how to access and interpret these signals is a key ‘genius trick’ for diagnosing engine stalling, providing a clear starting point for troubleshooting.

The OBDII port, your direct interface with the car’s computer, is conveniently located under the dash, typically beneath the steering wheel. By plugging in an inexpensive code scanner—which many auto parts stores will even let you borrow or use for free—you can retrieve specific error codes. These codes, a letter followed by numbers, precisely identify the system or component experiencing a fault, eliminating blind guesswork.

While a scanner might not always provide an immediate English description, these codes are standardized and can be cross-referenced with your vehicle’s repair manual for a full explanation. This direct access to your car’s self-diagnosis allows you to quickly pinpoint whether the stalling issue stems from fuel delivery, air flow, or an electrical fault, making your repair efforts incredibly targeted and efficient from the outset.

Read more about: Ready to Mod? The 12 Critical Aftermarket Parts to Skip for Uncompromised Reliability and Value

6. **Mass Air Flow Sensor Issues**The Mass Air Flow (MAF) sensor is a critical component in fuel-injected vehicles, diligently measuring the precise amount of air entering the engine. This data is vital for the engine’s computer to maintain the optimal air-to-fuel ratio, ensuring efficient combustion. If the MAF sensor becomes dirty, clogged with debris, or simply fails, it sends inaccurate information, causing the engine to struggle and potentially stall.

You’ll typically find the MAF sensor positioned immediately after the air filter, at the end of the air intake system, often secured to the airbox with a couple of bolts and identifiable by its connecting wires. A visual inspection should be your first step: look for visible dirt or caked-on debris on its sensing elements. In many cases, carefully cleaning the sensor with a specialized MAF cleaner can resolve minor performance issues and stalling.

Should cleaning not restore proper function, or if the sensor appears physically damaged, replacement is the necessary next step. Always use your vehicle’s specific VIN, year, make, and model information to procure the correct replacement part, as precise calibration is crucial. Swapping out the sensor is usually a straightforward bolt-on, plug-in job, but its impact on preventing stalling and restoring engine efficiency is immense.

Read more about: Beyond the Battery: 12 Smart Ways to Slash Your Car’s Emissions (No EV Needed!)

7. **Oxygen Sensor Failure**Mirroring the MAF sensor’s role on the intake side, the oxygen (O2) sensor monitors exhaust gases, playing an equally critical part in managing the air/fuel ratio for optimal engine performance and emissions control. Situated on the exhaust system, often distinguished by its wiring harness, this sensor continuously reports oxygen levels to the engine’s computer, allowing for precise adjustments to fuel injection.

When an O2 sensor malfunctions, it feeds erroneous data to the engine control unit, leading to an improperly balanced air/fuel mixture. This imbalance can cause the engine to run inefficiently, consume more fuel, and, significantly, result in unpredictable stalling, especially during varying driving conditions. A “check engine” light and a specific OBDII error code are common indicators of O2 sensor trouble.

Locating the O2 sensor involves inspecting the exhaust system for the wired component. If diagnosis confirms its failure, replacement is key. While cleaning can sometimes offer a temporary fix for dirty sensors, a truly damaged unit necessitates removal via an oxygen sensor socket and replacement with a new, correctly specified part. This ensures accurate exhaust monitoring, restoring engine stability and preventing further stalling.

As we continue our exploration into the ‘genius’ tricks for conquering engine stalling, it’s time to venture beyond the foundational checks of fuel delivery and initial diagnostics. This second, comprehensive section is dedicated to unraveling the more subtle yet equally critical issues that can bring your vehicle to an unexpected halt: the intricate world of airflow, perplexing electrical glitches, and advanced component solutions for persistent stalling. Prepare to elevate your diagnostic prowess and gain understanding that empowers you to tackle even the most stubborn automotive mysteries without always needing to open the hood.

The strategies we’re about to unveil are rooted in principles of authoritative knowledge and practical application, aligning perfectly with Popular Mechanics’ spirit. We’ll explore sophisticated system failures and component-specific troubleshooting, transforming you from a bewildered motorist into a confident, efficient problem-solver. Each solution emphasizes ingenuity and clarity, ensuring you grasp the ‘why’ and ‘how’ behind your engine’s health. Let’s delve into these advanced insights and secure your peace of mind on the road.

Read more about: Dashboard Warning Lights Decoded: Your Essential Guide to Understanding Vehicle Alerts and When to Act Now

8. **Clogged Catalytic Converter**Deep within your vehicle’s exhaust system lies the catalytic converter, a crucial component often overlooked until it causes significant problems. Its primary function is to filter out harmful pollutants from exhaust gases before release, making it essential for environmental compliance. However, over extended periods or due to other engine issues, this intricate device can become clogged with carbon and debris, creating a major obstruction to exhaust flow.

When the catalytic converter is severely restricted, your engine faces immense back pressure, essentially struggling to exhale. This increased effort translates into reduced engine power, poor acceleration, and a noticeable decrease in fuel efficiency. This strain on the engine can prevent it from maintaining steady operation, leading to intermittent or persistent stalling, especially under load or when trying to accelerate from a stop.

Modern vehicles are adept at self-diagnosis, and a clogged catalytic converter is a common culprit that triggers the “check engine” light. When this light illuminates, plugging in an OBDII code scanner will often reveal a specific error code pointing directly to catalytic converter inefficiency or blockage. This direct digital feedback is an invaluable ‘genius trick,’ guiding your troubleshooting efforts and preventing you from chasing symptoms in unrelated systems.

While replacement is often the definitive solution, its complexity varies. For some vehicles, you might find the catalytic converter secured by bolts on its flanges, allowing for a relatively straightforward removal and replacement. For others, particularly older or more integrated systems, employing a hacksaw might be necessary to cut out the old unit. Once installed, ensure the new converter is properly sealed with exhaust clamps to prevent leaks, restoring optimal exhaust flow and eliminating the stalling issue.

Read more about: Beyond the Battery: 12 Smart Ways to Slash Your Car’s Emissions (No EV Needed!)

9. **Faulty Spark Plugs**At the very heart of your engine’s combustion process are the spark plugs, small but indispensable components. They are responsible for igniting the compressed air-fuel mixture within each cylinder, delivering the electrical spark that initiates thousands of controlled explosions every minute. Over time, these plugs naturally wear down, their electrodes erode, or they can become fouled with carbon deposits, hindering their ability to fire effectively.

When spark plugs lose efficiency, the ignition becomes inconsistent, leading to misfires. These misfires manifest as a rough engine idle, noticeable hesitation during acceleration, or a general feeling of power loss. Your engine might feel sluggish, and you could experience a significant drop in fuel economy. These symptoms, especially when combined with stalling, are strong indicators that your ignition system needs attention.

Diagnosing faulty spark plugs is often a hands-on task. After safely disconnecting the spark plug wires, use a specialized spark plug socket to carefully remove each plug for inspection. Look for signs of wear such as a severely eroded electrode, excessive carbon buildup, or even oil fouling. These visual cues can confirm if a plug is failing to ignite the fuel mixture properly, directly contributing to your stalling problem.

Replacing worn-out spark plugs is a fundamental maintenance step that yields immediate and dramatic improvements in engine performance and stability. It’s an excellent opportunity to inspect and, if necessary, replace the spark plug wires themselves, as deteriorated wires can also impede spark delivery. Ensuring the new plugs are correctly gapped and properly installed, with wires reconnected to their respective cylinders, guarantees a robust ignition and eliminates stalling caused by incomplete combustion.

Read more about: Beyond the Battery: 12 Smart Ways to Slash Your Car’s Emissions (No EV Needed!)

10. **Weak or Dirty Battery Connections**The steady pulse of electricity is non-negotiable for your engine’s continuous operation. While the alternator is the primary generator once the engine is running, a robust connection to your battery is absolutely critical for consistent power delivery to all vital systems. Surprisingly, one of the simplest yet most overlooked causes of engine stalling can be compromised battery connections – terminals that are loose, corroded, or caked with grime.

If the electrical connection between your battery and the rest of the car is intermittent or weak, the engine’s onboard computer and ignition system won’t receive the consistent voltage needed. This disruption can cause the engine to abruptly lose power and shut down, leading to frustrating and unpredictable stalling. The subtlety of this issue often leads drivers to suspect more complex problems, making this a prime example of a ‘genius trick’ through simple observation.

Identifying this issue is a quick visual and tactile inspection. Examine the battery terminals for any powdery, often blue or white, corrosive buildup. This corrosion acts as an insulator, impeding electrical flow. Additionally, physically check the tightness of the terminal clamps; even a slight looseness can allow vibrations to momentarily break the electrical circuit, cutting power to your engine and causing a stall.

The fix is often wonderfully straightforward and requires no specialized mechanic. Disconnect the battery (always negative first to avoid short circuits), and thoroughly clean the terminals and cable clamps using a wire brush and a solution of baking soda and water to neutralize acid. Once clean, reconnect the cables securely, ensuring a tight, unyielding connection. This simple act can restore consistent electrical supply, preventing power interruptions that cause stalling and ensuring all electrical components function as intended.

Read more about: Conquering Cold Starts: A Popular Mechanics Guide to Diagnosing and Fixing Winter Car Troubles

11. **Malfunctioning Car Alarm**Modern vehicle security systems, especially aftermarket installations, often include an engine immobilizer feature designed to prevent theft by cutting off critical engine functions. While a valuable deterrent, a glitch in this complex electronic system can become a source of profound frustration for the vehicle owner. A malfunctioning car alarm, or more specifically, its immobilizer, can misinterpret normal operation as a theft attempt and prematurely shut down your engine, causing unexpected stalling.

The challenge with a malfunctioning car alarm as a cause of stalling lies in its intermittent and often unpredictable nature. There typically won’t be a “check engine” light or a specific OBDII code pointing directly to the alarm system, making diagnosis a process of elimination. If your stalling issues began or worsened after an alarm installation, or if you notice other erratic electrical behavior alongside the stalling, the alarm system should be high on your suspect list.

Attempting to diagnose or disable a problematic car alarm can be a delicate operation. Many aftermarket alarms are designed to be extremely difficult to bypass or disconnect without specialized knowledge, often rendering the car completely immobile if the wrong wire is cut or a component is removed improperly. This security feature, while great for theft prevention, becomes a significant hurdle for troubleshooting.

For these intricate electrical systems, professional assistance is usually the most prudent course of action. A mechanic or an automotive electrical specialist possesses the diagnostic tools and expertise to safely test the alarm system’s components, identify any faulty relays or wiring, and either repair the malfunction or safely remove/bypass the immobilizer feature. This ensures that your security system protects your car without inadvertently becoming the very thing that prevents you from driving it.

Read more about: More Than Just Speed: Unpacking Dealership Remorse with 15 Vehicles Owners Wish They Never Bought, Including Unexpected Sports Car Regrets

12. **Defective Idle Control Motor/Valve**Maintaining a smooth, consistent engine speed when your foot isn’t on the accelerator is the primary role of the idle control motor, often referred to as the idle air control (IAC) valve. This precision component manages the amount of air bypassing the throttle body, finely tuning the engine’s idle to meet manufacturer specifications for fuel economy and emissions. When this motor fails or becomes clogged, the engine’s ability to “breathe” properly at idle is severely compromised, directly leading to stalling.

Symptoms of a failing idle control motor are quite specific and often manifest when the vehicle is slowing down, idling at a stoplight, or in situations where the engine is expected to maintain a steady low RPM. You might experience a fluctuating or unusually low idle speed, a rough idle that feels like the engine is about to die, or, most tellingly, outright stalling when you take your foot off the gas or shift into neutral.

A clever diagnostic trick involves observing your engine’s tachometer for its idling RPMs. Your vehicle’s specific repair manual will provide the manufacturer-recommended idle speed. If your actual RPMs deviate significantly, you can then locate the idle control motor (often on the throttle body) and, following the manual’s guidance, temporarily disconnect it. If the engine’s idle behavior remains unchanged or still struggles after disconnection, it’s a strong indicator that the motor was faulty and not performing its regulating function.

If this diagnostic step confirms the idle control motor as the culprit, replacement is typically the most effective solution. While cleaning can sometimes offer a temporary reprieve for a dirty valve, a truly defective motor requires a new part to restore precise idle control. Replacing this component ensures your engine maintains a stable and proper idle speed under all conditions, eliminating those frustrating stalls that occur when you’re not actively pressing the accelerator.

13. **Vacuum Leaks**The engine vacuum is a fundamental principle that powers many auxiliary systems in your car, assisting with everything from your power brakes to the heating and ventilation. It’s created by the engine’s pistons drawing air, and a network of hoses and seals maintains this vacuum. A “vacuum leak” occurs when a crack, hole, or loose connection allows unmetered air to sneak into the engine, bypassing the precisely regulated air intake system.

This influx of uncontrolled air throws off the critical air-to-fuel ratio that your engine’s computer strives to maintain for optimal combustion. When the mixture is incorrect, the engine struggles. As Paul Knoll, an automotive expert, notes, “This disrupts the optimal air-fuel ratio needed for efficient combustion.” The direct result is a variety of performance issues including a rough idle, poor acceleration, and frequently, engine stalling, as the engine cannot effectively ignite the improperly mixed charge.

One of the most telling signs of a vacuum leak is an audible “hissing” sound coming from the engine bay, often more noticeable when the engine is running. Beyond the sound, the engine might exhibit an erratic or unusually high idle, which is its attempt to compensate for the extra air. A “check engine” light and corresponding diagnostic codes are also common indicators, providing a vital roadmap to the leak’s location.

Locating a vacuum leak can sometimes be challenging, requiring careful inspection of all vacuum hoses and connections, often involving a spray test with a non-flammable substance around suspected areas to listen for changes in idle. Once identified, repairing a vacuum leak can be as simple as replacing a cracked rubber hose or tightening a loose clamp. More complex leaks, such as those in intake manifold gaskets, may require professional repairs, but initial detection is often within the keen observer’s capability.

Read more about: Decoding Your Car’s Cries: A Popular Mechanics Guide to Diagnosing Strange Noises, From Squeaks to Knocks

14. **Dirty or Clogged Fuel Injectors**While earlier we discussed the broader fuel system, the fuel injectors represent the final, critical stage of fuel delivery, directly influencing engine performance and the potential for stalling. These precisely engineered components are responsible for atomizing and spraying fuel into the engine’s combustion chambers with incredible accuracy. Over time, however, deposits can accumulate within these tiny nozzles, obstructing the spray pattern and reducing the amount of fuel delivered.

When fuel injectors become dirty or clogged, the engine doesn’t receive the consistent and finely atomized fuel mist it needs for efficient combustion. Instead, it might get an uneven spray, an insufficient amount, or even no fuel from a particular injector. This leads to a lean air-fuel mixture in one or more cylinders, causing misfires, a rough or stumbling idle, hesitation under acceleration, and a significant propensity for the engine to stall unexpectedly, particularly under varying engine loads.

Diagnosing dirty fuel injectors can often involve observing specific symptoms: a noticeable loss of power, reduced fuel economy, and a strong smell of unburnt fuel from the exhaust are all red flags. While a “check engine” light might not always immediately point to injectors, consistent misfire codes in specific cylinders, or codes indicating a lean condition, can strongly suggest an injector issue. This is where combining observed symptoms with diagnostic codes becomes a powerful ‘genius trick’.

Fortunately, addressing dirty fuel injectors often starts with accessible, ‘without opening the hood’ solutions. Adding a high-quality, concentrated fuel system cleaner to your gas tank can help dissolve and remove carbon deposits, restoring the injectors’ proper spray pattern and fuel flow. For more severe cases, professional ultrasonic cleaning or outright replacement of the injectors might be required to ensure your engine receives its vital fuel supply precisely and consistently, eliminating stalling and restoring smooth, efficient operation.

Read more about: Enthusiasts Read This: 10 Types of Performance Upgrades You Should Seriously Think Twice About Funding.

The journey to understanding and preventing engine stalling is a testament to the intricate dance of components under your hood. By systematically troubleshooting through fuel, air, and electrical systems, you equip yourself with the confidence and know-how to tackle these issues head-on. Whether it’s a simple filter replacement or a more complex sensor adjustment, the ‘genius trick’ truly lies in empowering yourself with knowledge and a methodical approach, ensuring your vehicle remains a reliable partner on every journey. Keep those wheels turning, safely and smoothly!